Introduction:

The new medical and hazardous waste incinerators in Abu Dhabi and Al Ain are being completed by Tadweer, the Abu Dhabi Waste Management Center. A capacity of 7,500 tonnes of waste per year is provided by the Abu Dhabi facility. The latest incineration technologies are being used at both sites to ensure that waste is collected and treated safely and in an environmentally friendly way. The projects in Abu Dhabi and Al Ain have been reported to have reached 100% completion 5 years ago. Two warehouses and cold storage rooms have been included at each site to store ash and other residues from the incineration process safely. Notice for this project Tialoc is the sub contractor under Tadweer, and TONGLI serves as the OEM manufactuer of Tialoc had provided full sets of the incineration rotary kiln to the client Cleanco waste treatment LLC, Abu Dhabi(كلينكو لمعالجة النفايات ذ.م.م).

Cleanco Waste Treatment: Leading Sustainable Waste Management in the UAE

Cleanco Waste Treatment (CWT) follows the vision of the UAE leaders and the expectations of the government. The company focuses on expanding its services and creating sustainable systems and solutions to lead the global development of waste management. CWT is part of the H.E. Yousef Khouri Group, founded in 1980. The group is one of the leading Emirati family-owned businesses in the UAE. Cleanco is a major provider of hazardous and medical waste collection, transportation, treatment, and disposal services for both public and private sectors, including industrial, commercial, institutional, and healthcare clients. Its projects cover the design, construction, operation, and maintenance of advanced waste management facilities. These facilities handle hazardous and medical waste according to laws and regulations, ensuring high-quality services while supporting sustainable development goals. Dr. Khalid Khouri, CEO of Cleanco Waste Treatment, said: “Our vision is clear. Following the UAE government and Abu Dhabi Waste Management Centre (Tadweer) strategies, we adopt global best practices and meet the highest international standards to improve public health and the environment in our country.”

When the cleanco project started? Abu Dhabi Opens Eco-Friendly Waste Treatment Complex ‘Eco Park’

Abu Dhabi Waste Management Centre (Tadweer) has opened a new eco-friendly waste treatment complex called Eco Park. The project is part of Tadweer’s ongoing efforts to promote sustainable waste management in Abu Dhabi. The complex is located about 70 km from Abu Dhabi city on Hamim Road. It covers 27 plots and spreads over 1.8 million square meters. Tadweer said the complex will be an important step in creating an integrated ecosystem that supports the Abu Dhabi Environment Vision 2030. The opening ceremony was attended by H.E. Dr. Salem Al Kaabi, Director General of Tadweer; Rahul Dua, General Manager of Al Ahlia Waste Treatment; Dr. Khalid Khouri, CEO of Cleanco Waste Treatment; senior Tadweer officials; and representatives from Tadweer’s strategic partners in both government and private sectors. After the ceremony, Tadweer presented details about the complex, including its operational model, goals, nearby facilities, and the companies running the plants. Tadweer also shared information about its current and future recycling projects. Special attention was given to the safe and eco-friendly disposal of medical and hazardous waste, as well as animal carcasses. The complex includes dedicated facilities for treating medical and hazardous waste. Built with an investment of AED 100 million, these facilities are operated under the supervision of Al Ahlia Waste Treatment and Cleanco Waste Treatment. The facilities have a total capacity of 7,500 tons per year, which equals about 1,560 kg per hour.

Tadweer announces the opening of the Al Ain tongli incinerator, strengthening the compliance of medical and hazardous waste treatment

Abu Dhabi Waste Management (Tadweer) has officially opened its medical and hazardous waste incinerator in Al Ain, following a Dh25 million expansion. With a daily processing capacity of nearly 12 tons of medical and hazardous waste (500 kilograms per hour), the incinerator will contribute to Tadweer's strategic goal of improving the efficiency of Abu Dhabi's integrated waste management sector, as outlined in the Abu Dhabi Environmental Vision 2030. Operated in partnership with Cleanco Waste Management, the incinerator utilizes a state-of-the-art rotary kiln (manufactured by Tongli) to collect and process various types of medical and hazardous waste generated by hospitals, clinics, medical centers, pharmacies, educational institutions, government agencies, and commercial entities in Al Ain. According to a Tadweer statement, through close public and private sector collaboration, the incinerator enables Abu Dhabi's medical waste generators to comply with relevant regulations for medical and hazardous waste disposal.

Furthermore, Tadweer stated that an e-waste tracking system has been established to ensure that waste collection and transportation adhere to the highest international safety standards. The Tongli-designed and manufactured incinerator burns hazardous waste at temperatures up to 1200 degrees Celsius, meeting UAE environmental regulations on incineration gas emissions and ensuring that emissions do not exceed EU standards. The incineration process generates 5% ash per ton of waste, which is transported sustainably to a dedicated sanitary landfill in Al Ain. The facility operates in coordination with Tadweer's strategic partners, including the Environment Agency - Abu Dhabi (EAD), the Abu Dhabi Health Services Company (SEHA), and the Department of Municipalities and Transport (DMT), while safeguarding the interests of waste generators and alleviating any additional burden on them.

Abu Dhabi's Medical Waste Management Challenge and Tadweer's Quick Response

Waste management authorities faced the challenge of properly handling and disposing of large volumes of highly infectious medical waste, including consumables used by healthcare workers and patients. Furthermore, large volumes of contaminated waste generated by quarantine facilities also needed to be handled. The Abu Dhabi Waste Management Centre (Tadweer) acted swiftly to address this challenge, deploying existing incineration facilities, including backup incinerators, and procuring mobile incinerators at short notice.

Tadweer Experts Focus on Waste Management Issues and Measures

Dr. Udayan Banerjee and Engineer Abdul Mohsin Mubarak Al Katheeri highlighted the challenges Tadweer faces and the key measures it has implemented to manage these complex waste streams.

The Serious Hazards of Improper Handling of Medical and Hazardous Waste in Abu Dhabi Dubai UAE

Improper handling and disposal of medical waste poses a significant risk of secondary disease transmission, as waste handlers/workers, healthcare professionals, patients, and the community at large are exposed to infectious pathogens when waste is temporarily stored in temporary storage areas and ultimately improperly disposed of. Similarly, hazardous waste poses serious health hazards not only to waste handlers/workers and the community at large, but also has significant adverse impacts on the environment.

Specific Classification and Characteristics of Medical Waste

Medical waste includes pathological waste (including but not limited to tissue and blood), other infectious waste, pharmaceutical waste including cytotoxic waste, sharps (including needles, blades, surgical instruments), hazardous chemical waste including residues, and radioactive waste. Pathological and infectious waste is considered to contain pathogens (disease-causing bacteria, viruses, parasites, or fungi) in concentrations or quantities sufficient to cause disease in vulnerable hosts that may be exposed to these wastes.

Medical Waste Treatment Technologies and Related Regulations

Currently, no single solution for medical waste treatment can mitigate its potential hazards. While a variety of technologies are available, the selection of destruction and decontamination technologies primarily focuses on mitigating potential hazards and taking into account local factors. Some technologies, such as incineration, are considered effective when the equipment is well-maintained and operated under strict monitoring, compliance, and oversight. At the same time, incinerators that are poorly maintained or operated beyond their design parameters can be potentially hazardous. The UAE Federal Ministry of Climate Change and Environment has established regulations (Ministerial Decree No. 37 of 2001) that primarily utilize incineration for the treatment of medical waste, with the exception of radioactive waste, which requires separate treatment.

Application and Regulatory Requirements of Autoclave Sterilization

In addition to incineration, some medical waste treatment facilities use autoclave sterilization. However, the sterilized waste ultimately needs to be landfilled. In the UAE, this is a dual regulatory requirement: Ministerial Decree No. 37 of 2001 and the UAE National Agenda 2021, which sets targets for diverting waste from landfills.

History of Medical Waste Management in Abu Dhabi Regions

In the Emirate of Abu Dhabi, the Abu Dhabi Waste Management Centre has operated a medical waste incinerator in Al Ain since 2009, which treats medical waste generated solely in the Al Ain region. Medical waste generated in Abu Dhabi and Al Dhafra regions, on the other hand, has traditionally been managed by private environmental service providers, who either use some form of thermal treatment (but not autoclaving) or hydrated lime. Both technologies fail to meet regulatory requirements. Furthermore, the treated waste is landfilled, which is inconsistent with the goals set by the UAE Agenda 2021.

Planning and Construction of Medical and Hazardous Waste Management in Abu Dhabi

Before the COVID-19 pandemic, the Emirate of Abu Dhabi generated approximately 6,000 tons of medical waste annually. In addition, a significant amount of incinerable hazardous waste is either exported abroad or illegally mixed with non-hazardous waste and dumped in landfills. To address this issue, as part of its integrated waste management master plan, the Abu Dhabi Waste Management Center (ADMC) decided to construct rotary kiln incinerators with sufficient capacity to safely incinerate both medical waste and incinerable hazardous waste.

How to proceed?

Thus, the Abu Dhabi Waste Management Center (ADMC) invited investors through a competitive bidding process to design, build, own, and operate three rotary kiln incinerators. In Abu Dhabi, Al Ahalia Waste Treatment LLC and Cleanco Waste Treatment LLC have already constructed two rotary kiln incinerators with a design capacity of 1.5 tons per hour. These incinerators serve the Abu Dhabi and Al Dhafra regions, respectively. In the Al Ain region, Cleanco Waste Treatment LLC is constructing another rotary kiln incinerator with a design capacity of 0.5 tons per hour, in addition to the existing medical waste incinerator. Rotary Kiln Incinerator Configuration and Treatment of Non-Incinerable Hazardous Waste. All three rotary kiln incinerators are designed for the incineration of medical and hazardous waste and are equipped with advanced air pollution control devices and a continuous emissions monitoring system (CEMS) directly connected to the Abu Dhabi Environment Agency's online monitoring network. This robust system ensures compliance with emission standards. Abu Dhabi also has a hazardous waste stabilization unit to effectively manage non-incinerable hazardous waste. After stabilization and leachability testing, this waste is ultimately transported to an engineered landfill for disposal.

New Requirements for Medical Waste Management During the COVID-19 Pandemic

With the global spread of the COVID-19 pandemic, the potential hazards of medical waste have increased exponentially. The European Commission has issued waste management guidelines in response to the COVID-19 crisis, requiring that waste generated by cleaning services in healthcare facilities be treated as infectious medical waste. Some countries have formally mandated that general waste generated by infectious disease patients and quarantined individuals be treated as medical waste. Tadweer's COVID-19 Response and Abu Dhabi's Management Mechanis. The Abu Dhabi Waste Management Center quickly responded to the additional burden of medical waste generated by COVID-19 treatment and isolation facilities. The center deployed existing incineration facilities, including a backup incinerator (for use during maintenance on the main rotary kiln incinerator), and procured and commissioned three mobile medical waste incinerators equipped with appropriate air pollution control devices. As a result, the Emirate of Abu Dhabi has an effective medical and hazardous waste management mechanism.

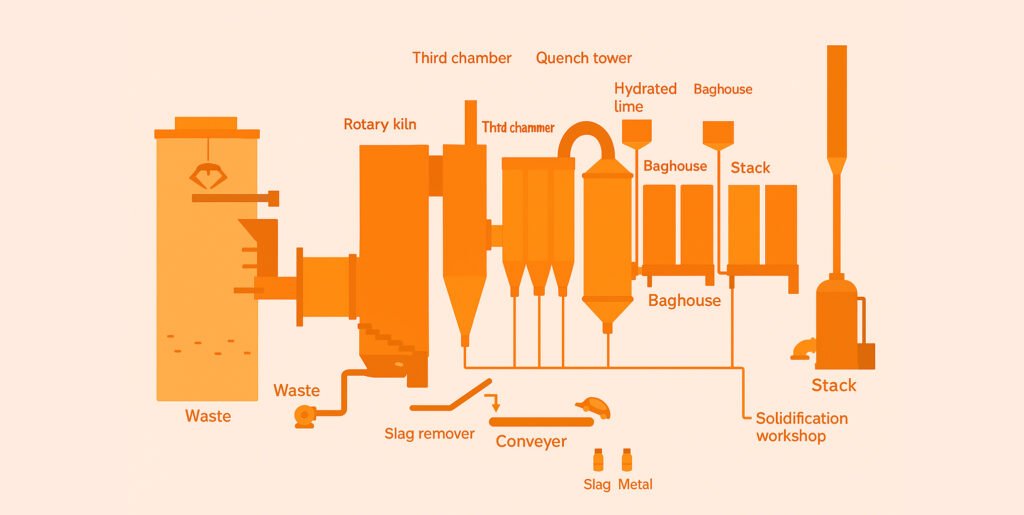

What is the process flow of hazardous waste incineration in cleanco waste treatment llc?

- Feeding: Medical waste (such as pathological waste, infectious waste, and sharps) is transported to the incineration system's starting point and begins the treatment process.

- Rotary kiln: Medical waste is fed into the rotary kiln, where it undergoes initial heating and decomposition, marking the first step in the incineration process. The kiln's rotation ensures more even heating of the waste.

- Secondary combustion chamber: This stage involves secondary combustion of the flue gas, further decomposing any incompletely burned pollutants and improving incineration efficiency.

- Waste heat boiler: Flue gas enters the waste heat boiler, where heat generated by incineration is recovered for use in steam generation, achieving energy recovery and initially reducing the flue gas temperature.

- Quench tower: Flue gas enters the quench tower, where rapid cooling (typically through the injection of cooling water) prevents the re-formation of pollutants such as dioxins and controls pollutant formation.

- Purification: Flue gas undergoes sequential treatment, passing through a reaction tower that injects calcium hydroxide to neutralize acidic gases (such as hydrogen chloride) in the flue gas. Activated carbon adsorption removes persistent pollutants such as heavy metals and dioxins. A two-stage baghouse process intercepts particulate matter and purifies the flue gas.

- Some processes also include a wet scrubber for further purification to ensure flue gas pollutant levels meet standards.

- Emission: The purified flue gas is discharged through a chimney, meeting the environmental regulations for incineration gases in the UAE and EU.

- Slag treatment: Slag generated by incineration is transported through a slag remover and conveyor, where recyclable materials such as slag metal are sorted. The remaining slag is transported to a solidification workshop, where it undergoes stabilization treatment and is then transferred to a dedicated sanitary landfill.

Cleanco waste treatment llc: Leading the Way in Waste Management

In recent years, Cleanco Waste Treatment (CWT) has signed several new projects with Tadweer. The company has been awarded contracts for the design, construction, operation, maintenance, and control of waste treatment facilities in Al Ain and Abu Dhabi. CWT also received contracts to collect, transport, treat, and dispose of COVID-19 waste in Abu Dhabi. In addition, the company has managed the construction of testing tents and screening centers in the northern emirates.

“Today, CWT is one of the largest providers of hazardous and medical waste management solutions in the region. We operate and maintain the most incineration facilities in the UAE. A single incinerator alone has a processing capacity of over 60 tons per day. We are now expanding our solutions by building more disposal units at hazardous waste landfills, adding neutralization and redox systems, evaporation ponds, and solidification and stabilization facilities. This will make CWT the leading provider of integrated facilities in the region, offering complete solutions for all clients,” said Dr. Khalid Khouri.

CWT was also a frontline service provider during the COVID-19 pandemic. In Abu Dhabi, Cleanco operated the only incineration facility authorized to manage COVID-19 waste according to laws and regulations. During the early stages of the pandemic, all COVID-19 waste in Abu Dhabi was collected by Tadweer and sent to the medical waste incinerator in Al Ain. CWT’s dedicated fleet collected and transported the waste while disinfecting refrigerated transport vehicles, bins, and the facility itself.

“Handling COVID-19 waste first was very challenging, but we knew our responsibility was great, and we had to lead by example,” said Dr. Khouri. At the same time, CWT began building its latest project in the Al Dhafra region of Abu Dhabi — an integrated waste treatment plant. The facility was officially opened later that year in the Tadweer Eco Park.

Cleanco waste treatment llc advanced facilities and cutting-edge technology

Cleanco Waste Treatment (CWT) uses advanced tongli rotary kiln incineration technology and global best practices to ensure that its plants and facilities operate according to EU directives, standards, and regulations, as well as local and federal laws. The company started providing services in the UAE in 2009, beginning with a high-pressure sterilizer for treating medical waste from healthcare facilities. Today, CWT operates multiple units and works with various clients to handle larger volumes of waste. This is part of the company’s integrated hazardous and medical waste management solutions. CWT also provides overseas treatment for certain “special wastes” that cannot be processed locally in the UAE. The company collaborates with international consultants and waste treatment companies to deliver solutions that meet EU-standard practices and regulations. Its goal is to become a one-stop service provider for all client needs in this sector. “Our plant control systems ensure fully automated processes, minimizing human interference. All operations are continuously monitored, and data is carefully recorded,” said CWT management.

Cleanco: Handling Different Types of Waste

CWT processes many types of hazardous waste according to strict acceptance standards. This includes combustible hazardous waste and industrial waste, such as contaminated packaging and treated wastewater. Chemical waste, including solvents, acids, alkalis, paints, coatings, agricultural pesticides, oily rags, and sludge, is also managed. CWT even exports certain “special wastes” that cannot be treated locally to Europe for proper disposal. The company uses the best available technologies and practices to manage multiple operational units, from incinerators to pre-treatment facilities and landfills. All operations follow EU directives and regulations to ensure safe and compliant hazardous waste management.

Abu Dhabi’s Vision for Circular Waste Management

“CWT’s vision is to support a circular economy in Abu Dhabi, especially in hazardous waste management. This includes a cradle-to-grave approach covering both combustible and non-combustible waste, from reuse and recycling to final treatment and disposal, providing a one-stop service,” said Dr. Khaled Khouri, CEO of CWT. He added that waste generators and environmental service providers (ESPs) will work together to build a sustainable framework that aligns with the UAE government’s environmental goals and Abu Dhabi Vision 2030. Policies from the past decades, including strategies developed by Abu Dhabi Environment Agency (EAD) and Tadweer, have improved waste management services and set international standards.

Facing Challenges in Hazardous Waste Management

Managing hazardous waste involves many challenges. One major challenge is the risk to employees’ and the public’s health and safety. CWT addresses this by providing top-level training, protective equipment, and strict health and safety procedures. Environmental risks are minimized through best practices in hazardous waste management according to regulations. Another challenge is resistance from waste generators, often due to the high costs of disposal. Dr. Khaled Khouri explained that CWT implements cost-effective technologies and systems, optimizes resources, and works closely with clients to provide guidance and answer questions. Strict compliance procedures are also in place to meet all local and international regulations for waste transport, treatment, and disposal.

Innovation: High-viscosity sludge treatment process and biodiesel application

The approval of CWT's high-viscosity sludge treatment process marks a significant milestone in the company's journey towards sustainable waste management. Incineration technology provides a safe and effective treatment solution for high-viscosity sludge, a difficult-to-treat waste, reducing landfill waste and protecting the environment and public health. In addition, CWT has begun testing biodiesel blends for its waste collection and transportation vehicles. Dr. Al Khouri stated, "As a responsible industry leader, we continuously seek innovative solutions to reduce the ecological impact of our operations. This initiative not only contributes to a cleaner environment but also fosters a healthier future for our communities."

Oman's Be'ah Company's Industrial Waste Management Practices

Oman's Be'ah Company is a leading hazardous waste management company in the region, specializing in the treatment of non-radioactive and non-explosive industrial waste. Chief Operating Officer AbdulKareem Qasim Al-Balushi noted that the company provides specialized services to the mining, oil and gas, manufacturing, and water treatment industries. Be'ah Company has established advanced facilities, such as the Integrated Waste Treatment Facility (IWTF) in Sohar, which is considered one of the most advanced and comprehensive waste management centers in the Middle East. The facility is capable of processing a wide range of industrial waste from across the country, including petroleum and chemical waste, and provides comprehensive infrastructure and management systems for hazardous waste generated by industrial facilities. Al-Balushi stated, "The goal of this facility is to improve the efficiency of hazardous waste treatment through centralized management while meeting stringent environmental standards and regulations." The company also actively adopts international standards to guide its operations, using its advanced facilities to address the evolving needs and complex challenges of the industry. The Be'ah team is committed to continuous improvement of its technologies and processes to ensure that every type of waste is handled safely and environmentally friendly.

Be'ah Waste Flow Tracking and Laboratory Monitoring

Be’ah has implemented an online inventory system that allows waste generators to record the flow of hazardous waste, from generation to final disposal. This system helps the team assess waste types, determine the most appropriate treatment options, and guide proper waste transportation, labeling, and packaging. Al-Balushi noted, "This system ensures compliance with environmental regulations at every step of our operations, while also enhancing safety and transparency." Be’ah also operates an ISO 17025-certified laboratory that specializes in testing liquid and solid industrial waste samples. The laboratory conducts environmental inspections, monitoring, waste treatment optimization, and informs decisions on treatment methods. Al-Balushi explained, "Testing waste before landfill or disposal is crucial. It not only protects the environment and public health, but also ensures that our processes comply with regulations and are handled safely and responsibly. In addition, the laboratory continuously strengthens its monitoring system and data collection, supporting the company's proactive management measures. This means Be’ah not only processes waste but also continuously optimizes its processes through data analysis to ensure safety and efficiency.

Be'ah Recycling and Sustainable Development Initiatives

Be’ah has implemented numerous initiatives in the areas of recycling and sustainable development. Al-Balushi noted that recycling programs are already in place across many industrial sectors, including for paper, plastics, metals, and glass. Furthermore, the company is researching how to recycle materials such as slag, exploring more innovative ways to convert waste into usable resources. Be’ah also operates recycling programs for specialized waste streams, including cooking oil, petroleum, lead-acid batteries, waste electrical and electronic equipment (WEEE), used tires, plastics, and green waste. The company collaborates with local recycling companies to help small and medium-sized enterprises better manage and recycle specific waste streams. Al-Balushi emphasized that "such initiatives not only reduce the burden on landfills but also contribute to the sustainable development of the entire industrial waste management industry."

Be’ah also places a high priority on regulation and compliance. The company strictly adheres to waste disposal regulations, implementing high-quality controls, detailed recordkeeping, and rigorous inspection procedures. Al-Balushi emphasized the importance of working closely with regulators and industry partners to ensure the highest standards of waste treatment and disposal, while also promoting sustainable practices within the industry.

Cleanco Revolutionizes Medical Waste Management

Cleanco Waste Treatment (CWT) utilizes advanced incineration technology to ensure safe, efficient, and environmentally friendly medical waste treatment. Chief Operating Officer Panchal noted, "Our incineration technology represents the gold standard in medical waste treatment. This method ensures the safe destruction of waste while significantly reducing emissions, in line with our commitment to sustainability." The system strictly adheres to UAE emission standards, effectively reducing environmental pollution. CWT's medical waste management emphasizes precision and accountability, seamlessly integrating safety, compliance, and efficiency. Waste is collected using red or yellow bags and yellow bins marked with the biohazard symbol, and sharps are placed in heavy-duty polyethylene containers to prevent accidental contact. Waste is transported via GPS-tracked, secure transport vehicles and refrigerated for safe transportation. These vehicles are registered with the waste industry regulatory agency, ensuring compliance with safety regulations throughout the transportation process and preventing leaks and contamination.

Advanced Processes and Transparent Management

"Every step of the process is meticulously designed," said Panchal. CWT's BOLISATY system integrates waste data, providing full transparency and meeting regulatory tracking requirements. Stakeholders are encouraged to participate to ensure the responsible disposal of waste. The company not only focuses on operational excellence but also collaborates with healthcare facilities to raise public awareness about the proper handling of medical waste. CWT conducts training sessions to educate medical staff on how to sort, package, and dispose of medical waste. These sessions emphasize safe and environmentally friendly practices, enabling healthcare facilities to implement cost-effective, sustainable waste management strategies over the long term.

Cleanco Community Education and Social Responsibility

“Education is a critical component of our mission,” Panchal noted. CWT organizes community events to promote the importance of sustainable waste management. These events range from blood drives to breast cancer awareness campaigns, often held in partnership with local healthcare facilities. CWT also collaborates with the Make-A-Wish Foundation to demonstrate its commitment to social responsibility. Through these efforts, the company emphasizes the importance of proper medical waste management for public health and the environment. Beyond waste disposal, the company actively promotes social education and community engagement, fostering a virtuous cycle of environmental awareness.

Addressing Regulatory and Health and Safety Challenges

Medical waste management presents multiple challenges, including regulatory compliance, waste characterization, and health and safety risks. The UAE enforces strict environmental laws, which are overseen by federal and local agencies, such as the Environment Agency-Abu Dhabi. CWT's emissions system is connected to a real-time monitoring system, providing real-time data to regulators. Panchal noted, "Compliance requirements, including equipment maintenance, waste segregation, and adherence to emission standards, are crucial to ensuring safety." Handling biohazardous waste presents risks such as needlestick injuries and chemical fumes. CWT adheres to strict health and safety procedures, including personal protective equipment (PPE), engineering controls, and OSHA-compliant practices. The company also continuously monitors air, emissions, and groundwater to ensure no impact on the environment or personnel safety.

Excellent Investment and Facility Construction

Panchal acknowledged that maintaining high standards of waste management requires significant investment, including maintenance of monitoring probes and air pollution control devices. However, he emphasized that these investments are crucial to ensuring operational excellence. The UAE's excellent regulatory framework and its history of medical waste management also provided guidance for CWT. In 2017, the UAE underwent major regulatory reforms, with the Waste Sector Regulatory Authority overseeing the new system. The government issued a public tender for the construction of rotary incinerators, utilizing the best available global technology. Cleanco was awarded the contract to build facilities in Abu Dhabi and Al Ain that meet UAE and EU emission standards. These facilities have been operating safely for over three years. The existing system significantly reduces waste volume, aligning with Abu Dhabi's 2040 Waste Management Plan and reflecting the company's long-term strategy.

Cleanco Vision 2025 and Beyond

CWT plans to expand its operations into the Middle East and North Africa region, applying its experience in medical and hazardous waste management to more waste infrastructure projects. The company is optimizing processes to improve resource efficiency and reduce waste, while creating value for clients and stakeholders. The company has established strategic partnerships with regional holdings and government agencies, investing in talent development and building a highly skilled workforce. CWT aligns its operations with the UAE's environmental vision and emphasizes its commitment to sustainable development. Panchal reiterated, "Our incineration technology represents the gold standard for medical waste treatment, ensuring safety while significantly reducing emissions and achieving sustainable development goals."

Cleanco and BEIL Partner to Win Al Qusais Project

Cleanco Waste Treatment LLC (CWTME), in partnership with BEIL Infrastructure Limited, has successfully won the contract for the Al Qusais landfill gas extraction and treatment network project. This joint project, completed by the consortium, is expected to mark a significant milestone in the UAE's pursuit of net-zero emissions by 2050. Dr. Khalid Al Khoori, CEO of CWTME, stated, "Our goal is to revolutionize landfill management, not only in the UAE but across the region." Awarded by Dubai Municipality, the project will utilize cutting-edge landfill gas management technology and is a prerequisite for the planned closure of the Al Qusais landfill in 2027. Dr. Jayesh Panchal, General Manager of CWTME, noted that this collaboration will help advance the UAE's sustainable development agenda and provide an innovative model for future waste management.

Strategic Collaboration with Dubai Municipality

Dr. Panchal stated that the project demonstrates Dubai's growing capabilities in waste management and its commitment to a circular and green economy. This agreement aligns with Dubai's Integrated Waste Strategy 2041, which aims to create innovative waste management solutions and minimize the environmental impact of waste. CWTME and BEIL will be responsible for the construction of the Al Qusais landfill gas extraction and treatment network, as well as its one-year operational management. Dr. Al Khoori emphasized, "Through this partnership, we are playing a key role in the UAE's commitment to achieving net zero emissions by 2050." Dr. Panchal added, "Our innovative approach to landfill gas management delivers significant environmental benefits and is fully aligned with the UAE's sustainable development vision."

Project Team and Partners

Dr. Panchal emphasized the crucial role played by Mr. Ashok Panjwani, Executive Director, and Mr. Bhupendrakumar Dalwadi, CEO, of BEIL Infrastructure Limited in the project's success. BEIL has been providing turnkey solid waste (including hazardous and municipal solid waste) and wastewater/sewage treatment projects in India and the Middle East/GCC region for over two decades. Dr. Panchal also thanked KEO Sustainability+ Consultants, KEO International Consultants W.L.L. Dubai, and SEF-Energietechnik GmbH of Germany (represented by CEO Dr. A. Seyfert) for their professional support. He noted, "Their expertise was crucial to the efficient and effective implementation of this project."

Landfill Gas Management and Regional Context

Dubai generates approximately 10,000 tons of waste daily. With the completion of the Warsan Waste-to-Energy Plant (processing approximately 5,666 tons of municipal solid waste daily) and the Materials Recovery Facility (processing approximately 1,200 tons daily), the authorities are committed to transforming landfill waste into a sustainable solution. The project supports the UAE's 2030 goal of reducing CO2 emissions by 40% and will be registered under the International Climate Action Framework, with First Climate assisting in its registration under the United Nations Framework Convention on Climate Change (UNFCCC).

Cleanco waste treatment llc Comprehensive and Innovative Project Design

The project is divided into two key phases:

Phase 1: Construction

The construction phase involves capping the approximately 390,000 square meters of landfill and installing the landfill gas collection, management, and treatment system. The project includes 233 vertical gas wells, a geomembrane cover, and critical infrastructure such as manifolds, a condensate management system, and flare units. Key equipment includes blowers, coolers, and two flare units, each with a processing capacity of 3,000 cubic meters per hour. The landfill capping will be a multi-layer design that meets European environmental standards.

Phase Two: Operations and Maintenance

Following completion, CWTME and BEIL will be responsible for operations and management for one year, focusing on maintaining the infrastructure and ensuring optimal performance of the gas extraction and processing network. Data will be collected and analyzed during this period to ensure efficiency and regulatory compliance. The landfill gas technology is provided by Hofstetter Gastechnik AG of Switzerland, a company renowned for its expertise in gas management technology. Dr. Panchal stated, "Hofstetter equipment is crucial to ensuring the Al Qusais project meets the highest environmental and operational standards."

Technical and Environmental Benefits

Dr. Panchal noted, "By employing cutting-edge technology, we believe this project will set a new benchmark in landfill gas management." CWTME's innovative management approach has delivered significant environmental benefits, fully aligned with the UAE's sustainable development vision.

Cleanco's Future Vision 2026

CWTME plans to expand this technology to the UAE and the Middle East and North Africa region. The successful implementation of this project will serve as a model for similar initiatives in GCC countries. Dr. Panchal stated, "The Al Qusais project is a significant milestone in our foray into the landfill gas sector. We are confident in its future expansion potential and the development of innovative waste management solutions."Dr. Al Khoori added, "Our goal is to revolutionize landfill management, not only in the UAE but across the region." CWTME currently processes municipal solid waste, industrial hazardous waste, and medical waste in the Middle East, partnering with material recovery organizations to divert waste from landfills. Future expansion plans include waste oil recovery, composting, lithium battery recycling, CO2 biofuel production, and sustainable aviation fuel. Furthermore, the company will develop integrated hazardous and medical waste treatment facilities, focusing on solidification and stabilization processes. Furthermore, the company will continue to advance landfill management and gas extraction through the signing of five priority partnerships.

Who is Zhejiang Tongli Heavy Machinery?

In the end of this article let us introduce ourselves, Zhejiang Tongli Heavy Machinery Manufacturing Co., Ltd., established in 1958 and restructured into a limited liability company in 2002, boasts a rich history and extensive industry experience. The company occupies a land area of 153,800 square meters, including 85,000 square meters of workshop space, providing the necessary space for large-scale production. The company specializes in the production and manufacturing of a wide range of heavy machinery and equipment, achieving significant success in the cement and building materials, mining, environmental protection, metallurgy, and chemical industries. Its core products include various vertical roller mills, such as raw meal mills, cement mills, slag mills, and coal mills; rotary kilns, including cement kilns, hazardous waste treatment kilns, and ceramsite sand kilns; and ball mills, including cement ball mills, overflow ball mills, and double-inlet and double-outlet ball mills. Ball mills are crucial for material grinding. In addition to these, the company's products also cover dryer series, crusher series, as well as equipment and large structural parts such as compound fertilizer, mining, power generation, sludge (garbage) incineration systems. The rich product line can meet the diverse needs of different customers.