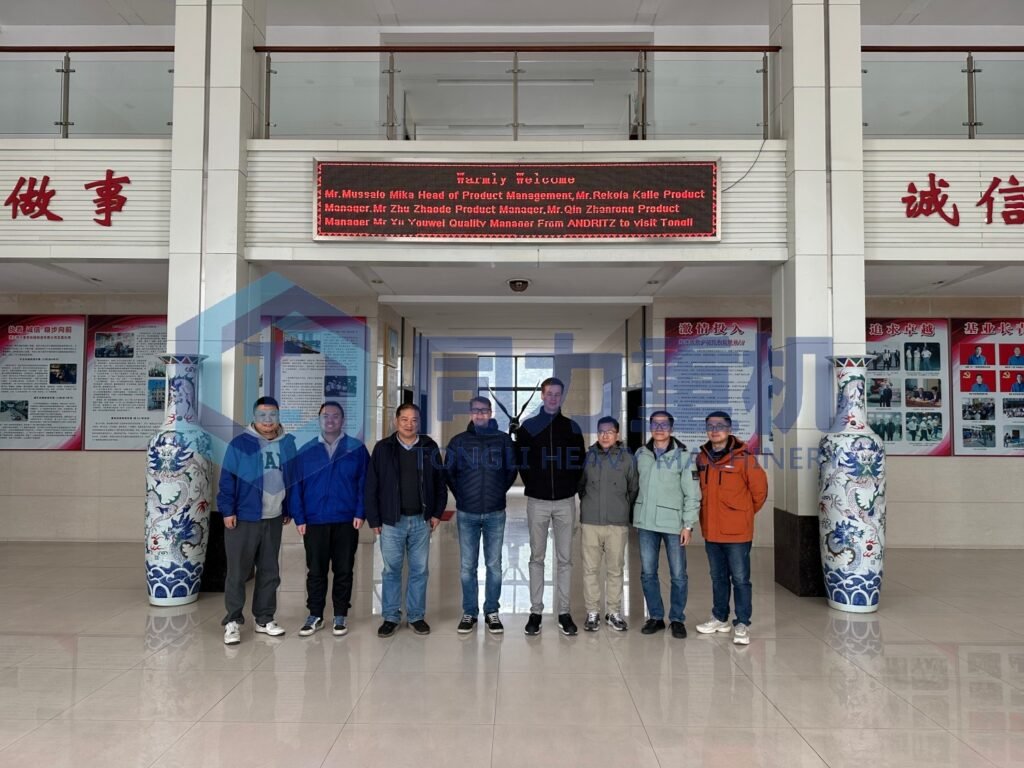

Andritz FAT Test Conducted At Tongli on Jan.27th 2026

On January 27, 2026, two senior representatives from ANDRITZ Hydro Austria visited Tongli Heavy Machinery to conduct an on-site inspection of the structural components currently under production for a pulp machine project. The visiting delegation included Mr. Mika Mussalo, Head of Product Management, and Mr. Kalle Rekola, Product Manager. During the visit, they carried out a comprehensive review of the manufacturing progress, production procedures, and quality control systems implemented for the project. The inspection focused in particular on welding quality and welding procedure compliance, including verification of welding process records, welder qualifications, and on-site weld appearance. Non-destructive testing (NDT) documentation, such as UT and MT reports, was carefully reviewed to ensure full conformity with ANDRITZ technical specifications and international standards.

In addition, the guests examined key manufacturing equipment and machining capabilities used in the production of large structural components. This included a review of Tongli’s 300-ton overhead crane, which ensures safe handling and assembly of heavy structures, as well as the 16-meter vertical lathe, critical for high-precision machining of large-diameter components. Equipment condition, machining accuracy, and process control were all discussed in detail. Throughout the visit, both parties exchanged technical insights regarding manufacturing sequences, dimensional control, inspection checkpoints, and quality assurance practices, reinforcing mutual confidence in Tongli’s production capacity and quality management system. The visit concluded with positive feedback on the workshop organization, manufacturing readiness, and progress status of the pulp machine structural components.

About Andritz AG Group

ANDRITZ AG also known as ANDRITZ Group, is a globally operating engineering and technology company headquartered in Graz, Austria. As the legal parent company of the group, ANDRITZ AG provides plants, systems, equipment, and services for a wide range of industries, including hydropower, pulp and paper, metals, and environmental and green energy solutions. The company is internationally recognized for its strong engineering capability, advanced manufacturing standards, and strict quality and safety management systems. The pulp and paper business of ANDRITZ AG is one of the company’s core divisions, providing complete technologies, equipment, and services for chemical and mechanical pulping, fiber preparation, stock processing, and recycling. ANDRITZ supplies turnkey solutions for pulp mills worldwide, with a strong focus on high-capacity, energy-efficient, and environmentally optimized systems, including advanced rotary drum pulping machines used in waste paper recycling and fiber recovery processes.

As an OEM manufacturing partner, Tongli Heavy Machinery is involved in the fabrication of key rotary drum pulper structural components and heavy-duty drum bodies, manufactured strictly in accordance with ANDRITZ engineering drawings, technical specifications, and quality standards. Leveraging Tongli’s large-scale fabrication capability, certified welding procedures, comprehensive NDT inspection, and heavy machining equipment such as 300-ton overhead cranes and 16-meter vertical lathes, Tongli ensures the reliable production of large rotary drum pulping machines that meet ANDRITZ’s performance, durability, and global delivery requirements which is suitable for all kinds of recovered paper.

What is a rotary drum pulping machine pulper for paper mill?

A drum pulper is a high-efficiency waste paper pulping and screening machine, mainly composed of a feeding hopper, rotating drum, screen drum, transmission system, base and platform, and water spray system-gentle slushing and efficient screening in a single unit. It integrates a pulping zone and a screening zone within one rotating cylinder, allowing pulping and coarse screening to be completed simultaneously. Waste paper is conveyed into the pulping area at high consistency (approximately 15%–25%), where it is repeatedly lifted and dropped by SS304 stainless steel scrapers and lifting flights mounted on the inner wall of the drum as the drum rotates. Through gentle impact with the rough inner drum surface, combined with light shear forces and increased fiber-to-fiber friction, the paper is effectively separated into individual fibers while minimizing fiber damage and preventing contaminants from being excessively broken down, making the drum pulper especially suitable for high-capacity waste paper recycling systems.

Tongli FibreFlow Drum pulping paper milling machine specification table:

| Drum Diameter (mm) | Capacity (T/D) | Pulp Consistency (%) | Installed Power (kW) |

| 2500 | 70–120 | 14–18 | 132–160 |

| 2750 | 140–200 | 14–18 | 160–200 |

| 3000 | 200–300 | 14–18 | 280–315 |

| 3250 | 240–400 | 14–18 | 315–400 |

| 3500 | 400–600 | 14–18 | 560–630 |

| 3750 | 600–800 | 14–18 | 710–800 |

| 4000 | 800–1000 | 14–18 | 900–1000 |

| 4250 | 1000-1300 | 14–18 | 1000-1250 |

| 4500 | 1200-1400 | 14–18 | 1250-1550 |

| 5000 | 1500-1800 | 14–18 | 1550-1850 |

| 6000 | 2200-2500 | 14–18 | 2000-2250 |

What is the inner structure of a drum pulper?

The drum pulper achieves continuous soaking, fiber liberation, screening, and reject separation within a single rotating enclosure, without internal rotors, knives, or high-shear components. This internal structural philosophy is fundamental to the drum pulper’s high fiber yield, low energy consumption, and superior contaminant control.

Inclined Rotary Drum and Internal Functional Zoning

The core inner structure of a drum pulper is a slightly inclined horizontal rotating drum, typically set at an inclination angle of about 1°–5°. Inside the drum, the internal space is organized according to the material treatment sequence and is functionally divided into three continuous internal zones: the feed pre-soaking zone, the main pulping zone, and the terminal screening zone.

Feed Pre-Soaking Zone (Inlet Section)

Located at the feed end of the rotating drum, the pre-soaking zone is the initial internal area where waste paper, process water, and chemical additives enter the drum. Internally, this zone is typically equipped with flow-guiding plates and pre-soaking baffles, and in some designs, loosening cones or dispersing cones are installed between baffles. These internal elements guide the incoming material to distribute evenly across the drum cross-section, while the cones help forcibly loosen large paper bundles. At a medium consistency of approximately 14%–18%, the material is thoroughly mixed and soaked, allowing water and chemicals to penetrate the paper structure and soften the fibers, thus preparing the material for gentle pulping downstream. The end of this zone incorporates a reliable internal dynamic–static sealing arrangement to prevent pulp leakage.

Main Pulping Zone (Gentle Fiber Liberation Section)

The main pulping zone is the longest and most critical internal section of the drum, typically accounting for 60%–70% of the total drum length. Its primary internal structures are lifting vanes or lifter plates, arranged in axial or helical patterns along the inner shell. These lifters are deliberately designed without blades or cutting edges, reflecting the concept of “gentle pulping.” As the drum rotates slowly at around 10–15 r/min, the lifters raise the pulp to a certain height and allow it to fall freely. Through repeated gravity impact, intense fiber-to-fiber friction, compression and release cycles, and the assistance of chemical action, waste paper fibers are gradually separated. This kneading and tumbling mechanism avoids high shear forces, effectively preserving fiber length while preventing plastics, metals, and other contaminants from being shredded, which significantly benefits downstream screening and cleaning.

Terminal Screening and Separation Zone

Situated at the discharge end of the drum, the screening zone is where fibers and contaminants are finally separated. The key internal component here is a curved perforated screen plate or screening drum section, with typical screen hole diameters in the range of 3–6 mm. Under the combined effect of internal pulp pressure and centrifugal force generated by drum rotation, fully pulped fibers pass through the screen openings and exit as accept pulp. To prevent screen blockage, high-pressure backflushing spray nozzles are installed above the screening area (acting on the inner surface), continuously spraying water to clean the screen holes. This washing action also removes usable fibers adhering to contaminants, reducing fiber loss. Coarse and heavy rejects such as plastics, metals, stones, and other debris remain inside the drum and are conveyed toward the reject outlet by the combined effects of drum inclination and internal spiral material movement.

What are the parts of a paper mill drum pulper?

Rotary Drum Shell

The rotary drum shell is fabricated from thick rolled and welded steel plates and installed horizontally with a slight inclination. Wear-resistant liners are fixed to the inner surface to resist abrasion from pulp and contaminants. Lifting vanes are welded directly to the inner wall and rotate with the drum, lifting and tumbling the pulp to achieve fiber separation by gravity impact and friction. The shell provides structural support for internal components and transmits rotational load from the drive system.

Drive System

The drive system consists of an electric motor, a reduction gearbox, and a gear transmission. Motor speed is reduced by the gearbox to the operating range required for drum rotation. Torque is transmitted through a pinion meshing with a ring gear mounted on the outer circumference of the drum shell, producing continuous low-speed rotation. Overload protection is incorporated to limit torque under abnormal loading conditions.

Screening System

The screening system is located at the discharge end of the drum and comprises a perforated screen plate or screen drum. Screen hole diameter is selected according to process requirements to allow pulp fibers to pass while retaining oversized contaminants. High-pressure backflushing nozzles are arranged to clean the screen openings and to wash fibers from reject surfaces. Separated contaminants are discharged through the reject outlet connected to the screening section.

Feed Hopper and Reject Discharge

The feed hopper is installed at the inlet end of the drum and directs waste paper and process water into the drum. Its geometry is designed to distribute material evenly across the drum cross-section. The reject discharge outlet is positioned at the terminal end of the screening section and allows continuous removal of coarse contaminants from the drum.

Key Manufacturing Standards for Rotary Drum Pulper Equipment

Rotary drum pulper equipment shall comply with EN 1034-4:2021, the dedicated EU safety standard for paper machinery, which defines requirements for mechanical guarding, electrical safety, and load limitation. The feed inlet must be equipped with a safety interlock to prevent unintended operation. The drive system shall include overload protection that automatically stops the machine when torque exceeds 150% of the rated value. All rotating components, including the ring gear and support rollers, must be fitted with protective guards with a minimum protection rating of IP54. In addition, GB/T 8196-2018 requires protective structures to withstand an impact load of 1000 N, with no sharp edges or corners, and mandates red mushroom-type emergency stop buttons with a response time of ≤0.5 s, installed within easy reach of operators. Electrical safety shall comply with GB/T 5226.1-2020, requiring motor protection grade ≥IP55, insulation class ≥F, and leakage protection with an operating current of ≤30 mA for operation in humid paper mill environments.

Materials and Manufacturing Accuracy Standards

The rotary drum shell shall be manufactured from Q345B or Q355B low-alloy high-strength steel in accordance with GB/T 1591-2018, with a minimum yield strength of 345 MPa and tensile strength of 470–630 MPa. Internal wear liners shall be made of high-manganese steel (ZGMn13) per GB/T 5680-2010, with hardness ≥HB200 and impact toughness ≥120 J/cm². The ring gear shall use 42CrMo alloy steel in accordance with GB/T 3077-2015, heat-treated to a hardness of HRC 28–32. Riding rings and support rollers shall be surface-hardened to ≥HRC45, with a hardened layer depth of 2–5 mm. Manufacturing accuracy requirements include drum roundness deviation ≤0.5‰ of diameter, straightness deviation ≤1‰ of length, welding in accordance with GB/T 985.1-2008, and ultrasonic testing achieving UT Level II acceptance.

International Management and Certification Standards

Manufacturers shall operate under ISO 9001:2015 quality management systems to ensure traceability of production, with material certificates, heat treatment records, and inspection reports provided for critical components such as ring gears and gearboxes. Equipment supplied to the EU market shall obtain CE certification, covering mechanical safety (EN 1034-4), electrical safety (EN 60204-1), and electromagnetic compatibility (EN 55011). Environmental management shall comply with ISO 14001:2015, requiring compliant discharge of wastewater and exhaust gas and a 100% classified disposal rate for solid waste such as worn liners and waste lubricating oil.

Environmental and Energy Efficiency Standards

Green design requirements shall comply with T/GDGM 0016-2021, which evaluates drum pulpers from resource, energy, environmental, and product perspectives. Equipment energy efficiency shall meet Grade 2 or above, with specific power consumption ≤8 kWh/t of pulp. Recyclable materials shall be prioritized, with recycled material content ≥30%. Noise emissions shall comply with GB 12348-2008, limiting plant boundary noise to ≤70 dB(A). Uncontrolled pulp leakage shall be ≤5 L/h to prevent water pollution.

Materials, Welding, and Machining Requirements for Drum Pulpers

Structural Materials for Drum Shell and Load-Bearing Components

The rotary drum shell shall be manufactured from structural steel equivalent to EN 10025-2 S355JR / S355J2 or ASTM A572 Grade 50. Minimum yield strength shall be ≥355 MPa, with tensile strength in the range of 470–630 MPa, suitable for combined static load, cyclic stress, and torsional loading during low-speed rotation. All plates shall be supplied with mill test certificates in accordance with EN 10204 Type 3.1.

Stainless Steel Wear-Resistant Materials for Internal Liners

Internal wear liners shall be manufactured from austenitic stainless steel, typically EN 10088-2 1.4301 (AISI 304) or 1.4404 (AISI 316L), or ASTM A240 Type 304 / 316L, depending on process chemistry and chloride content. Liners shall provide corrosion resistance to process water, chemicals, and pulp slurry, with a minimum hardness consistent with solution-annealed stainless steel. Liners shall be mechanically fastened or welded using compatible stainless steel consumables to prevent galvanic corrosion and ensure structural integrity under continuous abrasion and impact from pulp and entrained contaminants.

Materials for Transmission and Rotating Interfaces

The ring gear shall be manufactured from EN 10083-3 42CrMo4 or ASTM A29 / A322 4140, heat treated by quenching and tempering to achieve a final hardness of HRC 28–32. Riding rings and support rollers shall be surface hardened by induction or flame hardening to a surface hardness of ≥HRC45, with an effective hardened depth of 2–5 mm, ensuring resistance to rolling contact fatigue.

Welding Requirements and Non-Destructive Examination

All welding shall be executed in accordance with EN ISO 15614 (welding procedure qualification) and EN ISO 9606-1 (welder qualification). Weld joints shall comply with EN ISO 5817, quality level B or C depending on joint classification. Ultrasonic testing shall be carried out in accordance with EN ISO 17640, with acceptance criteria per EN ISO 11666 Level 2. No cracks, lack of fusion, or unacceptable indications are permitted.

Machining Accuracy and Geometric Tolerances

Drum shell rolling and machining shall achieve a roundness deviation of ≤0.5‰ of drum diameter and a straightness deviation of ≤1‰ of drum length, measured according to ISO 1101. Machined seating surfaces for riding rings, gears, and bearing interfaces shall conform to dimensional tolerances specified on approved drawings. Gear tooth geometry shall meet ISO 1328 Grade 9 or better, enabling controlled backlash and uniform load distribution.

Quality Control and Factory Acceptance Tests (FAT) for Drum Pulpers

FAT Documentation and Traceability

FAT documentation shall include EN 10204 3.1 material certificates, welding qualification records, NDT reports, heat treatment records, dimensional inspection reports, balancing certificates, and complete test data. Documentation shall be traceable to equipment serial numbers and maintained in accordance with ISO 9001:2015 quality management system requirements.

Assembly Alignment and Mechanical Interface Inspection

During assembly, the contact area between riding rings and support rollers shall be ≥70%, with uniform load distribution and a maximum local gap of ≤0.2 mm, verified using contact marking compound. Ring gear and pinion backlash shall be maintained within 0.2–0.4 mm, with tooth contact patterns covering ≥60% of tooth length and ≥40% of tooth height, evaluated in accordance with ISO 6336 principles.

Dynamic Balancing and Vibration Limits

The assembled rotary drum shall be dynamically balanced to ISO 21940-11 Grade G2.5. During trial operation, vibration velocity shall not exceed 4.5 mm/s RMS, measured in accordance with ISO 10816 / ISO 20816 at designated bearing and support locations. Any imbalance exceeding permissible limits shall be corrected prior to functional testing.

Functional Performance Testing

Performance testing shall be conducted under simulated operating conditions. When processing OCC waste paper, fiber disintegration rate shall be ≥98%, with good fiber loss ≤0.8%. Continuous operation shall be maintained for 72 hours, during which bearing temperatures shall remain ≤75 °C, motor temperature rise shall be ≤60 °C, and operating noise shall not exceed 80 dB(A) when measured according to ISO 3744.

Sealing and Leakage Tests

Sealing performance shall be tested under a static internal pressure of 0.2 MPa. No pulp leakage is permitted at the feed or discharge ends. Allowable water seepage shall not exceed 10 mL/h, verified over a defined holding period and documented in test records.

Screening Performance Verification

Screen plates or screen drums shall be inspected to confirm hole diameter deviation of ≤±0.1 mm, measured using calibrated gauges. Screening efficiency shall be ≥95%, and during operation with backflushing water pressure of 0.3–0.5 MPa, no plugging or abnormal pressure fluctuation shall occur. Inspection and test results shall be recorded as part of FAT documentation.

How to Choose an OEM Rotary Drum Pulper Manufacturer

- Verify Qualifications and Compliance: When selecting an OEM rotary drum pulper manufacturer, the first priority should be certifications and compliance capability. A qualified supplier must operate under ISO 9001 quality management, support CE conformity, and strictly follow internationally recognized safety and manufacturing standards such as EN 1034-4 for paper machinery safety. At TONGLI, all drum pulpers are designed and manufactured in compliance with these standards, and critical components are supplied with material certificates, heat treatment records, and inspection reports, ensuring full traceability and audit readiness for international paper groups.

- Evaluate Manufacturing Capacity/Technical capability: OEM drum pulpers are large, load-bearing, low-speed rotating machines that place high demands on fabrication accuracy and process control. A reliable manufacturer must possess large CNC machining capacity, heavy-duty rolling and welding equipment, in-house heat treatment, and complete non-destructive testing (UT, MT) capability. TONGLI operates heavy machining centers, large rotary component processing equipment, and dedicated fabrication lines for drum shells, ring gears, and screening sections. Backed by an experienced engineering team, TONGLI provides customized designs tailored to required capacity, raw material type, and integration with existing recycling lines.

- Experience in the paper recycling industry is critical. Manufacturers with 10+ years of drum pulper experience and references from large paper mills demonstrate process understanding beyond drawings. TONGLI has long-term involvement in waste paper recycling and pulping equipment, including OEM and replacement drum pulpers for established recycling lines. Our equipment is operating in multiple projects processing OCC, mixed waste paper, and MSW-derived fiber, with performance verified under continuous industrial operation.

- Confirm a Complete Quality Control and FAT System: A credible OEM manufacturer must control quality from raw material procurement to final delivery. This includes dimensional inspection of drum roundness and straightness, gear tooth contact verification, dynamic balancing, and full assembly checks. At TONGLI, every drum pulper undergoes comprehensive inspection and testing, including dynamic balancing, gear meshing verification, sealing checks, and 72-hour load test operation prior to shipment. This ensures that equipment performance, stability, and reliability are verified before arriving at site.

- Assess After-Sales Support and Delivery Capability: Beyond manufacturing, long-term operation depends on after-sales responsiveness and spare parts support. A qualified OEM partner should provide fast technical response, sufficient spare parts availability, and structured operator training. TONGLI maintains a dedicated after-sales service team with 24-hour response capability, supports commissioning and training, and provides long-term spare parts supply. Delivery schedules are clearly defined, balancing reasonable lead time, controlled cost, and long-term operating reliability, avoiding the hidden maintenance costs often caused by low-grade materials or shortcuts in fabrication.

Industrial Drum Pulper Manufacturer China

As a leading industrial drum pulper manufacturer in China, TONGLI provides OEM rotary drum pulpers engineered to meet the requirements of modern paper recycling and pulping lines worldwide. Choosing TONGLI means selecting a manufacturing partner that combines international compliance, heavy-duty fabrication capability, proven industry experience, and strict quality control systems, backed by responsive and reliable after-sales service. TONGLI drum pulpers are designed and manufactured in accordance with recognized international standards, supporting CE conformity and ISO 9001 quality management, ensuring safety, reliability, and full traceability of critical components. With advanced heavy machining equipment, large-scale welding and assembly facilities, and experienced engineering teams, TONGLI is capable of producing drum pulpers for high-capacity OCC and waste paper recycling applications.

Andritz Rotary Drum Pulper vs Other Drum Pulper Brands

The Andritz FibreFlow rotary drum pulper is a continuous drum pulping system widely applied in recycled fiber stock preparation, with more than 300 installations globally demonstrating its use across OCC, mixed office waste, and other recovered paper grades; it combines pulping and screening in a single rotating unit that gently separates fibers from coarse contaminants with minimal fiber loss and relatively low power consumption, and its simple drum design without internal high-shear parts contributes to high availability and reduced maintenance compared with conventional multi-component pulpers, while leading projects such as large capacity installations for DS Smith in Europe and Visy Paper in Australia confirm its industrial acceptance; other drum pulper brands also serve the pulp and paper market, but differ in design, installed base scale, and application experience — meaning buyers should compare actual performance data, installed references, maintenance requirements, and energy consumption rather than general claims when evaluating Andritz against alternatives. Other international drum pulper technologies (from major stock preparation suppliers such as Voith and Valmet) also serve the recycled fiber market and may feature alternative internal mechanics or control philosophies tailored for specific furnish types, and supply comparable pulping capacity and contaminant removal performance; when comparing Andritz with these competitors, mills typically evaluate installed references, fiber retention, energy use, maintenance needs, automation integration, and service support, with Andritz’s installed base and continuous improvement history often cited in technical literature and industry discussions as a benchmark for gentle, continuous drum pulping.

Valmet’s Drum Pulper

Valmet’s Drum Pulper technology also addresses drum pulping for recycled fiber, with design features focusing on energy efficiency and fraction separation. Valmet’s drum pulper claims up to 15–30% lower specific pulping energy relative to conventional drum pulpers and uses multi-fraction screening to separate fine and coarse fractions early in the drum, which can improve slushing efficiency and adaptability to different grades. Its integration of shredding, screening, and slushing in a compact layout and adjustable spray dilution piping broadens its operating range for various raw materials.

Voith

Voith does not promote a single specific “drum pulper” brand equivalent to FibreFlow or Valmet’s drum unit but offers a range of pulping solutions under its BlueLine portfolio. These include IntensaPulper and BluePulp LC systems that use rotor-based pulping and optimized vat/rotor geometry for rapid mixing and bale intake, particularly in low-consistency (LC) and high-throughput pulping scenarios. Voith’s systems emphasize mixing intensity, rotor-screen interaction, and flow-optimized pulper vat design to achieve fiber liberation and contaminant removal. They tend to be configured with more active internal elements (rotors, screens) compared with single-drum designs.

In conclusion: Andritz drum pulpers emphasize gentle, continuous pulping with low fiber loss and high installed base; Valmet drum pulpers focus on energy-efficient processing with fraction separation; and Voith pulping systems often utilize rotor-driven mixing tailored for high throughput and flexible furnish handling, so the best technology choice depends on process goals (energy, fiber quality, contaminant load), furnish characteristics, and integration within overall stock preparation.

Conclusion:

The on-site inspection by senior ANDRITZ representatives confirmed that Tongli Heavy Machinery possesses the manufacturing discipline, technical capability, and quality management systems required for the production of large-scale rotary drum pulper equipment. From certified materials and controlled welding processes to heavy-duty machining, dimensional accuracy, and comprehensive factory acceptance testing, Tongli’s fabrication practices fully align with international paper machinery standards and ANDRITZ’s stringent technical requirements. Combined with proven experience in waste paper recycling applications and the ability to deliver high-capacity, low-shear drum pulping solutions, Tongli demonstrates its role as a reliable OEM partner capable of supporting global pulp and paper projects with consistent quality, long-term reliability, and lifecycle-focused manufacturing excellence.