Material agglomeration, a process in which tiny particles are aggregated to form larger agglomerates through physical or chemical methods, has widespread application in industrial production. This process not only improves the physical properties of materials but also optimizes production processes and enhances the performance of the final product. In fertilizer manufacturing, agglomeration technology plays an irreplaceable role, serving as a crucial bridge between raw materials and high-efficiency fertilizer products. From a global market perspective, demand for agglomeration technology and its equipment continues to grow. According to market research, the global agglomeration machine market is expected to reach 14.39 billion yuan in sales by 2031, with a compound annual growth rate of 6.0% (2025-2031). This data fully demonstrates the importance of agglomeration technology across various industries and its development potential. In the fertilizer industry in particular, agglomeration granulation technology has become a key means of improving fertilizer utilization and reducing environmental pollution. This article will systematically explain the basic concepts of material agglomeration, explore key applications of agglomeration technology in fertilizer manufacturing, and analyze key points in agglomeration process and equipment selection, providing a comprehensive technical reference for relevant industry practitioners.

Concept and types of material agglomeration

Scientific definition of reunion

Material agglomeration, often referred to as "granulation" in the industrial field, refers to the process of physically, chemically, or mechanically agglomerating fine particles to form larger, more stable aggregates. Scientifically speaking, the original particles within an agglomerate are called "primary particles," the pores between them are called "primary pores," and the agglomerates themselves are called "secondary particles." This process involves more than simply agglomerating particles; it involves the reorganization and balancing of the forces between particles. From an engineering perspective, agglomeration is defined as "any process that aggregates small particles into larger entities." This definition encompasses a wide range of processes, from simple powder compaction to complex chemical reaction granulation. For fertilizer production, agglomeration aims to transform powdered raw materials into granules with the ideal structure and shape for subsequent storage, transportation, and application.

Classification of aggregates

Agglomerates can generally be divided into two basic types based on the nature and strength of the forces between particles:

- Hard agglomerates: These agglomerates are formed by strong bonds (such as chemical bonds) or by partial sintering, resulting in high mechanical strength. During the powder compaction process, even after the agglomerates have reached a dense packing, primary pores within the agglomerates still exist. The bulk density of the powder body only increases when the pressure is high enough to break the agglomerates. Hard agglomerates help maintain particle integrity in fertilizer production and prevent excessive dust generation during storage and transportation.

- Soft agglomerates: These agglomerates are formed by weak forces such as intermolecular forces and hydrogen bonds, resulting in relatively low strength. Soft agglomerates can disperse under certain external forces, a property that is crucial in certain applications. For example, for fertilizer products that require rapid dissolution, an appropriate soft agglomerate structure ensures both particle stability and rapid dispersion after application.

| Characteristic | Hard Agglomeration | Soft Agglomeration |

| Bonding Type | Chemical bonds, partial sintering | Intermolecular forces, hydrogen bonds |

| Mechanical Strength | High | Low |

| Dispersion Difficulty | Difficult | Easy |

| Primary Porosity | Remains intact | May collapse |

| Typical Applications | Compound fertilizers, controlled-release fertilizers | Instant fertilizers, soil conditioners |

Why aggregate materials?

Disadvantages of fine powder materials and advantages of agglomeration

In the fertilizer industry, many raw materials and finished products, such as ammonium nitrate, urea, potassium salts, and mixed NPK compound fertilizer raw materials, initially exist in the form of fine powders. Although this physical form has a large specific surface area, it brings a series of severe challenges in the actual production, storage, transportation, and use. These challenges directly restrict production efficiency and product effectiveness:

- Dust: Fine powders are highly susceptible to dust generation during the feeding, mixing, conveying, and packaging processes. This not only leads to direct product losses (up to 5% of total yield), but also pollutes the work environment and poses a threat to the respiratory health of operators. During application, dust dispersion can cause environmental pollution and nutrient loss.

- Poor flow characteristics: Powders are cohesive and prone to "arching" and "ratholes" in silos, hoppers, and fertilizer spreaders, leading to flow interruptions or instability. This makes automated, precise metering and application extremely difficult, failing to meet the requirements of modern precision agriculture.

- Unavoidable component segregation: In the production of compound fertilizers (NPK), raw powders containing different nutrients (such as nitrogen, phosphorus, and potassium) naturally vary in particle size, density, and shape. During transportation, handling, or vibration, these components can separate due to their varying motion characteristics. The direct consequence is that fertilizer from different parts of a bag of fertilizer, or from different areas of a fertilizer spreader, can contain vastly different nutrient ratios, leading to uneven crop growth and severely impacting fertilization effectiveness.

- Low Bulk Density: Powdered materials are fluffy and have high porosity, resulting in a low bulk density. This means that storing and transporting the same weight of product requires more space, significantly reducing storage and transportation efficiency and increasing logistics costs.

- Agglomeration Tendency: Certain hygroscopic fertilizer powders (such as ammonium nitrate and urea) tend to absorb moisture from the air during storage, forming crystal bridges at the contact points of the particles, ultimately agglomerating into a hard solid. Application requires an additional crushing process, which is time-consuming and labor-intensive, and may generate increased dust.

- Difficulties and Waste During Application: Powdered fertilizers are difficult to spread evenly by machine. Manual spreading is labor-intensive and uneven, while mechanical spreading is susceptible to wind, resulting in drift and waste, and potentially harming the surrounding environment and non-target crops.

The agglomeration process was developed to address these shortcomings. It is not a simple "granulation", but a precise size enlargement process that optimizes the handling performance and functional characteristics of the material by changing its physical form.

Process performance improvement

In industrial production, material agglomeration is a key tool for optimizing process flows. For example, in the fertilizer industry, if raw powders are not granulated, dust is easily generated, leading to a deteriorating production environment, increased product losses, and reduced mixing uniformity. Directed agglomeration, which produces uniformly sized granules, significantly improves the powder's flowability and filling properties, ensuring smooth production.

For automated production lines, agglomeration is essential for ensuring continuous and stable operation. Powdered materials often suffer from poor flowability and bridging, leading to uneven feeding, impacting product quality and production efficiency. Granulation creates uniform granules with excellent flow characteristics, meeting the stringent requirements for accurate and consistent feeding in automated production. This is one of the main reasons for the rapid development of granulation technology in the 1930s: "High-volume automated production requires excellent feed flow."

Agglomeration also plays a crucial role in the storage and transportation of fertilizer products. Granulation increases the volume and mass of powders, significantly improving storage efficiency and reducing packaging and transportation costs. At the same time, the compressive strength of granular fertilizer is usually higher than that of powder, which can withstand storage pressure and transportation vibration, and reduce dust problems caused by granule breakage.

Product function improvement

Material agglomeration improves product functionality in many aspects, especially in the fertilizer field:

- Controlling Dissolution Rate: Agglomeration can be used to adjust the dissolution characteristics of a product to meet different application requirements. For example, controlling the dissolution rate of a product is one of the key objectives of granulation. In the production of slow-release fertilizers, specialized agglomeration and coating techniques can precisely control the nutrient release rate to align with crop needs, thereby improving fertilizer utilization efficiency.

- Improving Physical Properties: The agglomeration process can adjust the porosity and specific surface area of the finished product, thereby affecting its application performance. For fertilizers, an appropriate pore structure helps regulate the water-to-air ratio within the granules, influencing microbial activity and nutrient conversion. In soil, this structure also improves air permeability and water retention, creating a more favorable growth environment for crop roots.

- Enhancing Functionality: Agglomeration technology enables the production of multifunctional compound fertilizers. By organically combining different nutrients and additives during the granulation process, specialized fertilizers can be prepared to meet specific agricultural needs. Research has shown that functional agglomerated fertilizers can promote the formation of more water-stable large aggregates in the soil, improve the aggregate structure, loosen the soil, and prevent soil compaction.

Key applications of agglomeration technology in fertilizer manufacturing

Fertilizer agglomeration process

Fertilizer agglomeration primarily utilizes two main process methods: dry agglomeration and wet agglomeration. Both technologies occupy a significant position in the agglomeration machine market.

Dry agglomeration relies on mechanical pressure to compact powdered materials into dense granules. This process does not require the addition of liquid binders, instead utilizing the plastic deformation of the granules under high pressure and intermolecular forces to achieve bonding. Dry agglomeration offers advantages in process simplicity, low energy consumption, and high product density and strength. For certain fertilizer formulations prone to chemical reactions in the presence of water, dry agglomeration is the preferred granulation process.

Wet agglomeration, on the other hand, uses a liquid binder to form liquid bridges between particles, which are then consolidated through drying to form a stable granular structure. Wet agglomeration typically involves mixing, granulation, drying, screening, and cooling. This method offers advantages in wide applicability, ease of forming, uniform granule shape, and good flowability. Wet agglomeration is more widely used in compound fertilizer production because it can uniformly combine raw materials with different physical and chemical properties.

Binder selection in fertilizer agglomeration

In the fertilizer agglomeration process, the selection of binder is crucial, as it directly affects the strength, solubility and chemical stability of the particles. Depending on the fertilizer formula and production process, it is necessary to select the appropriate binder type:

- Inorganic binders: These include calcium carbonate and desulfurized gypsum. These binders typically bind fertilizer components by chemically reacting with them. Research has shown that using calcium carbonate as a carrier and sulfuric acid as a binder, under specific process parameters (calcium carbonate dosage of 2-5%, sulfuric acid dosage of 2-4% of the raw material weight, and a granulation temperature of 60-80°C), can achieve excellent granulation of nitrogen-phosphorus-potassium compound fertilizers. Similarly, in ammonium sulfate granulation, calcium sulfate and PVA serve as the optimal solid and liquid binders, respectively.

- Organic binders: These include humic acid, sodium polyglutamate, seaweed polysaccharides, starch, molasses, lignin sulfonates, guar gum, and cellulose derivatives. These materials not only act as binders but also improve soil structure and provide additional nutrients. Patented research has shown that a special formulation containing sodium polyglutamate, seaweed polysaccharides, and lysozyme powder can promote the formation of more water-stable macroaggregates in the soil, improving the aggregate structure. Another type of biomass organic fertilizer is made from raw materials such as flue-cured tobacco leaf powder, bentonite, and polyaspartic acid. It can quickly increase the content of water-stable macroaggregates in soil and enhance soil porosity.

- Composite binders: In practical applications, multiple binders are used in combination to balance the strength and agronomic properties of the granules. For example, in ammonium chloride granulation, calcium carbonate can be used as a solid binder and sulfuric acid as a liquid binder. The chemical reaction between the materials produces calcium sulfate (adsorbent) and urea sulfate (adhesive), which coat the raw materials to form granules.

| Binder Type | Representative Substances | Applicable Fertilizers | Advantages | Limitations |

| Inorganic Binder | Calcium carbonate, calcium sulfate | NPK compound fertilizer, potassium chloride, ammonium sulfate | Low cost, enhances particle strength | May alter the chemical properties of the fertilizer |

| Organic Binder | Humic acid, sodium polyglutamate | Organic fertilizer, functional compound fertilizer | Improves soil, provides additional functions | Higher cost, larger usage amount |

| Polymer Binder | PVA, polyaspartic acid | High-end compound fertilizer, slow-release fertilizer | Strong binding force, small usage amount | Expensive |

| Mineral Binder | Bentonite, zeolite | Various fertilizers | Improves soil, good adsorption performance | May reduce nutrient content |

Technical advantages of fertilizer agglomeration

After agglomeration and granulation, fertilizers exhibit many technical advantages:

- Improving fertilizer utilization efficiency is one of the most important advantages of agglomeration technology. Granulating powdered fertilizers slows down their dissolution and release rates, improving their utilization. This slow-release property allows for more complete nutrient absorption by crops, reducing losses due to leaching and volatilization. Research shows that granular fertilizers can increase nutrient utilization by 10-30% compared to powdered fertilizers.

- Improving soil structure is a particular advantage of functional agglomerated fertilizers. Some specially designed agglomerated fertilizers directly affect the physical structure of the soil. For example, fertilizers designed to increase water-stable macroaggregates in soil promote the formation of soil aggregate structure through specific ingredients. Water-stable macroaggregates are unique components that bind soil particles together, including calcium, magnesium, organic matter, and mycelium. They significantly improve soil structure, forming a complex pore network that creates optimal conditions for plant growth.

- Easy mechanized application is a fundamental requirement for fertilizers in modern agriculture. Granular fertilizers, with their excellent flowability and uniform particle size, are well-suited for mechanized fertilization. Compared with powdered fertilizer, granular fertilizer has less drift loss and higher distribution uniformity during mechanical fertilization, which can meet the needs of precision agriculture.

Agglomeration process and equipment selection

Comparison of dry and wet agglomeration processes

Before choosing fertilizer granulation equipment, you first need to understand the core differences between dry and wet agglomeration processes:

- Dry agglomeration primarily includes roller granulation and mechanical compression granulation. Its characteristics include a simple process flow, the absence of a drying step, and relatively low energy consumption. Dry agglomeration uses mechanical pressure to plastically deform the powdered material, generating strong intermolecular forces between particles and forming a stable agglomerated structure. This process is particularly suitable for heat-sensitive materials and fertilizer formulations that are prone to chemical reactions in the presence of water.

- Wet agglomeration encompasses technologies such as spray granulation, fluidized bed granulation, and mixing granulation. The key lies in the addition of a liquid binder and the subsequent drying process. Wet agglomeration can process a wider range of raw materials and is particularly suitable for compound fertilizer production, which requires uniform mixing of multiple raw materials with different physical properties. By adjusting the type and amount of binder and process parameters, the particle size distribution, density, and strength of the granules can be precisely controlled.

| Process Parameter | Dry Agglomeration | Wet Agglomeration |

| Energy Consumption | Lower | Higher (requires drying process) |

| Equipment Investment | Relatively low | Higher |

| Product Density | High | Medium to high |

| Particle Shape | Irregular | More regular, good sphericity |

| Applicable Raw Materials | Limited | Wide range |

| Binder Requirement | Usually not required | Must be added |

| Environmental Impact | Dust control important | Waste gas emission management |

Main process routes and core equipment for fertilizer agglomeration

The fertilizer industry primarily utilizes two agglomeration processes, each based on different principles: compaction granulation and wet granulation. The choice of process depends on the raw material characteristics, target product specifications, and overall economic benefits.

Compaction granulation

Process principles and procedures

Compaction or extrusion granulation is a purely dry process. Its core is the use of two high-pressure, counter-rotating rollers to compress dry powders into dense flakes or briquettes. The process works as follows: The dry powdered raw material is mixed with recycled fine powder (return material) and continuously and evenly fed into the nip between the two rollers. Under extremely high linear pressure (up to 10 tons/inch), the material is forcibly compressed, causing the particles to plastically deform and mesh tightly, forming flakes. These flakes then enter a crusher (typically a chain or hammer crusher) to be broken into smaller pieces. The crushed material is then classified by a series of screens (vibrating screens or vibrating screens). Oversized particles are returned to the crusher for further crushing; particles of acceptable size are discharged as product; and undersized fines are recycled back to the rollers as return material to re-enter the compaction process. This return cycle is crucial to maintaining system stability.

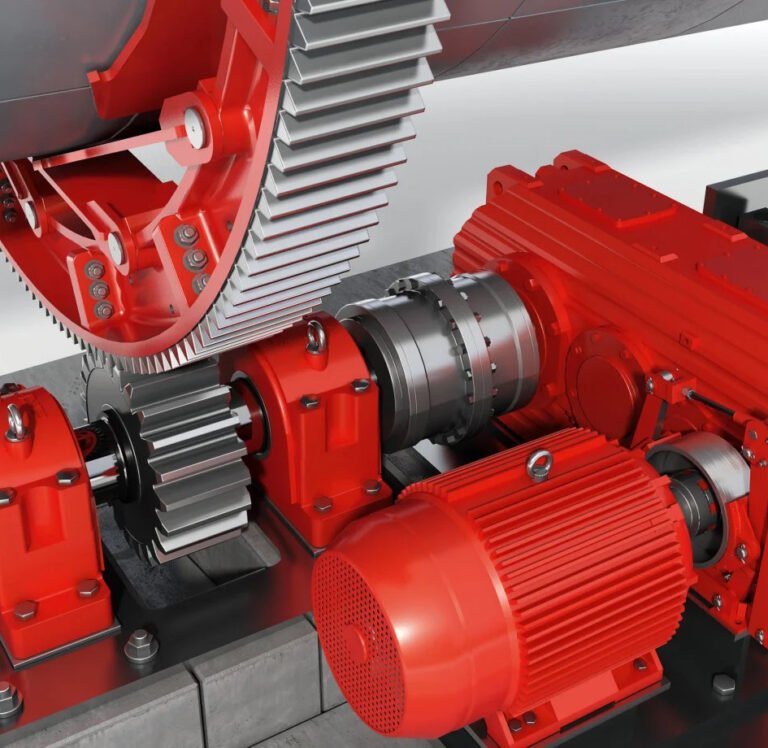

core equipment

High-pressure roller briquetting machine (the core of the system, determines the production capacity and flake density), crusher (controls the size range of the final particles), vibrating screen (for precise classification).

Process characteristics

Advantage

- Low Energy Consumption: The entire process requires no drying or cooling steps, resulting in lower energy consumption than wet processes.

- Suitable for Sensitive Materials: This process is particularly suitable for highly water-soluble or heat-sensitive fertilizers (such as potassium nitrate, potassium sulfate, urea, and ammonium nitrate), as it avoids heating and moisture introduction, preventing product degradation or agglomeration.

- High Product Density and Strength: Pellets produced under high pressure have high bulk density, excellent mechanical strength, and are not prone to pulverization.

- Simple and Flexible Process: The process flow is relatively short, with few operating parameters, easy control, and flexible and rapid product formulation changes.

Shortcoming

- Irregular particle shape: The particles are polygonal after crushing, and their appearance is not as beautiful as wet-process spherical particles.

- Fine powder recycle: The production process generates a certain amount of fine powder, requiring an efficient recycle system, which increases equipment investment and load.

- Equipment wear: Rollers and dies operate under extremely high mechanical pressure. Wear is a major operating cost and maintenance concern, requiring regular repair or replacement.

Application: Mainly used for producing high-concentration single fertilizers or physical mixed fertilizers, such as calcium ammonium nitrate, urea granules, potash fertilizer granules, etc.

Wet granulation

Process principles and procedures

This process is based on liquid bridging and rolling growth mechanisms or steam drum granulation. In a rotating device (such as a drum or disc), a liquid (water, a chemical solution such as phosphoric acid or sulfuric acid, or ammonia gas) is sprayed onto the powder material. This liquid forms bridges between the powder particles, creating initial bonding forces through capillary forces. Under the continuous rotation of the device, the moistened fine powders collide, adhere, and coat each other, growing like a snowball into spherical "green balls." The green balls emerging from the granulator are plastic but have limited strength. They are then fed into a rotary dryer, where hot air evaporates the water and replaces the liquid bridges with solid bridges (formed by crystallization of dissolved substances, hardening of the binder, or chemical reactions between the materials), giving the granules their final hardness and strength. The dried granules are typically cooled in a cooler to stabilize their properties and facilitate subsequent storage and packaging. Finally, the material is screened. Acceptable product is discharged, while fine powder and partially crushed large particles are returned to the beginning of the granulator as regrind, providing nuclei for the formation of new granules.

Core equipment

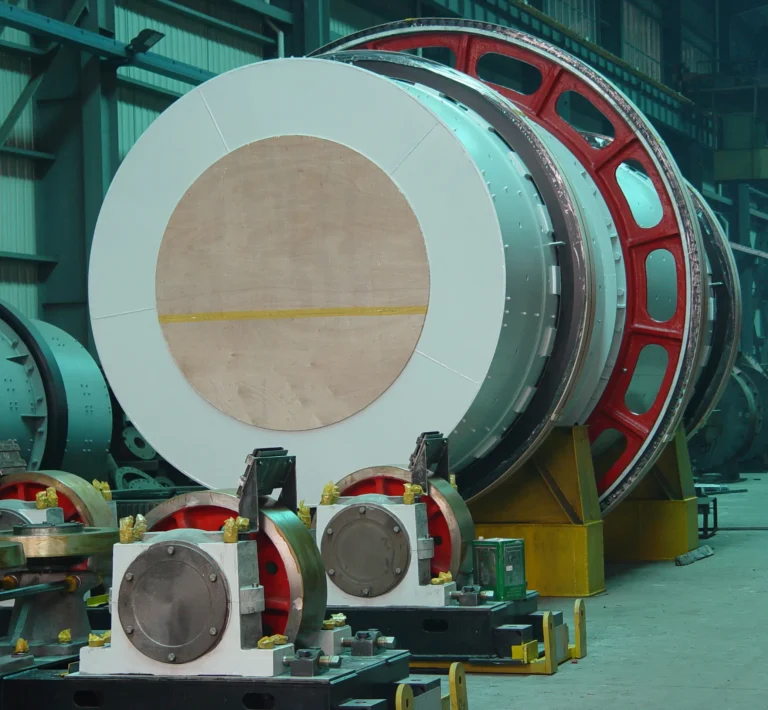

- Rotary drum granulator: A slowly rotating, slightly inclined, large-diameter drum. Inside the drum, material is lifted by a lifting plate and then tumbles down, creating a typical "snowball" growth pattern. By adjusting the drum's inclination and rotational speed, the material's residence time and tumbling intensity can be controlled. It is a core piece of equipment for large-scale NPK fertilizer production, capable of handling large quantities of return material.

- Disc granulator: A tilted, rotating disc. Material is lifted to a certain height within the disc by friction, then tumbles down the inclined surface under the influence of gravity. This motion pattern provides automatic grading, with fine particles remaining at the bottom of the disc and continuing to grow, while particles that have reached a certain size overflow from the sides. This produces highly uniform, spherical granules. By adjusting the disc's inclination, rotational speed, and retaining ring height, the final granule size can be precisely controlled.

Process characteristics

Advantage

- Excellent granule quality: It produces hard, spherical granules with a smooth surface and uniform size, enjoying high market acceptance.

- Liquid raw material utilization: The process allows for the direct use of liquid raw materials (such as wet-process phosphoric acid and aqueous ammonia), which is highly economical in NPK formulations, eliminating the need for drying these liquids into solids.

- Standard method for compound fertilizer production: This is the most traditional and widely used method for producing NPK compound fertilizers with uniform nutrient content, with mature technology.

Shortcoming

- High energy consumption: Subsequent drying and cooling steps are required, resulting in significantly higher energy consumption (heat and electricity) than compaction granulation.

- Environmental challenges: The drying process generates exhaust gases containing dust, ammonia, and potentially condensable gases, requiring the installation of expensive exhaust gas treatment systems (such as scrubbers, condensers, and bag filters).

- Complex process control: Precise control of multiple parameters, including liquid addition amount, pelletizer fill rate, tumbling time, and drying temperature, is required, posing a high level of operational complexity and requiring high automation requirements.

Application: This is a standard method for producing NPK compound fertilizers. It is also used to produce granular organic-inorganic compound fertilizers, soil conditioners, etc.

Conclusion

Material agglomeration, as an important material design and processing strategy, demonstrates multifaceted value in fertilizer manufacturing. Essentially, a controllable agglomeration process bridges fertilizer raw materials and final products. By precisely controlling interactions between particles, it achieves the synergistic optimization of fertilizer functionality, process performance, and economic efficiency. For fertilizer granulation equipment manufacturers, a deep understanding of agglomeration mechanisms and mastering the characteristics and process requirements of different raw materials are fundamental to providing advanced solutions. With the increasing demand for efficient and environmentally friendly fertilizers in agriculture, agglomeration technology will play an even more crucial role in improving fertilizer utilization, reducing environmental pollution, and improving soil health. By converting fine powders into granules, agglomeration not only optimizes material physical properties (such as flowability and bulk density) and eliminates operational hazards (such as dust and segregation), but also directly enhances fertilizer agronomic efficiency by controlling the spatial distribution and release rate of nutrients. Understanding and applying agglomeration technology is fundamental to the development of the modern fertilizer industry. It transforms fertilizer from a basic chemical raw material into a modern agricultural product with controllable properties, convenient application, and stable results.