Sulfate-resistant cement (SRC) is a hydraulic binder specifically designed to withstand sulfate attack. It holds irreplaceable value in applications such as marine engineering, underground infrastructure, and saline soils. By strictly controlling the clinker mineral composition (especially the C3A content) and optimizing the gypsum dosage, SRC significantly improves concrete durability and extends its service life, making it a preferred material for construction projects in harsh sulfate environments. Sulfate-resistant cement (SRC) is a hydraulic binder with sulfate ion resistance. It is made by finely grinding Portland cement clinker, an appropriate amount of gypsum, and blast furnace slag. Compared to other Portland cements, SRC cement exhibits strong sulfate resistance, frost resistance, and a low heat of hydration. Sulfate-resistant cement has low tricalcium aluminate and tetracalcium aluminoferrite content and a high tricalcium silicate content. This structure reduces sulfate formation, thereby improving the sulfate resistance of the concrete aggregate and enhancing its durability in most corrosive environments. It is suitable for seaports, water conservancy projects, and underground projects susceptible to sulfate attack, freeze-thaw, and alternating wet and dry conditions. This article systematically analyzes its mechanism of action, core components, production process, international standards, and typical application scenarios .

What is sulfate attack

Sulfate attack is one of the main forms of chemical attack that can cause the durability of concrete structures to deteriorate or even fail. Its sources of attack are widely found in:

- Soil and groundwater: saline soil containing sulfate (such as inland saline-alkali land and coastal areas), groundwater in mining areas, and sewage leachate.

- Seawater and marine environment: Seawater itself is rich in sulfates (mainly magnesium sulfate and sodium sulfate), and erosion is particularly serious in splash zones and tidal zones.

- Industrial environment: wastewater, waste residue and air pollution discharged by chemical plants, metallurgical plants and fertilizer plants.

- Some aggregates: Some natural aggregates or industrial waste aggregates may contain soluble sulfates.

The erosion mechanism is complex and destructive

1.Sulfate ion penetration and reaction: Sulfate ions (SO₄²⁻) in the environment migrate into the interior through concrete pores and microcracks.

2.Reaction with cement hydration products:

- Reacts with calcium hydroxide to produce gypsum (CaSO₄·2H₂O), which expands in volume by about 1.24 times.

- Reaction with calcium aluminate hydrate (key step): In particular, it reacts with monosulfide calcium sulfoaluminate hydrate to form high-sulfide calcium sulfoaluminate hydrate, namely ettringite (3CaO·Al₂O₃·3CaSO₄·32H₂O). Ettringite contains a large amount of crystal water, and its volume expands by more than 2.5 times.

3.Reaction with calcium silicate hydrate (magnesium salt corrosion): When the corrosive medium is magnesium sulfate, it will also react with calcium silicate hydrate (CSH) to generate non-gelling magnesium silicate hydrate (MSH) and gypsum, causing CSH to decompose and lose strength and adhesion.

4.Destructive Expansion and Cracking: Expansive products such as gypsum and ettringite generated by the above reactions crystallize and grow within the concrete's pores and interfaces, generating enormous crystallization pressure. When this pressure exceeds the concrete's inherent tensile strength, it causes cracking, spalling, and collapse, leading to a significant loss of strength and structural integrity.

What is sulfate-resistant cement?

Sulfate-resistant cement (SRC cement) is a hydraulic binder that resists sulfate ion attack. It is made by finely grinding Portland cement clinker, an appropriate amount of gypsum, and blast furnace slag. Compared to other Portland cements, SRC cement exhibits superior sulfate resistance, frost resistance, and low heat of hydration.

Sulfate-resistant cement has low tricalcium aluminate and tetracalcium aluminoferrate contents and a high tricalcium silicate content . The tricalcium aluminate (C3A) content is less than 5%, and the (2C3A + C4AF) content is less than 25%, thereby reducing sulfate formation. This structure reduces sulfate formation, thereby improving the concrete's resistance to sulfate attack and enhancing its durability in most corrosive environments. It is suitable for harbor, hydraulic, and underground projects susceptible to sulfate attack, freeze-thaw cycles, and wet-dry cycles.

Core anti-erosion principle

- Limiting the aluminum source (C3A content): The formation of ettringite requires tricalcium aluminate (C3A) or its hydration products as an aluminum source. A key SRPC measure is to strictly control the C3A content in the clinker to a low level (typically ≤5%, or even lower depending on the standard requirements). The lower the C3A content, the less raw material is available to form expansive ettringite, and the cement paste's resistance to sulfate attack is enhanced.

- Controlling the Iron-to-Aluminum Ratio (C4AF Effect): Tetracalcium aluminoferrate (C4AF) can also form aluminum-containing hydration products (such as monosulfide-type calcium sulfoaluminate (ferrite) hydrate) during hydration. However, its tendency to react with sulfate to form expansive ettringite is much lower than that of C3A. The presence of C4AF helps consume some sulfate, generating less expansive calcium sulfoferrate (aluminate) hydrate. Therefore, while limiting C3A, SRPC typically maintains or appropriately increases the C4AF content.

- Optimizing gypsum dosage: An appropriate amount of gypsum (CaSO₄·2H₂O) is used to adjust the setting time of cement. In SRPC, the gypsum dosage must be precisely controlled. Too little gypsum will not form sufficient ettringite early enough to provide early strength (the small amount of ettringite formed early exists in the paste with ample space, minimizing expansion damage). Too much gypsum may increase the risk of later reaction with residual C3A or C4AF to form secondary ettringite, or directly react in a sulfate environment to form expansive gypsum crystals.

- Reduce the content of calcium aluminate hydrate: Low C3A directly leads to a reduction in the content of tricalcium aluminate hydrate (C3AH₆) and monosulfide calcium sulfoaluminate hydrate (AFm) that are easily reactive with sulfates after cement hydration, fundamentally reducing the sulfate attack reaction .

- Improve density (indirect effect): The hydration heat of low C3A cement is relatively low, and the gel ratio in the hydration product is relatively high, which helps to form a denser microstructure, reduce harmful pores, thereby reducing the rate of sulfate ion penetration and diffusion, and delaying the erosion process.

Composition of sulfate-resistant cement

1. Lower tricalcium aluminate (C₃A) content:

- The C₃A content in ordinary cement is about 10-12%, while the C₃A content in sulfate-resistant cement is only 4-5%.

- Since C₃A reacts with sulfates, reducing its content minimizes the risk of sulfate attack.

2. Increase silicate content:

Contains higher amounts of dicalcium silicate (C₂S) and tricalcium silicate (C₃S), which improve strength and durability.

3.Specific composition ranges (typical values, vary by standard):

- C3S (tricalcium silicate): 45-60% (provides primary strength)

- C2S (dicalcium silicate): 15-30% (provides later strength)

- C3A (tricalcium aluminate): ≤ 3% - 5% (key limit)

- C4AF (Tetracalcium Aluminoferrate): 12-18% (relatively high, helps consume sulfate)

- f-CaO (free calcium oxide): ≤ 1.0% (affects stability)

- MgO (magnesium oxide): ≤ 5.0% (affects stability)

- SO₃ (sulfur trioxide): ≤ 2.3% - 3.0% (control gypsum content)

Sulfate-resistant cement properties

Sulfate-resistant Portland cement is further divided into medium-sulfate-resistant cement and high-sulfate-resistant cement, with strength grades of 32.5, 42.5, and 52.5 respectively.

Medium sulfate-resistant cement (P-MSR) can resist the attack of moderate sulfate concentrations, with a tricalcium silicate content not exceeding 55.0% and a tricalcium aluminate content not exceeding 5.0%. High sulfate-resistant cement (P-HSR) can resist the attack of high sulfate concentrations, with a tricalcium silicate content less than 50% and a tricalcium aluminate content less than 3%.

| Compressive strength | Loss on ignition | Free lime content | Magnesium oxide content | Insoluble matter content | Specific surface area | Initial setting time | Final setting time |

| 10Mpa after 3 days, 16Mpa after 7 days, 33Mpa after 28 days | ≤3% | ≤1.0% | ≤5% | ≤1.5% | ≥280 m2/kg | ≥45 minutes | ≤10 hours |

Characteristics of sulfate-resistant cement

- It has excellent processability and pumpability.

- Sulfate-resistant cement is characterized by its low water demand.

- Sulfate-resistant cement clinker contains less C3A and C3S and has lower hydration heat.

- Concrete prepared with sulfate-resistant cement has higher compressive strength and economical mix design.

- Sulfate-resistant cement enables concrete to maintain high performance and structural integrity in harsh environments, thereby extending its service life.

Uses of sulfate-resistant cement

Uses of sulfate-resistant cement

Concrete made with sulfate-resistant cement has a strong resistance to pure sulfate with sulfate ion concentrations below 2500 mg/L. It is very suitable for concrete projects in contact with acidic soils, groundwater, seawater, etc. SRC cement is recommended for the following applications:

- Underground structures; tunnels, culverts, bridge foundation engineering;

- seawall, dam, and reservoir construction; water and sewage pipelines and treatment plants;

- Food processing, chemical and fertilizer industries; mines and other acidic soil environments;

- ordinary concrete work using ordinary Portland cement;

Uses and advantages of using SRC

- Wastewater treatment facilities.

- Chimneys and cooling structures.

- Coastal defense structures such as seawalls, breakwaters, and tetrapods.

- Construction works located on the coastline.

- Chemical plants, reservoirs, sump and drainage facilities.

- Suitable for underground structures where the soil and water contain sulfates.

- Basic elements.

- Piling activities.

- Construction activities associated with soil or groundwater containing sulfate levels exceeding 0.2% or 0.3% g/l, respectively.

- Concrete areas subject to alternating wet and dry conditions, such as bridge supports, tidal zone concrete, aprons, and similar surfaces.

Key Advantages of SRC

- Extended durability: The use of sulfate-resistant cement can better prevent the formation of sulfoaluminates, thereby improving the durability of concrete to sulfates.

- Reduced maintenance costs: Excellent compressive strength achieved through economical concrete mix design. Reduced need for repair and restoration work.

- Enhanced Structural Integrity: Low heat of hydration helps prevent shrinkage cracks. Prevents breakage and deterioration due to chemical reactions.

- Suitable for harsh conditions: Improves durability and service life of structures in harsh environments. Able to withstand harsh environmental conditions.

Disadvantages of sulfate-resistant cement:

- Sulfate-resistant cement is not suitable for use in areas where there is a risk of chloride exposure as this can cause corrosion of the reinforcement.

- In the presence of both chlorides and sulfates, experts recommend using ordinary Portland cement with a C3A content between 5 and 8.

- They do not recommend it for marine construction purposes.

- The team should carefully follow the curing procedure for at least 8 to 10 days.

Three types of sulfate-resistant cement

Sulfate-resistant Portland cement

| type | C3A content of clinker |

| CEMI-SR 0 | 0% |

| CEM I-SR 3 | ≤ 3% |

| CEM I-SR 5 | ≤ 5% |

Sulfate-resistant blast furnace slag cement

| type | C3A content of clinker |

| CEM III/B-SR | No requirements |

| CEM III/C-SR | No requirements |

Sulfate-resistant pozzolanic cement

| type | C3A content of clinker |

| CEM IV/A-SR | ≤ 9% |

| CEM IV/B-SR | ≤ 9% |

Sulfate-resistant cement manufacturing process

The raw materials required to produce sulfate-resistant cement are basically the same as those of ordinary Portland cement, mainly including calcareous materials, clayey materials and iron-containing correction materials, but its mineral composition is very different from that of ordinary Portland cement.

1. The hydration product of C3A is the most susceptible component in cement. Since C4AF has stronger corrosion resistance than C3A, C4AF is used to partially replace C3A in sulfate-resistant cement to improve the corrosion resistance of cement.

2. CH generated during the hydration of C3S is another factor that causes corrosion. Therefore, appropriately reducing the C3S content and correspondingly increasing the more excellent C2S is also an effective measure to improve the corrosion resistance of sulfate cement.

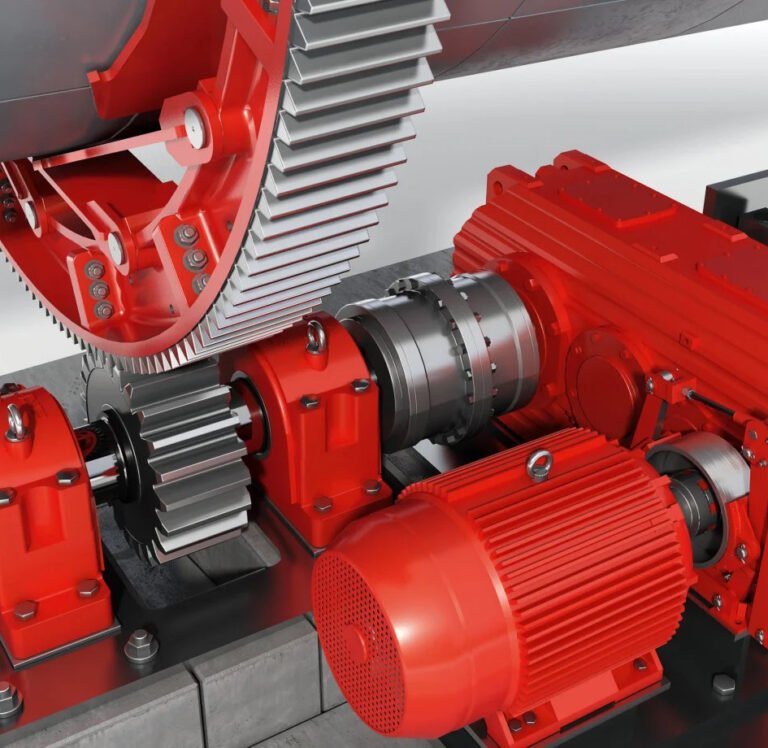

The production process of sulfate-resistant cement is basically the same as that of ordinary Portland cement and can be divided into:

Raw material preparation

Raw materials such as limestone and clay are first crushed in a cement crusher to the raw mill feed size. They are then stored in a pre-homogenization yard, mixed according to the appropriate proportions, and fed into the cement raw mill for subsequent fine grinding using vertical roller mill. The finely ground raw meal is then stored in a silo awaiting calcination.

Clinker calcination

During the calcination process, the raw cement meal first enters the preheater and calciner for preheating and partial carbonate decomposition. It is then fed into the cement kiln for the main calcination process until clinker is formed. The hot clinker is then cooled to room temperature in a post-kiln cement cooler.

Cement grinding

before being fed into a cement ball mill. There, the clinker is finely ground to the desired fineness for cement production. The ground cement is stored in cement silos and then packaged in cement packaging machines.

The detailed manufacturing steps are as follows:

- Raw material selection and proportioning: Strictly select low-aluminum clay (or use corrected raw materials such as iron powder, bauxite, etc.) and high-grade limestone, accurately calculate the proportioning plan, and ensure that the raw material meets the requirements of low aluminum and high iron.

- Raw material preparation and homogenization: Raw materials are crushed, ground, mixed and homogenized to ensure uniform and stable composition.

- Clinker Calcination: Calcination is performed in a rotary kiln or shaft kiln at approximately 1450°C. Controlling the appropriate calcination temperature, atmosphere, and time is crucial to ensure that the C3A mineral content is within the target range. Excessively high temperatures or a reducing atmosphere may increase the C3A content.

- Clinker cooling: Use rapid cooling technology (such as grate cooler) to prevent C3S decomposition and C2S crystal transformation, and fix the clinker mineral composition.

- Cement Grinding: Clinker is ground together with an appropriate amount of natural gypsum (or industrial by-product gypsum) to the required fineness. Strict control of the gypsum content is the key to this process.

- Quality Inspection and Control: Strict quality control throughout the entire process, especially the petrographic analysis, chemical analysis and mineral composition calculation (such as the Bauer formula) of the clinker, as well as the physical properties and chemical analysis of the cement (especially C3A content and SO₃ content).

International standards and technical specifications

Major global standard systems have clear provisions for SRPC:

Chinese Standard (GB)

1. GB 748-2005 "Sulfate-Resistant Portland Cement": This is a specialized Chinese standard. It is divided into two grades based on sulfate resistance (corrosion resistance coefficient): medium sulfate-resistant Portland cement (MSRC) and high sulfate-resistant Portland cement (HSRC).

- MSRC: Requires 14-day antenna expansion rate ≤ 0.060%, C3A ≤ 5.0% (clinker), SO₃ ≤ 2.5%.

- HSRC: Requires 14-day antenna expansion rate ≤ 0.040%, C3A ≤ 3.0% (clinker), SO₃ ≤ 2.0%.

2. GB 200-2003 "Medium-heat Portland Cement, Low-heat Portland Cement, and Low-heat Slag Portland Cement": Medium-heat cement (MH) also requires C3A ≤ 6%, so it also has a certain degree of sulfate resistance and is often used in projects such as dams that require low heat and a certain degree of sulfate resistance.

3. GB 175-2007/XG1-2009 "General Portland Cement": Ordinary Portland cement (PO) does not have specific requirements for sulfate resistance. However, the Portland cements (PI and P.II) specified in the standard may have some sulfate resistance if their C3A content is low (although this is not guaranteed).

European Standards (EN)

EN 197-1: 2011 Cement - Part 1: Composition, specifications and conformity assessment criteria for general purpose cements:

- CEM I-SR (Portland sulphate-resisting cement): C3A ≤ 3.0% in clinker.

- CEM III/B-SR, CEM III/C-SR (Blastfurnace cement sulphate-resisting): Sulphate-resistant slag cement with a high slag content, offering excellent resistance to chemical attack (including sulphates).

American Standard (ASTM)

ASTM C150 / C150M - 22 Standard Specification for Portland Cement:

- Type II: Moderate heat of hydration and moderate sulfate resistance. Requires C3A ≤ 8.0% (when C4AF + 2*C3A ≤ 25%) or C3A ≤ 5.0% (when C4AF + 2*C3A > 25%).

- Type V: High Sulfate Resistance. Requires C3A ≤ 5.0% and C4AF + 2*C3A ≤ 25%.

British Standard (BS):

BS 4027: 1996 Specification for Sulfate-Resistant Portland Cement: Requires C3A ≤ 3.5%, SO₃ ≤ 2.5%.

Indian Standard (IS):

IS 12330: 1988 Specification for Sulfate-Resistant Portland Cement: Requires C3A ≤ 5.0%, SO₃ ≤ 2.5%, and specifies compressive strength requirements and anti-expansion requirements.

Comparison of key indicators

| index | China (GB 748) HSRC | China (GB 748) MSRC | European (EN) CEM I-SR | American (ASTM) Type V | American (ASTM) Type II | United Kingdom (BS 4027) |

| Clinker C3A ≤ | 3.0% | 5.0% | 3.0% | 5.0% | 5.0% or 8.0% | 3.5% |

| SO₃ ≤ | 2.0% | 2.5% | 3.5% (total cement) | 2.3% (when C3A < 8%) | Same as left / 3.0% (when C3A>8%) | 2.5% |

| MgO ≤ | 5.0% | 5.0% | 5.0% | 6.0% | 6.0% | 5.0% |

| Corrosion resistance grade | High resistance | Zhongkang | High resistance | High resistance | Zhongkang | High resistance |

Key Differences Between SRC and Ordinary Portland Cement (OPC)

| characteristic | Sulfate Resistant Cement (SRC) | Ordinary Portland Cement (OPC) | Advantages/Purpose of SRC |

| Design Goals | Resistant to sulfate chemical attack | General structural strength | Targeted solution to sulfate corrosion problem |

| Clinker C3A content | Strictly limited (usually ≤3-5%) | Relatively high (usually 5-10% or higher) | Reduce the source of expansive ettringite |

| Clinker C4AF content | Relatively high or maintain | No special requirements | Consumes sulfate to produce low-swelling products |

| Gypsum content (SO₃) | Strictly control the upper limit | Relatively wide control range | Prevent excess plaster from causing expansion or participating in erosion reactions |

| Sulfate resistance | Excellent (core performance) | Poor to moderate | Significantly extends the life of structures in sulfate environments |

| Heat of hydration | Medium (usually lower than OPC) | Higher (especially early) | Beneficial for temperature control and crack prevention of large volume concrete |

| Early strength (3,7 days) | Maybe slightly lower | Usually higher | - |

| Late strength (28 days+) | Good, usually catches up or exceeds | good | - |

| Typical application environment | Seawater, saline-alkali land, high sulfate soil/groundwater | General atmospheric environment, environment without significant sulfate threat | Designed for harsh environments |

| cost | Usually higher | Relatively low | The necessary cost of durability |

Conclusion

Sulfate-resistant cement is an essential construction material in environments where sulfate attack can weaken ordinary cement. By reducing the tricalcium aluminate (C₃A) content, it ensures the durability of marine structures, sewage systems, and underground projects. It helps prevent cracking, expansion, and structural failure, making it an ideal choice for long-lasting concrete structures. Strict control of the clinker mineral composition and optimized gypsum dosage minimize the cement paste's ability to react with invading sulfates to form damaging expansion products (primarily ettringite). This chemical stability enables SRC to exhibit excellent durability in harsh environments such as the ocean, saline soils, sulfate-laden underground soils, and industrial pollution . Sulfate-resistant cement requires synergy with low water-binder ratio design, high-quality raw materials, careful construction, and rigorous maintenance to reduce concrete permeability, slow the intrusion of aggressive media, and ultimately achieve the goal of a long-lasting structure.