Pipe Reaction is suitable for NPK fertilizer production and DAP manufacturing, TONGLI has intergrated slurry pipe reactor on our granulator for CNCEC Egypt DAP fertilizer plant.

The Pipe Reactor Fertilizer Granulation Plant, also known as a Cross Pipe Reaction plant, is an integrated acid–base reaction process widely used in NPK plant and especially DAP chemical granulation systems for producing phosphate and nitrogen-based fertilizers such as Monoammonium Phosphate (MAP), Diammonium Phosphate (DAP), Ammonium Sulfate, and specific NPK formulations. TONGLI has worked with CNCEC for more than 10 reference project regarding this type of granulation plant. Inside the reactor, phosphoric acid or sulfuric acid is fed from one side of the pipe while anhydrous or liquid ammonia is injected from the opposite inlet. The two reactants meet at high velocity in the reactor chamber, where an intense neutralization and ammoniation reaction occurs, generating a superheated molten slurry. This hot reaction melt is directly discharged into the rotary drum granulator, where it mixes with recycled solids to form uniform fertilizer granules. The reaction heat generated inside the pipe reactor serves as a primary drying energy source, instantly flash-evaporating the initial moisture and significantly reducing the thermal load of the rotary drum dryer, leading to lower fuel and energy consumption across the production line. As a continuous flow reactor, the pipe reactor enables precise control over temperature, residence time, and reaction kinetics, making it highly efficient for large-scale fertilizer manufacturing compared to traditional batch reactors. Moreover, the process helps reduce the content of citrate-insoluble P₂O₅, improving nutrient availability and overall fertilizer quality. Properly tuned operating conditions—such as acid–ammonia ratio, inlet pressure, and pipe length—allow the pipe reactor to optimize reaction completion, granulation moisture, and product homogeneity, enhancing the performance and stability of downstream granulation and drying systems. Now if you want to learn more about the complete process flow of the whole pipe cross reactor fertilizer production line click here.

PIPE REACTOR GRANULATION PRODUCTION LINE EQUIPMENT LIST

The granulator receives hot slurry from the pipe reactor and mixes it with recycled solids such as fines and crushed oversize material. Inside the rotating drum, continuous rolling and layering form uniform spherical granules. The direct injection of slurry from the reactor ensures even coating, rapid particle growth, and a high granulation efficiency.

The dryer removes moisture and residual reaction water from freshly formed granules using high-temperature air. This step stabilizes the chemical composition, strengthens granules, and prepares them for cooling and coating. The residual heat from the pipe reactor reaction lowers drying energy demand, enhancing overall thermal efficiency.

The coating machine applies a thin film of anti-caking or anti-dust agent to the dried granules, improving their flowability, storage stability, and appearance. The coating prevents moisture absorption and surface sticking, which is especially critical for high-nitrogen or potassium-based NPK fertilizers.

Pipe Reaction Chemical Granulator ADVANTAGES

Reduce urea usage and nitrogen costs: In traditional NPK steam drum granulation lines, approximately 70–90% of the nitrogen source comes from urea. However, the tubular reactor utilizes ammonia (NH₃) to react with phosphoric acid (H₃PO₄) or sulfuric acid (H₂SO₄) to produce ammonium phosphate or ammonium sulfate, partially replacing the urea nitrogen source. Because liquid ammonia has a high nitrogen content of 82% N (compared to urea's 46%), ammonia offers higher reaction efficiency under the same nitrogen content. Economically, the unit nitrogen cost of ammonia is approximately 15–25% lower than that of urea, resulting in an 8–12% reduction in overall raw material costs. Furthermore, direct nitrogen supply reduces nitrogen losses due to urea hydrolysis or volatilization.

Reaction heat can replace drying energy consumption: The reaction of ammonia with phosphoric or sulfuric acid is a highly exothermic neutralization reaction, releasing heat values of up to –70 to –90 kcal/mol NH₃. The slurry generated in the reaction tube reaches temperatures of 160–200°C, sufficient to "flash" off the reaction water and some of the feedstock moisture. This reduces the initial moisture content of the material entering the dryer from 10–12% in conventional processes to 5–7%. Consequently, dryer fuel consumption can be reduced by 20–40%. For example, for a 100,000 ton/year DAP production line, this theoretically saves approximately 300–500 tons of fuel oil or natural gas annually. In theory!

Improves the available phosphorus content and phosphorus (P₂O₅) utilization rate in the product: The instantaneous, high-temperature reaction produces fine, evenly distributed ammonium phosphate crystals, effectively suppressing the formation of insoluble salts (such as iron, aluminum, and calcium phosphates). Based on our previous project experience, using the tubular reactor process can reduce the citric acid-insoluble phosphorus (P₂O₅) content from 2–3% to 0.5–1%, while increasing the available phosphorus (P₂O₅) content by 2–3 percentage points. This means that nutrients are more readily absorbed by crops, increasing the actual field utilization rate of the fertilizer by approximately 8–10%.

Continuous Reaction: The tubular reactor is a continuous-flow reactor capable of real-time adjustment of acid flow, ammonia pressure, and reaction temperature at 160–180°C, with a reaction time of just 0.1–1 second. Combined with a Siemens PLC or DCS control system, the acid-ammonia molar ratio (DAP approximately 1:2, MAP approximately 1:1) can be precisely controlled to ensure a constant N:P ratio in the product. Using metering pumps, this system achieves product quality fluctuations of less than ±0.5%, continuously delivering stable NPK and DAP fertilizer formulations.

Adaptable to multi-formula production: The same tubular reactor can flexibly switch between products by adjusting the acid type (phosphoric acid or sulfuric acid), the amount of ammonia, and the masterbatch ratio: MAP (Monoammonium Phosphate), DAP (Diammonium Phosphate), AS (Ammonium Sulfate), NPK (with KCl or other fillers added according to the acid-ammonia ratio). For large-scale production lines, automatic valve blocks can be used to control the switching time to less than 15 minutes, greatly improving production flexibility and equipment utilization.

High reaction rate and conversion efficiency: Because the reactants enter the reaction tube at high speed, the local Reynolds number exceeds 10⁴–10⁵, resulting in highly turbulent mixing. Over 90% of the neutralization reaction is completed in just about 0.1 seconds, and the final conversion rate can reach >99%. This efficient mixing and instantaneous reaction mechanism significantly reduces byproducts such as unreacted acid or free ammonia, preventing subsequent scaling and equipment corrosion.

Improved particle uniformity and granulation efficiency: Because the reaction products are sprayed into the drum granulator as a high-temperature slurry (molten state), they react with the surface of the recycled particles to form a liquid film, promoting rapid particle growth. Granulation efficiency can reach 90–95%, approximately 8–10% higher than traditional spray or steam granulation methods. The resulting particles have a concentrated particle size distribution within the 2–4 mm range, exhibit a smooth appearance, high strength, and low moisture absorption (<1%).

Significant environmental and emission reduction advantages: The tubular reactor utilizes a closed reaction structure, allowing ammonia to react completely within the sealed tube, resulting in an ammonia escape rate of less than 0.1%. The heat of reaction also reduces dry combustion, reducing CO₂ emissions by 15–25 kg per ton of product. Furthermore, by reducing dust and NH₃ odor emissions, the system more easily meets EU and Southeast Asian clean production standards, making it particularly suitable for export-oriented fertilizer plants.

Pipe Cross Reactor Chemical Granulation PRODUCTION PROCESS

1. Raw Material Storage and Feeding System

The process begins with the storage and metering of main liquid raw materials: Phosphoric acid storage tank, equipped with heating and circulation systems to maintain the acid at 60–80°C and prevent sedimentation. Sulfuric acid storage tank, typically constructed with acid-resistant alloy or FRP material, connected to acid-proof pipelines with flow control valves. Ammonia storage and vaporization unit, where liquid ammonia is stored under pressure and vaporized through a steam or hot-water exchanger to ensure stable gas flow. All acids and ammonia are routed through precise metering systems (mass flowmeters, control valves, or diaphragm pumps) that regulate the feeding ratio according to the target formula (for example, DAP: acid–ammonia molar ratio ≈ 1:2). The accurate dosing and flow balance are critical to achieving full neutralization and consistent product composition.

2. Neutralization and Reaction in the Pipe Reactor

At the heart of the process lies the Pipe Reactor, a specially designed cross-pipe system installed at the inlet of the rotary drum granulator. Inside the reactor, phosphoric acid or sulfuric acid is injected from one side, while anhydrous or gaseous ammonia is introduced from the opposite direction at high velocity. The two streams meet in a turbulent mixing zone, initiating an instantaneous acid–base neutralization reaction: 𝐻 3 𝑃 𝑂 4 + 2 𝑁 𝐻 3 → ( 𝑁 𝐻 4 ) 2 𝐻 𝑃 𝑂 4 + 𝐻 𝑒 𝑎 𝑡 H 3 PO 4 +2NH 3 →(NH 4 ) 2 HPO 4 +Heat or 𝐻 2 𝑆 𝑂 4 + 2 𝑁 𝐻 3 → ( 𝑁 𝐻 4 ) 2 𝑆 𝑂 4 + 𝐻 𝑒 𝑎 𝑡 H 2 SO 4 +2NH 3 →(NH 4 ) 2 SO 4 +Heat The reaction is strongly exothermic, generating temperatures of 160–200°C within milliseconds. The resulting molten ammonium phosphate or ammonium sulfate slurry is discharged directly from the pipe reactor outlet into the granulator. The reaction heat instantly flash-evaporates the free moisture in the mixture, thereby reducing the subsequent drying load and energy consumption by 20–40%. The degree of neutralization, pipe length, and residence time (typically 0.1–1.0 seconds) are carefully controlled to ensure complete conversion and minimal residual acidity.

3. Slurry Granulation in Rotary Drum Granulator

The superheated slurry from the Pipe Reactor mixes with recycled fines and solid seed materials inside the rotary drum granulator. The liquid phase forms a thin coating on the surface of the rolling particles, binding them together into uniform granules. Because the pipe reactor slurry has high temperature and high viscosity, it acts as a powerful binding agent, improving granulation efficiency (typically >90%) and producing granules with strong mechanical strength and low moisture content.

4. Drying, Cooling, Screening, and Coating

After granulation, the wet product is transferred to the rotary dryer, where remaining moisture is reduced to below 2%. The hot air used is much less than in conventional processes thanks to the prior flash-drying effect of the pipe reactor. The dried granules are then cooled in a rotary cooler, screened into oversize, undersize, and qualified products, and finally coated with anti-caking agents before storage or packaging. The recycle loop returns fines and crushed oversize back to the granulator feed for reprocessing.

VIDEO

WHY CHOOSE US

Premium Quality Compare to Other Supplier

CFO

Germany Welding Quality With Chinese Price

CEO

State-of-art granulation technology love it

CEO

We usually don't give compliment, but they did a good job

CEO

FAQ: Frequently Asked Question about Pipe Reaction Granulation

Case1: Anhui huilong Chemical Co., Ltd. is the first enterprise in China to adopt the "sulfuric acid - ammonia tubular reactor" technology for compound fertilizer production. It owns the first domestic production line with an annual output of 150,000 tons of high - concentration compound fertilizer using this pipe reactor technology by tongli, with a total production capacity of approximately 900,000 tons.

Case2: Wuhan Wanbang Fertilizer Co., Ltd. invested 30 million yuan in June 2008 to introduce the "sulfuric acid - ammonia tubular reactor" compound fertilizer granulation technology. From March 2009 to December 2010, it invested an additional 35 million yuan in phases to build three production lines for ammoniated compound fertilizers, slow - and controlled - release fertilizers, and bulk blended fertilizers, achieving an annual production capacity of 500,000 tons.

Case3: For the 1.2 million tons/year new compound fertilizer project of Jiaxing Xinyangfeng Fertilizer Co., Ltd., materials such as urea, potassium chloride, monoammonium phosphate, and ammonium chloride are crushed and mixed with washing water to form a slurry. After heating, the slurry is sent to the tubular reactor. Gaseous ammonia is metered and fed into the tubular reactor, and diluted sulfuric acid is also sent into it. Neutralization reactions occur among the materials in the tubular reactor to produce compound fertilizers. In addition, the humic acid chelated compound fertilizer of

Case4: Hubei HM Holding Group Co., Ltd. adopts the AZF tubular reactor technology and is chemically synthesized through the spray granulation process, which can adjust the product structure according to market demands and produce various products such as monoammonium phosphate, diammonium phosphate, and nitrogen - phosphorus - potassium fertilizers.

A pre-neutralizer is a tank-type neutralization device, usually adoptes a pressurizsed tank shape. It plays a key role particularly in the preparation of various granular nitrogen-phosphorus-potassium (NPK) fertilizers and the manufacturing of MAP and DAP powder. The core advantage of this tank-type neutralizer lies in its ability to flexibly control the chemical reaction between acid and ammonia, precisely achieving the critical thermal and liquid phase conditions necessary for optimal pipe reactor granulation. These conditions are crucial for producing granular NPK fertilizers of varying specifications and formulations. It's called a "pre-neutralizer" because the chemical reaction between acid and ammonia often doesn't complete completely within this type of tank-type equipment. The reaction is often only partially complete, not reaching the final neutralization state, requiring further treatment to achieve complete neutralization. Pre-neutralizers are widely used in most ammonium phosphate production plants and many nitrogen-phosphorus-potassium (NPK) fertilizer plants, becoming an essential piece of equipment in these plants' production processes. 316L stainless steel is the most common material. The molybdenum it contains significantly improves corrosion resistance to acidic media such as nitric acid and phosphoric acid. It can withstand typical reaction temperatures of 40-80°C during equipment operation, as well as operating pressures from atmospheric pressure to 0.3 MPa (pressurized), and performs stably in the neutral to weakly acidic conditions found in ammonium phosphate and NPK plants. For processing high-concentration acids (such as phosphoric acid with a concentration greater than 85%) or raw materials containing high levels of impurities, duplex stainless steel (such as 2205) is used. It combines the corrosion resistance of austenitic stainless steel with the high strength of ferritic stainless steel, enabling it to withstand even harsher corrosive environments.

In the pipe reaction granulation process, the core function of the preneutraliser is to provide a slurry with optimized fluidity and controllable reactivity for subsequent pipe granulation. The granulation principle revolves around "partial neutralization reaction control" and "ensuring slurry fluid properties." First, the preneutralizer receives phosphoric acid (H₃PO₄) and ammonia (NH₃) as raw materials. A stirring system allows for partial neutralization. Unlike complete neutralization, this stage allows the reaction to proceed only to a specific degree. The core goal is not to produce a final product, but rather to produce a fluid slurry with excellent pumpability. This slurry must be smoothly transported through the pipeline to the granulator and evenly distributed on the rolling material bed once entering the granulator, laying the foundation for subsequent granule formation. The control of the reaction degree is affected by multiple factors, including raw material concentration, stirring intensity, etc., but the most critical control indicators are the NH₃:H₃PO₄ molar ratio, reaction temperature and slurry free water content: the molar ratio determines the depth of the reaction, the temperature affects the reaction rate and slurry viscosity, and the free water content is directly related to the slurry fluidity. The three must be precisely coordinated to avoid the slurry being too thin (resulting in insufficient strength of subsequent granulated particles) or too thick (clogging the pipeline and preventing uniform distribution). After the pre-neutralized slurry is piped to the pelletizer, the neutralization reaction continues there. Additional ammonia is added beneath the pelletizer's rolling material bed. This added ammonia reacts further with unreacted phosphoric acid in the slurry to produce nitrogen-phosphorus compounds (such as monoammonium phosphate and diammonium phosphate) that meet the required standards. Furthermore, under certain operating conditions, if the molar ratio during the pre-neutralization stage deviates, additional phosphoric acid can be added to the pelletizer to adjust the NH₃:H₃PO₄ molar ratio in real time. This ensures that the composition and physical properties (such as crystallinity and cohesiveness) of the reaction product meet pelletizing requirements, ultimately achieving uniform pellets with acceptable strength.

In terms of ratio control, the NH₃:H₃PO₄ molar ratio in the pre-neutralizer needs to be adjusted differently depending on whether the raw material contains sulfuric acid. Under conventional operating conditions without sulfuric acid, proportion control focuses on ensuring slurry fluidity. By adjusting the molar ratio (typically a basic range is set based on specific product requirements, followed by fine-tuning based on temperature and free water content), the slurry is ensured to be both pumpable and react efficiently with the supplemental ammonia in the granulator. However, when the raw materials contain sulfuric acid (required for the reaction to form ammonium sulfate), the proportion must be strictly controlled at a low level. This is because the presence of sulfuric acid significantly affects the slurry properties. When the NH₃:H₃PO₄ molar ratio is approximately 1.5 and the pH is approximately 6.8, the resulting ammonium sulfate precipitates as crystals. These crystals increase the slurry viscosity dramatically, making pumping difficult and even clogging the pipeline. Therefore, when feeding sulfuric acid into the pre-neutralizer, it is generally necessary to control the NH₃:H₃PO₄ molar ratio to a low level of approximately 0.4 and the pH to a low level of approximately 2.0. The low molar ratio and low pH can inhibit the large-scale formation of ammonium sulfate crystals, reducing the impact of crystals on the fluidity of the slurry. At the same time, it ensures that sulfuric acid can react with some ammonia to form soluble components, avoiding the precipitation of impurities, thereby maintaining the pumpability of the slurry and the stability of subsequent granulation. In addition, regardless of the ratio, before determining the structural materials of the pre-neutralizer, the candidate materials must be tested under actual operating conditions to ensure that the materials can withstand the corrosive environment under the specific ratio (such as acid corrosion at low pH values and ammonia corrosion at high molar ratios) to avoid equipment damage that affects process continuity.

In the mid-19th century, Germans gasified coal in vertical vessels, the earliest form of fixed-bed reactor, laying the foundation for the development of tubular reactors.

In 1884, the French designed a catalyst-filled tubular reactor for contact sulfuric acid production, marking the industrial application of fixed-bed tubular reactors.

By the early 20th century, with rapid advances in industrial chemistry, continuous-flow tubular reactors became essential for large-scale production. In 1933, the ICI (Imperial Chemical Industries) group in the United Kingdom achieved a major breakthrough by synthesizing polyethylene in an ultra-high-pressure tubular reactor system. This was the first example of commercial polymerization under continuous conditions. By 1939, a pilot plant was operational, and by 1943, American companies such as DuPont and Union Carbide (UCC) refined tubular reactor technology to full industrial scale for polyethylene production, optimizing heat transfer, reaction kinetics, and flow control.

TVA engineers demonstrated that acid-base neutralization could occur rapidly and efficiently inside a tubular or "tee" reactor, allowing direct ammoniation of phosphoric acid in a confined, high-turbulence zone. This eliminated the need for large pre-neutralization tanks and improved process control. Shortly afterward, TVA evolved the tee-type design into a “cross” configuration, enabling better mixing of multiple reactant streams (phosphoric acid, sulfuric acid, and ammonia). This innovation became known as the Pipeline Cross Reactor (PCR) — the true prototype of today’s pipe reactor used in NPK and DAP granulation plants.

By the 1980s and 1990s, pipe reactor systems were widely adopted in nitrophosphate and complex fertilizer plants, particularly for producing slurry-based granulation feedstocks. The main advantages included: Instantaneous neutralization with precise stoichiometric control Higher reaction temperatures leading to more complete conversion and lower free acid Reduced ammonia loss and less scaling or fouling Compact equipment layout, improving plant efficiency and reducing investment cost.

Modern pipe reactor granulation plants integrate the PCR directly above or inside the rotary drum granulator, enabling the hot acid-ammonia reaction to occur in-flight, with the resulting slurry sprayed directly onto recycled granules. This ensures uniform coating, high granulation efficiency, and energy savings due to the exothermic heat released during neutralization. Today’s tongli pipe reactor designs have evolved further to include: Multi-stream inlets for flexible feeding of phosphoric, sulfuric, and nitric acids Lined or alloy-steel construction for corrosion resistance Advanced control systems (DCS/PLC) for precise reaction and temperature control.

Traditional tank-type pre-neutralizers are limited by single-stream feeding and poor mixing efficiency, making it difficult to precisely balance different acid sources such as phosphoric and sulfuric acids. The multi-channel feed configuration of the pipeline reactor, however, employs independent metering modules that accurately regulate each acid feed rate before converging with the ammonia stream.

From a process engineering perspective, the thermal and hydrodynamic characteristics of the pipe cross reactor play a decisive role in reaction efficiency. The high linear velocity within the reactor — often exceeding 8–12 m/s — promotes intense turbulence and micro-mixing, which ensures near-complete neutralization within 0.1–0.3 seconds of residence time. The rapid heat release elevates the reaction temperature to 150–180°C, instantly forming a molten slurry with optimal viscosity for granulation. The design’s compactness also minimizes ammonia slip and acid vapor losses, while the short residence time prevents localized overreaction and scaling on internal walls.

Such flexibility allows operators to adjust the acid ratio dynamically based on raw material market fluctuations: for example, increasing sulfuric acid feed when its price drops, or supplementing with dilute phosphoric acid during periods of tight phosphoric acid supply. Beyond cost optimization, the combination of acids also improves slurry rheology: a proper dose of sulfuric acid reduces slurry viscosity and enhances its spreading uniformity on the granulator bed, minimizing localized agglomeration, while phosphoric acid ensures consistent nutrient composition. This “on-demand blending” capability optimizes both granulation performance and production economics.

More importantly, the pipe cross reactor system can efficiently process low-grade or secondary raw materials that are typically difficult to utilize in conventional setups — such as 30–50% dilute phosphoric acid or phosphorus-rich process effluents from fertilizer washing sections. These materials, if discharged directly, cause both waste and environmental pollution, and if treated conventionally, require additional concentration steps and higher energy input.

Inside the intense reaction environment of the pipeline acid-base reactor, the active components in dilute acids are rapidly converted into reactive slurry, while the exothermic neutralization heat partially evaporates the free moisture: eliminating the need for a pre-concentration unit. Minor impurities in wash liquors (such as trace chlorides or suspended solids) become uniformly dispersed during high-turbulence mixing, posing no adverse effects on subsequent granulation.

When integrated directly above the rotary drum granulator, the pipe cross reactor enables a “hot melt” spray-injection granulation process — the reactive slurry coats recycled granules instantly, creating uniform particle growth and high mechanical strength. Combined with advanced PID-controlled feed systems and corrosion-resistant alloys (such as SS316L or Hastelloy), this system represents one of the most efficient and adaptable neutralization technologies available in modern compound fertilizer production.

In NPK fertilizer formulations containing Muriate of Potash (MOP), the Pipe Cross Reactor (PCR) fundamentally resolves the long-standing issue of ammonium chloride fume formation that plagues conventional production processes.

In traditional tank-type pre-neutralizers, direct contact between sulfuric acid and potassium chloride triggers a displacement reaction that generates hydrochloric acid (HCl). This HCl then reacts with excess ammonia to form ammonium chloride (NH₄Cl). Under the high-temperature conditions of the granulator, ammonium chloride readily volatilizes, producing dense white fumes.

These fumes not only corrode internal equipment surfaces, especially the carbon steel shell of the granulator, but also lead to nitrogen loss — industry data shows up to 3–5% nitrogen reduction due to NH₄Cl fume volatilization. Furthermore, they contribute to environmental pollution and worsen the working conditions inside the plant.

The multi-zone feed architecture of the pipeline cross reactor completely eliminates this problem. Sulfuric acid and ammonia are first introduced into a dedicated reaction channel, where they undergo a controlled neutralization to form an ammonium sulfate intermediate. Meanwhile, potassium chloride enters the granulator directly along with the solid recycle stream. Since the two reactants never meet within the same reaction zone, the reaction pathway for ammonium chloride formation is entirely interrupted at the source.

This innovation not only extends equipment lifespan — with granulator maintenance intervals increasing from roughly 3 months to 12 months — but also reduces nitrogen loss, ensuring more stable nutrient composition in the final NPK granules.

From a process control standpoint, this segregated feed strategy demonstrates how reaction sequence engineering can directly influence product quality and plant reliability. By decoupling acid-base neutralization from salt interactions, the reactor achieves a cleaner thermal profile and avoids local acid “hot spots” that could otherwise promote unwanted side reactions. The reduced emission of corrosive vapors also means that downstream gas scrubbing systems operate with lower load and longer service intervals.

Moreover, by producing a well-defined ammonium sulfate-rich slurry before granulation, the pipe cross neutralization reactor enhances the adhesion characteristics between the melt and recycled fines, improving granule density and hardness. This synergy between chemical control and mechanical granulation underlines the reactor’s role not only as a neutralization unit but as a core efficiency driver for the entire NPK process line.

by precisely controlling the molar ratio of ammonia to total acid (phosphoric acid + sulfuric acid), typically maintained between 1.2 and 1.6, the neutralization reaction is designed to proceed almost completely inside the reactor. The resulting superheated melt slurry then flows directly into the granulator without the need for additional ammonia injection, simplifying plant operation and ensuring stable product quality.

In certain operating scenarios, however, the reaction level inside the pipeline reactor can be intentionally reduced — for instance, lowering the molar ratio to 0.8–1.0. This lower reaction extent minimizes the generation of free ammonia, thereby reducing ammonia slip concentration from the usual ~500 ppm to below 100 ppm, significantly improving workplace air quality and safety.

At the same time, the unreacted acid components entering the granulator continue to react gradually with ammonia added downstream. This controlled secondary neutralization releases a gentle amount of heat, preventing localized overheating and over-melting of granules. The result is enhanced slurry-to-solid adhesion and improved granule morphology — with particle roundness increasing from about 85% to over 95%, meeting the stringent standards required for premium-grade NPK fertilizers.

Additionally, when the concentration of feed acids fluctuates, a small phosphoric acid trim feed can be introduced directly into the granulator to fine-tune the total acid molar ratio. This adjustment ensures that the final nutrient ratio of the fertilizer product remains within a ±0.5% precision tolerance, achieving both chemical accuracy and process consistency.

From a process engineering perspective, this “reaction breakpoint control” strategy effectively decouples thermal management and nutrient stoichiometry, allowing the reactor to function under either complete-neutralization mode or partial-neutralization mode depending on production objectives. Advanced PLC/DCS systems monitor pH, temperature rise rate, and outlet density in real time to maintain the desired reaction completion level.

The ability to shift the neutralization front between the pipe reactor and granulator provides operators with a unique tool for balancing energy release, granule binding force, and ammonia loss — optimizing both process efficiency and environmental performance. This control flexibility is particularly valuable in multi-grade NPK plants where raw acid quality and feed ratios frequently change, ensuring consistent product characteristics without mechanical adjustment of equipment.

In large-scale NPK fertilizer complexes, a single pipe cross reactor can support a production line with an annual capacity of up to 600,000 tons. Its compact structural design significantly saves plant space.

In DAP (Diammonium Phosphate) or MAP (Monoammonium Phosphate) facilities, the reactor’s construction material and operating parameters can be adjusted for specialized applications — for example, using duplex stainless steel to withstand corrosion from high-concentration phosphoric acid — thus enabling efficient single-nutrient fertilizer production.

For small and medium-sized enterprises, the pipeline cross reactor is often used in combination with traditional tank-type pre-neutralizers. In such hybrid configurations, the tank pre-neutralizer handles standard concentrated acid feedstocks, while the PCR unit is dedicated to processing dilute acids and phosphate-rich wash liquids. Together, they form a complementary raw material processing system, retaining the operational stability of traditional equipment while leveraging the PCR’s strength in handling diverse and variable feed materials.

This flexible integration mode allows plants of different capacities and feed conditions to enhance production efficiency through PCR technology without undertaking full-scale process reconstruction, effectively lowering the technical upgrade threshold.

However, successful application of PCR technology requires accurate pre-assessment of process conditions. For example, high fluoride concentrations in the feedstock (e.g., phosphoric acid with >1.5% F content) can accelerate corrosion of stainless-steel reactor internals; similarly, if the solid content exceeds 60%, slurry fluidity decreases, increasing the risk of reactor blockage.

Therefore, each enterprise must conduct comprehensive evaluations considering raw material properties, product formulation, and production capacity to ensure optimal utilization and to fully realize the technical and economic benefits of the Pipe Cross Reactor system.

In recent years, the pipe reactor granulation process has become increasingly popular in fertilizer production plants around the world. The main reason is its high efficiency, flexibility, and environmental advantages compared with conventional granulation systems. A new generation of pipe reactors is now designed to operate using diluted phosphoric acid and/or sulfuric acid, together with ammonia and scrubbing liquid, while completely avoiding corrosion and erosion problems that were common in older designs.

One of the biggest benefits of this process is its adaptability. When operated with diluted phosphoric acid and sulfuric acid, it perfectly fits any compound fertilizer granulation plant, especially where the cost of acid concentration needs to be reduced or when a concentration unit is not available. In plants where only sulfuric acid is available, the system can also be used efficiently for solid granulation, allowing production of high-quality NPK or ammonium sulfate-based fertilizers without needing phosphoric acid.

The pipe reactor works as a compact, high-temperature reaction zone, where acids and ammonia react instantly to form ammonium salts before entering the granulator. This pre-neutralization step ensures more uniform granule formation, better chemical reaction control, and reduced dust formation. It also enhances the granulation efficiency of rotary drum or pugmill-type granulators, leading to stronger and more uniform fertilizer granules.

Another key advantage is its energy and water-saving performance. The pipe reactor process utilizes the heat of reaction to evaporate most of the water contained in the scrubbing liquid. This means that nearly all the water used in the gas scrubbing system is recycled in the process itself, eliminating the need for liquid effluent treatment and achieving a zero-liquid-discharge operation. This not only lowers environmental impact but also simplifies plant operation and reduces maintenance costs.

From a production standpoint, fertilizer manufacturers report that pipe reactor granulation allows for better control of product quality, higher throughput, and lower energy consumption. It also reduces the amount of recycle material and enhances the overall yield. With today’s growing demand for sustainable and cost-effective fertilizer manufacturing, these benefits make the pipe reactor system a preferred choice for many new and upgraded granulation plants.

In summary, fertilizer companies are adopting the pipe reactor granulation process because it combines process simplicity, energy efficiency, environmental friendliness, and high product quality—making it a smart and modern solution for the next generation of compound fertilizer production lines.

In many fertilizer tenders (ITBs), producers are requested to manufacture NPK grades using only diluted phosphoric acid.

First, the use of diluted phosphoric acid allows companies to reduce the final product cost by saving on phosphoric acid concentration expenses. Concentrating phosphoric acid requires a separate evaporation unit that consumes a lot of energy and maintenance resources. By using diluted acid directly in the pipe reactor or granulator, producers can achieve significant operating cost savings.

Second, some fertilizer plants do not have a phosphoric acid concentration unit at all. For these facilities, using diluted acid is not just a choice—it’s a practical necessity. The pipe reactor granulation process provides an ideal solution for such plants because it can operate effectively with diluted acid, producing consistent granules without needing any modification to the main process line.

In other cases, plants that do have a concentration unit may face capacity limitations. When production demand increases, operators often prefer to use the concentrated phosphoric acid for high P₂O₅ grade fertilizers (such as DAP or MAP), while allocating diluted acid for other NPK formulations where acid strength has less influence on the final product quality. This strategy optimizes the overall production capacity and allows manufacturers to handle varying product demands more flexibly.

Additionally, some producers concentrate phosphoric acid only for export purposes. For their own NPK production, they continue using diluted acid because it improves plant economics and reduces operational complexity. This method also minimizes the environmental footprint of acid concentration, which can otherwise release vapors and require additional scrubbing systems.

Another important factor influencing this trend is the market price of sulfur and ammonia. When sulfur prices are low, it becomes more cost-effective to use sulfuric acid and ammonia directly in the reaction system instead of solid ammonium sulfate or urea. At the same time, some fertilizer producers who previously depended on by-product ammonium sulfate from other industries are facing supply shortages or rising prices. As a result, switching to a process using sulfuric acid and diluted phosphoric acid provides a more economical alternative.

When designing an NPK fertilizer plant, one of the key decisions is choosing the granulation technology. Traditionally, fertilizer producers have relied on either steam drum granulation or slurry (pre-neutralizer) granulation, but in recent years, the pipe reactor granulation process has become a more attractive and energy-efficient alternative.

1. Conventional Slurry Process (Steam Drum Granulation)

The conventional slurry process is based on a pre-neutralizer system, where phosphoric acid reacts with ammonia to form a slurry before granulation. This process can produce acceptable NPK quality, but it also comes with several disadvantages. Because the reaction occurs at a lower temperature, the slurry has high water content, which results in: High recycle ratio inside the plant, Increased energy and utility consumption, and Higher moisture in the final product, leading to lower product hardness and more dust. Moreover, steam drum granulation plants require additional steam input to support granule formation and drying. This increases the overall operating cost and makes the process less efficient compared with modern systems. In many older plants, steam granulation was used when no phosphoric acid was available locally. These plants relied on solid intermediate materials such as MAP (Monoammonium Phosphate) or TSP (Triple Superphosphate) as the P₂O₅ source. However, using solid intermediates increases the raw material cost, energy demand, and final product cost. Another major drawback is product caking. Because of higher moisture and lower granule strength, fertilizers produced by steam drum granulation are more likely to cake during storage and transport. Additionally, handling the scrubbing liquid becomes a serious issue. The water used in the scrubbing system often exceeds what the process can safely recycle, leading to effluent generation and environmental management problems. Attempts to fix these issues — such as installing bag filters, hot air additions, or scrubbing liquid filtration systems — have proven only partially successful. These solutions add to capital cost, maintenance, and layout complexity, without fully eliminating the challenges of moisture control and dust recovery.

2. Pipe Reactor Granulation (Co-Neutralization Process)

In contrast, the pipe reactor granulation process represents a new generation of fertilizer production technology. It uses a co-neutralization reaction between diluted phosphoric acid, sulfuric acid, and ammonia directly inside a pipe reactor. The high-temperature reaction instantly forms ammonium salts while simultaneously evaporating much of the water from the acids.

This results in a slurry with much lower water content than that produced by the conventional pre-neutralizer process. Because of this, the granulator operates more efficiently, producing stronger, more uniform, and lower-moisture granules with a lower recycle ratio.

Another major benefit is energy efficiency. The reaction heat generated inside the pipe reactor replaces part of the steam normally needed for drying, which significantly reduces utility consumption. The process also allows complete reuse of scrubbing liquid, leading to zero-liquid-effluent operation — a key advantage for meeting modern environmental standards.

Older generations of pipe reactors once faced corrosion and erosion issues, which limited their lifetime. However, modern designs now use special alloy linings and optimized flow geometry, eliminating these problems and extending reactor service life to over a decade.

3. When Steam Drum Granulation Is Still Used

In china or developing country, manufacturers continue to use steam granulation due to limited acid availability or logistical challenges. For:

When phosphoric or nitric acid supply is unavailable or transport is too costly,

When no acid storage or concentration unit is installed,

When cheaper local sources of solid phosphate materials (MAP, TSP) are accessible, or

When gypsum disposal and environmental regulations discourage phosphoric acid production.

In these scenarios, a steam drum granulation plant may still be the only practical choice, though it typically operates with higher production costs, lower product quality, and more complex effluent management.

To meet modern fertilizer production needs, TONGLI Heavy Machinery has developed a new generation TL Pipe Reactor system. This upgraded design builds on decades of experience and solves the erosion, corrosion, and raw material limitations seen in earlier pipe reactor technologies.

The first TONGLI pipe reactor, introduced in 1985, used a Teflon-lined chamber capable of handling diluted or concentrated phosphoric acid, sulfuric acid, and ammonia. It operated successfully in several plants but experienced wear and corrosion after long-term operation. At that time, most producers still used concentrated phosphoric acid, so further research was postponed.

In recent years, fertilizer production has shifted toward using diluted acids or operating without phosphoric acid, relying mainly on sulfuric acid and ammonia. This change led TONGLI to redesign and launch the TL Pipe Reactor, engineered for greater durability, flexibility, and energy efficiency.

The new TL Pipe Reactor features an optimized mixing head and distribution tube that ensures uniform reaction and minimizes turbulence, effectively preventing erosion and corrosion. It operates efficiently with diluted phosphoric acid, sulfuric acid, or scrubbing liquid, using the heat of neutralization to evaporate water and achieve zero-liquid-effluent discharge. The reactor body is built with advanced corrosion-resistant alloys and linings, extending its service life and ensuring stable operation under harsh conditions.

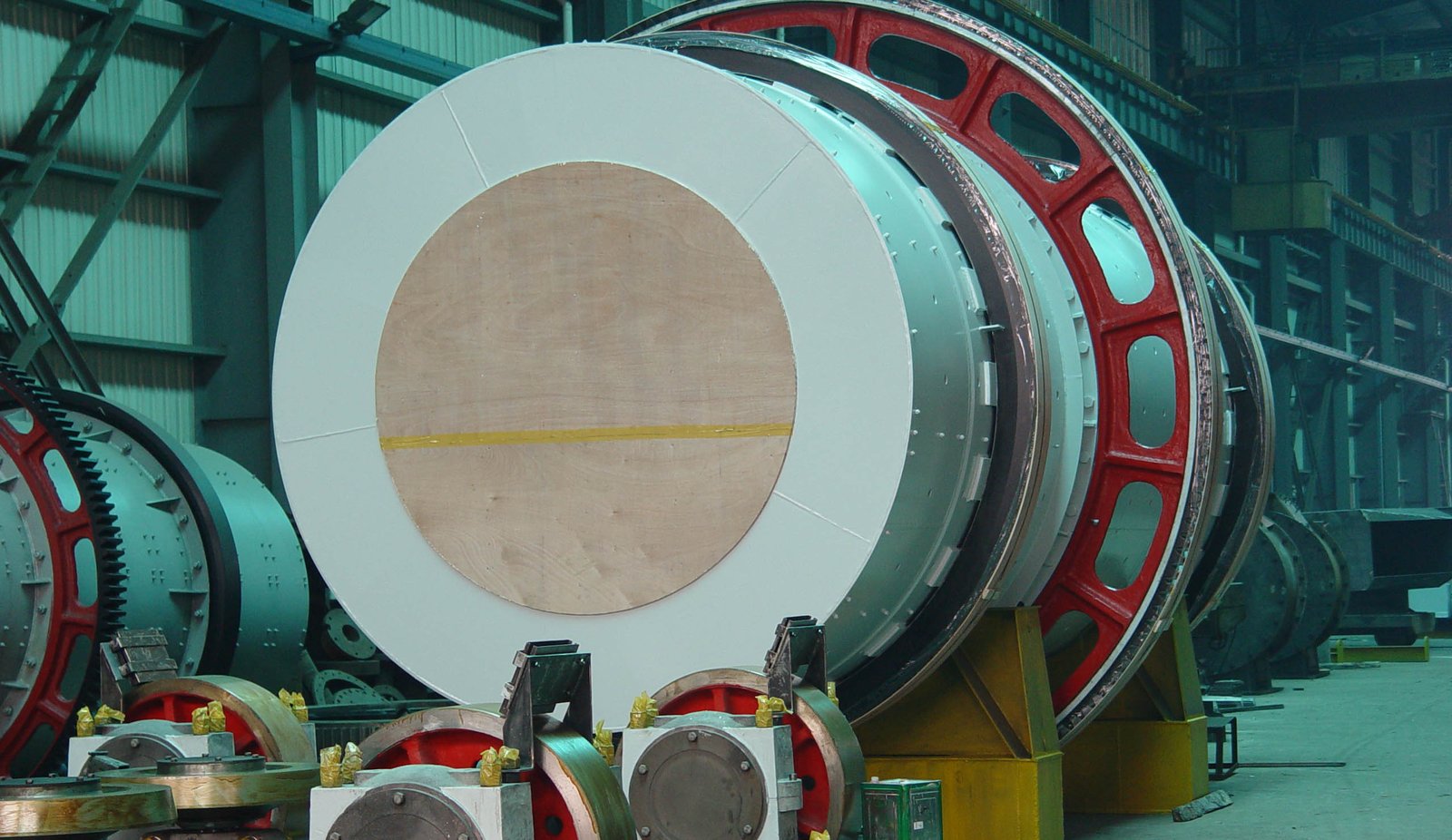

Industrial applications confirm its success: a 40 TPH system in TONGLI’s own facility and a 20 TPH parallel line have operated reliably. A 50 TPH TL Pipe Reactor was later licensed for a 300,000 TPY NPK plant at Huilong Fertilizers Ltd. in Anhui, China, which started up successfully in July 2002.

The TONGLI TL Pipe Reactor represents the next generation of pipe reactor granulation technology—more efficient, cleaner, and fully adaptable to today’s fertilizer production requirements.

1. Enhanced Raw Material Flexibility

The TL Pipe Reactor is designed to operate with either diluted or concentrated phosphoric acid, and/or sulphuric acid, combined with ammonia. It can also run using only sulphuric acid, which eliminates the erosion and corrosion problems that are typically encountered in traditional reactors when processing aggressive raw materials. This flexibility allows fertilizer producers to manufacture a wide range of NPK formulations using multiple combinations of raw materials.

2. Lower Operating Cost and Energy Consumption

By allowing different grades of raw materials, the TL Pipe Reactor enables operators to select the most economical combination, thereby reducing overall production costs. In addition, the process requires less steam for phosphoric acid concentration, contributing to lower utilities consumption.

3. Improved Reaction and Granulation Performance

The reaction inside the TL Pipe Reactor is more uniform, producing a better-distributed slurry that enters the granulator. This results in improved particle size consistency, fewer lumps and fines, and a larger proportion of on-size granules at the granulator discharge. Consequently, the recycle ratio is reduced, and the load on cyclones and scrubbing systems is significantly decreased. These improvements ensure smoother operation and more stable granulation performance.

4. Better Product Quality

Fertilizer granules produced by the TL Pipe Reactor exhibit improved particle size distribution, hardness, shape, and lower moisture content. Compared with slurry from conventional preneutralizer or traditional pipe reactor systems, TL-based granulation produces more uniform and stable granules with reduced dust formation.

5. Reduced Ammonia Losses

Despite operating with higher heat release and a larger ammonia feed, ammonia losses in the TL Pipe Reactor remain comparable to traditional pipe reactors using concentrated phosphoric acid only. This is achieved through the reactor’s optimized internal design and efficient reaction kinetics, ensuring that the larger heat load and increased ammonia quantity do not compromise process efficiency or product quality.

6. Simplified System Integration and Multi-Product Capability

The TL Pipe Reactor can produce DAP, MAP, and NPK fertilizers without any modification, providing high versatility within a single plant setup. The granulator internals are modified to achieve the best slurry distribution for increased throughput, while the granulator fan and scrubbing system are upgraded to handle higher steam and fume volumes efficiently. Additionally, a larger open-circuit chiller can be installed for cooling air due to the increased ammonia circulation, ensuring process stability and reliability.

One of the biggest advancements in modern agriculture is the understanding of soil quality and specific crop nutrient requirements. Farmers today can determine the right type and quantity of fertilizer to use, based on soil analysis and crop needs, to achieve maximum efficiency and yield. Fertilizers are categorized by their nutrient content and ratio, such as urea (46% nutrients, 1-0-0 ratio) or compound types like 20-20-20 (60% nutrients, 1-1-1 ratio). Each stage of plant growth requires a different balance of nitrogen (N), phosphorus (P), and potassium (K). For example, phosphorus-rich fertilizers (1-2-1) promote root growth, while potassium-rich ones (1-1-2 or 2-1-2) support flowering and fruiting, and nitrogen-based fertilizers (2-1-1 or 3-1-1) enhance leafy growth. The P source can come from phosphate rock or phosphoric acid, with phosphoric acid offering higher purity and flexibility in fertilizer production. Potassium sources are usually potassium chloride or, for specialized needs, potassium sulphate. NPK fertilizers—containing all three essential nutrients—can be made either as blends (simple physical mixtures of separate nutrient granules) or as compound NPKs, where nutrients are chemically and physically combined in a single granule through granulation. Compound NPK fertilizers are generally preferred because they prevent nutrient segregation during transport and storage, ensuring even nutrient distribution in the field. These fertilizers are produced using raw materials such as ammonia, urea, ammonium nitrate, phosphoric acid, and potassium chloride. Advanced production processes, such as Tongli’s granulation technology, create homogeneous, high-quality compound NPKs that deliver balanced nutrition to crops and improve overall soil fertility management.

The phosphoric acid-based NPK fertilizer production process, centered around Tongli's advanced tubular reactor granulation technology, offers a modern solution that balances efficiency and flexibility. This process is highly adaptable to site conditions and can enhance nutrient content by removing natural calcium compounds from phosphate rock, meeting the multi-grade fertilizer requirements of diverse crops and soils. It eliminates the need for traditional pre-neutralizers, feeding solid feedstock and recycled pellets directly into the granulator. Liquid feedstock (primarily phosphoric acid and ammonia) is mixed and neutralized within the granulator's tubular reactor (GPR). Precisely controlling the molar ratio (MR) of phosphoric acid to ammonia between 0.7-0.8 and 1.2-1.4 ensures slurry fluidity. Sulfuric acid can be introduced into the GPR to produce high-sulfur fertilizers. Specialized, highly corrosion-resistant materials are employed to address high-temperature corrosion and extend equipment life. In addition, the system uses ammonia injectors with a movable bracket-shaped arm design (which can be lifted from the rolling bed during shutdown) to keep the interior of the granulator clean and avoid fouling. A discharge chute made of advanced materials reduces the risk of blockage, further improving operational stability. Compared with the pre-neutralizer system, it requires less equipment, reduces energy loss in the neutralization process, and reduces the size of the granulation circuit. Some plants can even produce three different NPK formulations per day, which has significant advantages in cost-effectiveness, operational safety, and production flexibility.

The Single Pipe Reactor (SPR) process for NPK fertilizer production features a granulation plant that integrates a PIpe drum granulator, a drum dryer, screens, crushers, cooling equipment, and an coating drum. Beyond these core components, transportation equipment and advanced gas treatment devices are also deployed, which can reduce airborne contaminant emissions by over 90% compared to older systems. Solid raw materials, along with recycled solids from the process, are directly fed into the granulator. Liquid raw materials, primarily phosphoric acid and ammonia, are introduced into the single pipe reactor (SPR) where neutralization occurs. A critical control parameter here is the molar ratio (MR) of phosphoric acid to ammonia, which is typically maintained at 0.7–0.8 or 1.2–1.4 to maximize slurry fluidity—this precise range ensures a 25% improvement in mixing efficiency compared to less controlled ratios. For NPK formulations requiring high sulfur content (derived from sulfuric acid), the acid is also fed into the SPR. While the SPR can handle nearly any proportion of sulfuric acid for neutralization, heat-induced corrosion is a challenge, addressed by using specialized corrosion-resistant materials that extend equipment lifespan by an average of 8–10 years.

Additional ammonia is introduced into the granulator via an ammonia sparger, which helps fine-tune fertilizer composition and boosts granulation efficiency by 15%. The sparger is equipped with a brace-shaped movable arm, allowing it to be lifted out of the granule bed during plant stoppages or maintenance. This design prevents material buildup inside the granulator, ensuring uninterrupted operation. The granulated product exits the granulator through a specially designed chute to the dryer; this chute uses a proprietary material that reduces granule adherence by 40% and, combined with an automatic hammering system, minimizes clogging risks.

The dryer is a rotary drum with co-current hot air flow, fitted with optimized lifters that increase the contact area between granules and hot air by 30%, while a ring at the outlet regulates residence time as needed. A lump screen at the dryer’s outlet separates large agglomerates, sending them to a lump breaker and thus preventing blockages in the downstream elevator—this step reduces equipment downtime by 20%.

Post-lifting, granules are sorted by two-deck screens with unbalanced shafts, which divide them into three fractions: undersized granules (recycled directly via a belt conveyor), oversized granules (crushed and then recycled), and on-size granules (sent to the cooling system). The cooling system can be a fluid bed cooler, rotary drum cooler, or bulk flow cooler, selected based on client preferences and site conditions, each offering thermal efficiency rates of 75–85%.

Once cooled, the product is often coated before storage or packaging. The process generates large volumes of air, potentially contaminated with ammonia, acids, fluorine, and dust, which undergoes rigorous treatment. Dry air is first passed through cyclones, capturing over 95% of dust for direct recycling to the granulator as solid material. Contaminants not captured as solids are removed in a wet scrubbing system consisting of venturi and cyclonic columns, with all scrubbing liquors recycled within the process—achieving zero liquid effluent under normal operating conditions, a benchmark for environmental sustainability in the fertilizer industry.

1. Higher Production Capacity Without Expanding Equipment

In a single pipe reactor system (GPR only), all phosphoric acid and ammonia are reacted in the granulator, producing a slurry that must be dried later. As production increases, the granulator and dryer quickly reach capacity limits because more liquid feed requires more solid recycle and larger drying capacity.

The dual pipe reactor system (GPR + DPR) overcomes this by diverting part of the reaction to the dryer through a second pipe reactor (DPR). The DPR produces solid monoammonium phosphate (MAP) directly inside the dryer, which is then recycled into the granulator. This effectively increases throughput without needing to enlarge the granulation loop (granulator, dryer, elevators, screens, etc.).

2. Improved Energy Efficiency

The reaction between phosphoric acid and ammonia in the DPR is highly exothermic, releasing substantial heat directly inside the dryer. This heat contributes to drying the fertilizer, thereby reducing or even eliminating the need for external fuel for the dryer.

In some plants, DPR-generated heat alone is enough to sustain drying, cutting operating energy costs by up to 20–30% compared to single-pipe systems.

3. Better Process Stability and Control

In single-pipe systems, all reaction heat and slurry are handled within the granulator, which can cause temperature fluctuations, caking, and inconsistent granule formation.The dual-pipe configuration divides the reaction load: The GPR manages slurry formation for granulation. The DPR converts part of the feed into solid MAP in a controlled environment. This separation leads to more stable operating conditions, smoother granulation, and fewer shutdowns for cleaning or unblocking.

4. Reduced Recycle Load and Lower Maintenance

Since the DPR produces dry solids instead of slurry, the liquid load entering the granulator is lower. This reduces the required recycle ratio (the amount of returned solids needed for granulation), meaning less material passes repeatedly through crushers and screens.

As a result, wear and tear on mechanical components decreases, leading to longer equipment life and less maintenance downtime.

5. Higher Nutrient Efficiency and Product Quality

Dual-pipe granulation improves the uniformity of nutrient distribution, especially for nitrogen (N) and phosphorus (P), by producing MAP in solid form and integrating it back into the granulator.

The end product typically shows: More uniform granule size and hardness. Better nutrient homogeneity. Lower moisture content, improving storage and transport stability.

6. Flexibility for Multi-Grade Production

Because the dual-pipe setup allows independent control of the GPR and DPR feed ratios, it’s easier to switch between fertilizer grades (e.g., 15-15-15, 16-16-8, 20-10-10) without long downtime.

This flexibility enables producers to manufacture multiple NPK grades in one day, which is difficult to achieve in traditional single-pipe systems.

The Dual Pipe Reactor (DPR) process is an advanced enhancement of the conventional pipe reactor granulation system. It optimizes plant performance by installing a second pipe reactor inside the dryer, in addition to the existing Granulator Pipe Reactor (GPR). While the GPR is designed to produce a slurry mixture for granulation, the DPR operates in the opposite manner—it produces a solid-phase reaction product, typically monoammonium phosphate (MAP).

Located directly in the dryer, the DPR is engineered to perform in-situ neutralization of phosphoric acid with ammonia under carefully controlled conditions. To prevent clogging and ensure smooth operation, the molar ratio (MR) of ammonia to phosphoric acid is precisely adjusted so that the DPR produces solid MAP crystals instead of a slurry. Importantly, no sulfuric acid is used in the DPR reaction. Aside from this addition, the rest of the NPK production line—granulator, dryer, screens, and crushers—remains unchanged, simplifying integration.

The DPR process allows true optimization of plant capacity without the need for major equipment expansion. In standard NPK plants, increasing production output requires feeding more liquid materials (acid and ammonia) into the granulator, which leads to excess moisture and demands a higher solid recycle ratio. This, in turn, overloads the granulation loop—requiring larger granulators, dryers, elevators, and crushers.

By contrast, the DPR diverts a portion of the phosphoric acid and ammonia feed directly into the dryer, where they react to form solid MAP granules. These solids are then recycled back to the granulator as high-quality seed material. This innovation effectively increases overall production without increasing the circulation load on the granulation loop. The DPR thus supplies additional nitrogen (N) and phosphorus (P) directly in solid form, improving nutrient balance and granulation efficiency.

Furthermore, the exothermic heat generated by the DPR’s in-dryer neutralization reaction significantly contributes to drying the material. In many cases, this heat output is sufficient to partially or fully replace conventional fuel heating, reducing operational energy consumption and improving thermal efficiency. Some plants have reported operating their dryers entirely on the reaction heat from the DPR, eliminating the need for auxiliary burners.

The DPR process is also widely used in revamp projects to modernize existing fertilizer plants. Common upgrade scenarios include: Replacement of traditional pre-neutralizers with a GPR or a full GPR–DPR configuration. Addition of a DPR to an existing GPR-based plant to boost output.

Installation of a DPR in older pre-neutralizer plants to enhance efficiency and reduce energy demand. One of the most notable advantages of the DPR upgrade is its short shutdown period compared to conventional granulation loop modifications. Since the system is modular and primarily installed in the dryer section, it can be implemented with minimal disruption to production.

We design and build advanced granulation plants that produce different types of granular fertilizers, including DAP, MAP, TSP, and NPK. Since 1995, over 100 production lines have been installed in China, with a total capacity of more than 90 million tons per year.

Our granulation process is highly flexible. With only small adjustments, the same line can produce TSP, NPK, or DAP powder fertilizers. Trace elements can also be added to improve the nutrient content of the final product through the trace element micro nutrient weighing scale.

When producing NPK fertilizers, the process flow is modified to include feed systems with weigh belt feeders for urea, map, dap and other nitrogen sources such as ammonium sulfate. If large amounts of urea are used, the secondary dryer and 3 stage screening and cooling systems are adjusted to control the granulation temperature. This helps prevent the product from becoming too soluble and reduces build-up inside the coating machine.

NPK fertilizers, especially those containing urea, need a longer drying time and lower drying temperatures because of their low melting points. The final product must also have very low moisture content—usually below 2%, depending on the grade.

To prevent caking during storage, the fertilizer granules are coated. For urea-based fertilizers, a fine resin coating is most effective. A small amount of anti caking powder and coating oil is added to help the clay stick to the granules. This coating process is usually done in a 2m diameter rotary drum coater.

Tongli’s fertilizer granulation plant is designed to produce DAP, MAP, APS, and NPK fertilizers with high efficiency and flexibility. In Tongli’s system, phosphoric acid reacts with ammonia in a stirred pre-neutralizer tank. The slurry is kept at the optimal solubility point to minimize water use. Additional ammoniation in the granulator adjusts the N:P ratio to 1.1–1.25 for MAP or 1.6–1.85 for DAP, producing large, hard, and spherical granules. The optional pipe reactor works in series with the pre-neutralizer, reducing water content and allowing higher throughput. Dual-mole scrubbing ensures clean air emissions by removing nearly all ammonia and fluorine. The result is a high-quality, uniform fertilizer product with excellent physical properties and environmental performance.

1. Stable Operation at Minimum Recycle Ratios

Our plant maintains smooth and stable operation even when operating at low recycle ratios — typically around 2.5:1, compared to 4–5:1 in conventional systems. This reduces internal material circulation, cuts down dust generation, and enhances system efficiency.

2. Compact Equipment Design for Large Capacities

Even for high-capacity plants producing multiple fertilizer grades, our equipment is compact and space-saving. Smaller granulators, dryers, and coolers lower both capital expenditure (CAPEX) and operating costs (OPEX) while maintaining full production flexibility.

3. High Product Uniformity Index (UI)

Our process achieves a Uniformity Index (UI) above 95%, meaning most granules fall within the target size range. Because of this, the screening area can be reduced by up to 30%, improving energy use and minimizing material loss.

4. Maximum Ammonia Recovery and Low Fluorine Emissions

The integrated scrubbing system captures more than 99% of ammonia from exhaust gases while keeping fluorine emissions below 10 mg/Nm³. This ensures environmental compliance and reduces chemical waste, improving both safety and sustainability.

5. High On-Stream Factor

With durable components and a reliable process design, our plants achieve an on-stream factor of over 95%, meaning minimal downtime and higher annual output.

6. Energy Savings and Reduced OPEX

Optimized heat recovery and reduced recycle ratios lower fuel and power consumption by 10–15% compared to traditional granulation systems. This directly cuts production costs while maintaining consistent quality.

7. Efficient Pre-Neutralizer Design

The pre-neutralizer ensures precise control of the reaction between phosphoric acid and ammonia, operating at an optimal N:P ratio of 0.7 to 1.45. This produces a stable slurry with minimal water, improving granulation efficiency and reducing drying load.

8. Pre-Neutralizer and Pipe Reactor Combination

When used together, the pre-neutralizer and pipe reactor improve process flexibility. The pipe reactor reduces water in the slurry by adding strong phosphoric acid and gaseous ammonia, lowering the recycle ratio and boosting production rates without sacrificing product quality.

9. Advanced Drilled Pipe Granulator NH₃ Sparger

The ammonia sparger inside the granulator ensures even distribution of ammonia, improving the consistency of chemical reactions and granule strength. This design minimizes hot spots and extends equipment life.

10. Product Screen Control System

An intelligent screen control system automatically adjusts to maintain the correct granule size distribution. Oversize and undersize fractions are efficiently recycled, ensuring smooth operation and reducing operator workload.

11. Accurate Recycling Control

A precise recycling system manages the flow of fines and oversize materials to keep granule size uniform. This improves yield and reduces unnecessary power use in crushing and reprocessing.

12. Dual-Mole Ratio Scrubbing System

The dual-mole scrubbing setup removes ammonia and fluorine efficiently in two stages. The first stage (MR 1.5) minimizes fluorine stripping, while the second stage (MR 0.7) captures the remaining ammonia, ensuring clean exhaust and environmental compliance.

13. Energy-Efficient NH₃ Vaporization

Our ammonia vaporization system uses waste heat from the process to convert liquid ammonia into gas efficiently. This reduces external heat demand and lowers overall energy consumption.

In Tongli’s pipe reactor NPK fertilizer plant, recycling control keeps the granulation process stable and the product quality uniform. The goal is to maintain the right amount of recycled material returning to the granulator so that the granules grow evenly in size and strength and the oversized particle can be re-crushed and return to improve the overall efficiency.

After granulation, the product passes through a double-deck screen or recently rotary drum screener . The large granules above 4 mm go to the crusher, the medium-sized granules between 2–4 mm go to the cooler, and only a part of the fine product below 2 mm is sent back to the granulator. By recycling only small-sized material, the process increases the total surface area available for coating with slurry, which helps the granules grow faster and reduces the total recycle rate, also by screening, unqualified particle leaves the system at once so that the dryer and cooler and coating machine can have a smaller load therefore the energy is saved which means less fuel consumption.

In most traditional systems, the recycle ratio can reach 4–6 tons of recycle per ton of product. In Tongli’s design, thanks to the pipe reactor’s lower slurry moisture and precise rotary screen screening, the recycle ratio is usually only 2.2~2.6. This lowers energy use, reduces dust generation, and makes the granulation temperature easier to control. It also means less wear on the equipment and longer operating time between maintenance stops.

The recycled material is weighed on a conveyor belt equipped with an automatic scale. The control system continuously measures the flow and adjusts how much material is diverted back into the granulator. When the product becomes too coarse, the system reduces recycle feed; when it becomes too fine, it increases the feed. This automatic adjustment keeps the particle size distribution steady without the need for manual changes.

For a clean working environment, the recycle conveyor is fully enclosed and connected to the plant’s dedusting system. This prevents dust release and keeps the air in the plant safe for workers.

With accurate recycle control, the Tongli granulation system maintains a high uniformity index (above 95%) and stable production. The result is a consistent, high-quality NPK fertilizer with lower energy use and reliable plant performance.

Pipe reactor granulation produces fertilizer with better roundness and smoother surface compared to traditional steam drum granulation. The main reason is the way the slurry is formed and sprayed inside the granulator.

In the pipe granulation process, the reaction between ammonia and phosphoric acid happens inside the pipe reactor under controlled pressure and temperature. This produces a fine, hot, and highly reactive slurry with lower moisture content and uniform viscosity. When this slurry is sprayed into the granulator, it coats the small seed particles evenly from all directions, allowing them to grow layer by layer into smooth and round granules.

In contrast, the steam drum granulation process uses steam to heat and partially react the slurry inside the granulator. The slurry often has higher water content and less uniform composition, which causes uneven coating and irregular granule growth. As a result, steam granulated products tend to have rougher surfaces, more elongated shapes, and lower roundness.

The controlled reaction conditions of the pipe reactor, combined with stable recycle control, create a more balanced granulation environment. This gives the fertilizer a roundness index typically above 0.9, compared to 0.8 or lower for standard steam drum systems.

Although pipe cross reactor granulation produces good-quality and round fertilizer granules, it cannot match the perfect sphericity and surface smoothness achieved by high tower prilling technology.

In a high tower prilling process, the fertilizer melt is sprayed from the top of a tall tower (usually 80–120 meters high). As the droplets fall through the tower, they solidify in free air under gravity. This natural cooling process allows the droplets to maintain a perfect spherical shape, resulting in nearly 100% roundness and very low surface roughness.

Pipe reactor granulator, however, forms granules by coating and layering slurry on recycled seed particles inside a rotating drum. This mechanical process always introduces some collision, rolling, and abrasion between granules. Even under optimized conditions, these physical forces create minor flat spots or uneven surfaces. The product roundness is therefore high, but not perfect.

In short, pipe reactors granulation offers a balance of good roundness, high strength, and lower cost, making it ideal for large-scale NPK, DAP, and MAP production. High tower prilling, on the other hand, is mainly chosen when superior appearance and perfect sphericity are required, such as for urea or high-grade compound fertilizers.

PIPE REACTOR CHEMICAL GRANULATION FERTILIZER PRODUCTION LINE TECHNICAL PARAMETERS(REFERENCE)

| No. | Equipment Name | Specification / Model | Material | Quantity | Remarks |

| 1 | Phosphoric Acid Storage Tank | Ø3000 × 6000 mm | C.S | 2 | With heating coil and insulation |

| 2 | Sulfuric Acid Storage Tank | Ø2800 × 5500 mm | C.S | 1 | Corrosion-resistant internal lining |

| 3 | Liquid Ammonia Storage Tank | 50 m³, 1.8 MPa | C.S | 2 | Pressure vessel, with safety valve |

| 4 | Ammonia Vaporizer Staion | 1.0 MPa, 300 kg/h | SS304 | 1 | Owner Scope |

| 5 | Acid Metering Pump | J5–1500 | SS316L | 2 | One duty, one standby |

| 6 | Ammonia Flow Metering Skid | DN50, 0–100 Nm³/h | SS304 | 1 | Includes flowmeter and control valve |

| 7 | Acid Preheating Tank | Ø1800 × 1600 mm | SS304 | 1 | Preheating of phosphoric/sulfuric acid |

| 8 | Primary Dissolving Tank | Ø2200 × 2000 mm | SS304 | 1 | With mechanical agitator |

| 9 | Secondary Dissolving Tank | Ø600 × 1250 mm | SS304 | 1 | With filtration unit |

| 10 | Slurry Dosing Pump | J5–1500 | SS304 | 1 | Controls acid–ammonia neutralization ratio |

| 11 | Slurry Transfer Pump | qV = 6 m³/h | SS316L | 2 | One in operation, one standby |

| 12 | Pipe Reactor Assembly | Ø100 mm × 2000 mm | SS316L | 1 | Integrated reaction pipe with nozzles and thermocouple |

| 13 | Slurry Spray Nozzle | PQ100–4×5 | SS316L | 1 | qV = 0–6 m³/h |

| 14 | Steam Injection Shaft | L150–5 | SS304 | 1 | qV = 0–2 t/h |

| 15 | Steam Regenerator | Ø1200 × 1500 mm | Q235 | 1 | Not applicable |

| 16 | Rotary Drum Granulator (with Pipe Reactor) | Ø3000 × 10000 mm | Q235 + SS316L lining | 1 | Integrated slurry spraying and granulation zone |

| 17 | Rotary Dryer | Ø2200 × 18000 mm | Q235 | 1 | Hot air temperature 350°C |

| 18 | Rotary Cooler | Ø2200 × 16000 mm | Q235 | 1 | Cooling air volume 25,000 Nm³/h |

| 19 | Bucket Elevator | TD250 | Carbon Steel | 2 | For material transfer |

| 20 | Rotary Screener | Ø1800 × 5000 mm | Q235 | 2 | Double-deck screening mesh |

| 21 | Rotary Coating Drum | Ø1200 × 4000 mm | Q235 | 1 | With anti-caking oil spraying system |

| 22 | Automatic Weighing Scale | Belt Type, 10–50 kg | — | 2 | For accurate product weighing |

| 23 | Automatic Packing Machine | 10–50 kg range | — | 1 | With automatic sewing system |

| 24 | Bag Filter Dust Collector | PPC96–6 | Q235 | 2 | For granulator and dryer exhaust gas |

| 25 | Induced Draft Fan | 45 kW | Q235 | 2 | For drying and dedusting system |

| 26 | PLC Control Cabinet | Siemens PLC | — | 1 | Fully automatic process control |

| 27 | Belt Conveyor System | 800 mm width | Q235 | 3 | For product conveying between units |

| 28 | Process Pipeline and Valves | DN25–DN100 | SS316L | Lot | For acid, ammonia, and steam lines |

| 29 | Instrumentation Set | Pressure, Temperature, Flow sensors | — | Lot | For process control and safety monitoring |