Introduction:

Our company, Tongli Heavy Machinery, is a professional manufacturer of crushing and grinding equipment. Our products are SGS and Bureau Veritas certified. Although our quality has reached the standards of Home Depot suppliers, our equipment is too large and mainly used in industrial applications, so customers cannot purchase it directly from Home Depot. This article will introduce What is crushed limestone and its application along with a breif intro of our stone crusher. For videos of our stone crusher click here.

The Basics: What is crushed limestone?

Crushed limestone is a common aggregate composed of calcium carbonate (also known as calcite). After being mined from the quarry, limestone is crushed in a jaw crusher to break large lumps into smaller pieces. Cone crushers or impact stone crushers then perform secondary and tertiary crushing to produce particles of varying sizes. Finally, screening equipment is used to grade and classify the particles. Open-graded crushed limestone is ideal for a variety of projects, such as sidewalks, drainage systems, stormwater management, and roadbeds. High-quality crushed limestone requires certification from the New Jersey Department of Transportation(NJ DOT) and the New York Department of Transportation(NYC DOT).

What is gravel?

Gravel and crushed stone are similar in that they are both rocks, but the two materials are formed differently. Gravel is a loose collection of rock fragments formed naturally through geological processes such as weathering, water erosion (e.g., from rivers and streams), or glacial activity. Its particle size typically ranges from 2 mm to 64 mm, distinguishing it from finer materials like sand (less than 2 mm) and coarser materials like pebbles (greater than 64 mm). Crushed stone is artificially manufactured, while gravel is formed through natural processes. One of the main differences in appearance and texture between crushed stone and gravel is the edges of the stones.

Gravel and crushed limestone are not the same! the difference is easy to spot.

Crushed stone often has sharp, jagged edges due to the crushing process. Gravel, on the other hand, typically has a very smooth texture and surface due to natural weathering and water erosion. Unlike crushed stone, gravel is typically sold and used in its natural state. If gravel is broken down, it loses its distinctive smooth, rounded texture and eventually becomes crushed stone. The composition of gravel varies greatly, as it is formed from the disintegration of various parent rocks. Common minerals and rock types found in gravel include quartz, feldspar, granite, basalt, limestone, and sandstone, depending on the local geology. Its texture is typically smooth or rounded due to erosion by water or wind, with sharp edges smoothed over time. Gravel is widely used as a base material for roads, driveways, and foundations, providing drainage and stability. In landscaping, it enhances the aesthetics of paths, gardens, and water features. Furthermore, due to its permeability and load-bearing capacity, it is a key component in concrete mixes, drainage systems, and filtration media.

Differences Between Gravel and Crushed Limestone table comparison

| Feature | Gravel | Crushed Limestone |

| Formation | Naturally formed by weathering, water erosion, or glaciation. | Man-made by mechanically crushing and screening limestone rocks. |

| Shape | Typically rounded or sub-rounded with smooth surfaces due to natural abrasion. | Angular with rough surfaces, retaining sharp edges from mechanical processing. |

| Composition | Diverse; may include quartz, feldspar, granite, basalt, and other rock fragments. | Uniform; primarily composed of calcium carbonate (CaCO₃) from limestone. |

| Primary Applications | Road bases, driveways, landscaping, drainage systems, concrete aggregates. | Soil amendment (pH adjustment), construction (for riprap), metallurgical flux, livestock feed additive, pharmaceutical calcium supplements. |

| Permeability | High, due to rounded particles and interparticle voids. | High, but varies with particle size; often optimized for specific drainage needs. |

| Cost | Depends on local availability of natural deposits; may be higher in areas far from sources. | Generally cost-effective, as limestone is widely mined and easily processed. |

How is crushed limestone made?

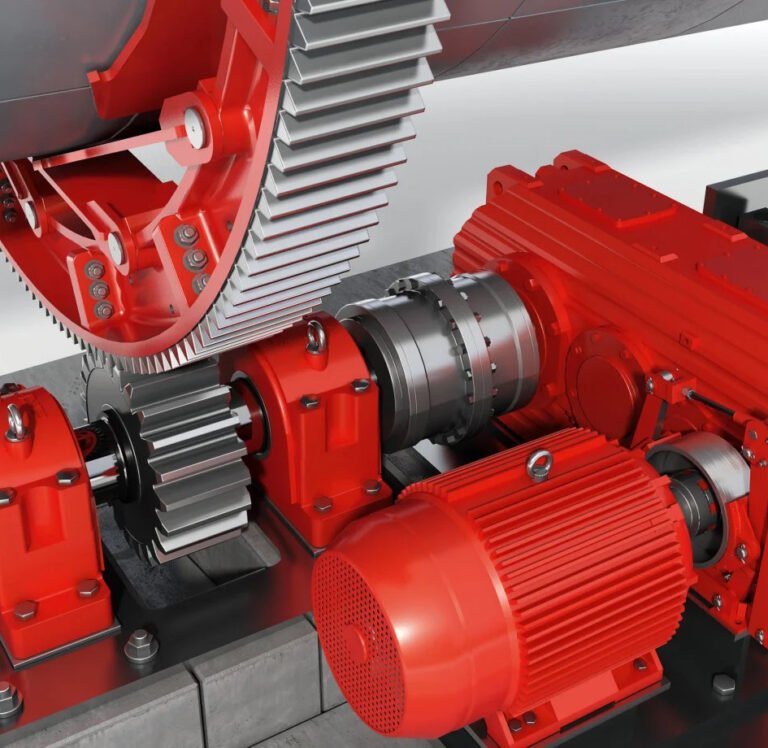

The production process of crushed limestone is roughly as follows: first, large pieces of limestone are mined from the mine, and primary crushed by a jaw crusher to obtain 10-30 cm stones. Then, secondary crushing is completed by a cone crusher to 3-10 cm. Then, a counterattack or impact crusher is used for fine crushing to reduce the particles to the target particle size of 0-5 mm. The crushed particles are then screened and graded by a vibrating screen. Non-compliant coarse particles are returned to the corresponding crushing equipment for reprocessing. If the finished product contains a lot of impurities, it can also be cleaned and dehydrated by a sand washer to finally obtain a finished product that meets the particle size and purity requirements.

Raw Material Mining

First, raw materials must be obtained from limestone mines. Pre-mining operations involve geological surveys to determine the reserves, quality, and distribution of the limestone. Large lumps of limestone are then separated from the ore body using methods such as blasting and mechanical excavation. Loaders, trucks, and other equipment then transport the lumps to the crushing and processing site. The limestone raw material is typically naturally occurring carbonate rock, primarily composed of calcium carbonate (CaCO₃). Its purity and hardness directly impact the quality of the subsequent product.

Primary Crushing (Coarse Crushing)

Primary crushing aims to break the large lumps of mined limestone into smaller pieces. A commonly used machine is a jaw crusher, which uses the relative motion of its movable and fixed jaws to squeeze, split, and bend the limestone. Once in the jaw crusher, the large lumps of limestone are broken into particles approximately 10-30 cm in size for subsequent secondary crushing. This step significantly reduces the size of the limestone, making it easier to process.

Secondary Crushing

After coarse crushing, the limestone enters the secondary crushing stage for further particle size reduction. Cone crushers are commonly used for secondary crushing. They utilize a cone that oscillates within a cone housing, squeezing, bending, and impacting the material. The particle size of the limestone after secondary crushing is typically controlled at around 3-10 cm, resulting in more uniform stone sizes suitable for the next stage of fine crushing.

Fine Crushing (Final Crushing)

Fine crushing involves processing the secondary crushed limestone into a finished product of the required particle size. Impact crushers or impact crushers are commonly used for this process. They use high-speed rotating hammers or impellers to impact and collide the material, breaking it into even finer particles, typically 0-5 mm in size, to meet the needs of various applications, such as construction aggregates and cement raw materials.

Screening and Classification

The crushed limestone particles are screened using screening equipment (such as a vibrating screen) to separate particles of different sizes and achieve classification. During the screening process, undesirable coarse particles are returned to the appropriate crushing equipment for re-crushing until the specified particle size is reached. This step ensures a uniform particle size in the finished product, meeting the standards of various industries. For example, road construction may require limestone aggregate within a specific particle size range.

Common types and properties of crushed limestone in USA

1 1/2" (approximately 38mm) Crushed Limestone

Corresponding Standard: This is #3 Crushed Limestone in the New Jersey DOT specification.

- Main Applications: Driveway bedding, trail base, drainage systems (such as soakaways), septic tank backfill, dry wells, road base, and railroad ballast.

- Features: Large particles, high porosity, good water permeability, and strong load-bearing capacity, making it suitable for heavy loads or applications requiring high drainage.

3/4" (approximately 19mm) Crushed Limestone

Corresponding Standard: Commonly found as #57 Crushed Limestone (unwashed) or 3/4" Clean Crushed Limestone (cleaned). Main applications are:

- Unbound: Used for road base, paving, patio, and parking lot bedding.

- With Binder: Used as an asphalt mixture or concrete aggregate for highways, pavement repair, residential, and commercial projects.

- Features: 3/4" Clean is the most widely used particle size, offering a moderate size and a wide range of applications.

3/8" (approximately 9.5mm) Crushed Limestone

Corresponding Standard: New Jersey DOT #8 Crushed Limestone

- Main Applications: Parking surface, septic tank drain fields, bike paths, walking paths, roofing stone, and tar and chip driveway seals.

- Features: Small particle size, resulting in a smooth, comfortable pavement surface, suitable for light loads or landscaping.

1/4" (approximately 6mm) Crushed Limestone

Corresponding Standard: New Jersey DOT #10 Crushed Limestone (also known as limestone dust, limestone screenings)

- Main Applications: Pavement screeds (such as paving slabs), bike paths, drain ditch bases, parking areas, landscaping, and track mixes.

- Features: Extremely fine, almost powdery particles, easily compacted, resulting in a dense, stable surface after paving.

Common Crushed Limestone Sizes & Uses in Canada

50mm+ Clear Limestone

- Equivalent to: 2″ Clear Stone

- Uses: Heavy-duty drainage layers, erosion control, large-scale road base, railway ballast.

- Features: Large particle size, high permeability, ideal for heavy load areas or water management.

40mm Clear Limestone

- Equivalent to: 1 1/2″ Clear Stone

- Uses: Driveway base, drainage ditches, septic systems, dry wells, railway ballast.

- Features: High load-bearing capacity, good drainage, suitable for heavy-duty surfaces.

25mm Clear Limestone

- Equivalent to: 1″ Clear Stone

- Uses: Road base, industrial yards, heavy-traffic pathways, drainage layers.

- Features: Versatile size for structural base layers, stable under compaction.

19mm Clear Limestone

- Equivalent to: 3/4″ Clear Stone

- Uses: Road base, concrete aggregate, asphalt mixes, parking lots, landscaping.

- Features: Most commonly used size in Canada, excellent all-rounder for construction and landscaping.

12.5mm Clear Limestone

- Equivalent to: 1/2″ Clear Stone

- Uses: Residential driveways, pathways, concrete finish aggregate.

- Features: Produces a smoother surface finish, stable after compaction.

10mm Clear Limestone

- Equivalent to: 3/8″ Clear Stone

- Uses: Bike paths, parking areas, decorative landscaping, tar-and-chip paving.

- Features: Small size, comfortable underfoot, visually neat.

Limestone Screenings (≤6mm)

- Equivalent to: Stone dust

- Uses: Paver base leveling layer, racetrack mix, underdrain bedding, landscaping.

- Features: Fine particles, compacts tightly, creates a smooth, dense surface.

Notice the fact that crushed limestone specifications vary from country to country, and even within regions, the same size can be called by different names. For example, a “3/4″ Clear Stone” in Canada is equivalent to a “#57 Crushed Limestone” in the United States and a “16–20mm Crushed Stone” in China. Without a unified reference, it can be difficult for international buyers, engineers, and contractors to match the correct material for their projects.

International Crushed Limestone Size & Use Comparison Table (English)

To help bridge this gap, we compiled an International Crushed Limestone Size & Use Comparison Table that brings together the common specifications used in the United States, Canada, and China. This table is designed to:

| Size (inch) | Size (mm) | US / NJ DOT Designation | Canada | China | Main Uses | Features |

| 2″–3″ | 50–75mm | #1 or #2 | 50mm+ Clear Stone | 50–70mm Crushed Stone | Railway ballast, slope protection, heavy-duty drainage layers | Large particles, excellent permeability, heavy-load capable |

| 1 1/2″ | 38mm | #3 | 40mm Clear Stone | 31.5–40mm Crushed Stone | Driveway base, drainage ditches, dry wells, railway ballast | High load capacity, large voids for drainage |

| 1″ | 25mm | #4 | 25mm Clear Stone | 20–31.5mm Crushed Stone | Road base, industrial paving, drainage layers | Good stability, strong compaction base |

| 3/4″ | 19mm | #57 (uncleaned) / 3/4″ Clean (washed) | 19mm Clear Stone | 16–20mm Crushed Stone | Road base, concrete aggregate, asphalt mixes | Most widely used size, versatile |

| 1/2″ | 12.5mm | #67 | 12.5mm Clear Stone | 10–16mm Crushed Stone | Concrete finishing, light-traffic roads, landscaping | Smooth surface, stable after compaction |

| 3/8″ | 9.5mm | #8 | 10mm Clear Stone | 5–10mm Crushed Stone | Bike paths, parking lots, tar-and-chip paving | Fine texture, neat appearance |

| ≤1/4″ | ≤6mm | #10 / Screenings | Limestone Screenings | Stone Dust | Paver leveling base, racetrack mix, underdrain bedding | Fine particles, compacts densely |

| Limestone Dust | ≤1mm | - | Limestone Dust | Limestone Powder | Soil pH adjustment, water treatment, industrial filler | Powder form, chemical and agricultural uses |

Physical Properties of Crushed Limestone Aggregate

| Property | Type 1(20 mm max) | Type 2(15 mm max) | Type 3(10 mm max) | Type 4(5 mm max) | British Std. Limit / Common Spec |

| Relative Density – SSD | 2.68 | 2.67 | 2.68 | 2.68 | – |

| Relative Density – Dry | 2.67 | 2.65 | 2.65 | 2.62 | – |

| Apparent Specific Gravity | 2.70 | 2.71 | 2.73 | 2.80 | – |

| Water Absorption (% of dry mass) | 0.65 | 1.00 | 1.01 | 1.20 | Typically ≤2.0% |

| Aggregate Impact Value (% fines) | 19.87 | – | – | – | ≤25% (BS 812) |

| Aggregate Crushing Value (%) | 25.38 | – | – | – | ≤30% (BS 812) |

| Los Angeles Abrasion Value (% wear) | 23.5 | 24.0 | 25.0 | 26.0 | ≤30% (EN 1097-2 / ASTM C131) |

| Flakiness Index (%) | 14 | 12 | 11 | 9 | ≤25% (BS 812) |

| Elongation Index (%) | 13 | 12 | 10 | 9 | ≤25% (BS 812) |

| Dust Content <75 µm (%) | – | – | – | 13 | ≤3% for concrete, ≤16% for unbound |

| Moisture Content (% by mass) | 0.5 | 0.6 | 0.7 | 0.9 | Project-specific |

| Particle Shape | Angular | Angular | Angular | Cubical | – |

| Surface Texture | Rough | Rough | Rough | Smooth | – |

What is crushed limestone used for?

Crushed limestone has a wide range of uses: it can improve acidic soil, adjust pH and replenish minerals; it is used as a cushioning material in civil engineering to enhance structural stability; it is used as a flux in metallurgy to help separate impurities; it is also a calcium supplement for livestock feed and can be purified for medical calcium supplementation, making it both practical and economical.

Drainage Ditches

For those living in areas with frequent rainy seasons and heavy surface runoff, preventing rainwater from accumulating around homes is a major challenge. In such areas, constructing drainage ditches is crucial for protecting the exterior structure of homes. They effectively channel rainwater and reduce erosion on foundations, walls, and other structures. To prevent soil erosion caused by water erosion in drainage ditches, paving them with gravel or natural crushed stone is a widely used solution. Crushed limestone, as a natural stone, is an ideal choice due to its stable performance and wide applicability. When laying these gravels, different sizes of crushed limestone can be selected based on the actual amount of rainwater runoff in the area:

- Larger-grained limestone is typically used as a base stabilizer, enhancing the stability of the ditch structure and resisting strong water flow.

- Smaller-grained limestone is used as a filler, filling the gaps between larger particles to further strengthen the integrity of the drainage system and improve drainage efficiency.

This method of selecting stone specifications based on actual conditions allows the drainage ditch to maintain good drainage effects and structural stability when dealing with rainwater of different intensities.

Landscaping and Walkways

When you hire a landscape designer to design your backyard, they'll plan and divide different uses and areas for you, as well as design various walkways. There are many materials that can be used for these walkways. Crushed limestone is a common material, available in a variety of colors and shades, easily meeting your specific needs. Therefore, a crushed limestone walkway can add a unique touch to your backyard or garden. It's important to note that crushed limestone is a more economical material than other natural stone pavers. Furthermore, it's easy to install; simply remove the grass, lay down the landscaping cloth, and then lay the stones on top.

Driveways

Another common use for crushed limestone is as a driveway. If you're looking for an economical and attractive alternative to asphalt or gravel driveways, consider crushed limestone. Crushed limestone is less expensive than asphalt, especially for long driveways. Furthermore, crushed limestone offers nearly all the advantages of crushed stone, with a more attractive natural color palette. Compared to asphalt, crushed limestone is more durable and less prone to cracking over time. This is because crushed limestone is less susceptible to weathering and more permeable to water. Another benefit of crushed limestone is that it requires less maintenance than other driveway materials. In short, crushed limestone is an excellent driveway material, especially for those looking to increase property value without the expense or hassle of installation. Crushed limestone comes in a variety of colors, but the most recommended color for driveway pavers is an off-white with darker specks. It enhances the appearance of any landscape while easily supporting the weight of vehicles

Applications in Soil Improvement/enrichment

Crushed limestone plays a vital role in soil improvement, primarily regulating soil pH. For acidic soils, components like calcium carbonate in crushed limestone react with hydrogen ions in the soil, neutralizing the acidity and raising the soil pH. Soil with a pH close to neutral is more conducive to plant nutrient absorption, creating a suitable pH environment for crop growth. It also replenishes minerals like calcium and magnesium in the soil, improving soil structure and enhancing its water and nutrient retention capacity. The minerals in dolomite and limestone are alkaline, and acid-neutralizing chemicals are present in the soil. Therefore, crushed limestone aggregate mixed with appropriate gypsum-grade minerals (phosphorus, zinc, and copper) can enrich the soil and improve soil productivity.

As an Ideal Bedding Material for Riprap

In civil engineering, crushed limestone is an ideal bedding material for riprap operations. Its uniform particle size distribution and stable physical properties make it an effective base material for distributing overhead loads and reducing foundation settlement when laid beneath riprap. Crushed limestone also has excellent water permeability, allowing it to drain water from the base layer quickly and prevent structural damage caused by water accumulation. Limestone aggregates of varying particle sizes can form multiple protective layers, effectively lining ditches. Soil erosion also occurs along riverbanks and coasts. Crushed limestone aggregate can be used to make high-quality riprap to control erosion in such areas. Limestone aggregate is an ideal base material for riprap.

Applications in Flux Stone

In the steel and glass manufacturing processes, removing various mineral and organic impurities is crucial. Crushed limestone is often used as a flux stone in the metallurgical industry. During metal smelting, it chemically reacts with impurities in the ore (such as silica and alumina) to produce low-melting-point slag/liquid slag, thereby lowering the smelting temperature, facilitating the removal of these impurities, and promoting the separation of impurities from the metal. Crushed limestone is an indispensable flux material in both steel and non-ferrous metal smelting due to its low cost and suitable reactivity. It plays a key role in processes such as blast furnace ironmaking and converter steelmaking.

Uses in Livestock Feed

Crushed limestone is also an important mineral supplement in livestock feed. It's rich in calcium, a nutrient essential for physiological processes such as bone development, muscle contraction, and nerve conduction. Adding an appropriate amount of crushed limestone to feed, crushed into a fine powder, effectively meets livestock's calcium needs and prevents calcium deficiency-related diseases such as rickets and osteoporosis. It is particularly suitable for poultry and livestock farming. However, the particle size and addition ratio must be strictly controlled to ensure digestibility and feed safety.

Uses in Medicine and Calcium Supplements

In the pharmaceutical field, crushed limestone, after purification, can be used as a raw material in the preparation of calcium supplements. Its main component, calcium carbonate, is an important source of calcium for the human body and is suitable for preventing and treating calcium deficiency disorders such as osteoporosis, tetany, and osteodystrophy. Finely processed pharmaceutical-grade calcium carbonate has the characteristics of high purity, low impurities, and good bioavailability. It can be made into various dosage forms such as tablets, capsules, and granules to meet the calcium supplement needs of different groups of people. At the same time, it can also be used as an excipient in some pharmaceutical preparations to play a role in filling and stabilizing.

8 Major advantages of crushed limestone

1 Excellent Drainage

The large interstices between crushed limestone aggregate particles create natural infiltration channels, effectively promoting the infiltration of rainwater and snowmelt, reducing road surface waterlogging and ice formation after snowmelt. When used in driveways, courtyards, or sidewalks, this natural drainage property helps extend the pavement's service life and reduces the risk of freeze-thaw damage caused by accumulated water. For projects requiring stormwater management (such as permeable paving systems), crushed limestone can also serve as a permeable base material, meeting the requirements of urban sponge construction.

2 Easy Installation and Short Construction Period

Compared to asphalt or concrete, the construction process for crushed limestone driveways is relatively simple. Generally, it requires only leveling the roadbed, laying an appropriate amount of crushed stone, and mechanical compaction to create a stable bearing surface. It requires minimal equipment and can be completed manually, making it ideal for small and medium-sized projects or quick repairs. Furthermore, because the limestone aggregate particles interlock, compaction creates a dense structure, reducing subsequent settlement.

3 Durability and Strong Bearing Capacity

Limestone is a dense sedimentary rock composed primarily of calcium carbonate (CaCO₃), accompanied by minerals such as calcite and dolomite. Its compressive strength typically reaches 100–250 MPa, offering excellent wear and weather resistance. Using crushed limestone in driveways or road bases can withstand long-term vehicle loads and repeated rolling, reducing loosening and rutting. For heavily loaded roads, it can also be combined with graded crushed stone to enhance the overall bearing capacity of the structural layer.

4 Natural and Beautiful Appearance with a Variety of Colors

Crushed limestone's colors range from light cream and honey yellow to dark gray and even bluish-gray, blending seamlessly with diverse landscape designs. The subtle variations in texture and color of each stone create a more natural and layered paving effect. By selecting different particle sizes and colors, specific aesthetic effects can be achieved, such as a rustic driveway or a modern landscape paving. Furthermore, limestone resists fading under UV light, ensuring a long-lasting aesthetic.

5 Abundant Supply and Convenient Access

Limestone resources are widely distributed globally, with large quarries in China, the United States, Australia, and other regions. Therefore, crushed limestone is easily available from building materials markets and sand and gravel companies worldwide. Due to its large production volume and convenient transportation (especially in areas with established rail or bulk carrier transportation facilities), it offers a short procurement cycle and minimal price fluctuations, making it ideal for bulk purchases for construction projects.

6 Cost-Effective and Highly Cost-Effective

Compared to materials like asphalt and concrete, crushed limestone offers a lower initial investment cost, a longer service life, and lower maintenance costs, resulting in significant overall economic advantages. Its raw material costs are less susceptible to international market fluctuations, and the application of modern mining and crushing technology makes its unit cost even more competitive. For projects with limited budgets but demanding durability, crushed limestone is an ideal choice.

7 Versatile and Widely Applicable

Beyond driveway and road bases, crushed limestone is widely used in construction fill, concrete aggregate, landscaping paving, agricultural soil improvement, water treatment filtration media, and environmental remediation projects. Limestone is a key raw material in cement production. In agriculture, crushed limestone regulates soil pH and improves crop yields. This versatility makes it valuable in residential, commercial, and industrial projects.

8 Maintenance and Seasonal Challenges

In cold, snowy regions, crushed limestone pavements require careful snow removal to prevent snowplows from digging up the stone and causing uneven surfaces. Care should also be taken during autumn leaf removal, as debris can become trapped between the particles, making maintenance more difficult. Furthermore, to maintain a good appearance and structural stability, it is recommended to regularly replenish the stone, remove debris, and perform surface compaction maintenance over time.

Why crushed limestone is better than gravel? 5 facts

- Crushed limestone aggregates are about 10% stronger than traditional gravel used in concrete mixers. This extra strength comes from the sharp edges and angular shapes of crushed limestone, unlike the smooth, round shapes of natural gravel formed by weathering.

- Crushed limestone grit weighs less than limestone gravel and other natural stones. This means you can save about 12% of the total volume needed when mixing concrete for construction.

- Compared to gravel concrete, concrete made with crushed limestone expands and contracts less when temperatures change. This is because crushed limestone concrete has a lower thermal expansion rate.

- Because of this thermal stability, concrete slabs made with limestone cure better. They tend to have fewer cracks, with wider spacing between cracks and smaller crack widths.

- Crushed limestone is a type of calcite rock, which is softer than silicate rocks like some gravels. This softness makes it easier to cut or saw through compared to harder silicate gravel.

What are the disadvantages of crushed limestone?

Crushed limestone, while widely used in construction, agriculture, and other fields, has several notable disadvantages:

- Susceptibility to weathering: It is prone to degradation when exposed to prolonged moisture, especially in areas with freeze-thaw cycles. Water absorption can cause the material to expand and crack over time, reducing its structural integrity.

- Limited load-bearing capacity in wet conditions: When saturated, crushed limestone loses some of its load-bearing strength, making it less suitable for applications where consistent weight support is critical, such as high-traffic roadbeds in rainy regions.

- Potential for alkalinity issues: Its high calcium carbonate content can increase soil or water alkalinity if overused. In agriculture, excessive application may disrupt soil pH balance, harming plant growth. In construction, leaching of alkaline compounds can affect adjacent materials like concrete or vegetation.

- Transportation challenges: Due to its weight and bulk, transporting crushed limestone is energy-intensive and costly, especially over long distances, which raises its overall carbon footprint and operational expenses.

- Inconsistent quality: Variations in the original limestone’s purity (e.g., presence of impurities like clay or silica) can lead to inconsistent quality in the crushed product, affecting its performance in applications requiring uniformity, such as concrete production.

What are the environmental impacts of crushed limestone?

The crushing and handling processes produce significant dust, which can pose health risks to workers like respiratory issues and require additional measures like dust suppression systems to mitigate environmental and safety concerns. When we design the stone crushing line we take into consideration of the dust and equipped with bag house filter dust collector to protect the environment.

Does crushed limestone get hard?

Yes, crushed limestone will gradually harden under certain conditions. This hardening phenomenon is mainly related to the moisture and carbon dioxide in the environment: the crushed limestone particles are mainly composed of calcium carbonate, which will slowly react chemically with water and carbon dioxide in the air to produce harder calcium carbonate crystals. This process is similar to the "carbonation" of concrete, which can gradually increase the density and strength of the material. However, this hardening has limitations: on the one hand, the hardening speed is slow and is greatly affected by factors such as environmental humidity and carbon dioxide concentration; on the other hand, if it is exposed to humidity or immersion in a humid or soaking environment for a long time, especially in the presence of acidic substances such as acid rain, the limestone may be weakened by dissolution or weathering, which will reduce its hardness. Therefore, its hardening effect needs to be judged in combination with the specific usage scenario. It is more obvious in a dry and ventilated environment, but it may be difficult to effectively harden or even deteriorate in a humid or corrosive environment.

Is crushed limestone expensive? How much is crushed limestone

Crushed limestone is considered an affordable and cost-effective building material. The price is usually lower than granite or marble and often cheaper than concrete or asphalt.

Bulk Suppliers / Gravel Yards

AggregateMarkets.com

Crushed limestone (e.g., #53 ranging from dust to 1.5") starts from $18 per ton

Young’s Sand & Gravel — Prices vary by grade:

- #57 Limestone: $34.25/ton

- #8 Limestone: $39.00/ton

- #4 Limestone: $31.50/ton

- Limestone Screenings: $31.50/ton

Colson’s Gravel — For “#57 Limestone (1” clean)”, prices range from:

- 1 ton: $165

- 5 tons: $300

- 10 tons: $480

Average Market Rates

- Plain pea gravel or limestone: $28–$45 per ton

- Bulk crushed stone & gravel: $10–$50 per ton

- Small-quantity purchases can exceed $100 per ton

Bagged or Retail Pricing (Home Depot Milwaukee)

- Home Depot carries bagged crushed stone at around $22.99 per 0.25 cu. ft. The Home Depot.

- Bulk purchases from big-box stores range from $400 to $2,000, depending on rock type and volume The Home Depot.

- An anecdote from Reddit suggests a local cost of $4.50 per 0.5 cu. ft. bag, equating to approximately $243 per yard, which is typically more expensive than buying in bulk

What are the alternatives to crushed limestone?

There are many alternative materials for crushing limestone, and the specific choice depends on the usage scenario.

In terms of Construction and Infrastructure:

Granite crushed stone has high hardness and strong wear resistance, making it suitable for high-load pavements or structural foundations. Basalt crushed stone has excellent compressive strength and is often used in projects requiring high strength, such as highways and railway tracks. Recycled aggregates, such as concrete blocks and bricks made from crushed construction waste, are environmentally friendly and reduce resource consumption, making them suitable for low-load construction scenarios. Sand and gravel—mixtures of natural sand and gravel—are widely used in concrete and roadbed fills, and are relatively low-cost.

Replacement of crushed limestone In terms of Agriculture:

Dolomite powder (containing calcium carbonate and magnesium oxide) regulates soil acidity and provides magnesium for crops, making it suitable for soils with high magnesium requirements. Gypsum (calcium sulfate) improves soil structure, reduces alkalinity in saline-alkali soils, and replenishes calcium and sulfur. Wood ash (rich in alkaline substances such as potassium and calcium) neutralizes soil acidity and provides potash fertilizer for crops, making it a natural organic amendment.

Industrial and environmental protection fields alternatives for crushed limestone:

Activated alumina can replace limestone in water treatment for purification processes such as fluoride removal, with stronger adsorption performance; calcium carbonate powder (after fine processing) can replace part of crushed limestone in industries such as plastics and coatings, and its purity and particle size are easier to control; fly ash (power plant waste) can be used as an alternative material in building materials production and soil improvement, realizing waste resource utilization.

Why do we claim our Tongli limestone crusher and milling machine have achieved Home Depot quality?

Even without formal application,ours stone crushers and grinding vertical roller mill meet or exceed the technical, operational, and quality standards expected by Home Depot. Our global certifications, quality control systems, export experience, and service support infrastructure demonstrate readiness for immediate integration into the Home Depot supply chain—both online and in-store(even though our product is too big)

Long-Term Export Experience to North America & Europe

We have a proven track record of supplying heavy industrial equipment to clients in:

- The United States, Canada, Germany, and Australia

- Meeting each market’s import standards for mechanical, safety, and environmental compliance

Internationally Certified by SGS and Bureau Veritas

Our factory and products have passed rigorous inspections and quality audits conducted by global third-party organizations like SGS and Bureau Veritas and TUV —3 of the most trusted names in certification. These verifications confirm:

- Factory environmental and safety compliance

- Product quality control systems

- Material traceability and testing protocols

- Export readiness in accordance with U.S. and EU retail standards

ISO 9001 Certified Quality Management System

Tongli implements a full ISO 9001:2015 QMS across production, ensuring:

- Consistent manufacturing standards

- Batch-level quality tracking

- Corrective and preventive actions (CAPA) in place

- Supplier management aligned with Home Depot’s QSA (Quality System Assessment)

Industrial-Grade Design for U.S. Market Demands

Our stone crushers are engineered for long service life, minimal maintenance, and high throughput—critical factors for Home Depot's DIY and contractor clientele. We meet:

- ANSI/OSHA safety compliance

- UL-compliant motor and switchgear integration (when applicable)

- Robust powder-coated structures resistant to rust and wear

Pre-Shipment Testing and Batch QC

Every machine undergoes:

- No-load and load testing before dispatch

- Dimensional and mechanical verification

- Full inspection documentation, photos, and serial tracking—aligned with Home Depot's Pre-Shipment Inspection (PSI) and FAR (First Article Review) protocols

Engineering Support and Spare Parts Readiness

We provide full technical documentation (manuals, exploded diagrams, parts lists), ensuring:

- Ease of maintenance for end users

- Availability of fast-moving spares

- Ready support for warranty handling and CAPA logs

Digital Integration Ready (EDI Alternative Support)

While we are not yet integrated with Home Depot’s EDI system, we maintain:

- Cloud-based ERP for order processing and traceability

- Readiness to work with Sterling Web Form or EDI partners as required by Home Depot onboarding

Commitment to Green Manufacturing and Compliance

Our production aligns with RoHS, REACH, and environmental emissions controls—a growing concern for large U.S. retailers. Our waste management and energy efficiency standards exceed local norms, aligning with Home Depot's environmental responsibility goals.