Fly ash, the collective name for the combustion residue that rises with flue gases , is the primary solid waste emitted by coal-fired power plants . Nearly half of this fly ash is reused for applications such as cement production line. Fly ash has a wide range of chemical and physical forms, depending on the type of fuel burned and the method of handling. Fly ash typically contains high levels of silica and calcium oxide, making it abrasive and abrasive. Fly ash typically has a very fine particle size distribution after being ground by our vertical roller mill, with most particles smaller than 100 microns. Due to its fine particle size, abrasive properties, and high temperatures, fly ash can be challenging to reliably handle. As a byproduct of coal-fired power plants, its efficient and environmentally friendly storage and transportation are crucial to plant operations and resource utilization. Customized, high-efficiency fly ash silos are key to solving these storage challenges. Fly ash, due to its fineness, variable flow properties (prone to moisture and compaction), and abrasive properties, poses unique challenges to storage facilities. Standard silos often fail to meet the requirements for long-term stable, trouble-free operation. They are prone to problems such as bridging, rat holes, compaction, and poor unloading, which seriously impact power plant operating efficiency and fly ash resource utilization. Therefore, customizing efficient fly ash silos based on specific project requirements is key to achieving safe, economical, and environmentally friendly storage and transportation.

Why must fly ash be stored in customized steel silos?

Fly ash is a fine, granular material used in many applications, such as power plants. Collected fly ash and stored outdoors not only takes up significant land but also pollutes the air and groundwater where it accumulates, significantly harming the environment. Therefore, open-air storage is unsuitable. Instead, fly ash needs to be stored in steel silos. Here are some reasons why steel silos are the right choice for fly ash storage.

1. The construction period of fly ash steel silo is short and the construction cost is low.

2. The fly ash steel silo is convenient to use and easy to maintain.

3. The storage capacity of a single fly ash steel silo is up to 100,000 tons, but the investment is only less than 150 yuan per ton, saving money.

4. The fly ash steel silo has mature technology, with a discharge emptying rate of up to 98%, while the dust emission can be controlled below 15mg/m3, which is very efficient.

5. The energy consumption of fly ash steel plate silo per ton of discharge is controlled within 1 kWh. If the fly ash steel plate silo does not discharge for a long time, it is equipped with a gasification pipe discharge system, which can reverse the storage by itself to prevent compaction.

6. The gasification pipe has low cost, strong pressure resistance and plasticity, which can allow the steel silo to discharge materials 360 degrees without dead angles. It is both wear-resistant and corrosion-resistant, and can also prevent dust from entering the gasification pipe.

7. The fly ash steel silo has a long service life of up to 15 years. The steel silo equipped with a gasification tube device is an important means of storing fly ash.

What is a fly ash steel silo?

Fly ash steel silos are high-strength steel structure silos specially designed for storing fly ash, providing a closed and safe storage environment to avoid moisture, contamination or loss. Based on the structure and construction method, fly ash steel silos are mainly divided into the following categories:

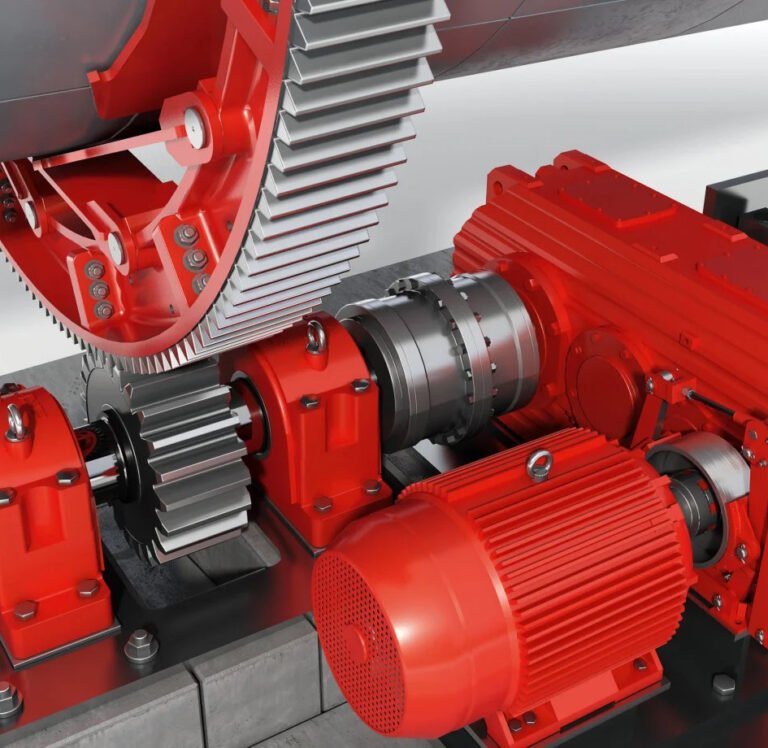

- Spiral steel plate silo: It is rolled and formed on site by rolling equipment and has the characteristics of good sealing and stable structure.

- Welded steel silo: Assembled by welding technology, high strength, suitable for large-capacity storage.

Compared with traditional open-air storage or cement silo storage, fly ash steel silo has many advantages:

- Short construction period: The construction is quick and can be put into use quickly.

- Low investment cost: Compared with traditional concrete storage silos, steel silos have lower construction costs.

- Large storage capacity: It can be customized according to demand, and the capacity of a single warehouse can reach tens of thousands of tons.

- Good environmental performance: closed storage, reducing dust pollution, in line with environmental protection standards.

How does fly ash enter the steel silo?

Fly ash is produced by coal-fired boilers in thermal power plants. It is collected from fine particles in flue gas by a device such as an electrostatic precipitator. Due to its high fineness and light weight, appropriate dust and moisture control measures must be taken during storage.

There are two main ways to transport fly ash from the collection point to the steel silo:

Pneumatic conveying

- Principle: Use air power to transport fly ash to the steel silo through a sealed pipe.

- Equipment: including blowers, conveying pipelines, separators, etc.

- Advantages: Closed transportation, no dust pollution, suitable for long-distance transportation.

- Note: The air pressure needs to be controlled to prevent pipe blockage.

Mechanical conveying

Method: Common mechanical conveying equipment includes screw conveyor, bucket elevator, belt conveyor, etc.

Compared with pneumatic conveying: Mechanical conveying has low energy consumption, but the conveying distance and height are limited, and it is suitable for short-distance conveying.

How to store fly ash in steel silo?

1. Warehouse

After fly ash enters the steel silo, it needs to be distributed properly to prevent excessive accumulation in some areas that could affect subsequent material removal. Pneumatic conveying is usually used to evenly distribute the fly ash within the silo.

2. Storage Management

Ventilation: Fly ash particles are small and easy to get damp and clump together, so the steel silo is equipped with a ventilation system to maintain air circulation and reduce the temperature inside the silo.

Temperature and humidity control: The in-warehouse environment monitoring system can monitor the temperature and humidity in real time to prevent the fly ash from condensing into lumps due to excessive humidity.

Anti-caking measures: In order to prevent fly ash from clumping after long-term storage, special equipment such as airflow arch breaking device can be used, or an appropriate amount of anti-caking agent can be added to the fly ash.

3. Monitoring

Modern fly ash silos are typically equipped with automatic monitoring systems, including:

- Material level monitoring: Real-time display of the amount of material in the warehouse to prevent overflow.

- Safety alarm system: Automatically alarm in abnormal situations to ensure safety.

How to remove fly ash from steel silo?

1. Unloading method

- Gravity unloading: utilizing the fluidity of fly ash and relying on gravity to flow out from the bottom outlet of the silo.

- Pneumatic unloading: Fly ash is transported to the end of use through negative pressure pneumatic conveying.

- Other methods: such as screw conveyor, scraper conveyor, etc.

2. Unloading equipment

- Screw conveyor: suitable for short distance transportation.

- Scraper conveyor: suitable for large flow and continuous unloading.

- Pneumatic conveying equipment: suitable for long-distance transportation to cement plants or mixing stations.

Structural design of fly ash steel silo

Silo structure and selection

Form

- Flat-bottom silos: Suitable for ultra-large storage, they feature multiple discharge points and a high-efficiency fluidization system (e.g., aeration boxes, perforated plates). They require a strong fluidizing air source. While they offer high space utilization, they also require a complex fluidization design and a high initial investment.

- Cone-bottom silo: The most common type. The cone angle is crucial! It must be greater than the effective internal friction angle of the fly ash, typically ≥ 65° - 70°. The cone requires a smooth interior and may be equipped with a flow-aiding device. This relatively simple structure primarily relies on gravity discharge.

- Cluster Silo Design: This design is often used when separate silos are needed to store fly ash of different grades or sources, or when the capacity of a single silo is limited. Considerations must be given to inter-silo layout, material transfer, and a centralized control system.

Size and capacity

Accurately calculate the material bulk density and storage requirements. Optimize the diameter-to-height ratio, taking into account structural stability, material flowability, and site constraints.

Structural strength and stability

Design must be conducted strictly in accordance with the "Design Code for Reinforced Concrete Silos" or relevant steel structure codes, fully accounting for full silo load, wind load, snow load, seismic load, equipment load, and internal air pressure (if applicable). Large silos require finite element analysis (FEA) to verify stresses in key areas.

Material selection for fly ash steel silo

When designing fly ash steel silos, material selection is a key factor in determining their service life and maintenance costs. Fly ash is alkaline, hygroscopic, and corrosive. Improper material selection can cause the steel silo to rust and delaminate, even compromising its structural strength and potentially leading to safety accidents. Therefore, when customizing a steel silo, "selecting the right material is more important than thickness."

Main material

Carbon steel (Q235B/Q355B) is most commonly used, but the interior wall requires special treatment. Wear-resistant steel plates (such as NM400/500) or thicker steel designs should be used in critical wear areas (around the cone and fluidizing plate). For corrosive environments, consider stainless steel linings (304/316L) or an all-stainless steel silo (which is more expensive).

| Material | Advantages | use |

| Q235B | Cost-effective, conventional carbon steel, easy to process | General industrial applications, dry areas or short-term storage projects |

| Q345R | High-strength steel specially designed for pressure vessels, suitable for pressure-bearing, large-capacity and high-load conditions. | Large steel silos, areas requiring high pressure |

| Stainless steel 304/316 | It has strong corrosion resistance and will not rust, and is particularly suitable for high humidity or acidic/alkaline environments. | Coastal areas, high humidity storage facilities, environmental protection projects |

For the storage of fly ash, if the working conditions are relatively general, it is generally recommended to use Q345R material, which has a good balance between strength and cost; but if it is often in a high humidity or highly corrosive environment (such as the rainy season in the south, hot areas, and around ports), it is recommended to upgrade to 304 or 316 stainless steel to avoid excessive maintenance costs in the future.

Internal surface treatment (extremely important)

Ultra-smooth treatment: Weld seams are ground flat, and the inner wall is polished or coated with a special ultra-smooth, low-friction wear-resistant lining (such as modified ultra-high molecular weight polyethylene (UHMW-PE), ultra-smooth ceramic coating, polyurea elastomer, fluoropolymer coating). This is a key measure to prevent material sticking and promote flow.

Welding and quality

Automatic welding is used to ensure quality, and 100% non-destructive testing (RT/UT) of key welds ensures overall rigidity and sealing.

Customization upon special requirements

For some special industries, such as fly ash fuel recovery, high-altitude and low-temperature storage and transportation, steel silos can also perform the following functions:

- Anti-static coating: prevents fine ash from accumulating electrical charge inside the silo, avoiding sparks that could cause an explosion;

- Insulation layer structure: suitable for cold areas to prevent condensation and agglomeration;

- Fire and explosion prevention system: used in high-risk areas to prevent gas accumulation and accidents.

Functional configuration of fly ash steel silo

When customizing steel silos, many people focus solely on structure and capacity, overlooking the more critical functional system configuration. This is especially true for fly ash, a material with poor fluidity and prone to moisture absorption and agglomeration. Traditional gravity unloading methods alone are no longer able to meet the continuous, efficient, and intelligent operational requirements of modern industry.

Fluidized system

- Fluidization type: pneumatic fluidization (low pressure, high air volume), pressure fluidization (high pressure, low air volume). Low-pressure fluidization is commonly used for fly ash.

- Fluidizing Elements: Porous fluidizing plates (most common): Material (sintered metal, ceramic, multi-layer fabric), porosity, and air permeability uniformity are critical. Anti-clogging design is required. Aerators/Nozzles: Placed in areas of the cone prone to bridging. Air discs/Air cushions: Installed above the cone or discharge port. Fluidizing rods: Placed along the cone wall.

- Air source system: Dedicated Roots blower or air compressor (degreased and dehydrated), pressure-surge tank, air heater (essential for cold/humid regions), precision filter, piping, and valves. Air volume, pressure, and dryness must be strictly guaranteed.

Pressure Safety and Ventilation

- Safety valve/explosion relief valve: Set reasonable pressure to prevent overpressure.

- Vacuum release valve: prevents deflation.

- Manholes and Inspection Doors: With quick-open locks and seals, located for easy access to key internal components (such as fluidizing plates).

- Breathing valve: Maintain micro-balance in the normal pressure chamber.

Efficient dust removal system

- Silo Roof Dust Collector: Pulse-jet bag filters are the absolute mainstream. Filtration air velocity must be strictly controlled (usually < 1.0 m/min), and the filter media must be selected (such as anti-static or water- and oil-repellent coated polyester). The handling air volume must cover the maximum feed exhaust volume and fluidization backflush volume. Explosion-proof design (explosion venting discs/valves, static discharge) is essential!

- Dust removal pipeline and sealing: The inlet of the feed pipe is well sealed, and a dust hood is installed at the unloading point and connected to the dust removal system.

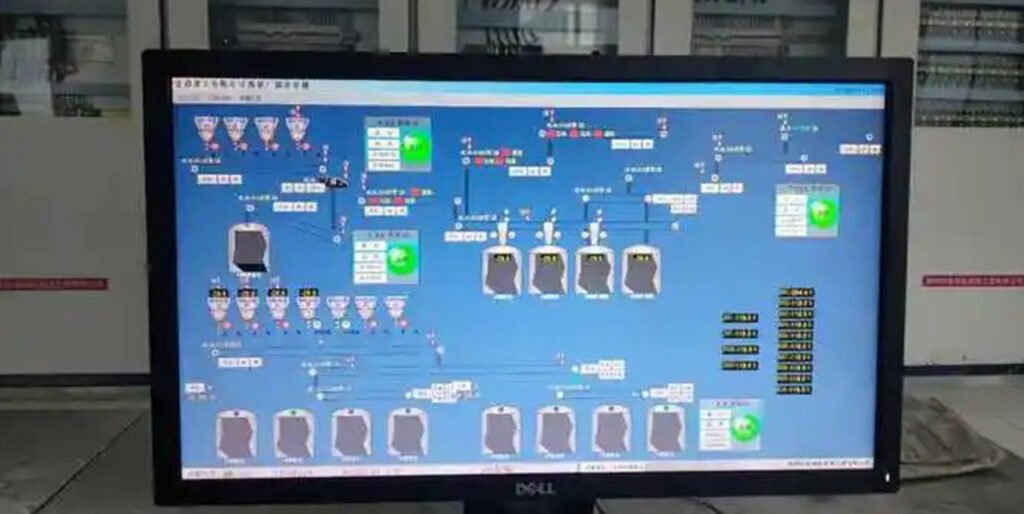

Electrical control and intelligence

- PLC control system: core, realizing automatic/manual control of feeding, unloading, fluidization, dust removal, material level monitoring, valve switching, safety interlock, etc.

- Human Machine Interface (HMI): Local touch screen to display operating parameters, status, alarms, and perform operations.

- Remote monitoring (SCADA): Connect to the power plant DCS or independent cloud platform to achieve remote monitoring, data storage, analysis, and alarm push.

- Key interlocks: For example: stop feeding when the material level is high, stop unloading when the material level is low, prohibit unloading when the fluidizing air pressure is insufficient, dust removal fan fault alarm/interlock, etc.

- Energy consumption monitoring: Monitor the energy consumption of fans, heaters, etc. to provide data for optimized operation.

Application of steel silo

The value of a fly ash silo lies not only in its ability to store ash but also in its suitability for the operating environment and process flow. Different regions, industries, and media characteristics place distinct demands on the silo's structure, function, materials, and even construction methods.

Cement industry

- Large-capacity cement storage silos for cement plants and batching units

- Ensure smooth material flow and efficient cement handling

Buildings and Infrastructure

- Reliable fly ash storage silos for thermal power stations and RMC sites

- Reduce material waste and support sustainable construction practices

Lime and chemical industries

- Durable lime storage silos for storing hydrated lime, quicklime and other chemicals

- Designed for fine powders, with anti-clogging system

Mineral processing and bulk material handling

- Custom mild steel silos for storing minerals, additives and fine materials

- Supporting continuous production in mining and processing operations

Agriculture and food processing

- Tailor-made bulk storage silos for grains, flour and organic powders

- Ensuring hygienic and efficient storage in the agricultural industry

Ready-mix concrete (RMC) plants

- Integrate cement silo and fly ash silo to achieve batching automation

- Compatible with conveyors, feeders and dust collection systems

Customize your fly ash steel silo

Customizing a high-efficiency fly ash silo is more than a simple equipment purchase; it's a systematic project that integrates in-depth needs analysis, precise design, precision manufacturing, and rigorous installation and commissioning. Its core lies in a deep understanding of fly ash's physical properties and process requirements, and the targeted application of optimized structural design, efficient fluidization technology, ultra-smooth, wear-resistant linings, reliable dust removal and explosion prevention measures, precise material level monitoring, and advanced intelligent control systems. Fly ash storage methods have evolved from open-air stacks and underground silos to reinforced concrete silos and now to high-performance steel plate silos. While there are many "available" solutions on the market, few truly deliver stable and reliable operation, durability, and long-term cost savings. Selecting a professional manufacturer with extensive experience and strong technical capabilities, and following a rigorous customization process, is the only way to achieve the ideal, high-efficiency fly ash silo.