What is a dap crusher double cage rotor mill?

The DAP double-cage crusher is a fertilizer machine used for crushing npk fertilizers raw materials, especially hard-grained materials such as monoammonium phosphate (DAP). It can also be used for organic fertilizer production. It consists of a frame, a casing, a large wheel set, a small wheel set, and two electric motors. Each wheel set is equivalent to a "cage", consisting of a steel disc fixed to the wheel hub and multiple rings of wear-resistant steel rods. The steel rods are arranged in concentric circles and perpendicular to the discs, and the other end of each ring of steel rods is fixed by a steel ring. In this article we will make a in-depth introduction of this machine including its application, working principle, every single parts of this crusher and so on. Then finally we will explain why you should chose our Tongli ZJTL WP series cage crusher for your npk organic-inorganic fertilizer production process.

What is the working principle of a dap cage crusher for fertilizer?

During operation, one motor drives the large cage to rotate forward, while the other motor drives the small cage to rotate in the opposite direction. Material passes through the hopper and enters the inner mouse wheel frame, where it is repeatedly struck and sheared by the high-speed rotating steel rods. At the same time, the collision of the two sets of rotors creates a "kneading" effect, thereby crushing the material into fine particles. The equipment has the advantage of high crushing efficiency. The proportion of fine powder particles with a diameter of 0.2mm after crushing is high, which is conducive to granulation molding.

The unique design of the dual rotors ensures that the material is subjected to a double crushing effect in the crushing chamber. For some materials, the single-pass crushing rate can reach 90%. The above features a low failure rate and is not strict on the moisture content of raw materials. Generally, it does not affect the crushing effect within 12%, and is not prone to clogging. The equipment uses high-strength, wear-resistant carbide cage bars with synchronous speed, which has a long service life and low maintenance costs. In addition, the crushing effect is good, the inlet and outlet are reasonably designed, the crushed material is evenly distributed, not easy to stick to the wall, and is easy to clean. The crushing fineness can also be controlled by adjusting the distance between the two rollers. The smaller the distance, the finer the fineness.

What are the parts of a compound fertilizer horizontal cage crusher?

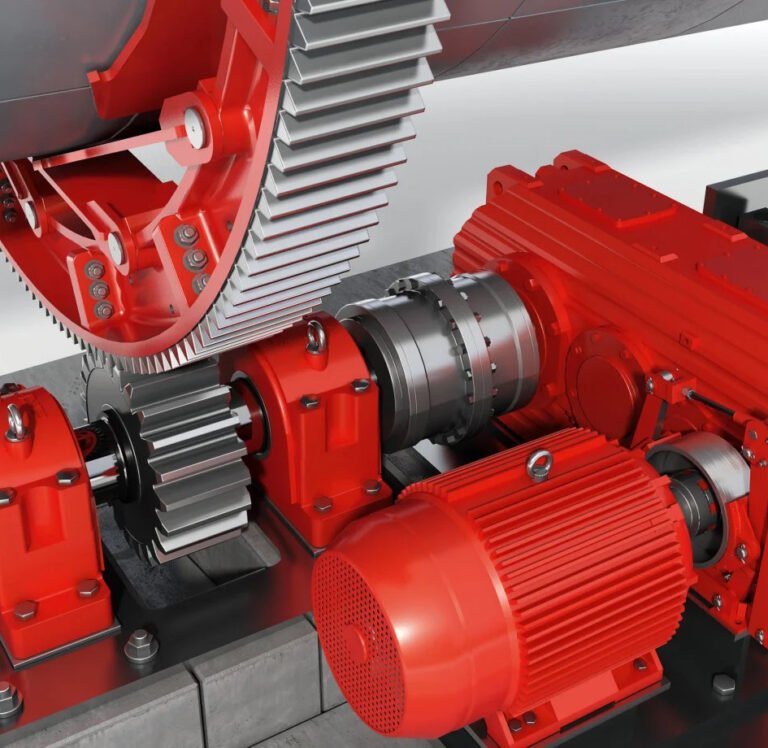

The DAP fertilizer double cage crusher is mainly composed of a casing, a feed port, a discharge port, two cage rotors, a transmission device and other parts. The casing plays a role in protecting and guiding the material. The feed port is located above the casing for feeding, and the discharge port is located at the bottom for discharging.

The cage rotor is a key component, consisting of a shaft, an annular cage, and a beating rod or claws. The transmission device connects the motor and the rotor, which can provide power to the rotors and make them rotate at high speed. It usually adopts a belt drive. In addition, there may be parts such as bearing seats, hand wheels, and screws to support the rotors and facilitate operations such as loading and unloading the cage. Below are the specific parts and drawings of the tongli

1. The Big rotor: Drawing Number(DAP-CA)

The large cage is one of the core crushing components of the DAP double-cage crusher, clearly labeled "BIG CAGE rotor" in the documentation. It is primarily constructed from high-strength steel materials such as SS400. Its structure consists of multiple concentrically arranged steel rods and fixed discs. The rods are secured at their ends by steel rings to ensure overall stability.

During operation, the large cage crusher rotates in counter-rotating directions with the small cage crusher. The high-speed rotating steel rods violently impact and shear the material entering the crushing chamber. This is a key component for achieving initial crushing and refinement, and is particularly suitable for crushing hard-grained materials such as diammonium phosphate.

2. Fertilzer crushing small cage rotor: Drawing Number (DAP-CB)

The small cage rotor is another core crushing component of the equipment, corresponding to the "SMALL CAGE rotor" in the documentation. Made from corrosion-resistant steel materials such as SS316, its structure is similar to the large cage crusher, but smaller in size, and similarly consists of multiple circles of steel rods, discs, and fixed steel rings.

Driven by a motor, the small and large cages rotate in opposite directions at high speed. The gap between them can be adjusted to control the crushing fineness. This "kneading" and secondary impact action further refines the material, ensuring a higher proportion of fine powder (e.g., 0.2mm particles) after crushing, facilitating subsequent pelletizing.

3. Crusher stainless steel/carbon steel casing: drawing number (DAP-H)

The casing, referred to as "HOUINO (HOUSING)" in the documentation, is a key component that encloses and protects the internal crushing components. It is typically made of high-strength steel (such as SS304) and possesses sufficient structural strength to withstand the impact of internal material.

The casing not only protects against material splashing and operator contact with hazardous components, but also guides material into and out of the crushing chamber along a predetermined path. This reduces noise and dust emissions during the crushing process, maintaining a clean and safe working environment.

4. 22GW Motor Pulley agricultural fertilizer crusher machine: Drawing Number DAP-FMI

The 22GW motor pulley, labeled "BET PULLY MONOE 22 GW," is primarily used to connect Motor 1 to the corresponding cage and transmit power. The 22GW specification matches the power requirements of Motor 1. Working in conjunction with the belt, it converts Motor 1's rotational motion into high-speed rotation within the cage, ensuring synchronized and efficient power transmission.

Its structural design ensures precise alignment with the motor and cage shafts, reducing vibration and noise during operation and ensuring stable equipment operation.

5. 30GW Motor Pulley fertilizer pulverizer equipment: Drawing number (DAP-PMA2)

The 30GW motor pulley, designated "BEST PULLY MOVIOR 30 GW" in the documentation, is a key transmission component connecting the motor and cage. This pulley, with a 30GW specification, is designed to meet the power output of the corresponding motor (e.g., Motor 2).

Connected to the cage pulley via a belt, it efficiently transmits the motor's rotational power to the cage, ensuring stable and low-loss power transmission. Typically made of high-strength cast iron or steel, it offers wear and impact resistance, making it suitable for the equipment's long-term, high-frequency operation.

6. Fertilizer grinding mill motor 1: Drawing number (DAP-M1)

Motor 1 is the equipment's second power source, designated "MOTOR-1" in the documentation. Although its power output is not explicitly specified, it serves as the power source for the other cage (small or large), working in conjunction with Motor 2 to drive both cages in counter-rotation.

The power specifications of Motor 1 must match the load of the cages it drives. Stable power output ensures the cages maintain the set speed, providing the foundation for the synergistic effect of the dual-cage crushing system and ensuring that the material is subjected to a double crushing effect within the crushing chamber.

7. Compound fertilizer crusher machine motor 2: Drawing number (DAP-M2)

Motor 2 is the equipment's primary power source, designated "MOTOR-2" in the documentation. Its power output is 80 kW. This motor primarily drives the large-cage crusher (or small-cage crusher). Its 80 kW output ensures high-speed cage rotation (typically matching the crushing requirements), providing sufficient kinetic energy for impact and shearing of the material. It works in conjunction with Motor 1, transmitting stable power to the corresponding cage via a pulley assembly. This is the core power component that ensures dual-cage counter-rotation and crushing efficiency.

8. Double cage crushing equipment base plate: Drawing number(DAP-62)

The base plate, labeled "BASE PLATE," serves as the fundamental support component of the equipment. Made of thick steel plate, it offers high strength and rigidity, capable of withstanding the weight of the entire equipment and the vibration loads generated during operation.

Bolted to the ground with bolts and other fasteners, the base plate ensures stability during the high-speed rotation of the dual-cage crushing system, preventing vibration-induced displacement or loosening of components, and providing a structural foundation for long-term, efficient operation.

9. Impact fertilizer crusher protective Cover: Drawing number(DAP-CO)

The protective cover, referred to as "COVER GUARD" in this document, is a safety feature of the equipment. It is typically installed on the outside of transmission components such as the motor and pulleys. Made of wear-resistant steel plate or metal mesh, it prevents foreign matter from entering the transmission system and disrupting operation, while also protecting operators from contact with high-speed rotating components and potentially causing safety accidents. At the same time, the protective cover must be designed to be easy to disassemble to facilitate daily inspection and maintenance of the equipment.

Why DAP needs specialized crushing using double cage crusher?

As a core raw material for fertilizers, DAP (diammonium phosphate) requires specially designed crushing equipment due to its physical and chemical properties. First, DAP is highly hygroscopic and prone to agglomeration in high humidity environments. This can easily clog the screens and hammers of conventional crushers, reducing efficiency. Second, DAP particles are relatively hard (approximately 2.5-3 on the Mohs scale), requiring high-speed impact for effective crushing. Conventional equipment may lack sufficient kinetic energy, resulting in substandard crushing fineness. Furthermore, DAP's corrosive nature requires equipment made of corrosion-resistant materials, such as stainless steel or surface coatings to prevent corrosion of metal components. For example, a double-cage crusher uses two sets of counter-rotating cage bars to generate high-frequency impact, effectively breaking up agglomerates while controlling fineness (down to 2mm) through gap adjustment, all while preventing screen clogging.

What are the Advanced Configurations & Material Specific dap urea cage Crushers:

Double-cage rotor collision structure:

Two sets of cage bars rotate in opposite directions at 800-1200 r/min. The impact and kneading action refines the material, improving processing efficiency by 40% compared to traditional hammer crushers.

Anti-stick and wear-resistant design:

The rotor is made of ss304 and surface is sprayed with a Teflon coating (friction coefficient ≤ 0.05). Combined with a bottom scraper, it can handle materials with a moisture content of up to 80% without sticking. The cage bars are made of 65Mn spring steel (hardness HRC 50-55), improving wear resistance by 50% and extending the replacement cycle to 60-90 days.

Variable frequency speed regulation and intelligent control:

The speed is adjusted by a frequency converter to adapt to different material characteristics (for example, high-moisture materials can be reduced to prevent blockage, while brittle materials can be increased to improve efficiency). Integrated overload protection and temperature monitoring prevent motor burnout.

Material customization:

For corrosive materials (such as brine), the cage body is made of stainless steel 2205. For high-hardness materials (such as coal gangue), silicon nitride ceramic cage bars can be used, with a hardness of HRA92 or above, extending the service life by 3 times.

What are the applications of DAP fertilizer double cage crusher?

In compound fertilizer plants, the DAP cage crusher is widely used for crushing hard granular materials such as ammonium phosphate (DAP) and urea. It can efficiently pulverize these materials into particles of 8-15 mesh, which perfectly meets the requirements of subsequent granulation processes. Compared with traditional crushing equipment, it boasts significant energy efficiency advantages, with a power consumption of only 8-12 kW·h per ton of material, reducing energy consumption by 40%. This not only lowers production costs but also enhances the overall efficiency of the fertilizer production line.

The crusher also plays a vital role in the treatment of agricultural and livestock solid wastes. When processing livestock manure with a moisture content of up to 70%, its specially designed anti-adhesive coating and adjustable gap technology effectively prevent material sticking and clogging. After crushing, the proportion of particles ≥5mm is controlled to ≤8%, which greatly increases the contact area of the material with air and microorganisms, significantly improving the efficiency of subsequent fermentation and composting, and promoting the recycling of solid waste resources.

What Material Is Suitable For Dap Cage Crusher?

Cage mills are suitable for materials with low to medium hardness, moderate viscosity and low corrosiveness, typically including:

- Fertilizers: Granular materials such as ammonium phosphate, urea, and potassium sulfate;

- Minerals: Coal, salt, and shale (compressive strength < 150 MPa);

- Biomass: Organic waste such as livestock and poultry manure and mushroom residue with a moisture content ≤ 80%;

- Chemical Raw Materials: Plastic granules and rubber fragments (the speed must be adjusted to below 600 rpm).

- Note: For materials with a hardness greater than 4 (such as quartz sand) or highly corrosive materials (such as concentrated acid), a tungsten carbide coating or a fully ceramic cage should be used; otherwise, rapid wear of the equipment may occur.

Maintenance Tips for DAP Cage Mill

- Clean the residual materials in the crushing chamber every 8 hours of operation to prevent material caking and blockage, which may affect the crushing efficiency and even cause equipment failure.

- Check the tightness of the drive belt regularly; if it is too loose, it will cause slipping and reduce power transmission efficiency, while over-tightening may lead to excessive wear of the belt and bearings.

- Use an infrared thermometer to monitor the temperature of the bearing every week. The temperature rise should not exceed 50℃; if the temperature is too high, it may indicate insufficient lubrication or bearing damage. At the same time, replenish No. 3 lithium-based grease to ensure good lubrication of the bearing.

What are the replacement of Wear Parts and Long-Term Maintenance of a cage dap crushing machine?

- Replace the cage bars in time when their wear exceeds 3mm, as excessive wear will reduce the crushing effect and may cause uneven particle size.

- The hammer heads can be flipped for use, which can double their service life and reduce replacement costs.

- Check the dynamic balance of the rotor every 500 hours of operation. Imbalanced rotors will cause severe vibration, which may damage other components and affect the overall stability of the equipment.

- Conduct a comprehensive disassembly of the equipment every year, clean the bearings and replace the lubricating grease, inspect the welding points of the cage bars for cracks, and perform surfacing repair if necessary to ensure the structural integrity and service life of the equipment.

What is the Difference Between Chain Crusher and Double Cage Crusher?

1. Different Structural Designs

- Chain crushers: The core component is multiple high-strength chains (or links) suspended from a rotor. As the chains rotate at high speed with the rotor, the impact and tearing action of the chains pulverizes the material. Its structure is relatively simple, consisting primarily of a rotor, chains, a casing, and a drive unit. The chain length and density can be adjusted according to the material characteristics.

- Double-cage crushers (using the DAP double-cage model as an example): Utilizing a double-cage structure, the crusher comprises two counter-rotating cages: a large cage (DAP-CA) and a small cage (DAP-CB). Each cage is composed of multiple concentrically arranged coils of steel rods fixed to a disc and steel rings to form a closed "cage." Two motors (DAP-M1 and DAP-M2) drive the cages in counter-rotating, high-speed rotation, utilizing the impact, shearing, and kneading action of the rods to pulverize the material.

2. Different pulverization principles

- Chain crushers rely on the high-speed swinging and impact force of the chain to pulverize materials in an "impact-tear" manner. They are more suitable for processing tough or fibrous materials (such as straw and plastic), but the pulverization fineness is less uniform and tends to produce coarse particles.

- Double-cage crushers: Dual-cage crushers use counter-rotating cages to create a "cross-crushing zone" where the material is subjected to dual impact, shearing, and kneading between the steel bars, resulting in more thorough pulverization and more uniform fineness (for example, the DAP double-cage crusher can produce a high proportion of 0.2mm fine powder). Their pulverization process combines impact and grinding effects, making them suitable for hard and brittle materials (such as diammonium phosphate and urea granules).

3. Different Application Scenarios

- Chain crushers: These are primarily used for coarse or medium crushing of biomass (straw, wood chips), plastics, construction waste, and other materials with medium to low hardness and high toughness. They are particularly suitable for applications where high crushing fineness is not a requirement.

- Double-cage crushers: Widely used in the fertilizer industry (such as compound fertilizer and diammonium phosphate), they can crush hard particles to 8-15 mesh, meeting pelletizing requirements. They are also suitable for fine crushing livestock and poultry manure in organic fertilizer production. By adjusting the gap between the two cages, the crushing fineness can be controlled, improving subsequent fermentation efficiency.

4. Performance Parameter Differences

- Grinding Efficiency: Due to the dual crushing action, a double-cage crusher can achieve a single-pass yield exceeding 90%. Its power consumption is 8-12 kW/h per ton of material, a 40% reduction compared to traditional equipment (including some chain crushers). Chain crushers are significantly affected by material toughness, resulting in relatively high energy consumption.

- Fineness Control: Double-cage crushers can precisely control fineness down to 0.2mm by adjusting the spacing between the two cages. Chain crushers have a narrow fineness adjustment range and poor uniformity.

- Failure Rate: Double-cage crushers are more adaptable to material moisture content (≤12%) and are less prone to clogging. When processing materials with high moisture content, chain crushers are prone to chain adhesion, leading to clogging and reduced efficiency.

5. Maintenance requirements vary

- Chain crushers: Regularly check the chain tension and wear, and replace worn chains. Due to uneven chain load, bearings are prone to overheating and require frequent monitoring and lubrication.

- Double-cage crushers: Clean the crushing chamber regularly to remove residual material. Monitor bearing temperature weekly (temperature rise ≤ 50°C) and replenish lithium-based grease. The cage bars are the only vulnerable parts (wear exceeding 3mm requires replacement). The overall structure is stable, and maintenance costs are low.

Comparison table dap horizontal doubel cage mill vs chainmill

| Comparison Dimension | Chain Mill Crusher | Double Cage DAP Mill |

| Core Structure | Single rotor with hinged chain hammers; material crushed by hammer impact | Dual rotors with cage bar matrix; two sets of bars rotate in opposite directions to create high-frequency impacts |

| Crushing Principle | Relies on high-speed chain hammer impact; material collides with liner plates before discharge | Material undergoes repeated impacts and shearing between inner and outer cage bars; centrifugal force moves material toward discharge outlet |

| Suitable Materials | Brittle materials (e.g., coal lumps, ores); not suitable for sticky or high-moisture materials | Sticky materials (e.g., caked fertilizer, high-moisture manure) and fine particle crushing (e.g., compound fertilizer raw materials) |

| Processing Efficiency | Single-stage crushing; high throughput (20–200 t/h) but coarser output (10–20 mm) | Two-stage crushing; moderate throughput (2–12 t/h); fine particle size (2–5 mm) with ≥90% uniformity |

| Anti-Clogging Ability | Prone to downtime if sticky material clogs chains; requires periodic cleaning of screen plates | No screen design; gap adjustment prevents clogging; continuous operation rate ≥95% |

| Energy Consumption & Wear Life | 15–20 kWh per ton; chain hammer life 30–60 days | 8–12 kWh per ton; cage bar life 60–90 days; maintenance cost reduced by ~30% |

| Particle Shape | Output tends to be irregular with more elongated fragments | Output is more uniform and granular, ideal for blending in fertilizer formulations |

| Maintenance Frequency | Higher—chain hammers wear quickly and require more frequent replacement | Lower—cage bars last longer and replacement is simpler |

| Noise Level | Higher, due to hammer impacts and vibration | Moderate, as impacts are distributed across multiple cage bars |

| Initial Investment | Usually lower purchase cost | Slightly higher purchase cost, but lower lifecycle cost |

| Application Focus | Suited for coarse crushing in pre-processing stage | Designed for fine, uniform crushing in final fertilizer preparation |

Why Choose Tongli FS series double cage rotor fertilizer raw material handling mill?

- Engineered for Sticky & Moist Materials – The FS Series is specifically designed to handle high-moisture, caked fertilizers like DAP, NPK, and manure without clogging, thanks to its no-screen, gap-adjustable design.

- Precision Crushing for Uniform Output – Dual counter-rotating cage rotors deliver consistent particle sizes (2–5 mm) with over 90% uniformity, ensuring optimal blending in fertilizer production.

- Lower Energy Consumption – With energy use as low as 8–12 kWh per ton, the FS Series offers up to 40% savings compared to traditional chain mills.

- Extended Service Life – Heavy-duty alloy steel cage bars last 60–90 days, reducing downtime and cutting maintenance costs by up to 30%.

- Stable Continuous Operation – Designed for uninterrupted production, the FS Series maintains a ≥95% continuous operation rate, even in demanding conditions.

- Built by Fertilizer Equipment Experts – Tongli Heavy Machinery brings over 65 years of manufacturing expertise, ensuring the FS Series is robust, reliable, and backed by strong after-sales support.

- Customizable to Your Process – Available in multiple rotor sizes, configurations, and wear-resistant options to match different production capacities and fertilizer formulations.

So this is the end of this article and if you are interested in our other products other than the dap crusher, please check out our all time favirote product vertical roller mill and ball mill.