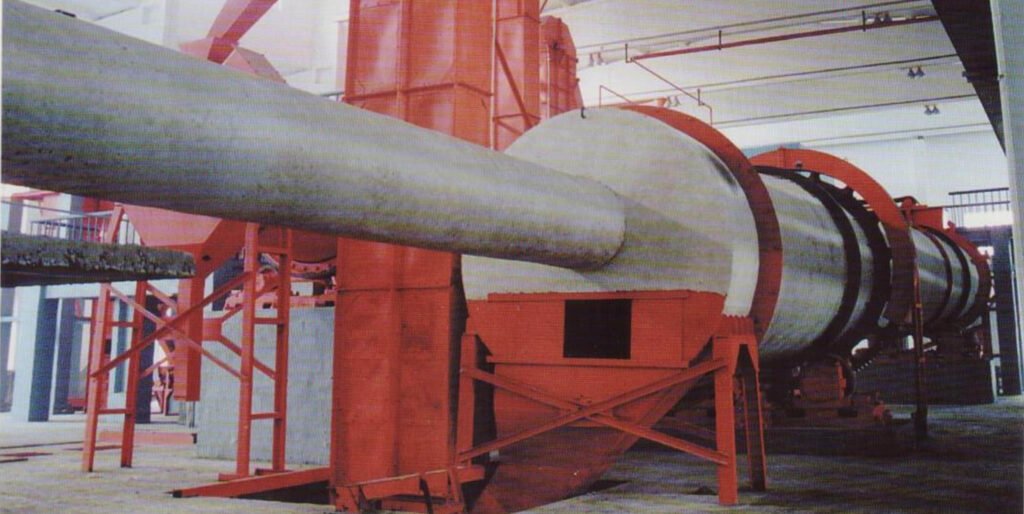

The agglomeration drum knockers aka ko drum is a core self-cleaning device ensuring the continuous and stable operation of the agglomeration drum system. Its core function is to remove material buildup on the inner wall of the drum, reducing energy consumption and product quality fluctuations. Agglomeration drums are widely used in mineral processing, npk compound fertilizer production, and specialty chemical preparation, where the rotation of the drum and the action of a binder agglomerate fine powder materials. During continuous operation, materials are easily affected by temperature changes, viscosity, and centrifugal force, leading to the formation of a buildup layer on the inner wall of the drum. The continuous thickening of this buildup layer results in uneven stress on the drum, increased operating load, and decreased product quality stability, becoming a key issue restricting production efficiency. In industrial settings, the material buildup problem is particularly prominent in rotary dryers, with buildup concentrated at the inlet end, where the incoming material has high moisture content and strong viscosity, making it a high-frequency area for buildup formation. To solve this problem, agglomeration drum knockers has undergone multiple generations of technological iteration, evolving from a simple mechanical linkage device and a pneumatic system relying on external power to a non-powered automated device deeply adapted to the system. The optimization of agglomeration drum knockers's structural design and operation directly promotes the improvement of the overall operating efficiency of the agglomeration drum system. This article reviews the technological evolution of knock out drum from mechanical hammers, covered ko drum devices, pneumatic hammer impact systems to ball-tube impact devices. It systematically analyzes the structural and performance differences of the three types of devices. The ball-tube impact device, through its powerless self-driven design and modular adaptation, performs best in terms of unclogging stability, maintenance economy, and system synergy, and can effectively support the needs of medium and large-scale continuous fertilizer production.

Why Agglomeration Drum Knockers is important? Watch this video:

Agglomeration drum knockers are critical to the reliable operation of rotary drum agglomerators because they prevent material buildup and ring formation on the internal drum wall, which can severely disrupt granulation performance. During agglomeration, sticky or hygroscopic materials tend to adhere to the drum surface; without effective knockers, these deposits harden into accretions that reduce effective drum volume, destabilize bed movement, cause uneven granule growth, and ultimately lead to process downtime. By delivering controlled mechanical impact to the drum shell, knockers continuously dislodge adhered material, maintaining a clean internal surface, stable rolling action, and consistent residence time. This ensures uniform granule size distribution, steady throughput, reduced maintenance frequency, and longer equipment service life, making drum knockers an essential component for continuous, high-capacity fertilizer and chemical granulation operations.

Remember this: A low-cost fertilizer production line may save money on day one, but it will cost far more over its service life.

Below is an example of a fertilizer plant owner in Africa who suffered significant losses due to a poor-quality fertilizer production line supplied by a small, low-cost equipment manufacturer in Henan, China. The owner expressed deep regret, stating that he should have partnered with us instead of choosing a cheap, unreliable production line.

Technological Evolution of agglomeration drum knockers device

Mechanical hammer striking device

Early agglomeration drums used a mechanical hammer knock out drum device to remove buildup. Its core structure consisted of a carbon steel hammer assembly fixed to the drum support, linked to the drum drive system via a cam mechanism or connecting rod. As the drum rotated, the drive mechanism drove the hammer to periodically strike the outer wall of the drum. The striking frequency was tied to the drum speed and had no independent adjustment function; the impact position was fixed within a preset area. This type of device had a rudimentary structure, lacked specialized protective design, and the impact force and frequency were uncontrollable. It could only meet the basic unclogging needs of low-capacity, intermittent operation scenarios. Because it was not optimized for high-frequency buildup areas such as the dryer inlet, the unclogging coverage was limited, and long-term operation could lead to localized stress concentration on the drum, affecting the equipment's lifespan.

Ko drum fixed knockout drum striking device

To address the safety hazards and limitations of first-generation devices in clearing blockages, industrial applications have gradually upgraded to covered mechanical impact devices. The core improvements include two aspects: first, adding a metal protective cover to the impact component, secured to the roller support with bolts to prevent material splashing and accidental contact by personnel; second, optimizing the transmission mechanism to support manual fine-tuning of the impact frequency and angle, allowing for targeted adaptation to critical areas such as the dryer inlet.

This type of knockout pots device still relies on mechanical linkage drive, lacking an independent power source, and has relatively low structural complexity. While the addition of the protective cover improves operational safety, the impact force adjustment range is limited, and the transmission components are susceptible to dust wear, requiring regular maintenance to ensure operational stability. Furthermore, its adaptability and blockage clearing accuracy still cannot meet the needs of medium to large-scale continuous npk organic-inorganic fertilizer production.

Ball tube type 2 in 1 knockout drum device - Agglomeration drum knockers

With the increasing production capacity and automation of agglomeration drums, ball-tube hammer agglomeration drum knockers are gradually replacing traditional hammer-type equipment, becoming the mainstream choice for over 1000+ feritilizer plant. Their core structure and working principle have been industrially validated and demonstrate significant advantages:

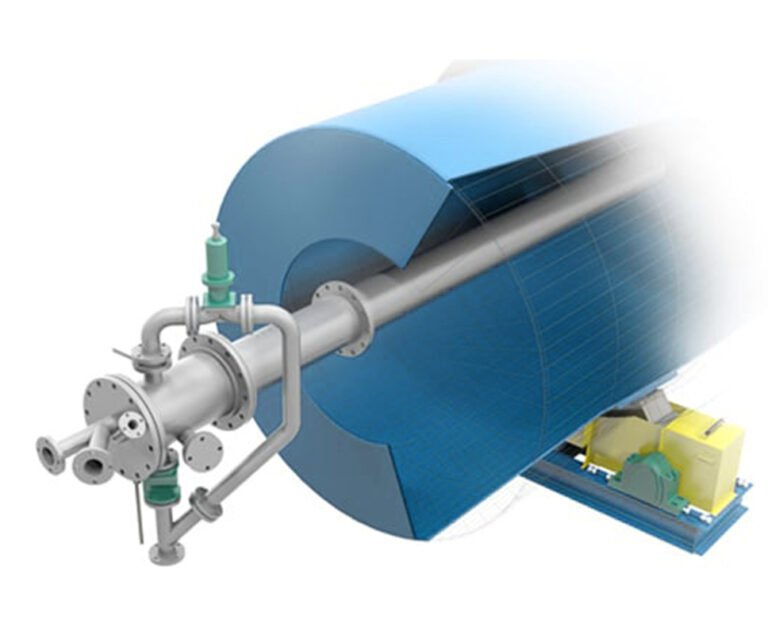

- Structurally, the device consists of a tube containing a solid ball, a wear-resistant plate, and fixing components. The tube is fixed to the outside of the drum, and the wear-resistant plate is installed on the drum shell surface to protect the shell from direct impact while ensuring that the impact force is effectively transmitted to the inner wall to remove the buildup.

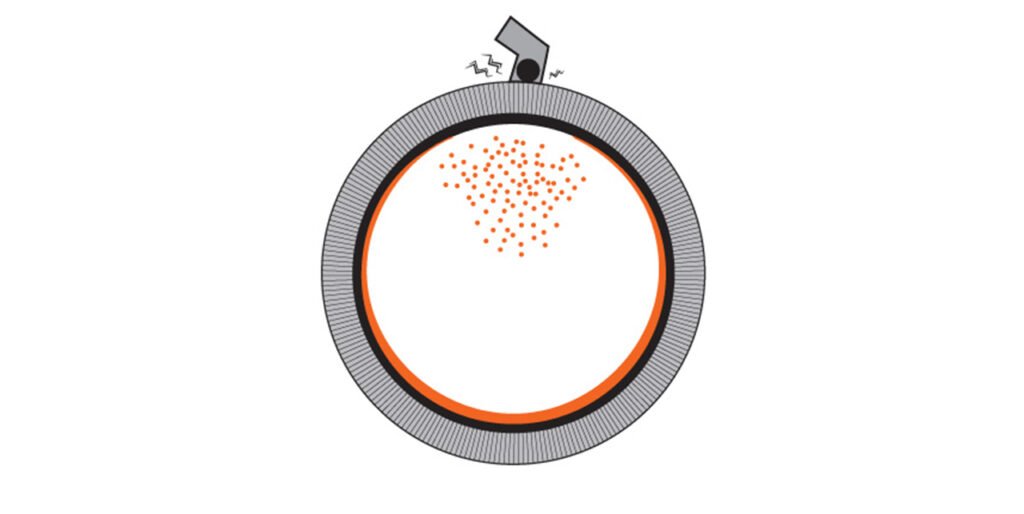

- In terms of working mechanism, it relies on the combined effect of drum rotation and gravity: when the drum rotates, the tube moves synchronously with it, and the solid ball inside falls under gravity and impacts the wear-resistant plate. The vibration waves break the bond between the buildup layer and the drum wall, causing the buildup to detach.

- In terms of design advantages, this type of device has a self-contained structure with few moving parts and low maintenance requirements; it is adaptable to various material application scenarios, can be installed in new equipment, or can be retrofitted to existing systems. It does not rely on an external power source; operation is achieved solely through the rotation of the drum itself.

Comparison of the Structure and Performance of Three Types of Striking Devices

The three types of agglomeration drum knockers differ in structural design, operation mode, safety performance, and system adaptability.

| Device Type | Structural Features | Operating Characteristics | Installation Adaptability | Safety Performance | Maintenance Requirements | System Compatibility |

| Mechanical Hammer Knocking Device | Carbon steel hammer assembly + cam/linkage transmission mechanism, no protective design | Mechanically linked drive, knocking frequency tied to drum speed, impact force non-adjustable | Fixed mounting on drum support frame, impact position preset, no adjustment possible | No protection, exposed transmission parts, risk of personnel accidental contact and material splashing | Transmission mechanism wears easily, requires frequent lubrication and part replacement, high maintenance frequency | Only suitable for small-capacity, intermittent-operation drums; cannot integrate with automated systems |

| Hooded Mechanical Knocking Device | Carbon steel hammer assembly + adjustable transmission mechanism + metal protective cover | Mechanically linked drive, supports manual fine-tuning of frequency and angle, limited force adjustment range | Can be fixed at dryer inlet end or similar areas, requires space for protective cover | Protective cover blocks splashing material, significantly reduces personnel contact risk, improved safety level | Transmission parts and cover need regular inspection, prone to jamming in dusty environments, medium maintenance demand | Suitable for medium-capacity drums, compatible with semi-automated systems, suitable for intermittent or short-duration continuous operation |

| Ball-in-Tube Hammering Device | Modular design including solid steel balls + containment tube + independent wear plate + anti-loosening fixing components | Passive self-driven (no external power), knocking frequency synchronized with drum rotation, impact force determined by ball weight and mounting angle | External modular mounting, supports multiple parallel groups, preferably at dryer inlet, easy retrofit for old equipment | No exposed moving parts, integrated protective design, meets industrial safety standards | Only periodic checks of bolt tightness and wear plate condition required, no transmission maintenance, very low frequency | Suitable for medium to large-capacity drums, seamless integration with fully automated control systems, supports 24/7 continuous operation |

Core device structural performance of agglomeration drum knockers

Detailed structure of the ball-tube hammer agglomeration drum knockers device

The core structure of the ball-tube agglomeration drum knockers device consists of three parts:

- Receiving tube: Made of wear-resistant steel, its length and inner diameter are designed according to the roller specifications. A solid ball is placed inside to ensure stable and continuous impact force.

- Wear-resistant plate: Made of wear-resistant alloy, it maintains a reasonable distance from the roller shell to avoid direct stress on the shell, while ensuring efficient vibration wave transmission and extending the roller's service life.

- Fixing components: Fixed to the outer wall of the roller with high-strength bolts and a welded base, ensuring the device is stable and does not loosen during roller rotation, suitable for long-term continuous operation.

Working principle and system coordination

The working principle is based on the synergy of gravity impact and vibration transmission: when the drum rotates, the receiving tube rotates synchronously with the drum, and the solid ball inside falls freely under the action of gravity, impacting the wear-resistant plate below. The impact force generated is transmitted to the drum shell through the wear-resistant plate, forming a vibration wave that propagates along the drum wall, causing the inner wall deposits to fall off due to fatigue failure and be discharged with the material bed.

The synergistic adaptation with the agglomeration drum system is reflected in three aspects:

- First, operational synergy: the device requires no additional power source, utilizing the drum's own rotation for operation, and is completely synchronized with the drum's running state, avoiding ineffective operation;

- Second, spatial synergy: the modular design allows for flexible configuration of the number and location of installation groups based on drum length and material accumulation distribution characteristics, especially providing precise coverage for high-frequency accumulation areas such as the dryer inlet;

- Third, control synergy: it can be connected to the drum's automated control system, providing real-time feedback on operating status and linking with drum speed adjustments, material conveying, and other aspects to ensure that the unblocking effect matches the production rhythm.

Key factors and compatibility principles of agglomeration drum knockers

Key factors to consider when selecting a model

The selection of agglomeration drum impactor should be based on the overall system requirements, taking into account equipment characteristics, material conditions, process requirements, and operating modes.

| Evaluation Dimension | Specific Indicators | Selection Principle |

| Equipment Parameters | Drum diameter, length, rotation speed, shell material | The device structure and installation method must match the drum specifications without affecting the original operating accuracy of the drum |

| Material Properties | Material moisture content, viscosity, caking tendency | For high-moisture, high-viscosity, and easily caking materials, prioritize the ball-in-tube hammering device with stable and consistent impact performance |

| Process Requirements | Production capacity, operation mode (continuous / intermittent), degree of automation | For continuous operation or highly automated production lines, prioritize the ball-in-tube device that requires no manual intervention |

| Operation Requirements | Safety standards, maintenance conditions, retrofit feasibility | In scenarios emphasizing safety and low maintenance, select the ball-in-tube device; for existing equipment retrofitting, prioritize highly adaptable modular products |

Selection and Adaptation Scenarios

- For small-scale intermittent production scenarios: If automation is low and maintenance resources are sufficient, a covered hammer can be selected to meet basic unblocking needs;

- For medium to large-scale continuous production scenarios: Regardless of material type, a ball-tube agglomeration drum knockers device is recommended. Its automated operation, low maintenance requirements, and system integration make it more suitable for the stability requirements of large-scale continuous production;

- For existing equipment retrofit scenarios: The modular design of the ball-tube device allows for installation without major modifications to the drum, offering greater adaptability, a shorter retrofit cycle, and rapid improvement in stacking control.

Maintenance and Replacement of agglomeration drum knockers

Maintenance focus

- Mechanical hammer impact device: Regularly check the lubrication and wear of the transmission mechanism, and adjust the linkage tension monthly; clean any material residue from the hammer impact surface to avoid affecting the impact effect;

- Enclosed mechanical impact device: Check the tightness of the protective cover fixing bolts weekly and clean internal dust; lubricate the transmission components monthly, and calibrate the impact angle and frequency quarterly;

- Ball-tube type agglomeration drum knockers device: Check the tightness of the fixing components quarterly, and clean dust and material debris from the steel tube; check the wear of the wear-resistant plate every 6-12 months, and replace it promptly when the wear exceeds the preset threshold; calibrate the verticality of the installation position annually to ensure impact accuracy.

Change of indications

- Safety Risks: Safety accidents may occur during the use of the original hammer, or the protective cover of the covered hammer may deform or break beyond repair, posing ongoing safety hazards;

- Performance Degradation: The device's unblocking effect decreases, and the frequency of buildup on the inner wall of the drum increases, affecting product quality or production continuity;

- System Upgrades: Increased agglomeration drum capacity and adjustments to the operating mode (e.g., from intermittent to continuous) may render the existing device unsuitable for new production demands;

- Cost Imbalance: The covered hammer requires excessive labor and maintenance, leading to increased operating costs and a lower cost-effectiveness compared to the ball-tube type device;

- Structural Aging: Significant structural deformation and component damage may occur, making it impossible to restore normal function through repair.

Agglomeration drum knockers industrial application scenarios

| Application Scenario | Production Scale & Mode | Adopted Knocking Device Type | System Collaboration & Actual Effect |

| Small-scale compound fertilizer granulation | Small to medium capacity, intermittent production | Hooded mechanical knocking device | Meets basic anti-blocking needs; requires regular maintenance of transmission parts; occasional recurring caking, but limited impact on production continuity |

| Medium-scale iron ore powder agglomeration | Medium to large capacity, continuous production | Ball-in-tube hammering device | Passive self-driven operation with no external power; effectively controls material buildup; stable drum operation, improved product consistency; maintenance costs significantly reduced |

| Large-scale mineral processing | Large capacity, fully automated continuous production | Ball-in-tube hammering device | Deep integration with automation system; real-time drum status monitoring via vibration sensors; anti-blocking effect precisely matches production rhythm; zero unplanned downtime caused by material caking |

Application results show that the pneumatic hammer impact system has an advantage in parameter adjustment flexibility, making it suitable for scenarios requiring frequent process adjustments; while the ball-tube agglomeration drum knockers performs better in terms of maintenance economy, operational stability, and lack of power dependence, especially suitable for large-scale continuous production and scenarios with limited maintenance resources. Both types of devices can meet the needs of medium to large production capacities, and the core selection depends on the on-site power conditions and maintenance requirements.

What is a Agglomerator? Why it needs agglomeration drum knockers?

An agglomerator aka granulator, is designed to transform powdery, fine-grained, or slurry materials into solid granules with a controlled 2-3mm particle size, mechanical strength, and internal porosity. By converting loose materials into stable granules, agglomerators turn powder into product. As a result, they are widely used across industries such as fertilizers, metallurgy, pharmaceuticals, food processing, and advanced materials.

Working Principle of Agglomerators

The fundamental principle of agglomeration is to apply external forces such as mechanical compression, rolling, mixing, shearing, or spray binding to promote adhesion and growth between fine particles. Under continuous motion, particles collide, bond, and reorganize, gradually forming granules that meet specific process requirements. Depending on the agglomeration mechanism and equipment structure, several types of industrial agglomerators are commonly employed.

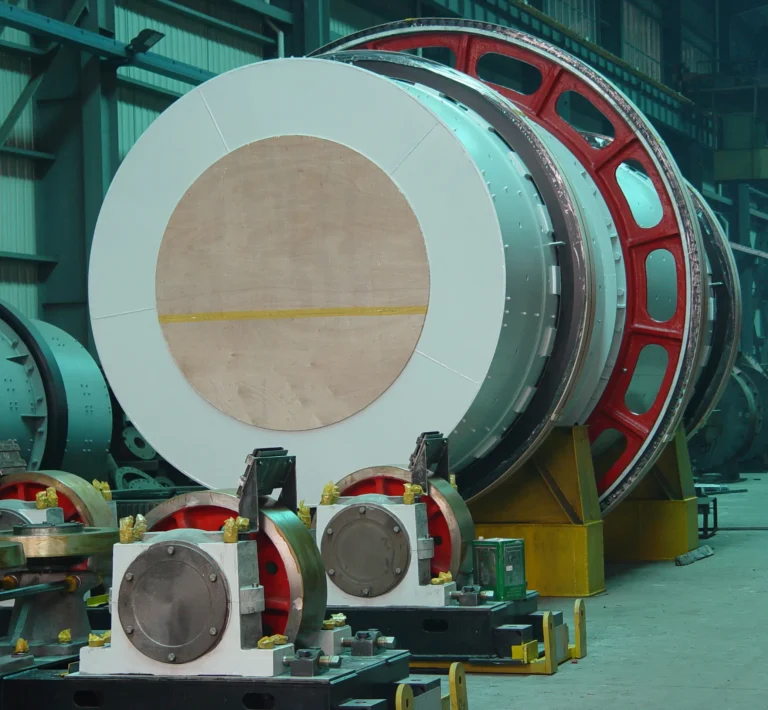

Rotary Drum Agglomerator

A rotary drum agglomerator consists of an inclined, rotating cylindrical shell. As the drum rotates, material continuously tumbles and advances through the drum while a binder is sprayed onto the particle bed. Through repeated collision, friction, and binder-induced adhesion, fine particles progressively grow into spherical or near-spherical granules. This type of agglomerator is especially suitable for high-capacity, continuous production, such as compound fertilizers and mineral powders. It is valued for its simple structure, stable operation, and uniform granule strength.

Pan (Disc) Agglomerator

The pan agglomerator features a rotating disc set at an adjustable inclination angle. Inside the pan, material is subjected to a combined action of centrifugal force, gravity, and surface friction, causing it to follow a spiral upward motion. With the controlled addition of a binder via a spray system, particles gradually layer and densify into well-defined spherical granules. Pan agglomerators are known for their excellent sphericity and precise particle size control, making them ideal for small-batch or high-precision granulation, such as catalysts, organic fertilizers, and feed additives.

Double Shaft Mixer Agglomerator

The double shaft mixer agglomerator integrates intensive mixing and granulation in a single unit. Two parallel counter-rotating shafts generate high-shear mixing, ensuring rapid and uniform material distribution. Integrated granulating elements—such as compression paddles or cutting tools—then promote in-situ agglomeration by compacting and shaping the material into granules. This design typically requires minimal binder addition and is well suited for sticky materials or processes that demand simultaneous mixing and granulation, such as chemical additives and agrochemical formulations.

Spray Agglomerator (Spray Drying Granulator)

Liquid or slurry feed is atomized into fine droplets and brought into contact with a hot gas stream. As moisture rapidly evaporates, the droplets solidify and agglomerate into granules. This method is particularly suitable for heat-sensitive materials, including food powders and pharmaceutical ingredients.

Extrusion Agglomerator

Material is forced through die openings using a screw or piston, forming dense cylindrical extrudates. These are subsequently cut and shaped into uniform granules. Extrusion agglomeration is commonly used to produce high-strength, high-density granules, such as fertilizer pellets and catalyst carriers.

Conclusion

The technological evolution of agglomeration drum impactors is essentially a development process from "mechanical linkage unblocking" to "powerless collaborative unblocking." Mechanical hammers and covered mechanical impactors met the basic needs of early low-capacity, low-automation scenarios, but suffered from insufficient safety, high maintenance costs, and limited unblocking accuracy. Ball-tube agglomeration drum knockers, through their powerless self-driven design, modular structure, and system compatibility, achieve a balance between unblocking effectiveness, operational stability, and economy. The core advantages of this device lie in its reliable structure, ease of maintenance, and ability to effectively collaborate with agglomeration drum systems of different sizes and levels of automation. Especially in high-frequency accumulation areas such as the dryer inlet, it can achieve precise unblocking through multiple modular configurations.