Introduction:

Among the core components of a single-shaft urea lump breaker, the cutterhead is the key factor in determining urea crushing efficiency and finished product particle size. Conventional, standardized cutterheads often struggle to adapt to the diverse characteristics of urea feedstock (such as high-moisture agglomerates and hard, brittle granules) and the diverse fineness requirements (e.g., 0.3-0.8mm ultrafine powder and 1.5-2.5mm conventional granules). This can lead to issues such as incomplete crushing, excessive fines, and rapid cutterhead wear. Customized cutterhead designs, by optimizing material, structure, tooth profile, and speed compatibility, enable single-shaft urea pulverizers to easily handle various urea crushing scenarios and consistently deliver finished product of the ideal fineness. This article will delve into the design logic, core technical key points, and practical application value of customized cutterheads, providing a reference for compound fertilizer companies seeking equipment upgrades.

Limitations of Conventional Standardized Cutterheads: Why is "Ideal Crushing" So Difficult to Achieve?

Most single-shaft urea pulverizers currently on the market are equipped with standardized cutterheads, often made of general-purpose steel (such as 45# steel). These cutterheads feature evenly spaced straight teeth with a fixed tooth spacing (typically 5-8mm). These cutterheads are not optimized for the characteristics of urea raw materials, resulting in significant limitations in practical applications:

Poor material compatibility and rapid wear

Although urea has a low hardness (Mohs hardness 2-2.5), some urea raw materials can easily form hard lumps (hardness can reach Mohs hardness 3 or above) due to improper storage or contain trace impurities (such as dust and small stones). The 45# steel used in standardized blade discs has a hardness of only HRC20-25. When breaking hardened urea lumps, the teeth are prone to chipping and wear, typically requiring replacement after 15-20 days of use. This not only increases consumable costs but also causes frequent downtime and impacts production. Furthermore, if the urea moisture content is high (>1.5%), ordinary steel blade discs are prone to rust. This rust can mix into the urea crushed material and affect the purity of the finished compound fertilizer.

Fixed structure and tooth profile, limited fineness adjustment

The tooth spacing, tooth height, and tooth profile of standardized cutter discs are all fixed, making them inflexible and unable to be adjusted to the target fineness. For example, when crushing ultrafine urea powder of 0.3-0.8mm, a cutter disc with a fixed tooth spacing (5mm) struggles to achieve "fine shearing," resulting in a large number of coarse particles (>1mm). Repeated crushing is required to meet the target, increasing energy consumption by over 30%. Conversely, when conventional 1.5-2.5mm particles are required, the overly dense teeth create an excessive amount of fine powder (<0.3mm), which does not meet the particle size requirements for compound fertilizer granulation. Furthermore, the fixed cutter disc structure cannot optimize the material's trajectory within the crushing chamber, leading to "material accumulation" and "impact blind spots," resulting in poor crushing uniformity and a particle size acceptance rate of only 70%-75%.

Inadequate speed adaptability can easily cause urea melting

Standardized cutter heads are not precisely matched to the spindle speed. When the speed is set too high (e.g., >1500 rpm) to achieve high fineness, friction between the cutter head and the urea granules generates increased heat, with local temperatures reaching 60-70°C (urea melts at approximately 132.7°C, but it absorbs moisture and softens above 50°C). This causes the urea granules to soften and "stick" to the cutter head, forming lumps that clog the screen. If the speed is too low (<800 rpm), insufficient impact kinetic energy is generated, resulting in a 50% drop in crushing efficiency and a difficulty meeting high production demands.

Key Design features of lump breaker Customized Cutter Heads: Comprehensive Optimization from Material to Structure

The customized blade design focuses on "adapting to raw material characteristics, meeting fineness requirements, and reducing energy consumption and wear." Through targeted optimization in the following four dimensions, the single-shaft urea lump breaker crusher achieves "efficient crushing + precise particle control":

1. Material Customization: Wear-resistant and anti-sticking materials are selected based on urea characteristics.

- Customized cutterheads begin with the material selection process. Suitable materials are selected based on the hardness, moisture content, and impurity content of the urea feedstock.

- For hard, agglomerated urea (hardness > Mohs 3): A tungsten carbide alloy composite material is used. The teeth are inlaid with tungsten carbide alloy (hardness HRC 65-70), and the cutterhead base is constructed from 40CrNiMo steel (hardness HRC 30-35). This ensures both wear resistance (extending the service life to 80-100 days, 4-5 times that of 45# steel) and the base toughness, preventing cutterhead breakage due to impact.

- For high-humidity urea (moisture content >1.5%): A 304 stainless steel + Teflon coating design is used. The 304 stainless steel prevents rusting, while the Teflon coating (with a surface friction coefficient of only 0.04) effectively reduces urea sticking to the cutterhead, reducing screen blockage by 60%. Above;

- For high-purity urea (impurity content <0.1%): Food-grade 316L stainless steel is used to prevent urea contamination from the blade disc material, meeting the production requirements of high-end compound fertilizers (such as organic fertilizers and water-soluble fertilizers).

2. Customized Structure: Adapts to the material trajectory in different crushing scenarios.

Customized cutterheads optimize the cutterhead diameter, thickness, and mounting angle to adjust the material's trajectory within the crushing chamber, improving crushing efficiency and uniformity.

Ultra-fine crushing (target fineness 0.3-0.8mm):

Utilizes a "large-diameter, thin-disc" design (disc diameter 300-350mm, thickness 8-10mm), increasing the disc's linear speed (up to 15-18m/s) and enhancing impact kinetic energy. The disc is also tilted 5-10°, creating a "spiral upward motion" in the crushing chamber, extending crushing time and ensuring thorough particle crushing, raising the fineness qualification rate to over 90%.

Conventional crushing (target fineness 1.5-2.5mm):

Utilizes a "medium-diameter, thick-disc" design (disc diameter 250-300mm, thickness 12-15mm), controlling the disc's linear speed to 10-12m/s to avoid excessive crushing and the generation of fine powder. A "guide groove" is added to the disc to evenly distribute the material, reducing accumulation and improving crushing uniformity by 15%-20%.

High-capacity crushing (>2 tons per hour):

Utilizes The "multi-set cutterhead series" structure installs 3-4 sets of cutterheads on the main shaft (the distance between each set of cutterheads is 15-20mm). Each set of cutterheads is responsible for the crushing task of different areas, forming "graded crushing". It not only increases the processing capacity (up to 3-4 tons per hour, a 50% increase over a single set of cutterheads) but also ensures stable particle size.

3. Customized Tooth Shape: Precisely Control Crushing Force and Fineness Distribution

The tooth shape of the cutterhead is crucial for determining crushing force and final particle size distribution. Customized designs allow for selection of different tooth shapes based on the target fineness:

Ultra-fine Grinding (0.3-0.8mm):

Using a "sharp teeth + dense teeth" design with a 30° tooth tip angle (enhanced shearing force) and a 2-3mm tooth spacing (ensures shearing of fine particles), combined with an ultra-fine screen (0.5mm aperture), this effectively crushes urea granules, keeping the proportion of fines (<0.3mm) to less than 5%.

Conventional Grinding (1.5-2.5mm):

Using a "blunt teeth + sparse teeth" design with a 60° tooth tip angle (prevents excessive shearing) and a 5-6mm tooth spacing (reduces fines). After crushing, the proportion of 1.5-2.5mm particles in the finished product can reach over 85%, meeting the requirements for compound fertilizer granulation.

Anti-sticking Crushing (High-humidity Urea):

Using a "curved teeth + chute" design. The curved teeth reduce the contact area between the material and the teeth. The chute guides the material quickly off the teeth, preventing sticking. The curved structure also disperses impact force, reducing the likelihood of urea clumping.

4. Speed Customization: Establishing a "Cutterhead-Speed" Matching Model

- Customized cutterhead design establishes a unique "Cutterhead-Speed" matching model based on the cutterhead material, structure, and tooth profile, in conjunction with the target fineness, to minimize frictional heat generation and energy waste:

- Tungsten carbide alloy sharp-tooth cutterhead (ultra-fine crushing): Optimized speed of 1200-1400 rpm, ensuring sufficient impact energy while keeping the local temperature below 40°C to prevent urea softening;

- 304 stainless steel blunt-tooth cutterhead (conventional crushing): Optimized speed of 900-1100 rpm, maintaining crushing efficiency while reducing energy consumption by 15%-20%;

- Multiple tandem cutterheads (high-yield crushing): Optimized speed of 800-1000 rpm. This increases throughput by increasing the number of cutterheads, rather than relying on high speeds, reducing equipment wear and energy consumption.

Practical case of customized lump breaker cutter head: data prove of Improved crushing capacity:

Case 1: Tanzanian Compound Fertilizer Company Treats High-Moisture Agglomerated Urea

The company's raw urea had a moisture content of 2.0%-2.5% and contained numerous hard agglomerates with diameters of 30-50mm. Using standardized cutterheads, the cutters wore rapidly (needing to be replaced every 10 days), and severe blade sticking and screen clogging occurred, necessitating four to five machine stops per shift for cleaning. The qualified particle size rate for the finished product was only 65%. By adopting a customized "304 stainless steel + Teflon-coated curved tooth cutterhead," the cutterhead life was extended to 90 days, the blade sticking and screen clogging rate was reduced by 70%, and the number of machine stops was reduced to one per shift. The qualified particle size rate for the finished product (1.5-2.5mm) increased to 92%, and production efficiency increased by 40%.

Case 2: A Zambian water-soluble fertilizer company needed ultrafine urea powder.

This company needed to crush urea into ultrafine powder of 0.3-0.6mm for use in water-soluble fertilizer production. Standardized blades could not meet the required fineness, and the fine powder was mixed with coarse particles. By adopting a customized "tungsten carbide alloy sharp-tooth thin blade" (2mm tooth spacing, suitable for a speed of 1300 rpm), the ultrafine powder yield reached 95%, and the proportion of fine powder (<0.3mm) was controlled to less than 3%, fully meeting the high-precision particle size requirements of water-soluble fertilizers while reducing energy consumption by 25% compared to the original equipment.

Customized lump breaker cutter head selection recommendations:

Compound fertilizer companies should consider their raw material characteristics, target fineness, and production requirements when selecting customized cutter heads. Follow these principles:

- Clear raw material parameters: Prioritize testing urea moisture content (≤1.0%: select conventional materials, >1.0%: select anti-stick materials), agglomerate hardness (≤Mohs 2.5: select common alloys, >Mohs 2.5: select tungsten carbide composite materials), and impurity content (≤0.1%: select food-grade stainless steel).

- Target fineness: For ultrafine powders of 0.3-0.8mm, choose a fine-toothed cutter head; for conventional particles of 1.0-2.0mm, choose a fine-toothed cutter head; for coarse particles of 2.0-3.0mm, choose a wide-toothed cutter head.

- Based on production requirements: For production of ≤1 ton per hour, choose a single-set cutter head; for 1-2 tons per hour, choose a dual-set cutter head; for >2 tons per hour, choose multiple tandem cutter heads.

- Focus on post-production service: Choose a system that offers "cutter head wear detection + Manufacturers that provide "parameter fine-tuning" services regularly test the wear of the cutter disc and fine-tune the cutter disc tooth shape or speed based on actual usage to ensure long-term stable operation.

So far we have explained the function of the cutter head of the lump breaker, now I'm going to introduce why lump breaker is important in fertilizer production just like why vertical roller mill is important in cement industry.

Four Key Impacts of Urea Particle Size on Compound Fertilizer Granulation

1. Impact on Granulation Cohesion and Granule Strength

Urea particle size directly determines its mixing uniformity and cohesiveness with raw materials such as phosphorus and potassium. If urea granules are too coarse (>3mm), they will not be able to fully contact other raw materials during the granulation process, which can lead to a "sandwich" phenomenon within the granules. This reduces the compressive strength of the finished granules (from 25N/granule to below 15N/granule) and increases the breakage rate during transportation by 5%-8%. If urea granules are too fine (<0.3mm), their large specific surface area allows them to absorb excessive water, resulting in "over-cohesion" during granulation, forming large lumps. This requires an additional crushing step, which not only reduces production efficiency but also increases energy consumption. Practice has shown that when the urea particle size is controlled between 0.8-1.5mm, it has optimal compatibility with monoammonium phosphate (MAP) (1.0-2.0mm) and potassium chloride (1.0-2.0mm). The resulting granules can achieve a compressive strength of over 30N/granule, with a breakage rate of only 2%-3%.

2. Impact on Granulation Moisture Control and Drying Efficiency

Urea is highly hygroscopic, and the smaller the particle size, the greater its hygroscopicity. If the proportion of fine urea powder is too high (>5%), it will rapidly absorb moisture from the granulator during the granulation process, causing the material moisture to increase. This requires increasing the dryer temperature (from 100°C to 120°C) or extending the drying time (from 20 minutes to 30 minutes). This not only increases energy consumption but may also lead to nitrogen volatilization losses in the finished product (loss rate can increase from 1% to 3%). If the urea granules are too coarse, moisture cannot penetrate the granules, and the granules are prone to cracking after drying, affecting the product's appearance and stability. Therefore, controlling the urea granulation particle size to 0.5-2.0mm can stabilize the granulation moisture content within the optimal range of 2.5%-3.5%, reduce dryer energy consumption by 15%, and control the nitrogen loss rate to less than 1%.

3. Impact on Granulation Yield and Production Stability

Urea crushed material with uniform particle size can significantly improve the granulator's processing capacity and operational stability. Excessive urea particle size fluctuations (e.g., the presence of both fine particles <0.3mm and coarse particles >3mm) can lead to uneven material flow within the granulator, resulting in broken particles or blockages. This can necessitate two to three machine shutdowns per shift for cleaning, each lasting approximately 30 minutes. This can directly reduce granulation yield by 15%-20%. When the urea particle size qualification rate is ≥85%, the granulator can achieve continuous and stable operation, reducing shutdowns to one to two times per week and increasing yield by 10%-12%. For example, on a 10-ton-per-hour compound fertilizer production line, failure to meet particle size control standards can affect annual yield by over 5,000 tons.

4. Impact on Nutrient Uniformity in Finished Fertilizer

One of the core quality indicators of compound fertilizer is nutrient uniformity. Urea, as the primary nitrogen source, has a particle size that is a key factor influencing nutrient distribution. If the urea granules are too coarse, density differences can easily lead to stratification during mixing, resulting in nitrogen content deviations exceeding ±1.5% in the finished fertilizer (exceeding the national standard requirement of ±1.0%), and some granules may even contain no nitrogen. If the urea granules are too fine, while mixing uniformity improves, the fines tend to adhere to the equipment walls, resulting in insufficient feed, which also affects nutrient content. By controlling the urea particle size to between 0.8-1.5mm, the nitrogen content of the finished fertilizer can be controlled within ±0.8%, and the nutrient uniformity pass rate can be increased from 75% to over 95%, meeting the production requirements for high-quality compound fertilizer.

How to optimize urea lump breaker crushing particle size? our suggestion

Set up a raw material pretreatment process

Before entering the urea crusher, hot air drying (controlled at 60-80°C) reduces the moisture content to below 1.0%. A vibrating screen is used to remove large, hard lumps (>50mm) from the raw material to prevent equipment overload and damage to the cutterhead.

Dynamically adjust equipment parameters

Based on real-time production conditions, the spindle speed is adjusted using a frequency converter (e.g., if the raw material moisture is high, the speed is appropriately reduced to below 1000 rpm). The screen wear is regularly checked (recommended cleaning once per shift and replacement once a month) to ensure effective screening.

Establish a particle size testing mechanism.

Samples are taken every two hours to test the particle size distribution of the urea crushed material. If the proportion of fines exceeds 5%, the cutterhead is checked for wear or the screen is checked for damage. If the proportion of coarse particles exceeds 3%, a finer-diameter screen is replaced or the spindle speed is increased. In addition, for companies pursuing higher quality, a "secondary classification device" (such as an air flow classifier) can be added after the single-shaft urea crusher to further remove fine powder and coarse particles, thereby increasing the particle size qualification rate of the urea crushed material to more than 95%, providing a more stable raw material guarantee for the subsequent granulation process.

Frequently Asked Question FAQ about lump crusher:

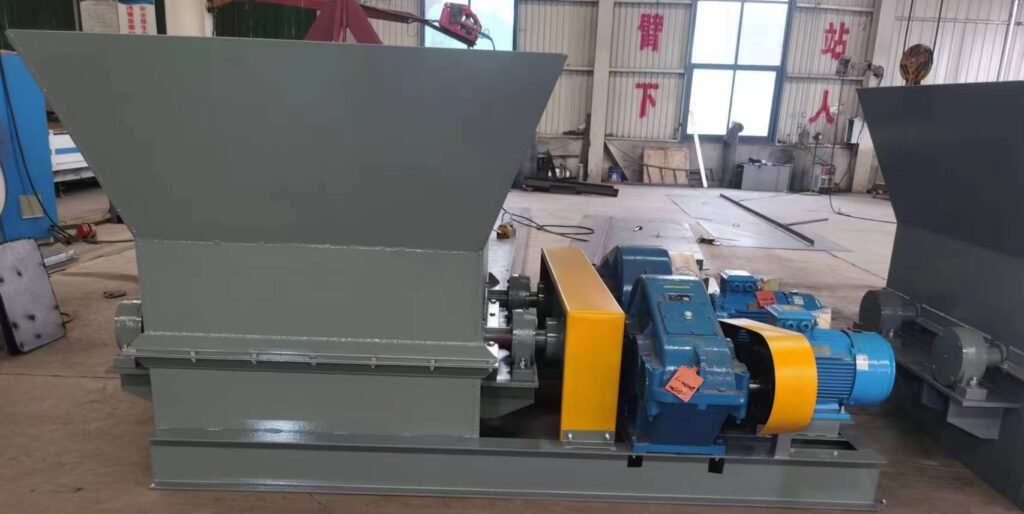

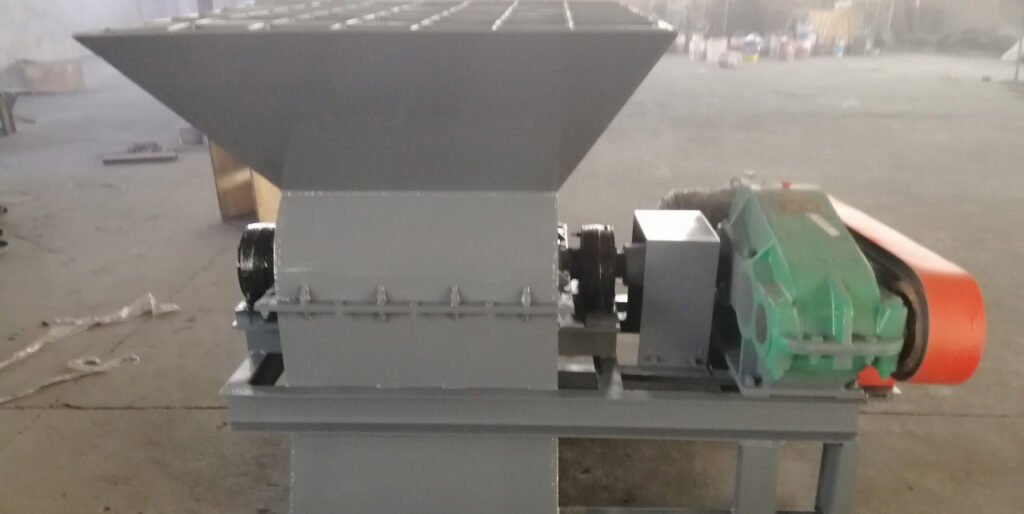

A single-shaft urea lump breaker is an impact-shear type crusher. Its core operating unit consists of a high-speed rotating main shaft, a removable alloy cutterhead, a fixed tooth plate, and a screening device. When lumpy urea (typically 20-50mm in diameter) enters the crushing chamber, the main shaft drives the cutterhead to generate centrifugal force. The urea particles are repeatedly impacted, sheared, and ground between the cutterhead and the fixed tooth plate, gradually breaking them into fine particles. Simultaneously, a grading screen at the bottom of the machine screens the pulverized material in real time. Coarse particles that do not meet the required particle size are trapped and re-enter the pulverizing chamber for secondary crushing until they meet the screening criteria and are discharged.

1. Blade speed: The speed range for conventional equipment is 800-1500 r/min. Higher speeds increase the impact kinetic energy and result in finer particle size. However, excessively high speeds can cause urea to melt and clump due to frictional heat, negatively impacting pulverization efficiency.

2. Screen aperture: This is a key component that determines the upper limit of the finished product particle size. Companies can choose a screen with an aperture of 0.5-5mm based on granulation requirements. The smaller the aperture, the more uniform the finished product particle size.

3. The characteristics of the urea raw material: If the moisture content of the urea raw material exceeds 1.5% or if it absorbs moisture and clumps, this can lead to blade sticking and screen clogging during the pulverization process, resulting in particle size deviations of over 30%.

The conventional crushing particle size range of a single-shaft urea grinder is 0.3-3mm. The finished product particle size distribution corresponding to different aperture screens is as follows: when using a 1.0mm aperture screen, more than 80% of the finished product particle size is concentrated in the range of 0.8-1.2mm, and the particle size qualification rate can reach 92%; when using a 2.0mm aperture screen, more than 75% of the finished product particle size is concentrated in the range of 1.5-2.5mm, and the particle size qualification rate is about 88%; if a finer crushing effect (such as 0.3-0.8mm) is required, a special ultra-fine blade and a 0.5mm aperture screen are required, and the feed rate is reduced (controlled below 500kg/h). At this time, the particle size qualification rate is about 78%, but the equipment energy consumption will increase by 20%-30%. It's important to note that the industry's testing of urea crushed material particle size requires a dual standard: screening and laser particle size analysis. First, urea is screened through a standard sieve (such as a Taylor sieve), and the percentage of residue on sieves of different apertures is calculated to determine the particle size distribution uniformity. A laser particle size analyzer is then used to measure the percentage of fine particles (<0.1mm) to avoid dusting or uneven granulation caused by excessive fines. According to the "Technical Specifications for Compound Fertilizer Production" (HG/T 4215-2011), urea crushed material used in compound fertilizer granulation must contain particles sized 0.5-2.0mm or greater, ≤5% fines (<0.3mm), and ≤3% coarse particles (>3mm). Failure to do so requires equipment parameter adjustment or sieve replacement.

Conclusion:

The customized cutterhead design breaks the "one-size-fits-all" limitations of standardized cutterheads. Through precise adaptation of material, structure, tooth profile, and rotational speed, the single-shaft urea pulverizer achieves "on-demand crushing." This not only solves the crushing challenge of urea raw materials with varying characteristics, but also consistently delivers finished materials of ideal fineness, ensuring high-quality raw materials for compound fertilizer granulation. As the compound fertilizer industry continues to demand higher levels of product quality and production efficiency, customized cutterheads will become a core competitive advantage for single-shaft urea pulverizers, driving the equipment from "general-purpose" to "specialized" design, helping companies reduce costs, increase efficiency, and achieve high-quality development. In the future, customized cutterheads will also incorporate technologies such as "wear warning sensors" and "intelligent parameter adjustment" to further enhance automation and provide stronger support for refined management of compound fertilizer production.