Many people misunderstand the term “organic fertilizer plant” because it can refer to two very different concepts. On one hand, organic fertiliser plant is the nutrient-rich product made from manure, compost, or other biodegradable materials to improve soil health. On the other hand, a fertilizer plant is the industrial facility where this organic fertiliser is manufactured, equipped with machines such as mixers, granulators, dryers, and packaging systems. Clarifying this distinction helps readers better understand both the product itself and the production process behind it. So in this article we will give a introduction of both to give you a better understanding.

Definition of natural fertiliser plant:

Natural fertiliser for plants are organic fertilisers derived from plant and animal remains or excrement, produced through natural processes or artificial treatment. Their core characteristic is to improve soil structure and provide the nutrients needed for plant growth. Compared to chemical fertilizers, natural organic fertilizers place greater emphasis on ecological sustainability, reducing environmental pollution through the recycling of waste. Natural fertilizer for plants primarily originate from biomass, such as plant remains, animal manure, or kitchen waste. These materials release nutrients through decomposition, which are then absorbed by plants. Based on their source and preparation method, organic fertilizer for plants can be categorized into several types. For example, compost is made from organic waste (such as vegetable peels or fallen leaves) through microbial decomposition; animal manure, including feces or bone meal, is rich in nitrogen and phosphorus; while plant-based fertilizers come from wood ash or seaweed extracts, providing potassium and trace elements. These fertilizers not only replenish soil nutrients but also enhance soil water retention and microbial activity. The selection of natural fertilizer for garden should consider their nutrient release rate. Slow-release fertilizers, such as compost, are suitable for long-term garden soil improvement, while fast-release fertilizers, such as fish milk fertilizer, are suitable for rapid fertilization. natures garden fertiliser typically contain minor nutrients and beneficial microorganisms, which contribute to healthy plant growth and reduce pests and diseases.

Definition of organic fertiliser plant:

Now this concept is important that: a nature organic fertiliser plant is a specialized facility for the industrial production of organic fertilizers. Their main function is to systematically process various organic raw materials into high-quality fertilizers that meet agricultural standards. This involves transforming organic waste from agriculture, animal husbandry, and food processing into valuable resources, achieving ecological transformation. Unlike traditional farmyard manure composting, modern organic fertiliser plants use scientific formulas and standardized processes to render organic waste harmless, stabilize, and standardize it, ultimately producing commercial organic plant fertilizer with clear ingredient labeling and efficacy guarantees.

3 Types of organic fertilizers

Organic fertilizers mainly originate from biomass, such as plant residues, animal manure, or kitchen waste. These materials release nutrients through decomposition, which are then absorbed by plants. Based on their source and preparation method, organic fertilizers can be classified into several types.

- Compost is made from organic waste (such as vegetable peels or fallen leaves) through microbial decomposition;

- Animal manure, including manure or bone meal, is rich in nitrogen, phosphorus, and other elements;

- Plant manure comes from wood ash or seaweed extracts, providing potassium and trace elements.

These fertilizers not only replenish soil nutrients but also enhance soil water retention and microbial activity. The Utah State University Extension Project points out that the selection of organic fertilizers should consider their nutrient release rate; slow-release fertilizers such as compost are suitable for long-term soil improvement, while fast-release fertilizers such as fish milk fertilizer are suitable for rapid fertilization. Organic fertilizers typically contain minor nutrients and beneficial microorganisms, which contribute to healthy plant growth and reduce pests and diseases.

Methods for making your own natural fertilizer at home for Gardening

Homemade natural fertilizer is an economical and environmentally friendly method that can be prepared using everyday waste. Common methods include composting kitchen waste, preparing wood ash, and making liquid fertilizer.

- Kitchen waste composting such as fruit peels and vegetable leaves with brown materials, piling them in a well-ventilated container for weeks to months, and turning them regularly to promote decomposition. This process produces humus rich in nitrogen, phosphorus, and potassium, suitable for improving garden soil.

- Another method is to make wood ash fertilizer, collecting the ash from burned wood and sprinkling it directly into the soil to provide potassium and regulate pH.

- Liquid fertilizers such as compost tea or fish milk fertilizer can be made by soaking organic materials such as compost or fish waste in water for several days. When using, dilute it before watering plants for a quick nutrient boost.

These methods are simple and easy to implement, but attention must be paid to proportion control. For example, the carbon-to-nitrogen ratio in compost should be maintained between 25:1 and 30:1 to ensure efficient decomposition. Homemade fertilizer not only reduces landfill waste but also allows for customized nutrient composition based on plant needs.

How to Choose and Use Natural Fertilizer

When choosing natural fertilizers, you need to consider the plant type, soil conditions, and growth stage.

- First, soil testing should be conducted to determine nutrient deficiencies. For example, nitrogen-deficient soils can be treated with high-nitrogen fertilizers such as blood meal or soybean meal. For vegetable gardens, slow-release fertilizers such as compost are more suitable for basal fertilization, while flowering plants may require high-phosphorus fertilizers such as bone meal.

- When using natural fertilizers, the principle of appropriate dosage should be followed. Over-application may lead to nutrient loss or salt accumulation. For example, manure must be fully decomposed before use to avoid pathogen contamination; liquid fertilizers should be diluted to an appropriate concentration to prevent root burn.

- The timing of natural fertilizer application should be matched with the plant's growth cycle. Spring is suitable for basal fertilization, while quick-acting fertilizers can be applied in summer.

- The application of natural fertilizers can also be combined with irrigation systems to improve efficiency.

Choosing natural fertilizers should be based on scientific analysis, rather than blindly following trends, in order to ensure plant health and environmental safety.

Benefits of natural fertilizers

The main benefits of natural fer are reflected in soil health, environmental sustainability, and plant growth.

- From a soil perspective, natures garden fertiliser improve soil structure, increase organic matter content, thereby enhancing water retention and aeration, and reducing the risk of erosion.

- Environmentally, recycling waste into fertilizer reduces waste disposal pressure and minimizes water pollution from chemical fertilizers, such as eutrophication caused by nitrogen and phosphorus runoff.

- Natural fertilizer for plants growth provide comprehensive nutrition, including micronutrients, promoting root development and resilience. Long-term use of organic fertilizers can increase soil microbial diversity and enhance nutrient cycling efficiency.

- Organic fertilizers typically do not contain synthetic additives, reducing disturbance to the ecosystem.

Although natural fertilizers release nutrients less than npk compound fertilizer, however their long-term effects are superior to those of chemical fertilizers, especially in sustainable agriculture.

Common types of organic fertilizers and their characteristics

| Type | Main Nutrients | Sources | Applicable Scenarios | Precautions |

| Compost | Nitrogen, Phosphorus, Potassium | Kitchen waste, yard waste | General soil improvement, vegetable gardens | Must be fully decomposed to avoid odors |

| Bone Meal | Phosphorus, Calcium | Animal bones | Flowering plants, fruit trees | Slow release, suitable for base fertilization |

| Fish Emulsion | Nitrogen, Phosphorus | Fish processing waste | Quick nutrient supplement, foliar application | Dilute before use, avoid overuse |

| Wood Ash | Potassium, Calcium | Burned wood ashes | Raise soil pH, potassium-demanding plants | Strongly alkaline, use cautiously on acidic soils |

| Soybean Meal | Nitrogen | Soybean processing residue | Leafy greens, nitrogen supplement | Slow release, combine with other fertilizers |

| Seaweed Fertilizer | Potassium, Trace Elements | Seaweed extracts | Promote root growth, stress resistance | Liquid form, easily absorbed |

Organic fertiliser plant for fertilizer manufacturing

Organic fertilizer production plants are key engineered nodes in the material cycle of agricultural ecosystems. Their core function is to transform environmentally hazardous organic waste, unsuitable for direct application, into stable, safe, and soil-enriching commodities through biological and engineering methods, this sounds too formal! The core functions of organic fertilizer plants are mainly reflected in three levels: at the waste treatment level, plants reduce environmental pollution by centrally processing organic waste such as livestock manure and crop straw; at the fertilizer production level, plants transform unstable organic matter into stable humus by controlling fermentation and composting processes, providing nutrients needed by plants; and at the agricultural service level, the different formulations of organic fertilizers produced by the plants can improve soil quality and increase crop yield and quality, this sounds also formal, let me explain it in short, organic fertiliser plant is a fertilizer production line that transfers cow dung manure, poultry to value added oragnic fertilizer through our steam drum rotary granulation organic fertiliser production line.

Raw material selection and formulation design

Organic fertilizer plants have a wide range of raw material sources, mainly including livestock and poultry manure, crop straw, food processing by-products, and organic household waste. These raw materials can be divided into two main categories according to their chemical properties: carbon source raw materials and nitrogen source raw materials.

- Carbon sources such as crop straw, rice husks, and sawdust primarily provide the energy needed for microbial activity and regulate the porosity of the compost pile.

- Nitrogen sources such as livestock and poultry manure, soybean meal, and kitchen waste provide nitrogenous substances such as protein and amino acids, which are the main sources of nitrogen nutrients in fertilizers.

Raw material ratio is the core element of formula design, directly affecting fermentation efficiency and product quality.

- A suitable carbon-to-nitrogen (C/N) ratio is crucial for successful fermentation, typically maintained between 25:1 and 30:1. An excessively high C/N ratio restricts microbial activity and slows fermentation; a too-low C/N ratio leads to nitrogen loss and the production of ammonia odor.

- The physical properties of the raw materials, such as particle size, moisture content, and porosity, also affect the fermentation process.

- In raw material pretreatment, large materials like straw are usually crushed to a particle size of 3-5 cm to increase specific surface area and promote microbial decomposition. Simultaneously, adjusting the moisture content to 55%-65% creates a suitable environment for microbial activity.

Formula design

Product positioning and intended use must be considered. Organic fertilizer plants adjust raw material ratios and add functional components to suit different crops and soil conditions. For example, for acidified soils, alkaline substances such as phosphogypsum can be added to adjust the pH; for areas lacking micronutrients, minerals such as borax and zinc sulfate can be added. Raw materials must not contain heavy metals, persistent organic pollutants, or other harmful substances, and livestock manure should not contain impurities other than bedding and feed residue. Some advanced organic fertilizer plants have established raw material traceability management systems, recording the source, composition, and characteristics of each batch of raw materials to provide data support for formula design. Taking refined organic fertilizer as an example, its raw materials are mainly natural organic matter and humic acid. Microbial fermentation technology is used to harmlessly treat organic waste such as livestock manure and plant residues, and multiple extraction processes are used to concentrate the organic matter components. Modern organic fertilizer plant formula design has evolved from simple material mixing to precise formulation based on crop nutritional needs and soil characteristics. By adding functional microbial agents, mineral conditioners, and soil amendments, specialized formulations can be created for specific soil crop systems.

Raw material detailed management and pretreatment process

The complexity of raw materials necessitates a variety of pretreatment processes. Single raw materials often fail to meet the ideal fermentation conditions (moisture content 50%-60%, carbon-nitrogen ratio 25-35:1), thus requiring precise formulation.

Raw material compatibility calculation

The factory's technical department needs to calculate the mixing ratio based on real-time testing data of incoming raw materials. For example, the mixing ratio of fresh pig manure (70% moisture content, C/N ratio 13:1) and wheat straw (12% moisture content, C/N ratio 80:1) can be estimated using the following simplified formula: Let the mass of pig manure be M, the mass of straw be S, and the target moisture content be 60%.

Then: (0.7M + 0.12S) / (M + S) = 0.6.

This calculation yields an approximate mixing ratio, providing a theoretical basis for on-site mixing.

Detailed Explanation of Core Pretreatment Processes

- Crushing and Grinding: For coarse fibrous materials such as straw and branches, a shredder or hammer mill should be used to reduce their length to below 3-5 cm to increase the surface area for microbial action.

- Solid-Liquid Separation: For liquid or semi-liquid livestock manure, a screw extrusion solid-liquid separator is a crucial step. The separated solid portion (60%-65% moisture content) enters the fermentation stage, while the liquid portion can be further processed into liquid fertilizer or used for biogas fermentation.

- Mixing and Homogenization: Multiple mixing operations using a twin-shaft mixer or forklift ensure uniform distribution of moisture, carbon-to-nitrogen ratio, and microbial agents throughout the material. The uniformity of mixing is one of the decisive factors affecting the synchronization of subsequent fermentation.

Core fermentation process

Aerobic fermentation is essentially a process in which organic matter is mineralized and humified by aerobic microbial communities under controlled conditions.

Microbiological processes

This process can be divided into three stages:

- Heating Phase (0-3 days): Mesophilic microorganisms rapidly multiply, decomposing easily degradable organic matter such as sugars and proteins. The pile temperature quickly rises from ambient temperature to 45-50℃.

- High-Temperature Phase (4-15 days): Thermophilic microorganisms become the dominant flora, and the temperature rises to 55-70℃. This stage is crucial for killing pathogens, parasite eggs, and weed seeds, and requires maintaining a high temperature above 55℃ for at least 5-7 days. Simultaneously, complex organic matter such as cellulose and hemicellulose begins to decompose.

- Cooling and Maturation Phase (16-25 days): Easily degradable organic matter is largely depleted, and the temperature begins to slowly decrease to ambient temperature. Microbial activity weakens, humus begins to form in large quantities, and the material tends to stabilize.

Throughout the process, the oxygen concentration in the pile needs to be maintained above 5% through aeration or turning. Moisture evaporation carries away a significant amount of heat, so timely moisture replenishment is necessary to prevent the material from becoming too dry and causing microbial activity to stagnate.

Technical and economic comparison between trough and windmill processes

| Comparison Dimension | Trough Aerobic Fermentation Process | Strip-Stack Aerobic Fermentation Process |

| Infrastructure Investment | High. Requires construction of concrete fermentation troughs, rails, and rain shelters. | Low. Only needs a leveled and hardened ground; rain shelter is optional. |

| Equipment Investment | High. Specialized rail-type turner is expensive. | Medium. Wheel-type turner or modified loader has lower cost. |

| Operating Costs | Higher energy consumption (turning + forced aeration), but lower labor costs. | Lower energy consumption (only turning), but higher labor and fuel costs. |

| Land Area | Smaller. Trough design is compact with high space utilization. | Larger. Requires space for pile-turning machinery access. |

| Fermentation Cycle | 15–20 days. Conditions are controllable, cycle is stable. | 20–30 days. Greatly affected by climate, cycle is unstable. |

| Environmental Impact Control | Easy to control. Gas collection hoods can be installed above the trough to collect and treat exhaust gases. | Difficult to control. Odor gases are emitted without organization, significantly affecting the surrounding plant area. |

| Applicable Scale | Suitable for medium-to-large-scale, continuous production plants with annual output over 10,000 tons. | Suitable for small-scale, seasonal production projects with annual output under 10,000 tons. |

Equipment and functions of the post-processing section

The post-processing stage determines the physical form and commodity attributes of the product.

- Crushing: Fermented materials may clump together, requiring the use of a vertical chain crusher or a screenless crusher to break up the clumps and ensure the quality of subsequent granulation.

- Screening: Two-stage screening is performed using a drum screen. Materials of the correct particle size proceed to the next process, while excessively fine powder is returned to the granulation stage, and excessively large particles are returned to the crushing stage, forming a closed loop.

- Granulation:

- Disc Granulation: Material is granulated into spheres by rolling a tilted, rotating disc. The resulting granules have lower strength but higher production capacity, suitable for ordinary organic fertilizers where high granule strength is not required.

- Extrusion Granulation: Material is forced through a die and formed under high pressure. The resulting granules are cylindrical, high-strength, and less prone to pulverization, but energy consumption is higher.

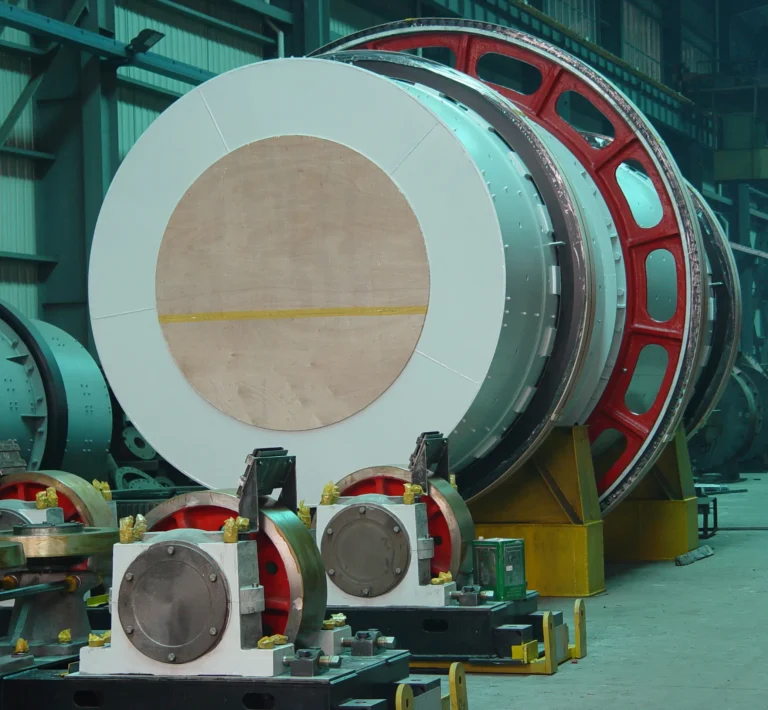

- Drum Granulator: Also known as a roller granulator, this is a slightly tilted, slowly rotating cylinder. Pre-treated powdered material is continuously and quantitatively fed into the drum inlet. As the cylinder rotates, the material is lifted and tumbled inside. Simultaneously, a suitable amount of water or binder solution (such as molasses waste liquid or humic acid solution) is evenly sprayed onto the material bed through atomizing nozzles. Under the surface tension of the liquid phase, fine powder particles adhere to each other, forming nuclei. These nuclei continuously adhere to more powder during the rolling process, gradually growing like a snowball to form uniform, dense spherical granules.

- Packaging machine: After extrusion granulation, it is connected to a spherical polishing machine to shape the cylindrical granules into smooth spheres, improving the appearance of the product.

- Drying and Cooling: The rotary drum dryer uses hot air (heat source can be natural gas, steam, or biomass fuel) to reduce the moisture content of the pellets to below the industry standard (≤30%). The pellets then enter a cooler where they exchange heat with ambient air to cool to room temperature, preventing condensation after packaging.

- Packaging: The fully automated packaging system (including automatic feeding, quantitative weighing, bag clamping, and sealing) completes 25 kg or 50 kg bagging and can print batch information via inkjet printer.

Factory Auxiliary Systems and Quality Control

Auxiliary systems

- Exhaust Gas Treatment System: Odorous gases such as ammonia and hydrogen sulfide generated during fermentation can be collected and treated through biological filters or chemical scrubbing towers, and discharged only after meeting standards.

- Wastewater Treatment System: Site flushing water and initial rainwater within the plant area should be collected and sent to wastewater treatment facilities. After treatment, they can be reused for production moisture regulation, achieving zero discharge.

- Laboratory: The laboratory should be equipped with basic equipment such as analytical balances, drying ovens, and muffle furnaces, capable of testing moisture, pH, organic matter, and total nutrients. Heavy metal and other indicators can be outsourced to third-party testing agencies.

Quality Management System

Quality control activities are conducted throughout the entire process, forming a complete chain:

Raw material incoming inspection → Fermentation process monitoring (temperature, oxygen) → Semi-finished product (fermented material) inspection → Finished product outgoing inspection.

Each batch of products should have traceable records, including the source of raw materials, fermentation tank number, production date, and inspection report.

Economic and environmental benefits of investing in organic fertilizer plants

Investment and return model (taking a 20,000-ton-per-year granular organic fertilizer plant as an example)

| Item | Estimated Range (USD) | Remarks |

| Fixed Asset Investment | 1.0 – 2.0 million USD | Includes land lease, plant building, fermentation troughs, full set of equipment, etc. |

| Raw Material Cost | 30 – 50 USD/ton | Varies depending on raw material source (purchased or collected with treatment fee) and transportation distance. |

| Production & Operation Cost | 15 – 20 USD/ton | Includes electricity, fuel, labor, equipment maintenance, packaging bags, etc. |

| Total Cost | 40 – 100 USD/ton | Raw material cost + production & operation cost + depreciation and amortization. |

| Product Market Selling Price | 100 – 200 USD/ton | Varies depending on product quality, regional market demand, and brand. |

| Gross Profit per Ton | 100 USD/ton | |

| Total Annual Gross Profit | 0.8 – 2.0 million USD | Static estimate; does not consider full production capacity or market fluctuations. |

Environmental benefits

An organic fertilizer plant with an annual production capacity of 20,000 tons can process approximately 28,000-32,000 tons of fresh livestock and poultry manure annually (based on a 70% moisture content). This is equivalent to a portion of the manure produced by a pig farm with 100,000 pigs or a dairy farm with 2,000 dairy cows. Its environmental benefits are specifically reflected in:

- Reduced pollutant emissions: Avoids the potential chemical oxygen demand (COD) load from the direct discharge of approximately 30,000 tons of feces.

- Reduced greenhouse gas emissions: Compared to natural waste disposal, aerobic treatment significantly reduces methane (CH₄) emissions.

- Carbon sequestration: The stable organic carbon (humus) in organic fertilizer, once applied to the soil, forms an effective carbon sequestration layer.

Conclusion

Organic fertilizer plants, as an important carrier for the resource utilization of organic waste, transform organic waste such as livestock and poultry manure and crop straw into high-quality fertilizers with soil-improving and nutrient-providing functions through systematic processing, achieving a unity of pollution control and resource regeneration. Modern organic fertilizer plants employ scientific formulas and standardized processes to produce diverse products, including refined organic fertilizers, bio-organic fertilizers, and specialized organic fertilizers, meeting different agricultural needs. The production process of organic fertilizer plants includes three core stages: raw material pretreatment, fermentation and maturation, and deep processing and shaping. Aerobic fermentation technology and specialized equipment are used to stabilize and render organic matter harmless. A strict quality control system ensures that products meet relevant standards, including organic matter content, nutrient content, heavy metal limits, and hygiene indicators. Through comprehensive environmental management measures, organic fertilizer plants effectively control the emission of waste gas, wastewater, and solid waste during the production process, achieving clean production. The construction and development of organic fertilizer plants are of great significance for achieving sustainable agricultural development, improving the rural ecological environment, and enhancing the quality and safety of agricultural products. Organic fertilizer plants are an important part of the modern agricultural system, as they centralize the processing of scattered organic waste to produce standardized organic fertilizers.