What is a bulk blending bb fertilizer production line?

First of all, let's start with the definition: BB fertilizer production lines are a type of NPK compound fertilizer production plant that precisely mix single-element fertilizers or pre-made compound fertilizer granules according to specific formulas, and then package them in measured quantities without the need for granulation - By Tongli a 65+ years experience fertilizer equipment manfuacturer.

3 Core adventage of BB bulk blending fertiliser process: simple set up, flexible formulation, and lower processing expense!

Simple Installation and Commissioning, Short Installation Cycle:

- BB fertilizer production lines have a very simple and compact structure, an automatic batching system, mixing system, and packaging system. They do not require complex equipment such as granulators, dryers, or coolers. The entire production line, from equipment delivery to factory, foundation construction, and commissioning, can generally be installed and put into operation within 15~30 days(under the assumption that the civil foundation is complete). Compared to the 3–6 months construction cycle of npk steam drum granulation compound fertilizer production lines, this significantly saves time.

Low Equipment Investment, Low Energy Consumption, and Low Maintenance Costs:

- The equipment investment for a BB fertilizer production line is only 10-15% of that for a compound fertilizer granulation production line of the same capacity. For example, a fully automated BB fertilizer production line with an annual output of 100,000 tons (approximately 50 tons/hour) requires a total equipment investment of approximately US$180,000-200,000, while a similarly sized NPK granulation line typically costs over US$1.6-1.8 million. Furthermore, due to the absence of high-temperature granulation and drying processes, the energy consumption per unit product is only approximately 2.8-4.5 kWh/ton, while traditional compound fertilizer lines typically consume 18-25 kWh/ton. Routine maintenance requires only 1-2 people for inspection, resulting in low operating costs.

Small area needed and easy upgrade:

- BB fertilizer production lines have a compact layout, generally requiring only 200-300 square meters of factory space to install a medium-capacity (40-50 t/h) automated production line. If production demand increases, simply adding a batching silo or replacing the mixer with a larger capacity one can increase the capacity to 100 t/h or even higher. The entire expansion process requires no large-scale civil engineering modifications and can be completed within 2–3 days.

What is the process flow of bb fertilizer production line in brief?

A bulk blending (BB) fertilizer production line begins with truck unloading of pre-granulated raw materials like urea, DAP, and MOP into separate storage hoppers. if the owner design the feeding to be underground then can feed at 0 ground level. Each component is automatically weighed by a PLC-controlled batching system (±0.2–0.5% accuracy) using belt or loss-in-weight scales, then lifted by bucket elevator into a BB rotary drum mixer for uniform blending (CV ≤ 3%). The mixed fertilizer is discharged into a buffer hopper and fed to a servo-controlled automatic packaging machine, which fills, folds, and sews 25~50 kg bags at a speed of 800–1200 bags/hour. The finished bags are conveyed to robotic palletizing and wrapping for storage or truck dispatch, while the entire system, made of 304 stainless steel and equipped with dust collection, ensures high efficiency, durability, and environmental cleanliness.

Is rotary drum mixer is needed for a BB fertilizer production line?

In BB fertilizer production lines, most manufacturers equip their products with mixers, some even adding a 1000mm screen at the end of the mixer to screen out fine powder and slightly broken particles, ensuring the uniformity and flowability of the final product. However, some manufacturers choose not to use mixers, directly using bucket elevators to lift the raw materials into the finished product silo to complete the "mixing." This method seems to simplify the process, but it requires continuous batching: that is, the components of the raw materials must be fed into the production line in strict proportions, continuously and stably. If there are interruptions or fluctuations in the ratio between batches, it can easily lead to uneven mixing of the finished fertilizer, high CV values in single sampling, and affect fertilizer quality and application effects. Continuous batching requires highly automated equipment and processes; otherwise, the uniformity of each bag of fertilizer cannot be guaranteed. In contrast, rotary drum mixers can maintain high uniformity even in non-continuous feeding conditions. Through slow tumbling and scattering by the drum, raw materials of different densities and particle sizes are fully mixed, achieving a mixing uniformity of CV≤3%, with minimal particle damage and stable and reliable operation. Therefore, even for production lines that prioritize high efficiency or simplified processes, we still recommend equipping BB fertilizer production lines with rotary drum mixers to ensure the quality and stability of the finished fertilizer.

When to skip or not to use a Rotary Drum Mixer in BB Fertilizer Production Line?

Small Factories with Limited Funds

Rotary drum mixers require relatively high initial investment, including the machine itself, drive system, installation, commissioning, and subsequent maintenance costs. For small fertilizer producers or startups with limited funds who cannot afford the investment in the short term, direct bucket elevator feeding into the finished product silo is recommended to reduce upfront investment.

Products with Low Requirements for Mixing Uniformity

When your target customer or market do not have strict requirements for the mixing precision of fertilizer products, such as low-end compound fertilizers or short-cycle crop fertilizers used for non-precision fertilization. If the mixing uniformity can fluctuate significantly (CV value can reach over 5%), factories can consider not using large rotary drum mixers and achieving "approximate mixing" directly through continuous batching and lifting conveyors.

Minimal or Intermittent Production Capacity

If the production line has very low output, small batch sizes, and intermittent production, the footprint and start-up/maintenance costs of a rotary mixer may be uneconomical. In this case, using a screw mixer or continuous bucket elevator for feeding can save space and energy while meeting production demands.

Extremely Simplified Production Process

Some small factories, especially those with limited resources for equipment maintenance and operation, may choose to omit the mixer and directly feed ingredients into the finished product silo via continuous batching. This approach reduces equipment complexity, but it relies on ensuring stable continuous batching; otherwise, the uniformity of the finished product cannot be guaranteed.

What Equipment is needed for 35-40t/h BB fertilizer production line/bulk blending fertiliser manufacturing?

Automatic batching system

We have two types of automatic batching machines: dynamic and static. Both are controlled by a Siemens microcomputer system that we programmed ourselves. Dynamic automatic batching machines work more efficiently than static ones. If you want a small-yield bulk blending (BB) fertilizer production line, we suggest you choose a static automatic batching machine. For a large-yield BB fertilizer production line, you’d better pick a dynamic automatic batching machine. Also, if you want to save space and feed materials at ground level (without using a forklift), we recommend digging a pit in the ground and putting the batching machine inside it.

Dynamic (Weigh-Loss) Automatic Batching Machine

In a continuous BB fertilizer production line, Weigh-loss scale system continuously measures the material flow rate in real time. Each SS304 stianless steel raw material hooper is equipped with a HMB load cell that tracks how much weight is being “lost” as materials are discharged. The Siemens PLC system instantly adjusts the belt speed by Omron speed sensor and gate opening to maintain the preset NPK ratio with a precision of ±0.2–0.5%. Because it measures dynamically, the process never stops materials flow, weigh, and mix simultaneously. As a result, dynamic weigh-loss batching machines can easily achieve 40–80 t/h or even 120 t/h capacity with consistent accuracy. They are ideal for large-scale, fully automatic BB fertilizer plants requiring high output and stable performance.

Standard Double Belt Scale weighing belt scale or weighing feeder

A standard double belt scale batching system, which further enhances accuracy and flow stability. The first belt is responsible for steady material feeding, while the second belt measures and corrects the flow in real time. This dual-layer design reduces vibration, prevents surges, and ensures continuous, uniform feeding even when raw materials have uneven particle sizes or densities. In comparison tests, a double-belt scale system improves weighing stability by 15–20% and can maintain a coefficient of variation (CV) below 3%, ensuring each formula batch meets strict precision requirements. This configuration is especially recommended for high-capacity production lines or for materials that tend to bridge or fluctuate in flow rate, such as ammonium phosphate or potassium chloride granules. But most importantly it is cheaper than the weight loss system.

Bucket elevator

In a bulk blending (BB) fertilizer production line, the bucket elevator is used to vertically lift and transfer granular materials from the batching scale to the mixer. After each raw material is automatically weighed, the elevator raises it 8 to 10 meters to the rotary drum mixer for continuous feeding. Its enclosed structure prevents dust escape and material spillage, maintaining a clean environment and consistent material flow. Compared with inclined belt conveyors, the bucket elevator occupies less floor space and offers higher lifting efficiency. The fertilizer line generally uses a belt or plate-chain bucket elevator, built for corrosion resistance and gentle material handling, ensuring fertilizer granules remain intact and evenly fed into the mixer.

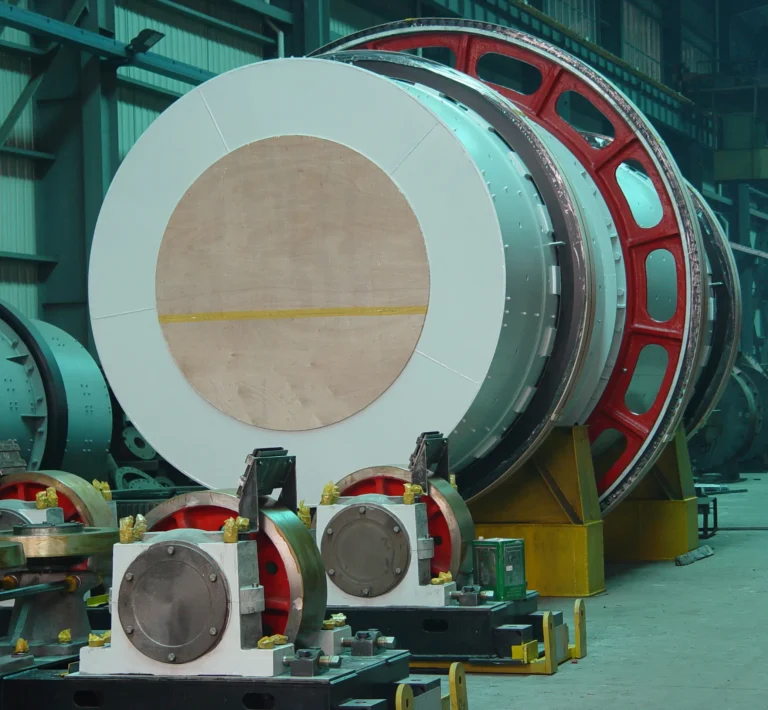

Rotary drum mixer

Our BB fertilizer rotary drum mixer is ideal for batch mixing of granular fertilizers. It is mainly used to uniformly mix various granular raw materials such as urea, DAP, and potash fertilizer according to the formula ratio to form high-quality BB fertilizer. It is suitable for continuous or intermittent production lines to meet different production demands. The equipment operates smoothly and can protect the integrity of the raw material granules to the greatest extent, avoiding nutrient stratification problems caused by breakage.

Adventage of our BB fertilizer rotary drum mixer: Transmission and Support Structure

Our Transmission and Support Structure is Casting, Durability Far Exceeds other company's models, most BB fertilizer mixers from small manufacturers use a simple structure "similar to a cement mixer," relying on hand welded or stamped parts for transmission that the support components are flimsy and prone to deformation and wear over long-term operation becasue they want their price to be competitive. Our mixer's core components are all manufactured using casting technology, including gears, tires, rollers, bearings, and bearing housings. This fundamentally solves the stability problems of ordinary models: Cast gears: High tooth surface precision and hardness, smoother meshing, no impact noise, and a service life 3-5 times that of other manufacturer's tiny gears, avoiding frequent parts replacements; Cast riding ring and support roller: Large contact area, strong load-bearing capacity, stably supporting the entire drum weight. Even under long-term full-load operation, there will be no tire misalignment or uneven roller wear; Integrated cast bearing housings: Excellent sealing performance, effectively preventing dust and fertilizer particles from entering the bearing, reducing the failure rate, and extending the maintenance cycle by more than 60% compared to ordinary models.

Adventage of our BB fertilizer production line mixer: Internal Lifting Plate flights Design Doubling Mixing Uniformity

Other small Henan fertilizer machinery company's hand-made crappy mixers lack internal structure, relying solely on drum rotation for simple mixing. This often leads to localized accumulation and insufficient mixing of raw materials, resulting in uneven nutrient distribution in BB fertilizers. They serve only an aesthetic purpose, offering little practical benefit in achieving uniform mixing; their only advantage is cheap. Our mixer, however, features multiple sets of spiral lifting plates inside the drum. During operation: the lifting plates rotate with the drum, lifting and scattering the raw materials at the bottom, creating a "full-range tumbling" effect and preventing sedimentation; the spiral structure guides the raw materials along the drum's axial direction, achieving both radial and axial mixing, ensuring uniform contact between all material particles; and the lifting plate angle can be flexibly adjusted for fertilizers of different particle sizes, guaranteeing effective mixing without damaging the particle shape. Ultimately, the uniformity rate of our BB fertilizer reaches ≥98%, far exceeding the industry average.

Automatic packaging machine 25kg/50kg/ton bag/jumbo bag

Our automatic weighing and packaging machine is specially designed for granular bulk blending fertilizer and npk compound fertilizers. It adopts a servo motor control system and high-precision load cell, achieving accurate weighing with an error of less than ±0.2%. The packaging speed reaches 800–1200 bags/hour (13–20 bags per minute), while small Henan manufacturers’ carbon-steel machines only reach 3–4 bags per minute and often time has a high break down rate. Want to know the difference? check the below adventages of our system so that you don't get confused! Our product is complete different from them.

1. High-Speed, High-Precision Servo Motor Control System

Our automatic quantitative packaging scale uses an imported servo motor drive system, combined with a high-sensitivity weighing sensor and PLC control program, to achieve precise control of feeding speed and weighing accuracy. The system can automatically adjust the screw feeder or gate feeder speed according to the material flowability, keeping the error per bag within ±0.2%. In actual operation, the packaging speed of this equipment can reach 800-1200 bags/hour. Taking 25kg fertilizer as an example, this is equivalent to 13-20 bags per minute. In comparison, traditional motor or pneumatic control scales used by ordinary small factories in Henan can only achieve 3-4 bags per minute, increasing production efficiency by nearly 4 times. The efficient servo system not only increases output but also significantly reduces material waste and error rate.

2. The entire machine is made of 304 stainless steel, making it more corrosion-resistant and durable.

Fertilizer materials are generally corrosive, especially nitrogen-, chlorine-, and sulfur-containing fertilizers, which accelerate the rusting and aging of carbon steel equipment. Our packaging scale's entire structure, including the hopper, discharge port, and sealing frame, is made entirely of 304 food-grade stainless steel. The surface is mirror-polished and dustproofed, ensuring stable operation even in high-humidity and highly corrosive environments. Under the same working conditions, 304 stainless steel equipment has a service life of 8-10 years, while ordinary carbon steel equipment only lasts 3-4 years. Furthermore, the stainless steel structure is easier to clean and maintain, meeting the fertilizer industry's requirements for hygiene, environmental protection, and pollution prevention.

3. Automatic Folding + Automatic Sewing:

Our system integrates automatic folding and automatic sewing into a single module. After weighing, the packaging bags are automatically conveyed to the folding mechanism. Worker can neatly folds the bag opening, and then the bag enters the sewing machine for automatic double-line overlock stitching, resulting in strong and aesthetically pleasing seams. The entire process requires almost no manual intervention; from material feeding, shaping, folding, sewing to finished product output, it takes only 2-3 seconds per bag. Compared to traditional manual operation, automatic sewing improves aesthetics also effectively prevents fertilizer from absorbing moisture and clumping. If equipped with an automatic coding system, batch numbers and production dates can be automatically printed, providing data support for subsequent warehousing and logistics traceability. Also hot sealing is also availbale, but just more pricy therefore not recommanded at this moment.

4. Digital Control System + Dual-Location Control

The equipment is equipped with a Siemens PLC and a touchscreen operating interface. All operating parameters, such as target weight, speed, error correction, and sealing temperature, can be set and adjusted in real time on the screen. The system features automatic fault alarms, self-diagnosis, and remote monitoring functions, and is equipped with dual-location control. Besides inputting the formula on the computer, operation can also be performed through instruments in the control cabinet, preventing production line interruptions in case of power failure or computer malfunction. Operators only require simple training to be proficient. Furthermore, the control program has multiple preset packaging modes, allowing for quick switching between 25kg and 50kg packaging specifications, achieving multi-specification compatibility without replacing major components. The equipment can also be integrated with automatic feeders, conveyors, and palletizing robots to form a complete automated packaging production line.

5. Energy Saving and Cost Advantages

The high-speed servo drive system offers superior energy consumption control compared to traditional motor-driven equipment. Under full-load production, the total machine power is only 3.5~5.5kW, and the energy consumption per ton of product packaging does not exceed 0.4kWh. In addition, automated operation reduces the need for manual labor, reducing the number of personnel per shift from the traditional 3–4 to 1, resulting in annual savings of over 30% in labor and maintenance costs.

Continuous VS Non-continuous BB fertilizer production line difference comparison:

There are two types of BB fertilizer production line, continuous and non-continuous also known as batch type, the core difference is the batching, continuous batching relies on "continuous dynamic measurement + real-time adjustment," while batch batching uses "batch static weighing + batch switching." continuous BB fertilizer production lines clearly outperform non-continuous ones. Although they cost about 15–20% more initially, their productivity is up to 3 times higher, energy use 30–40% lower, and labor demand nearly halved. Within a year, most producers recover their investment through reduced operating costs and higher output stability. Simply put, continuous BB fertilizer production lines are the smarter, more economical, and more future-ready solution for modern fertilizer manufacturing, especially for medium to large-scale plants targeting consistent, high-quality blended fertilizers.

1. Working Principle Difference

Non-continuous (Batch-type) BB fertilizer lines operate in a start-and-stop mode.Each batch of material is weighed, mixed, and discharged before the next batch begins. The process is: start to weighing to mixing to discharging to stop to refill, which causes intermittent production. In contrast, Continuous BB fertilizer lines use dynamic weighing systems that continuously feed raw materials according to the preset formula ratios. Materials flow into the continuous mixer and are blended in real time. The process runs nonstop, allowing the line to maintain stable output and precise control over each nutrient ratio.

2. Production Efficiency

Continuous BB fertilizer lines can produce 2–3 times more output per hour than batch-type lines of similar size. Since the materials flow without interruption, operators avoid repetitive start-stop sequences that waste time and energy.

| Parameter | Continuous Line | Non-continuous (Batch) Line |

| Typical Output Capacity | 40–80 t/h (can reach 120 t/h) | 10–25 t/h |

| Downtime per Shift | <2% (for maintenance only) | 15–25% (due to batch resets) |

| Mixing Cycle | Continuous, 30–60 seconds retention | 2–4 minutes per batch |

| Daily Output (8 hours) | 300–600 tons | 100–200 tons |

3. Weighing and Mixing Accuracy

- Continuous lines use real-time electronic belt weighers or dynamic flow meters with ±0.2–0.5% precision.

- Batch-type systems rely on static load cell weighers with ±1–1.5% accuracy.

This difference might seem small, but in practice, for a 50 t/h line, a ±1% deviation can cause up to 500 kg of incorrect nutrient ratio per hour — enough to alter the actual N-P-K content beyond tolerance limits. Continuous mixing systems also maintain a coefficient of variation (CV) < 5%, while batch mixers typically range from 6–10%, especially when materials have varying densities or moisture levels.

4. Maintenance and Equipment Life

Frequent start-stop cycles in non-continuous systems cause more wear on conveyors, mixers, and motors. Bearings and belts face repeated acceleration and deceleration stress. Field data show that maintenance frequency in batch-type lines is 1.5–2 times higher, and key mechanical parts have 20–30% shorter service life. Continuous lines operate under smoother load conditions, leading to longer component lifespan and lower vibration and dust emissions.

5. Most importantly: capacity and speed

The biggest difference between continuous and non-continuous BB fertilizer production lines is their production speed and capacity. A continuous line runs non-stop with dynamic weighing and mixing, reaching 40–80 tons per hour (and up to 120 t/h for large systems), while a non-continuous or batch line usually produces only 10–25 t/h because it must stop and reset after each batch. This means a continuous BB line can deliver 2–3 times higher output per hour and over 500 tons per day in an 8-hour shift, compared to just 150–200 tons from a batch system. Besides higher capacity, continuous lines also keep nutrient ratios stable since there’s no interruption or material residue between batches, making them far more efficient and reliable for large-scale fertilizer production.

6. Conclusion:

The core difference between continuous and intermittent BB fertilizer production lines lies in their metering methods, equipment configurations, and control logic. In a continuous BB fertilizer production line, the batching stage is the front-end. Key equipment configurations include: one continuous loss-in-weight scale or dual-belt scale (one for each raw material) for each material, raw material buffer silos, a variable frequency speed control system, and a PLC automatic control system. In addition, auxiliary components such as real-time flow monitoring sensors are essential; high-end production lines sometimes also include online raw material moisture detection modules. Each raw material is metered independently, and the feed rate is adjusted via variable frequency to achieve dynamic flow control without manual intervention. The dynamic metering accuracy is between ±0.5% and 1.5%, meeting the stability and accuracy requirements of large-scale production. Errors can be corrected through real-time system calibration. The PLC system monitors the flow rate of each raw material in real time according to the set formula ratio and automatically adjusts the feed rate to compensate for flow fluctuations (such as uneven feeding caused by changes in raw material moisture content). This device maintains accuracy through automatic system adjustment, making it ideal for long-term production with a fixed formula. In terms of efficiency, continuous batching can operate without waiting—once started, it can run continuously, with a stable hourly batching capacity (5-50 tons/hour, matching the total output of the production line) to meet high-volume demands. Operation only requires pre-setting the formula ratio and flow parameters; no manual intervention is needed during operation, only periodic equipment checks and raw material level checks are required. In contrast, batch batching follows the core logic of "single batch weighing + batch reset." It first weighs one raw material according to the formula weight, then weighs other raw materials in sequence, and only after all raw materials have been weighed is all the batching fed into the mixer. Batching is carried out in independent "batch cycles": after the batching, mixing, and discharging of one batch are completed, the next batch can begin, thus forming a clear production interval. Key equipment includes static electronic scales or quantitative hopper scales (for single or multiple materials), manual feed inlets or small feeders, and simple weight display instruments. Auxiliary configurations include manual gate valves (for controlling raw material discharge), hopper mixing devices (for preventing agglomeration), and some semi-automatic production lines also include weight alarm functions. Most equipment uses single or dual scales alternately, requiring manual assistance to switch raw materials; the hopper must be emptied before weighing the next raw material. Static measurement accuracy is high, ranging from ±0.2% to 0.5%, allowing for precise weighing of individual batches, but batch-to-batch errors may occur due to manual operation. Control methods include manually setting the weight for each batch and manually confirming it after weighing; changing formulas requires re-entering weight parameters, and some semi-automatic production lines can pre-store 3-5 formulas. This makes it suitable for small-batch production with multiple formulas, ensuring accuracy through standardized manual operation while allowing for flexible formula switching. In terms of efficiency, the preparation time for each batch is 5-20 minutes (depending on the quantity of raw materials and batch weight), with a 2-5 minute interval between batches, and a dispensing capacity of 0.5-5 tons per hour, ideal for low-volume demands. Operation includes: manually monitoring the weighing progress of each raw material, timely switching of raw materials, and cleaning residual materials in the hopper (to avoid cross-contamination between formulas); recalibrating the weighing equipment is required when switching formulas.

Why choose BB fertilizer production line instead of steam drum granulation feritliser plant? 6 reasons explained

The key difference between BB fertilizer production lines and rotary drum granulation NPK production lines is that the granulation process requires mixing nitrogen, phosphorus, and potassium raw materials with binders, then granulating and drying them in a rotary drum to form uniform granular compound fertilizer. This process is longer and consumes more energy, but the finished granules are regular and the nutrient release is more stable, making it suitable for large-scale standardized production. In contrast, BB fertilizer production lines eliminate granulation and drying processes, require less investment, allow for convenient formulation switching, and produce blended granules. The nutrient uniformity depends on the mixing process, making them more suitable for small-batch, multi-formulation customized production needs.

Reason 1: Simple process

BB fertilizer production lines employ "physical mixing," eliminating the complex processes of high-temperature granulation and chemical reactions inherent in traditional compound fertilizer production. Production is completed through only four key steps: raw material screening, precise batching, uniform mixing, and metering/packaging, reducing process complexity by over 60%. The core advantage lies in omitting energy-intensive processes such as granulation, drying, and cooling. Utilizing loss-in-weight batching scales and rotary drum mixers, precise control and efficient mixing of raw material ratios are achieved, with a mixing uniformity error of ≤3%, far exceeding the ≤5% requirement of the Chinese standard GB/T 15063-2020. Furthermore, the simplified process reduces intermediate transfer links, improves production flow continuity, and enables continuous production. The single-batch production cycle is shortened to 10-15 minutes, representing a 90% increase in efficiency compared to traditional compound fertilizer production lines. This makes it particularly suitable for small and medium-sized enterprises and startups for rapid commissioning and mass production, reducing the difficulty of process debugging and operation.

Reason 2: Low equipment costs with minimal space

BB fertilizer production lines are compact in structure, with core equipment including an automatic batching system, mixer, packaging machine, and dust removal system. Compared to traditional compound fertilizer production lines, the investment is only 30%. The initial investment for a small 20-25t/h production line can typically be controlled to around US$200,000; a large 80-120t/h production line costs approximately US$500,000, significantly lowering the barriers to entry for startups and expansion. In terms of floor space, a single production line requires only 640 square meters, with the batching and mixing area accounting for approximately 60% and the packaging area for approximately 40%. Compared to the equivalent output of an NPK rotary drum granulation compound fertilizer production line, which often requires 2800 square meters, this saves 80% of the space.

Reason 3: No emissioning

The raw materials for the BB fertilizer production line are mainly finished 15-15-15 NPK fertilizer or granular single-element fertilizer. Since there are no high-temperature combustion, chemical synthesis, or other reaction processes, the production process generates only a small amount of dust, primarily from the raw material feeding and mixing stages. High-efficiency dust removal is achieved using a pulse-jet bag filter(optional), with a dust collection efficiency ≥ 99.5% and an emission concentration ≤ 10 mg/m³, far exceeding the particulate matter emission limits for general industrial point sources in the UAE Free Zone (e.g., the limit for "other sources" in the Dubai Free Zone is 150 mg/Nm³, and for some combustion sources it is 250 mg/Nm³). This production line requires no water for the batching and mixing process, generating virtually no process wastewater. No chemical byproducts are produced during mixing and packaging, resulting in high raw material utilization and a production waste rate ≤ 1%. Small amounts of undersize material or overflow can be recycled and reused in production.

Reason 4: Flexible production scadule

BB fertilizer production lines has excellent formula compatibility and fast response to new order. They can customize the proportions of nitrogen, phosphorus, potassium, and micronutrients such as calcium, magnesium, sulfur, and zinc according to customer requirements, crop type, and soil fertility. A single production line can produce 5–20 different BB fertilizer formulas, with a formula changeover time of approximately 20–40 minutes. In contrast, traditional NPK compound fertilizer granulation production lines require emptying all materials from the system and 2–4 hours of transitional formula production to achieve formula adjustments. Leveraging our Siemens PLC automated control system for batching scales, operators can directly input formula parameters via a touchscreen. The batching system automatically weighs and transports raw materials, enabling flexible production of "small batches, multiple varieties." For example, to meet the needs of high-potassium formulas for greenhouse vegetables and balanced formulas for field crops, companies can produce 3–5 formulas within a single day, with minimum order quantities as low as 1 ton and order response times typically within 4–6 hours, significantly overcoming the limitations of traditional production lines that are "large-scale, single-formula." In recent years, domestic compound fertilizer manufacturers have added pesticides and organic fertilizers to BB fertilizers, giving the fertilizers multiple functions. The more diversified formulas have helped their products quickly seize the market.

Reason 5: Low energy consumption & operational cost:

BB fertilizer production lines are energy saving! because they do not require high-temperature granulation or drying. The specific energy consumption is only 2.8~4.5 kWh per ton, compared with 18~25 kWh per ton for npk compound fertilizer production lines, a power saving of more than 75%. For a plant with an annual capacity of 12,000 tons, this means an electricity saving of USD 31,000~42,000 per year, based on an industrial power tariff of 0.139 USD/kWh in UAE. In terms of operating cost, the BB line has additional advantages: raw-material utilization ≥ 99.5%, no chemical additives, and high automation, only two operators are needed per line, compared with 6~8 for a traditional line, reducing labor cost by about 65–70%. Overall, the operating cost per ton of finished BB fertilizer is approximately USD $11~$17, compared with USD $21~$28 for traditional compound fertilizer plants, a cost reduction of around 40%. This results in a significantly higher long-term profit margin for the enterprise.

Reason 6: Low maintenance cost

The material contact parts of the core equipment in the BB fertilizer production line are made of SS304 stainless steel. Key components, such as the batching scale sensor, have a design life of ≥6 years. The overall equipment failure rate is ≤2.5%, lower than the 9%-12% failure rate of traditional rotary drum granulation production lines. Routine maintenance only requires basic operations such as equipment cleaning, lubrication, and fastener inspection. No professional technical team is needed; ordinary workers can do the job, with a maintenance frequency of 1-2 times per month. Core components are highly versatile, widely available, and have low replacement costs. For example, the replacement cost of the batching scale sensor is approximately US$100-200. Based on an annual production capacity of 25-40 t/h, the annual maintenance cost accounts for only 1.8%-2.5% of the total equipment investment, significantly reducing long-term operational losses for enterprises.

What are the Factors that Affect the Fertilizer Bulk Blending Quality?

As a BB fertilizer production line plant manager you may want to know the following 5 aspects to produce better product:

Physical Uniformity of Raw Material Particles (Particle Size, Density, Roundness)

Significant differences in the physical properties of different particles can lead to stratification or hygroscopic clumping after mixing. When the particle size difference between nitrogen, phosphorus, and potassium fertilizers exceeds ±0.5 mm, segregation is likely to occur during storage or transportation, resulting in uneven fertilizer composition. Studies have shown that if the density difference between components exceeds 0.4 g/cm³, the formulation error can reach 10–15% after 3 hours of transportation. Furthermore, inconsistent particle roundness and strength make them prone to breakage during mixing or packaging, generating dust and affecting the fertilizer's appearance and uniformity. Ideally, BB fertilizer raw material particles should maintain a particle size within the range of 2–4 mm and a roundness ≥0.85.

Chemical Compatibility Between Particles and Critical Relative Humidity (CRH)

When different base fertilizers are mixed, certain chemical reactions can lower the critical relative humidity (CRH), leading to hygroscopicity and clumping. For example, when urea (CRH approximately 75%) is mixed with ammonium phosphate (CRH approximately 93%), localized reactions can reduce the CRH of the mixture to 45–55%. This means that in environments with high relative humidity (e.g., storage warehouse humidity >60%), it is highly susceptible to moisture absorption and clumping. To avoid this problem, the chemical compatibility of raw materials must be controlled, highly reactive fertilizers should not be directly mixed, and the granule surface must be dry and free of free moisture (<0.3%).

Ambient Humidity and Storage Conditions

The storage environment like moisture has a significant impact on the quality of BB fertilizer. When the relative humidity exceeds the product's CRH value, the granule surface will absorb water, leading to clumping or decomposition. For example, a study on NPK 15-15-15 mixed fertilizer showed that after 30 days of storage at 25°C and 75% relative humidity, the clumping rate reached 22%, while under the same conditions with humidity controlled below 50%, the clumping rate was only 2%. Therefore, warehouse humidity should be controlled below 50%, and good ventilation and insulation should be ensured, with a storage time not exceeding 3–6 months.

Mixing Precision and the Accuracy of the Automated Batching System

Batching errors directly affect the nutrient ratios in the final formula. Our BB fertilizer production line uses a Siemens automated electronic weighing and PLC control system, with a target error controlled within ±0.2–0.5%. If the error exceeds 1%, the N, P, and K content deviation in the finished product may reach ±3%, leading to unstable fertilizer efficacy. A high-precision batching system can achieve precise control through our multi-compartment graded feeding loss-in-weight weighing or frequency-controlled speed-regulating dual-belt scales, ensuring consistency across batches.

Mixing Uniformity and Stirring Time

Too short a mixing time will lead to uneven component distribution, while too long a time may cause particle breakage. Actual measurements show that in a drum mixer, an average mixing time of 90–120 seconds is ideal, at which point the mixing uniformity can reach over 95% (CV < 5%). When the mixer loading rate is controlled at 60–70%, the particle distribution is most uniform, and the breakage rate is less than 1%. Uniform mixing not only improves fertilizer efficacy consistency but also helps prevent particle stratification during storage. In China, a mixer is a mandatory requirement for BB fertilizer production lines; without one, the product will not be allowed to be sold.

BB fertilizer production line above ground feeding Vs underground feeding which is better? Difference and comparison:

In a BB fertilizer production line, the choice between underground feeding and above-ground feeding affects workflow, equipment layout, maintenance, and cost. lets talk about scenario 1 above ground which is also known as forklift feeding or hopper feeding:

1. Above-Ground Bulk blending fertilizer Feeding system

Above-ground feeding means that the raw materials are transported and delivered to the batching or mixing system from a platform, hopper, or silo that is located above the mixer.

Advantages:

- Easy installation: No need for excavation; simple layout.

- Lower construction cost: Avoids digging pits or building underground structures.

- Easy maintenance: All equipment is accessible, which simplifies inspection and cleaning.

Cons:

- Limited space usage: The plant footprint may be larger because you need elevated structures or platforms.

- Energy consumption: Materials must be lifted to a higher position, requiring more power for conveyors or belt elevators.

- Dust and spillage: Higher drop distances can increase dust generation and minor material loss.

2. Underground BB fertilizer batching system design

Underground feeding refers to raw materials being fed from pits, hoppers, or storage areas located below the ground level, often using bucket elevators to lift materials into the mixer.

Advantages:

- Compact layout: Makes better use of floor space, suitable for tight factory areas.

- Lower material drop: Reduces dust generation and material spillage.

- Gravity-assisted flow: Materials can flow naturally into hoppers or mixers, reducing energy use in some cases.

Cons:

- Higher construction cost: Requires excavation, concrete pits, or reinforced underground structures.

- Maintenance challenges: Underground conveyors, screw feeders, and pits can be harder to inspect and clean.

- Moisture and corrosion risk: Underground areas may be more prone to water accumulation or humidity, which can affect fertilizer quality.

If you want to see more explaination about the difference between above ground feeding and underground feeding please click this article link here.

What formula is suitable for BB fertilizer production line?

In United States, BB fertilizer production lines offer highly flexible formulations, designed around two core dimensions: crop-specific formulations and nutrient concentration. They are divided into high-grade and low-grade series, and can also be customized based on soil testing. Common formulations and related information are as follows:

General Formulas based on Nutrient Concentration:

Low-concentration formulations: These are mostly based on low-grade phosphate fertilizers such as superphosphate, for example, a 30% (CL) 16-5-9 formulation. It is often made by granulating superphosphate and powdered potassium chloride, then blending it with granular urea. This is suitable for basic soil improvement scenarios with low nutrient requirements. There are also ammonium chloride-superphosphate-potassium chloride formulations suitable for paddy fields; these are lower in cost and are typical low-concentration dual-chloride BB fertilizers.

Medium-high concentration formulations: These are mainly based on high-grade ammonium phosphate series, using direct blending of ammonium phosphate, urea, and potassium chloride granules. This is the mainstream formulation type. For example, 45% (CL) fertilizers have formulations like 20-12-13 and 27-10-5, while 45% (S) fertilizers have formulations like 15-15-15 and 22-9-9. 26-15-12 (53%) and 25-13-10 (48%) also fall into this category. Among high-concentration formulations, balanced formulations like 19-19-19 and 20-20-17 for 57% (CL) and differentiated formulations like 17-24-11 for 52% (CL) are also common, catering to the high-yield needs of most field crops.

Crop-Specific Formulas

Companies design customized formulas based on the nutrient requirements of different crops. For example, wheat-specific formulas like 28-10-7 (38%, CL) and 30-10-5 (40%, CL) are suitable for application during the jointing and booting stages; corn-specific formulas like 45% (CL) 28-10-7 can be used as basal fertilizer; cotton uses a 17-10-13 (CL) formula to meet its nutrient needs during the budding and boll-forming stages; vegetables like peppers use 18-12-20 (S, 50%) as basal fertilizer and 16-10-24 (S, 50%) as top dressing; peanuts commonly use a 45% (CL) 22-8-15 formula as basal fertilizer.

Special Formulas and Customized Formulas

In addition to conventional nitrogen, phosphorus, and potassium formulas, there are also formulas tailored to specific needs. For example, the production of medium-to-high concentration BB fertilizers using nitrate phosphate fertilizer and potassium chloride results in stable physicochemical properties after mixing. High-concentration formulations using urea, ammonium phosphate, and potassium chloride are widely used due to their good particle size and storage resistance. Furthermore, the company supports soil testing and customized formulations, allowing adjustments to nutrient ratios based on different soil fertility conditions. It can also flexibly add micronutrients. In addition, similar to bio-fertilizer production, organic granules and microbial agents can be granulated separately before mixing to avoid damaging functional bacteria and adapt to the individual needs of different crops and soils.

FAQ: Frequently asked question about bulk blending fertilizer production line:

If you want to start making bulk blending (BB) fertilizer in large quantities, preparing materials is something you must focus on. So what rules should you follow when choosing materials for BB fertilizer production? Usually, there are three key points to remember:

1. Choose proper chemical materials:

BB fertilizer is a type of compound fertilizer. Its raw materials are often different single chemical fertilizers or complex fertilizers. Examples include urea, gypsum, DAP, TSP, and ammonium sulphate.Most BB fertilizer plants process granular chemical materials into the fertilizer they need.

2. Uniform granule size:

using granular chemical fertilizers is a basic requirement for making BB fertilizer. Also, to make high-quality BB fertilizer, pick granules that are the same size. If the granules are not uniform, the fertilizer’s nutrients may separate during transportation. This will affect how well crops get the nutrients they need to grow.

3. Avoid chemical reactions

No chemical reaction: lastly, choose materials that do not react chemically with each other. A chemical reaction changes one set of substances into another. This change can alter the fertilizer’s nutrient balance. It may even create harmful substances.

We have designed special npk fertilizer bulk blending business plans with different capacities to meet fertilizer plant owner’ different needs: one is for small scale compound fertilizer making plants that need to produce 5-10 tons of BB fertilizer per hour, which includes a static batching machine, a large angle belt lifter, a BB fertilizer mixer and a single bucket quantitative packing scale, uses positive rotation for feeding and reverse rotation for discharging, is easy to operate, and can mix materials evenly without blocking when exporting fertilizer thanks to its special internal spiral mechanism and unique three- dimensional structure; the other is a rotary drum mixing fertilizer line suitable for large scale bulk blending fertilizer preparation, which replaces the BB fertilizer mixer with a drum type BB fertilizer blender, has an output of 30-40 tons per hour (that means 180,000-250,000 tons per year), and we suggest upgrading the single bucket packing machine to a double buckets automatic bagging scale so you can finish large scale mixing fertilizer manufacturing quickly.

The footprint of a BB fertilizer production line must include both equipment and raw material storage areas. The minimum equipment size is approximately 4 meters x 25 meters. The actual total footprint will be adjusted based on production capacity: For a small-scale production line of 5-10 t/h, the total footprint is approximately 4 meters x 30 meters, including approximately 15 square meters for the raw material batching system, 10 square meters for the BB fertilizer mixer, and 10 square meters for the single-barrel quantitative packaging scale.

For a large-scale drum-type production line of 30-40 t/h, the total footprint is approximately 4 meters x 35 meters, including equipment spacing and the operating area. The raw material batching system, which accommodates more raw materials, occupies approximately 20 square meters; the drum-type BB fertilizer mixer occupies approximately 20 square meters (3.5 x 2.8 meters); and the automatic quantitative packaging scale, including the steel frame platform, occupies approximately 20 square meters. This production line has an annual production capacity of 180,000-250,000 tons of BB fertilizer.

There are various types of NPK compound fertilizers, and BB fertilizer can actually be classified as a type of NPK compound fertilizer. If the definition of NPK compound fertilizer is "a bag of product containing nitrogen, phosphorus, and potassium", then a BB fertilizer production line can certainly produce it. The principle is to mix different finished fertilizer granules containing nitrogen, phosphorus, and potassium in a certain proportion to ultimately form NPK blended fertilizer (i.e., BB fertilizer) that meets the nutrient requirements. However, if the definition is "a single fertilizer granule containing nitrogen, phosphorus, and potassium simultaneously", then a BB fertilizer production line cannot produce this type of "true NPK compound fertilizer" because this type of product requires nutrient fusion through chemical synthesis and granulation processes, while a BB fertilizer production line can only complete physical mixing and cannot form granules with a single nutrient fusion.

Yes, a BB fertilizer production line can be used as an organic fertilizer mixing system for scenarios involving additives sensitive to liquids, high temperatures, or mechanical stress, such as biofertilizer production where preserving beneficial microorganisms’ viability is critical. Again, the bb fertilizer production line can mix organic fertilizer with other fertilizer but the system itself can not produce organic fertilizer from cow dung or peat, this has to be done using a steam drum granulation process.

For biofertilizer manufacturing, an ideal approach is to granulate organic materials like composted chicken manure, cow dung, crop residues, or bacteria carriers separately from microbial inoculants first; after granulation, the organic fertilizer pellets or composted fertilizer are mixed with the microbial inoculants or granulated microorganisms, humus using the BB fertilizer line’s batching, mixing, and packaging equipment. This separation prevents functional bacteria from being damaged by high pressure, friction, or occasional high temperatures during the granulation process, ensuring their activity is retained.

Additionally, this split-process design makes it easier to adjust microbial formulations for different crops and soils, as the BB line’s mixing system enables flexible dosing—ensuring the organic matrix and beneficial microbes complement each other perfectly. For granular organic fertilizer (or mixed granular organic-inorganic blends), the BB line can be used with little to no modifications; only minor adjustments (e.g., adapting the mixer for sticky or powdery materials) may be needed if non-granular organic components are involved.

Generally, traditional BB fertilizer production lines do not recommend using liquids or powders as raw materials because the entire process—including batching scales, lifting equipment, BB mixers, and packaging systems—is designed for free-flowing granular fertilizers. Liquids can cause granules to clump, adhere to the walls, and corrode, while powders, due to their poor flowability, are prone to bridging, clogging, and dust generation, affecting metering accuracy and mixing uniformity, ultimately leading to stratification and segregation. However, based on market trends and user demand for functional fertilizers, our BB fertilizer production line has been upgraded: while using belt scales for conventional granular materials, we have specifically configured independent liquid and powder addition hoppers, feeding screws, and metering systems, enabling precise feeding and stable delivery of powder and liquid additives. Through this system, the production line can flexibly add trace elements, functional powders, and even pesticide components to BB granular fertilizers, thereby manufacturing the currently popular medicated fertilizers (including pesticide-functional BB fertilizers), achieving higher added value and differentiated product production.

Bulk blending fertilizer is a simple fertilizer made by batching and mixing two or more types of granular fertilizers that contain N, P, and K. There is no chemical reaction in the process! the nutrients stay in their original granular form. Using a basic BB fertilizer production line, you can evenly mix straight granular fertilizers (like urea, DAP, MOP) or compound granular fertilizers to create many different NPK formulas quickly and at low cost. In the developed country like United States, becasue steam drum granulation method has a environmental impact therefore many fertilizer company install BB blending systems so they can mix fertilizers only instead of producing from powder.

The biggest difference lies in how the two fertilizers are made. NPK compound fertilizer is produced through a chemical or thermal process such as drum granulation, tower granulation, or extrusion granulation. In these processes, nitrogen, phosphorus, and potassium materials react or fuse together and are then granulated into new, uniform NPK pellets. This requires high temperature, drying, cooling, dust removal, and many machines. In contrast, BB (Bulk Blending) fertilizer is made through a simple physical mixing process. The raw materials are already-finished granular fertilizers—such as urea, DAP, MAP, MOP, SOP, and other NPK compound granules. These granules are only weighed and mixed according to formulas inside a mechanical BB mixer or rotary drum blender. There is no chemical reaction, no granulation, no drying, so the equipment cost and energy consumption are much lower.

Because compound fertilizers are chemically or thermally processed, each granule contains all three nutrients (N, P, K) in a fixed proportion—meaning every particle has the same nutrient ratio. This provides stable quality and is good for uniform nutrient distribution in the field. BB fertilizer, however, is a blend of different single-nutrient or multi-nutrient granules. Each type of granule still keeps its original composition, so N, P, and K remain in separate particles. As a result, BB fertilizer can offer more flexible formulas, and you can adjust ratios anytime to match soil conditions. But the product depends heavily on the strength, dryness, and uniform size of the raw granules; otherwise, it may segregate or absorb moisture during storage.

Becasue the rotary drum mixer is the ideal choice for a BB fertilizer production line because it offers a robust and durable structure that can handle large volumes of granular fertilizers without deformation or wear, ensuring long-term stable operation. Its rotating cylindrical design allows materials to tumble and mix thoroughly, producing uniform nutrient distribution even at high capacities of 30–40 t/h. Additionally, the rotary drum can be equipped with a coating function, which lets you add anti-caking agents, micro-nutrients, or liquid additives directly during mixing. This dual function not only improves the storage performance and flowability of BB fertilizer but also enables the production of value-added functional fertilizers, making it highly suitable for modern large-scale BB fertilizer plants.