A rotary kiln is a high-temperature heat treatment equipment based on a slowly rotating, slightly tilted cylindrical drum. Through controlled heat exchange between the material's continuous motion within the drum and the high-temperature airflow, it enables a variety of processes, including drying, calcining, sintering, pyrolysis, and incineration. As a continuous processing equipment, its core value lies in its ability to provide a stable, uniform, and efficient thermal environment. It is widely used in industries such as cement manufacturing, metallurgical processing, chemical production, waste treatment, and ceramic refractory materials. Structurally, a rotary kiln is a complex mechanical system consisting primarily of a kiln shell, a refractory lining, support devices (tires and rollers), a drive system, a heat exchanger, and an exhaust gas treatment system. The kiln shell is constructed of thick welded steel plates and is massive. The refractory lining protects the steel shell and maintains the internal high temperature. The support and drive systems ensure smooth rotation of the kiln body. Internal heat exchangers further enhance thermal energy efficiency. Its operating principle is based on a "rotation, tilt, and countercurrent" mechanism. By controlling the rotational speed, tilt angle, and heat flow direction, the material undergoes a series of drying, preheating, reaction, and cooling processes within the kiln. This article will provide a systematic process definition of rotary kiln, detailing the process flow, equipment classification, and its specific applications, supporting equipment, and selection and design points in different temperature ranges and industrial scenarios.

What is a rotary kiln

A rotary kiln is essentially a giant, slowly rotating, slightly tilted cylindrical drum. Its core process principle is to utilize the drum's rotation and tilt to allow solid materials to continuously move from the upper end to the lower end, undergoing sufficient and controlled heat exchange with the high-temperature airflow. This allows for a series of complex physical and chemical reactions to occur under a defined temperature, atmosphere, and residence time. It is specifically designed for drying, calcining, treating, or sintering bulk materials, and is a continuous process equipment.Due to the extremely high operating temperatures within the rotary kiln (often reaching thousands of degrees Celsius), direct observation of the dynamic changes and phase transitions within the kiln is extremely difficult, which has, to a certain extent, led to misunderstandings of its internal process mechanisms. Therefore, a comprehensive and in-depth understanding of the rotary kiln's process flow is the first step in correctly appreciating its versatility and assessing its suitability for specific heat treatment needs.

Historically, the prototype of the rotary kiln was invented by the British Frederick Ransome in 1873. He applied for several patents for this purpose between 1885 and 1887. Although his early experimental explorations failed to achieve commercial success, his groundbreaking design concept laid a solid foundation for the successful construction of the world's first practical rotary kiln in the United States in 1891. Since then, the technology has been rapidly promoted and applied around the world, becoming one of the important milestones of the modern industrial revolution.

The structure and components of rotary kiln

A complete rotary kiln is a complex mechanical system, which is mainly composed of the following core components, each of which has a specific function:

Kiln shell

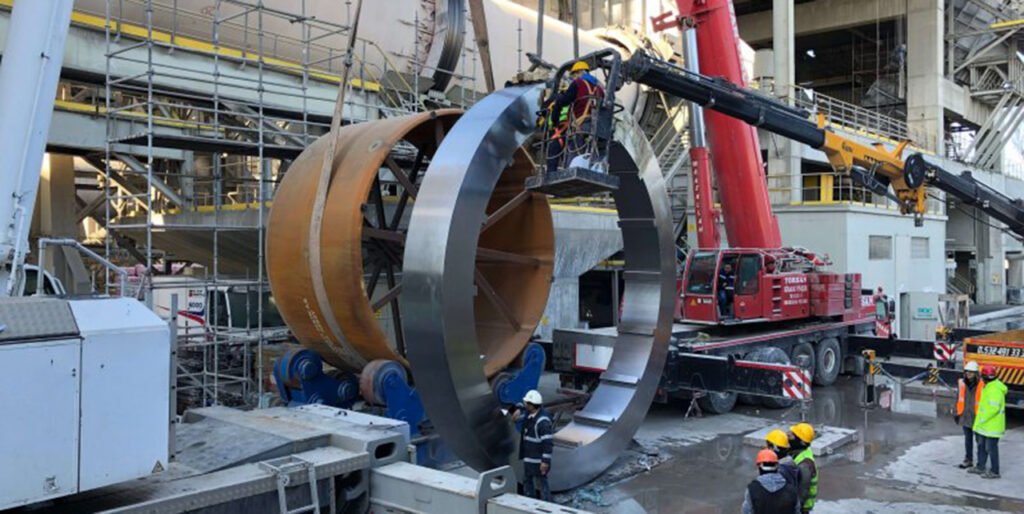

The kiln shell, the primary structure of a rotary kiln, is typically welded from rolled low-carbon steel plates. Its thickness ranges from 15 to 30 mm (0.6 to 1.2 inches), depending on the kiln specifications. Kiln shells can be large in size, reaching lengths of up to 230 meters (750 feet) and diameters of up to 6 meters (20 feet). The shell's tendency to deform into an elliptical shape under its own weight, as well as the cyclical stresses induced by rotation, must be carefully considered in its design. Thermal expansion and contraction during heating and cooling (typically 0.1% to 0.5% of the kiln shell's length) are also key structural considerations. The upper limit on the diameter is primarily limited by shell deformation and the resulting bending stresses.

Refractory Lining

The refractory lining is tightly adhered to the inner wall of the kiln shell. Its primary function is to protect the steel shell from the high temperatures within and from chemical attack and physical abrasion by the processed materials. Lining materials can be either refractory bricks or cast refractory concrete, depending on process requirements. Areas within the kiln below approximately 250°C are sometimes left unlined. Lining thickness typically ranges from 80 to 300 mm (3 to 12 inches). High-performance refractory materials can maintain a temperature differential of 1000°C (1,800°F) or more between their hot and cold sides. To ensure the safety of the kiln shell, its outer surface temperature must be maintained below 350°C (662°F), and continuous infrared scanning is often used to monitor and warn of "hot spots" that could indicate lining failure. In some processes, such as cement processing, the life of the refractory is extended by maintaining a coating of the processed material on the surface.

Support and drive system

- Tires and Rollers: The support system is crucial for ensuring smooth kiln rotation. Tires (or support rings) are large, annular steel castings that fit over the kiln shell. Machined to a smooth cylindrical surface, they are loosely secured to the shell using a special "chair" mechanism, ensuring a tight fit while allowing for expansion due to heat conduction. The tires sit on pairs of rollers, with the distance between them approximately half the diameter of the kiln. A well-designed support system provides minimal friction, allowing the kiln to swing like a pendulum several times before coming to rest even after a power outage. A typical 6 m x 60 m kiln (including refractory and feed material) weighs approximately 1,100 tons and is supported by multiple tires and roller sets distributed along the length of the kiln. The longest kilns may have eight sets of rollers, while very short kilns may have none. To prevent axial movement of the kiln due to tilting, upper and lower thrust rollers are installed, resting against the sides of the tires to constrain their position. The roller bearings must be able to withstand significant static and dynamic loads and be protected from kiln heat and dust intrusion.

- Drive Gear: The rotary kiln's rotational power comes from the drive system. Typically, a variable-speed electric motor drives a large ring gear connected to the cold end of the kiln through a gear train (sometimes also driven by a driven roller). This system must have high starting torque to overcome significant eccentric loads. For example, a 6x60 meter kiln operating at 3 rpm requires approximately 800 kW of power. Material flow rate is proportional to the rotational speed, so a variable-speed drive is required to control it. When driven by rollers, a high-torque hydraulic drive can be used. To cope with sudden power outages and prevent static deformation of the hot kiln and damage to the refractory lining, an auxiliary drive device, such as a small electric motor or diesel engine with an independent power supply, is required to ensure that the kiln can maintain extremely slow rotation in an emergency.

Internal Heat Exchangers

- To improve thermal efficiency, internal heat exchange devices are often installed in low-temperature processes and in the cooler sections of long kilns. These devices come in various forms, including:

- Buckets or "lifters": These lift and scatter the material, cascading it into the airstream and enhancing gas-solid contact.

- Metal inserts: These are heated in the upper portion of the kiln and then sunk beneath the material bed, transferring heat to the material.

- Curtain chains: These are suspended above the airstream and are one of the most common types.

Since lifters cause excessive dust, metal inserts and chains are preferred.

Auxiliary Equipment

- Material outlet hood and exhaust duct: Located at the lower end of the kiln, both ends must be airtightly sealed.

- Preheater: Exhaust gas enters the preheater for further heat exchange with the feed material.

- Exhaust fan: Drives exhaust gas through the kiln and preheater. In high-pressure drop preheater systems, the fan power can be very high.

- Exhaust gas treatment system: Includes equipment such as dust removal, desulfurization (e.g., removal of SO₂), and dechlorination (e.g., removal of HCl), purifying kiln exhaust gas to meet environmental emission requirements.

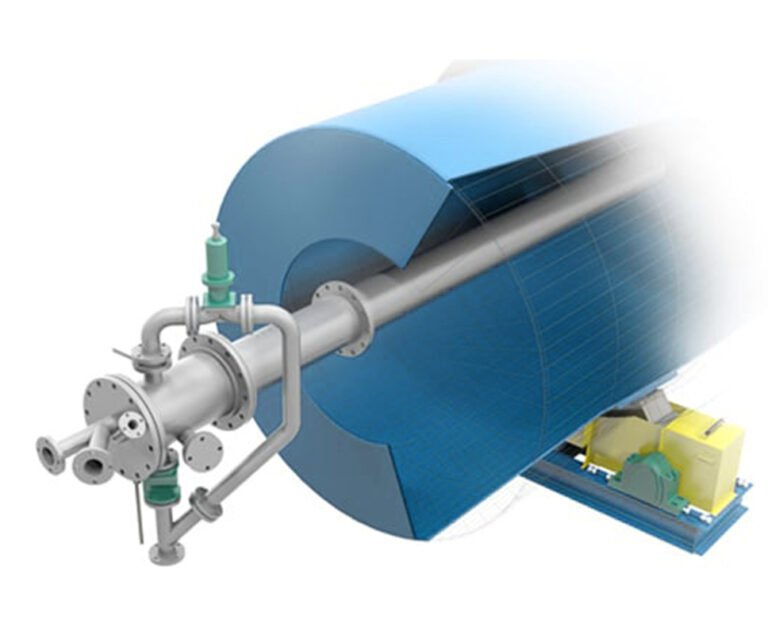

- Burner: Located at the kiln head, fuel can be natural gas, fuel oil, pulverized petroleum coke, or pulverized coal.

Working principle and process design of rotary kiln

The operating principle of a rotary kiln can be summarized as "rotation, inclination, and countercurrent." The kiln body, a slightly inclined cylindrical drum (1%-4%), rotates slowly around its longitudinal axis (0.2 to 5 rpm, with modern cement kilns reaching 4-5 rpm) driven by a drive system. The material to be processed is continuously fed in from the kiln tail (high end) and constantly stirred and mixed by the rotation of the drum. Simultaneously, due to the inclination and gravity, it gradually moves toward the kiln head (lower end).

The heat source typically comes from the main burner at the kiln head. The high-temperature gases generated and the material flow are typically countercurrent (i.e., hot gas flows toward the kiln tail, while the material moves toward the kiln head). This arrangement maximizes thermal energy utilization and achieves a heating gradient from the discharge end to the feed end. During this process, the material undergoes multiple process stages, including drying, preheating, chemical reaction (such as calcination and sintering), and cooling, before ultimately being discharged from the kiln head in its treated form. The material of the heating chamber (core tube or muffle furnace) is selected based on the operating temperature and can be either a high-temperature metal alloy or a ceramic composite.

Process design requirements: To determine the outer diameter, inner diameter, length, rotation speed, inclination angle and material of the rotary kiln pipe, the following key information is required:

- Production rate (lbs/hour)

- Bulk density of feed

- Angle of repose of feed

- Maximum temperature

- Duration at maximum temperature

Main process types of rotary kiln

The process diversity of rotary kiln is mainly reflected in the following aspects:

Calcination

This refers to the process of chemically decomposing materials at high temperatures to drive off volatile components (such as CO₂) or water of crystallization. A classic example is the calcination of calcium carbonate (CaCO₃) to produce calcium oxide (CaO) and carbon dioxide (CO₂). It is also used to remove "bound water" from viscous sludge, which cannot be completely removed by conventional drying or pressing.

Thermal Desorption

This process uses heat to separate organic pollutants (such as pesticides) from inorganic matrices (such as soil and sand). Crucially, thermal desorption is not incineration and does not produce harmful combustion pollutants. Instead, it utilizes the temperature difference between the organic matter and the mineral absorbent, volatilizing the organic matter at high temperatures, achieving non-combustion separation. For volatile and potentially flammable chemicals, indirectly heated rotary kilns are the best choice, as they can provide the necessary heat externally through an enclosed combustion chamber or heat shield, preventing direct contact between the material and the flames.

Organic Combustion

This process aims to destroy organic waste through thermal treatment, significantly reducing its mass and volume. It is primarily used in waste treatment plants to reduce landfill volume. Direct-fired rotary kilns are most common for this application, as direct contact between the burner flame and the material is acceptable.

Sintering / Hardening

Heating the material to a temperature close to its melting point allows diffusion and bonding between particles, significantly increasing the material's strength and density. A typical application is the manufacture of proppants for oil fracturing, which requires sand or ceramic particles to possess extremely high structural strength without significantly increasing their mass.

Thermosetting

This is a specialized coating process that heat-bonds a less heat-resistant coating material (mixed with a binder) to a heat-resistant core material. A rotary kiln heats the coating material to a temperature slightly below its liquefaction point, allowing it to evenly coat the core material. This chemical phase change makes it stronger and safer than traditional coatings. This process is commonly used to create colored roofing granules, such as coating granite with durable pigments.

Reduction Roasting

A process for removing oxygen from metal oxides, typically using carbon monoxide (CO) as a reducing agent. CO can be generated by mixing coal or coke with the ore or by feeding it separately. For example, hematite (Fe₂O₃) is reduced to magnetite (Fe₃O₄), which is magnetic and suitable for subsequent magnetic separation. In this process, zinc oxide (ZnO) from steel mill waste (flue dust) is reduced to metallic zinc vapor, which is then recovered in the exhaust system.

Rotary Kiln Classification, Comparison, and Product Lineup

According to different standards, rotary kilns can be classified in many ways. The comparison of their characteristics is shown in the table below.

| Classification criteria | type | Main Features | Applicable Scenarios |

| Operation | Intermittent | Process in batches, stopping the kiln to unload materials after processing is completed. Suitable for small batches, multiple varieties, and long cycle processes. Small processing capacity, suitable for longer processing time. | R&D, small-scale production, high value-added material processing |

| Continuous | Continuous feeding and discharging of materials, constant high temperature in the kiln, high production efficiency. Large processing capacity, suitable for short processing time. | Large-scale industrial production, such as cement and mineral calcination | |

| Heating method | Direct heating | The combustion flame is in direct contact with the material, resulting in high heat transfer efficiency. The kiln shell is lined with thick refractory material. | Cement clinker production, lime calcination, waste incineration |

| Indirect heating | Heat is transferred through the kiln wall, and the material does not come into contact with the flame and flue gas. The kiln shell is usually made of high temperature resistant alloy. | Materials that are thermally desorbed, easily oxidized, easily contaminated, or require a specific atmosphere | |

| Heat source type | Electric heating | The use of electric heaters allows for precise temperature control and a controllable furnace atmosphere (air, oxygen, nitrogen, argon, etc.). The heaters are arranged 360° around the furnace for high thermal efficiency and minimal heat loss. | Precision materials with high requirements for temperature control and atmosphere, such as LiB electrode materials |

| Gas heating | Gas burners are used, and the fuel can be heavy oil, kerosene, city gas, or LPG. Superheated steam (SHS) can be used as an energy-saving measure. | Metal chip degreasing, organic matter removal, general industrial heating |

Comparison of comprehensive performance between rotary kiln and shuttle kiln

| characteristic | Rotary kiln | Shuttle kiln |

| Material conveying method | Retort (still) rotation | Movement of special trolley |

| Facility Door | None (continuous feeding and discharging) | Yes (batch loading and unloading) |

| Energy loss | Small (no loss of heated kiln car) | Large (needs repeated heating of the kiln car and heat loss from opening and closing the door) |

| Facility Space | Large (large aspect ratio) | Relatively small |

| Production capacity | High (continuous operation) | Low (intermittent operation) |

| Heating uniformity | Good (materials are continuously stirred and there is no uneven firing) | Poor (materials are stacked statically, with temperature gradients) |

Rotary kiln product lineup example

- Aluminum Chip (Reactive Metal) Superheated Steam Cleaning/Degreasing System: Safely removes oil and moisture that can cause fires and explosions.

- Various Metal Chip Superheated Steam Cleaning and Degreasing Systems: High-value, energy-efficient superheated steam systems.

- Superheated Steam Metal Waste Organic Matter Removal System: Safely processes waste containing plastic or high-heating waste.

- Aluminum Can Superheated Steam Paint Stripping System (UBC): Safely removes coatings, deposits, and organic matter from metal surfaces.

- Continuous Externally Heated Rotary Kiln (Electric): Custom designs available, from small to mass production.

- Medium/Small Intermittent Externally Heated Rotary Kiln (Electric): Suitable for samples or small batches of high-value-added raw materials requiring long firing times (over 4 hours).

Industrial applications and temperature ranges of rotary kilns

Rotary kilns have a wide range of applications, covering virtually all industrial fields requiring high-temperature processing. Materials produced using rotary kilns include cement, lime (lime), refractories, metakaolin, titanium dioxide, alumina, vermiculite, and iron ore pellets. They are also used to roast various sulfide ores prior to metal extraction.

Typical application examples of rotary kilns divided by temperature range

| Temperature range | Application Examples |

| Up to 200°C | Drying of LiB (lithium-ion battery) cathode materials |

| Up to 500°C | Sludge drying (fertilizer making), carbon powder drying, burning resin powder, dry material powder dehydration; cleaning and degreasing of metal cutting chips such as copper alloy, stainless steel (SUS), cast iron, and aluminum alloy |

| 500 - 800°C | Annealed iron powder |

| 800 - 1100°C | Hydrogen reduction annealing of metal powders; sintering of LiB positive and negative electrode materials; tungsten powder sintering; catalyst/ceramic firing; magnetic material sintering; carbon combustion |

| Up to 2500°C | Firing of carbon materials; Firing of tungsten carbide (WC) raw materials; Firing of silicon-based negative electrode materials (requires support from carbon heater kiln) |

Supporting equipment verification testing and after-sales service

A complete rotary kiln system is much more than the kiln itself.

Supporting equipment lineup

- Continuous Rotary Cooler: Cools discharged raw materials through heat conduction via a cooling jacket structure.

- Continuous Screw Feeder: Cools materials through heat conduction via a water-cooled jacket structure.

- Direct-Fired Deodorizer (burner): Decomposes odorous components in exhaust gas through high-temperature oxidation.

- Exhaust Gas Treatment (Deodorization, Dust Collection) Equipment

Verification test process: For new materials or processes, verification tests can be carried out.

- Meeting to discuss test objectives and conditions.

- Draft a test plan.

- Verify equipment specifications at the customer site or through batch testing.

- Conduct a trial run and evaluate the data.

- Summarize the results and provide recommendations for equipment specifications.

After-sales service

- Regular Maintenance: Cleaning and replacing seals, inspecting heaters, cleaning the furnace interior, replacing rollers, and other consumables.

- Spare Parts Sales: Providing consumables and spare parts, and performing equipment diagnostics during maintenance.

- Renovation Support: Modifying furnace mechanisms to increase production capacity or change product offerings.

The difference between rotary kiln and similar equipment

Differences from shuttle kiln

The core lies in the material transportation method and thermal energy utilization rate.

Difference from rotary dryer

- Purpose: Rotary dryers are primarily used to remove moisture and operate at lower temperatures (800–1400°F); rotary kilns are primarily used to initiate chemical reactions or phase changes and operate at higher temperatures (1000–3000°F).

- Design: Direct-fired kilns have a refractory lining to protect the steel shell; indirect kilns use a high-temperature alloy shell. Dryers are typically unlined. If the sole objective is drying, a dryer is recommended; if heat-driven reactions are required, a kiln is essential.

Technological Development of Rotary Kiln

To meet the increasing requirements of energy efficiency and environmental protection, rotary kiln technology continues to improve, mainly in the following aspects:

- Automation and Intelligent Control: A SCADA (Supervisory Control and Data Acquisition) system is used to enable real-time optimization and remote monitoring of process parameters. Highly airtight seals (such as patented carbon seals) are provided to control positive and negative pressures, preventing powder gas leakage and air ingress.

- Advanced Materials and Structures: Refractory materials with longer life and higher corrosion resistance, as well as heat-resistant alloys with enhanced performance, are developed. Contact components (such as nickel alloys) can be customized to minimize metal contamination. Special structures can be installed to control material residence time.

- Energy System Integration and Energy-Saving Design: More efficient heat exchangers, preheaters, and waste heat recovery systems are widely used. Air cooling is used to prevent temperature overshoot. A 360° surround heater arrangement ensures close proximity to the reactor, ensuring uniform heat transfer and minimal heat loss.

- Emission Reduction and Environmental Protection Technologies: Advanced exhaust gas purification systems, such as dust collection, deodorization, desulfurization, and denitrification, are integrated to achieve near-zero emissions.

This is a fundamental classification based on the method of heat transfer.

Directly heated kilns: The flame and hot gases generated by the burner come into direct contact with the processed material. This method offers the highest thermal efficiency, but the material is exposed to combustion products. It is suitable for applications that are not sensitive to the atmosphere, such as cement clinker production, lime calcination, and waste incineration.

Indirectly heated kilns: Heat is indirectly transferred to the material through the kiln wall (usually an alloy "muffle" or "retort"), completely isolating the material from the flame and flue gases. This creates a pure or controlled atmosphere. These kilns are suitable for thermal desorption and processing sensitive materials that are easily oxidized or contaminated, or require a specific chemical reaction atmosphere (such as nitrogen or argon blanketing).

The core difference between the two lies in their process purpose and operating temperature.

The primary purpose of a rotary dryer is physical dehydration, that is, removing moisture from the material. Their operating temperatures are relatively low (typically between 800°F and 1400°F / 427°C and 760°C).

The primary purpose of a rotary kiln is to induce heat-driven chemical or phase changes, such as decomposition (calcination), changes in crystal structure (sintering), or chemical reduction. These processes require higher temperatures (typically from 1000°F to over 3000°F / 538°C to 1649°C). Therefore, the kiln design (such as the refractory lining) must be able to withstand more severe thermal loads.

Cement industry: Used to calcine raw materials such as limestone and clay into cement clinker at temperatures exceeding 1400°C.

Metallurgical industry: Used for reduction roasting of iron ore, zinc recovery in the Waelz process, sintering bauxite to produce alumina, and the reduction and sintering of metal powders.

Chemical industry: Used in the production of titanium dioxide (titanium dioxide), calcining kaolin (to produce metakaolin), and phosphate processing. Environmental Protection: Used for thermal desorption treatment of contaminated soil (separating organic matter without burning it) and incineration of hazardous waste.

Refractory Materials and Ceramics: Sintered refractory bricks and ceramic products.

The refractory lining is a protective layer on the inner wall of the kiln shell, performing crucial functions:

Thermal Insulation: It creates a barrier between the high internal temperature (up to 2500°C) and the outer steel shell, keeping the shell temperature below a safe level (typically below 350°C) and preventing steel softening.

Corrosion and Wear Resistance: It resists chemical attack and physical wear from high-temperature processed materials.

Energy Storage and Heat Transfer: As a heat storage medium, it helps stabilize the kiln temperature and transfers heat to the material through radiation and convection. Its material selection and thickness directly impact the kiln's operating efficiency, lifespan, and maintenance costs.

The auxiliary drive (typically a low-power electric motor or diesel engine) is a critical safety and asset protection feature. If a mains power failure causes a hot kiln to suddenly stop rotating, the significant temperature difference between the upper and lower parts of the kiln can cause the shell to permanently deform, causing it to "bow" or "sag." This can cause catastrophic damage to the refractory lining and damage the shell itself. An auxiliary drive prevents this deformation by enabling the kiln to rotate at an extremely slow speed (e.g., one revolution every few minutes) during a power outage, making it a key design feature for ensuring equipment safety.

Conclusion

The essence of the rotary kiln process lies in the ingenious combination of rotation and tilting, creating a dynamic, continuous, and controllable high-temperature reaction environment for materials. From basic calcination and drying to sophisticated thermal desorption and reduction roasting, rotary kilns can meet a wide range of processing needs, from common building materials to high-value-added lithium battery materials and metal powders, through direct or indirect heating, variable atmosphere control (such as nitrogen, argon, and superheated steam), and precise temperature zone and residence time control. This versatility makes it a versatile thermal processing equipment across numerous industries, including cement, metallurgy, chemicals, and environmental protection. In its engineering implementation, the rotary kiln embodies the deep integration of mechanical mechanics, materials science, and thermal engineering principles. From the support roller system that withstands enormous loads, to the refractory lining that isolates the material from high temperatures, to the internal heat exchange device that enhances thermal efficiency, every component serves to achieve its core process objectives. The choice between batch or continuous operation, and between direct or indirect heating, depends on a comprehensive trade-off between production capacity, energy consumption, and material properties. Innovations such as high-tightness sealing, intelligent control systems and efficient waste heat recovery are driving this classic equipment towards a more energy-efficient, environmentally friendly and intelligent direction.