Introduction:

As vertical roller mills operate under extreme grinding pressures, high temperatures, and severe abrasive conditions, conventional high-chromium cast iron or hardfaced steel solutions often face limitations in wear rate, crack resistance, and maintenance intervals. TiC-reinforced metal matrix composites (MMC) have therefore emerged as a high-performance alternative, combining the hardness of ceramic carbides with the toughness of alloyed metallic substrates. Two leading technology routes often come into comparison: the one-shot TiC composite casting approach developed by Magotteaux and the two-stage TiC-reinforced composite casting process promoted by Vega Industries under its parent company AIA Engineering Limited. Both technologies focus on improving the service life and wear resistance of VRM grinding roller tyres through the integration of titanium carbide (TiC) reinforcement within a metallic matrix. However, the manufacturing philosophy behind these two systems differs significantly. Magotteaux’s one-shot process integrates TiC reinforcement directly during a single casting operation, forming a monolithic composite wear surface. In contrast, the Vega/AIA two-stage process involves pre-manufactured TiC-alloy composite inserts or liners that are subsequently bonded to the roller body through secondary casting. These structural and metallurgical differences influence bonding mechanisms, carbide distribution, stress transfer behavior, crack propagation resistance, and ultimately field performance in cement and slag grinding applications. This article will provide a technical comparison of both casting routes, analyzing their manufacturing principles, microstructural characteristics, mechanical performance, and practical implications for VRM roller tyre service life.

Magotteaux S.A. Société Anonyme (Belgium)

Magotteaux is a Belgium-based global leader in wear-resistant solutions for the mining, cement, aggregates, power generation, and recycling industries, with more than 100 years of expertise in crushing and grinding optimization. The company specializes in high-performance grinding media (cast and forged balls, ceramic media), mill liners, crusher wear parts, and vertical roller mill (VRM) components, focusing on extending service life and reducing total cost of ownership. Its core competitive advantage lies in proprietary metal matrix composite (MMC) technologies such as neoX®, a ceramic-reinforced alloy designed for high-abrasion and high-impact applications like VRM grinding roller tyres, tables, blow bars, and VSI crusher parts; along with earlier composite innovations like Xwin® and other advanced alloy systems that significantly outperform conventional high-chromium cast iron in severe wear environments.

Vega Industry AIA Engineering Ltd., Ahmedabad, India

AIA Engineering Ltd., headquartered in Ahmedabad, India, is a major global supplier of high-chromium, wear-resistant parts for grinding and crushing equipment used in the cement, mining, thermal power, quarry and aggregate industries. Established in the late 1970s and operating for over 40 years, AIA Engineering together with its international marketing and sales subsidiaries under the Vega Industries brand designs, manufactures, installs and services a broad range of consumable mill internals, including high-chrome grinding media, mill liners, blow bars, energy-efficient pulp lifters, impellers and other wear components tailored to customer applications. With a global footprint in over 75 countries and production capacity in the hundreds of thousands of tonnes, the company is regarded as a leading benchmark in quality, innovation and technical service in the wear parts sector, directly competing with other wear-solutions providers such as Magotteaux.

What is Magotteaux single-stage ceramic composite casting and Vega two-stage ceramic composite process?

In grinding roller tyre manufacturing for vertical roller mills (VRMs), single-stage ceramic composite casting and two-stage ceramic composite process refer to two different methods of integrating ceramic reinforcement (typically TiC) into a high-chromium alloy matrix to improve wear resistance.

Single-stage ceramic composite casting

The Magotteaux single-stage ceramic composite casting also known as Primary ceramic composite casting process is an integral metal matrix composite (MMC) process in which ceramic particles are introduced directly into the molten alloy during casting. The roller tyre is formed in one step, and the ceramic phase becomes metallurgically bonded within the metal matrix during solidification. This creates a monolithic composite structure with strong interfacial bonding, good structural integrity, and better resistance to impact and thermal stress. It is generally preferred for heavy-load cement or slag grinding where both abrasion and impact are present. The One-shot TiC composite casting process is represented by Magotteaux Belgium.

Two-stage ceramic composite process

the Vega Industry two-stage ceramic composite process also called insert-type or secondary composite process involves manufacturing ceramic or TiC composite inserts separately first, then placing them into the mould before pouring molten metal around them. The reinforcement is therefore localized in high-wear zones. Bonding may rely on mechanical anchoring or partial metallurgical fusion. This method allows more flexible design and lower ceramic consumption, but the interface between insert and matrix must be carefully engineered to avoid delamination or spalling under impact and vibration. The Secondary TiC composite lining process is represented by Vega industry.

What Is Magotteaux One-shot TiC composite casting / Primary TiC reinforced composite roll?

The One-shot TiC composite casting technology developed by Magotteaux represents a true in-situ metal matrix composite (MMC) casting route for high-wear components such as vertical roller mill (VRM) grinding roller tyres and tables.

Magotteaux One-shot TiC Composite Casting

The most distinctive feature of the magotteaux One-shot process is that micron-scale titanium carbide (TiC) particles are generated in situ inside the molten metal during casting. TiC is not externally added ceramic powder simply stirred into the melt. Instead, it forms directly within the liquid alloy through controlled metallurgical reactions. As a result:

- The TiC particles are fine and size-controlled.

- Their morphology is regular and stable.

- They are uniformly and dispersively distributed throughout the iron-based or steel-based matrix.

- There is no local agglomeration, segregation, or clustering.

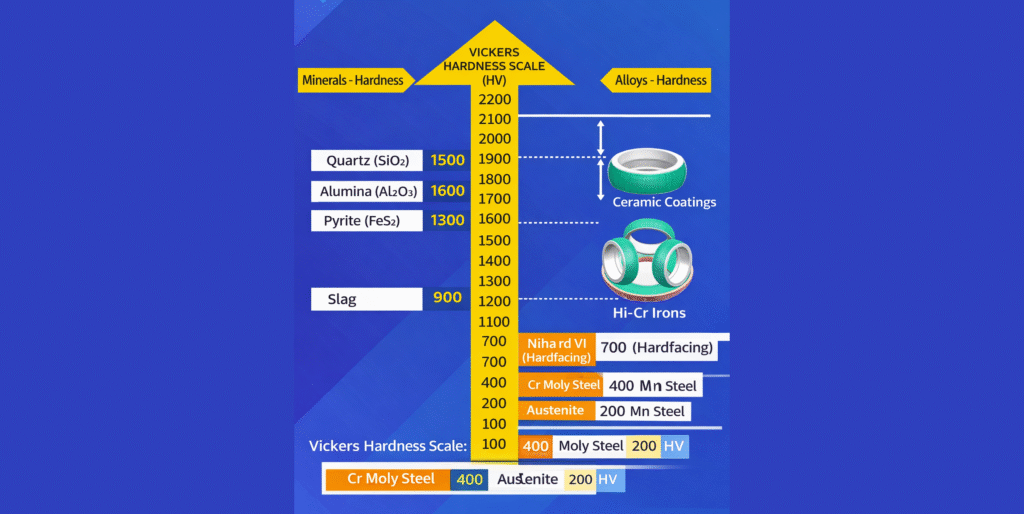

TiC has an intrinsic hardness of approximately 3000 HV, far exceeding conventional wear alloys, high-chromium cast iron, and wear-resistant steels. It acts as a rigid wear-resistant skeleton phase within the structure. Because the TiC particles are formed and fused simultaneously within the molten metal at high temperature, the bonding is metallurgical rather than mechanical. This ensures extremely high wear resistance, uniform wear behavior, and eliminates localized rapid penetration failure.

Magotteaux One-shot Single-Stage Casting – No Secondary Composite Step

Traditional ceramic composite castings are typically manufactured by:

- First producing ceramic blocks or ceramic preforms

- Then pouring molten metal in a secondary casting step to combine them

Such methods often suffer from:

- Weak ceramic-metal interfaces

- Layer separation or delamination

- Non-uniform structure

- Risk of ceramic detachment

The Magotteaux One-shot process is fundamentally different. The entire composite formation occurs within a single casting operation: Molten metal → In-situ TiC formation → Uniform dispersion → Direct solidification into final casting There is:

- No secondary reheating

- No secondary pouring

- No weak bonding interface

- No layered composite boundary

The final structure is continuous, uniform, and metallurgically integrated. This greatly improves structural reliability compared with insert-type or secondary composite designs.

Tough Matrix System: High-Chromium Iron or Martensitic Steel

While TiC provides extreme hardness, it must be supported by a tough metallic matrix to prevent brittle failure under impact loading. Magotteaux commonly employs:

- High-chromium cast iron – high hardness, excellent abrasion resistance

- Martensitic steel – high strength, high toughness, strong impact resistance

The design philosophy is clear:

- TiC provides wear resistance

- The metal matrix provides load-bearing capacity, impact resistance, and crack arrest

The result is the magotteaux composite structure that is externally hard but internally tough wear-resistant without spalling, and impact-resistant without cracking.

Magotteaux In-situ Primary TiC Reinforced Composite Roller

A Primary TiC Reinforced Composite Roll refers to a grinding roller or tyre manufactured entirely using the Magotteaux One-shot TiC composite casting technology. “Primary TiC” means:

- TiC is generated in situ within the melt

- It is not externally inserted

- It is not sprayed

- It is not welded or hardfaced

The reinforcement phase originates inside the molten alloy and bonds metallurgically with the matrix. The magotteaux vertical roller mill embedded ceramic composite casting grinding roller tyre is specifically developed for high-abrasion applications such as cement vertical roller mills, slag grinding mills, and coal mills. The roll adopts a hard-surface and tough-core composite design. Its working layer consists of a TiC-reinforced iron-based composite material that delivers extremely high hardness and exceptional abrasion resistance under severe grinding conditions. Beneath this wear-resistant surface lies a high-strength, high-toughness metallic core designed to absorb impact loads, resist bending stresses, and prevent structural fracture of the roller body. This engineered configuration ensures that the surface remains hard without becoming brittle, while the core retains toughness without sacrificing structural strength. In terms of performance, the working surface typically achieves a hardness of 60–68 HRC, which is significantly higher than conventional high-chromium rollers, ordinary alloy rolls, or weld-repaired components. Because the TiC reinforcement is generated in situ during the One-shot casting process, it is metallurgically bonded to the matrix at the atomic level rather than mechanically attached or “glued” onto the surface. This eliminates the risk of particle detachment or surface delamination during service. The fully integrated composite structure ultimately delivers substantially extended service life, allowing for longer replacement intervals, reduced shutdown frequency, lower spare parts consumption, improved mill availability, and more stable overall productivity.

What is the Vega industry AIA engineering Secondary TiC composite lining process / Two-stage TiC reinforced composite casting?

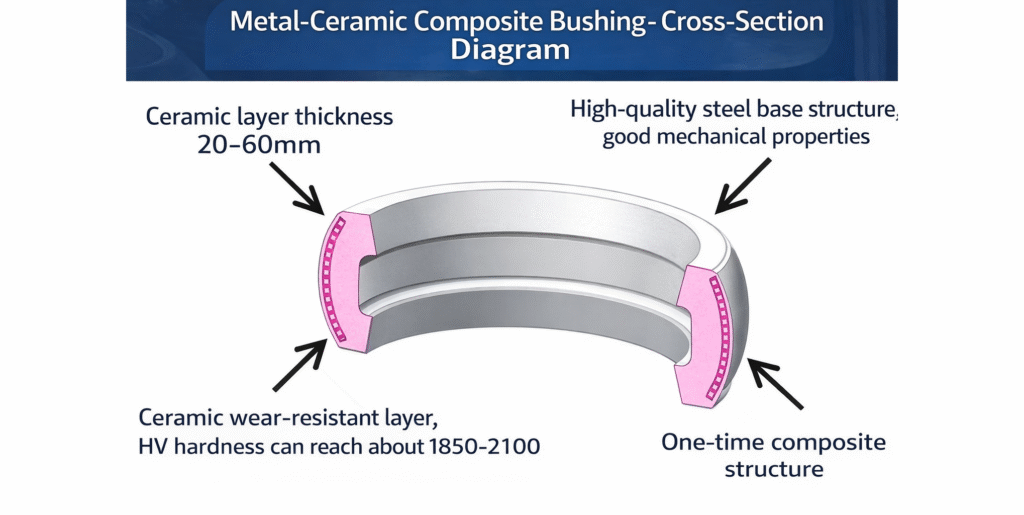

AIA Engineering Limited, through its global brand Vega Industries, has developed a specialized two-stage TiC reinforced composite casting technology for Vertical Roller Mill (VRM) grinding roller sleeves, commonly referred to as roller tyres. This technology is widely known in the industry as the “Two-Stage TiC Composite Process” or “Secondary TiC Reinforced Composite Casting.” It is designed specifically for severe cement and ggbfs slag grinding and coal grinding environments where both extreme abrasion resistance and structural toughness are required. At its core, the technology combines bimetal casting principles with ceramic particle reinforcement. Through two independent pouring stages, it forms a high-wear TiC composite working surface metallurgically bonded to a high-toughness alloy steel substrate. The final product is a fully integrated roller sleeve structure that simultaneously delivers surface hardness and internal strength.

Technical Definition of Vega industry secondary ceramic composite casting

The essence of this secondary ceramic composite casting process lies in its dual-material integration. Unlike conventional single-material castings or weld-overlay rebuilt rollers, the two-stage TiC composite structure is engineered to separate functional requirements within the same component. The outer layer is optimized for wear resistance, while the inner core is optimized for toughness and load-bearing capacity. This approach solves a long-standing metallurgical contradiction in grinding components: materials that are extremely hard typically lack toughness, while materials that are tough enough to absorb impact often sacrifice wear resistance. By dividing these roles into two metallurgically bonded layers, the process achieves performance balance without compromising structural integrity.

First Pouring: Formation of the TiC Reinforced Wear Layer

The first stage of the vega 2 stage TiC-reinforced metal matrix composite casting process focuses on creating the wear-resistant working surface. In the mold cavity corresponding to the roller tyre’s grinding zone, micron-sized titanium carbide (TiC) ceramic particles are pre-arranged or mixed with a metallic binder material. TiC is one of the hardest industrial carbide phases, with a hardness exceeding HV 3000, making it highly resistant to abrasive wear and micro-cutting. During the first pouring, molten wear-resistant alloy—typically high-chromium cast iron or Ni-hard type alloy is introduced into the mold. The high-temperature metal infiltrates and encapsulates the TiC particles, forming a metal matrix composite (MMC) structure. As the alloy solidifies, a reinforced wear layer is created in which TiC particles are uniformly dispersed within a hard metallic matrix. This outer layer becomes the primary grinding surface of the roller sleeve. The microstructure formed at this stage is critical. The TiC particles act as rigid wear-resistant skeletons, significantly reducing abrasive wear, while the surrounding alloy matrix provides structural continuity and impact buffering at the microscopic level.

Second Pouring: Formation of the High-Toughness vrm grinding roller tyre ceramic core

After the ceramic composite wear layer has partially solidified and developed sufficient structural stability, the second pouring begins. In this stage, molten medium-carbon low-alloy steel is introduced into the remaining mold cavity to form the internal body of the roller sleeve. Because the first layer is still at elevated temperature, the newly poured steel forms a metallurgical bond with the pre-formed TiC composite layer. This bonding is not mechanical attachment or shrink fitting; it is true metallurgical fusion at the interface. Once fully solidified, the result is an integrated structure consisting of an outer TiC-reinforced wear layer and an inner high-toughness alloy steel core. The internal steel substrate is engineered to absorb operational stresses, including radial grinding pressure, cyclic fatigue loading, and thermal stress variations. It prevents brittle fracture and enhances overall structural reliability during long-term operation.

Material Characteristics of vrm tyre Pre-cast TiC alloy lining + secondary cast process

The outer working layer of the Pre-cast TiC alloy lining + secondary cast process roller sleeve typically contains a TiC volume fraction ranging from approximately 30% to 50%. The hardness of this composite layer generally falls within HRC 62–68, significantly higher than many conventional high-chromium cast rollers. Due to the presence of dispersed TiC particles, the wear resistance can be two to three times greater than traditional high-chrome cast iron under similar operating conditions. The inner core, composed of medium-carbon low-alloy steel, provides high impact toughness and crack resistance. In heavy-duty Vertical Roller Mill applications, the roller experiences repeated compressive loads and shock forces. The steel core absorbs these stresses and prevents crack propagation from the surface inward. The bonding interface between the two layers is particularly important. Since the connection is metallurgical rather than mechanical, there is minimal risk of delamination or layer separation. This makes the design suitable for the high-pressure and high-impact environment typical of cement clinker and slag grinding.

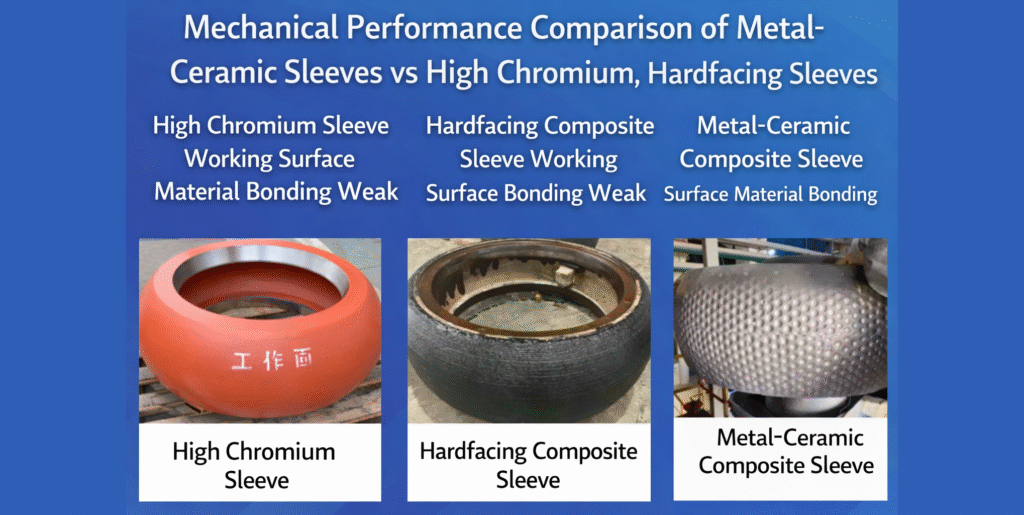

Comparison with Traditional Technologies

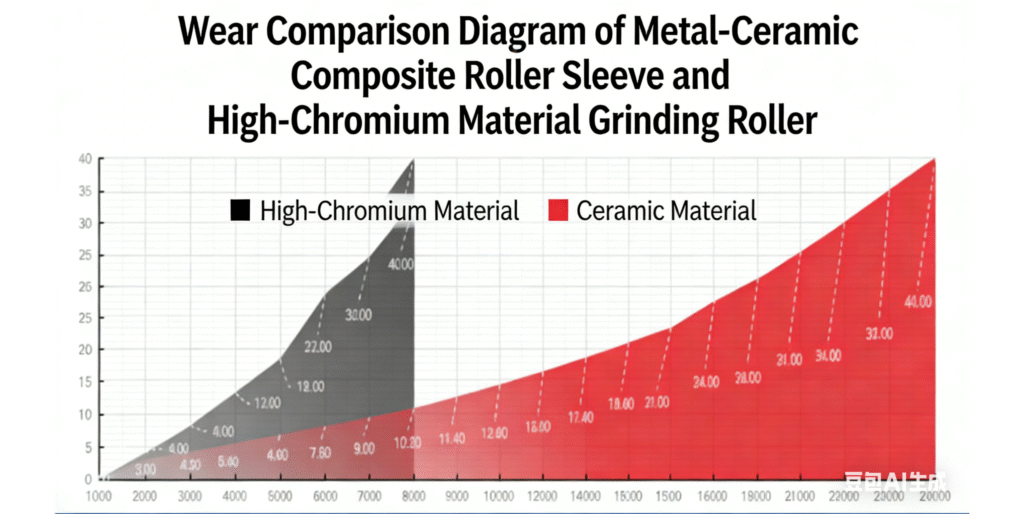

Compared to conventional high-chromium cast roller sleeves, the two-stage TiC composite design offers significantly improved wear life while maintaining structural safety. High-chrome materials can achieve high hardness but are inherently brittle. In contrast, the TiC composite outer layer provides extreme abrasion resistance, while the alloy steel core ensures mechanical durability. When compared to weld-overlay rebuilt rollers, the casting-based two-stage process offers superior consistency and quality control. Weld overlay performance depends heavily on operator skill, dilution control, and thermal management. Variations in welding parameters can lead to uneven hardness or residual stress issues. In contrast, controlled casting allows more stable and repeatable microstructure formation in mass production environments. Additionally, because the base structure is tough alloy steel, worn composite surfaces can still be repaired through secondary weld overlay, extending the overall lifecycle of the component and reducing replacement frequency.

What is the main application difference between Primary TiC reinforced composite roll process and Secondary TiC composite lining process?

For vertical roller mill (VRM) grinding roller tyres, the key application difference is size: for roller diameters below approximately 2.5 meters, the primary (integral) TiC-reinforced composite casting process—commonly associated with solutions such as Magotteaux neoX-type MMC technology—is generally more suitable; for roller diameters above 2.5 meters, the secondary TiC composite lining (insert-type) process—widely promoted by Vega Industries Ltd. under AIA Engineering Ltd.—tends to be more practical. The integral one-step casting method forms a monolithic TiC-reinforced structure with strong metallurgical bonding and high overall structural integrity, which is advantageous for small to medium-sized tyres where solidification control and thermal stress can be effectively managed. However, as diameter increases beyond roughly 2.5 m, the risks of segregation, shrinkage cavities, and thermal cracking in thick-section integral MMC castings rise significantly. In these large-scale applications, the two-stage insert process offers better stress management and manufacturing feasibility by embedding pre-formed TiC composite blocks into a high-chrome base, enabling localized reinforcement while reducing casting risk. Therefore, the main difference is not purely wear performance, but scalability, structural reliability, and production controllability at different size classes.

| Factor | Primary TiC reinforced composite roll | Two-Stage Insert Composite |

| Bonding Type | Fully metallurgical | Mechanical / partial metallurgical |

| Structural Integrity | High | Medium–High (depends on design) |

| Ceramic Distribution | Uniform / gradient | Localized |

| Impact Resistance | Better | Slightly lower |

| Cost Control | Higher initial cost | More flexible |

| Risk of Delamination | Low | Moderate if poorly designed |

Which TiC Composite Process Offers Better Impact Resistance in Slag Grinding?

Overall, for highly abrasive and high-impact applications where ultra-long service life and minimal downtime are critical, the Vega pre-cast TiC alloy lining + secondary cast process is generally preferred. In contrast, for moderate abrasion conditions where cost efficiency and good repairability are priorities, the Magotteaux In-situ TiC ceramic composite casting is often the more suitable solution.

Magotteaux Titanium carbide reinforced composite roll material process

The Magotteaux Titanium carbide reinforced composite roll material process employs a single-pour casting technique in which TiC particles, high wear-resistant alloy phases, and a tough base alloy are simultaneously introduced, mixed, and solidified within the same heat and mold cavity. This results in a functionally graded composite structure characterized by a gradual transition of TiC and hard phases from the working surface toward the core. The process features a relatively short production flow and simplified control requirements, leading to higher manufacturing efficiency, lower production costs, and a comparatively lower rejection rate. The working surface hardness of the roller tyre typically reaches HRC 58–63, with wear resistance approximately 1.5–2 times that of conventional high-chromium cast iron roller tyres. The graded structural transition promotes more uniform stress distribution, improves overall toughness, and allows for subsequent hardfacing repair, thereby reducing total lifecycle cost. This solution is well suited for grinding ordinary cement raw meal, limestone, and other moderately abrasive materials, as well as operating conditions involving moderate impact loads and no extreme requirements for roller toughness.

Vega Industry Metal-Ceramic Composite with TiC reinforcement process

In contrast, the pre-cast TiC alloy lining + secondary cast process utilizes two independent pouring operations. A TiC-reinforced wear-resistant outer layer is cast first; after partial solidification and the formation of a stable TiC-reinforced skeleton, a second pour of high-toughness alloy steel is introduced to form the inner core. The final product exhibits a clearly defined bi-layer structure consisting of a TiC-reinforced composite wear layer bonded to a high-toughness alloy steel substrate. This process requires stricter control of temperature and pouring sequence, involves greater operational complexity, and consequently results in lower production efficiency and higher manufacturing costs. The dual-pour configuration also increases the risk of interfacial casting defects, leading to a relatively higher rejection rate. However, due to the high TiC volume fraction, typically in the range of 30%–50%, the working surface hardness can reach HRC 62–68, and wear resistance can be as high as 2–3 times that of traditional high-chromium cast iron roller tyres. The dedicated high-toughness steel core significantly enhances impact resistance and resistance to spalling or edge chipping. The metallurgical bonding strength between the two layers is high, with no risk of delamination or layer separation. This design is particularly suitable for highly abrasive and high-impact materials such as granulated blast furnace slag, steel slag, and high-SiO₂ raw materials, as well as for large-scale or critical production lines where downtime costs are substantial and operational continuity, reliability, and extended roller service life are prioritized. Nevertheless, repairability is more challenging; the high-TiC wear layer is prone to cracking during welding, making post-service hardfacing repair less compatible compared to roller tyres produced by the Magotteaux one-shot composite process.

Is Insert-Type TiC Composite More Cost-Effective for Large Cement Mills?

In general, for large-scale cement production lines operating under high abrasion, heavy loading, and extremely high downtime costs, insert-type TiC composites tend to offer a stronger economic advantage. Conversely, under relatively moderate operating conditions, limited capital budgets, and where short-term procurement cost is prioritized, their cost-effectiveness is less compelling. The defining feature of insert-type TiC composites is the integration of high-hardness TiC ceramic particles, with a Mohs hardness of approximately 9–9.5 significantly higher than conventional wear-resistant alloys—into a tough metallic matrix through casting-in, embedding, or insert fixation techniques. This results in a composite structure characterized by a highly wear-resistant surface layer supported by a ductile metallic substrate. The wear resistance can reach 1.5 to 3 times that of traditional high-chromium cast iron roller tyres. For large cement plants, this performance differential is particularly significant. As the vertical roller mill serves as the core grinding unit, the replacement frequency of wear components such as roller tyres directly affects production continuity. According to internal audit data from Tongli’s client, UAE Integra Cement, a single unplanned shutdown for roller tyre replacement averages 18.5 hours, with total associated economic losses exceeding USD 200,000. Owing to its extended service life, insert-type TiC composite technology substantially reduces shutdown frequency and replacement intervals, thereby lowering downtime losses, lifting and installation costs, and auxiliary material expenses—this constitutes the primary source of its cost-effectiveness. From a procurement and manufacturing standpoint, insert-type TiC composite roller tyres are significantly more expensive than conventional high-chromium cast iron or standard alloy alternatives. High-performance composite roller tyres are typically priced above USD 10,000 per metric ton, whereas traditional high-chromium cast iron roller tyres cost approximately USD 6,000 per metric ton. The higher upfront investment is therefore a clear disadvantage. However, when evaluated from a total lifecycle cost perspective, large cement plants usually operate vertical roller mills continuously over long production cycles and frequently process highly abrasive materials such as high-SiO₂ raw meal or granulated slag. Under such conditions, conventional wear materials require frequent replacement, and the cumulative cost of repeated procurement, component replacement, and downtime losses may ultimately exceed that of insert-type TiC composites. Furthermore, the optimized combination of high wear resistance and adequate matrix toughness in insert-type TiC composites reduces the risk of spalling, cracking, and material detachment, thereby lowering maintenance and repair costs. This makes them particularly suitable for large cement plants operating under high grinding pressure and high material throughput conditions. However, if the processed material exhibits relatively low abrasiveness, such as ordinary limestone, and the equipment operates under stable load conditions, conventional wear-resistant materials may already meet performance requirements. In such cases, the higher initial cost of insert-type TiC composites may not translate into proportional economic benefits. Additionally, the manufacturing process of insert-type TiC composites is comparatively complex and demands advanced technical capability, and repair operations are more challenging than with conventional alloys. If the cement plant lacks specialized repair expertise and technical support, subsequent maintenance costs may increase, thereby affecting overall economic performance.

How Does Roller Diameter Influence Composite Casting Selection?

Within the industry, a roller tyre diameter of approximately 2.5 m is commonly regarded as a practical threshold for selecting composite casting technology. For roller tyres below 2.5 m, typically used in small to medium-sized vertical roller mills, grinding pressure and stress levels are relatively moderate, and wear demand is less severe. Under these conditions, a single-pour composite casting process is generally sufficient. This method forms a functionally graded structure in one casting operation, offers lower manufacturing cost, and allows for convenient hardfacing repair, making it suitable for grinding ordinary cement raw meal and other moderately abrasive materials while maintaining good economic performance. For roller tyres exceeding 2.5 m in diameter, mainly applied in large-capacity cement grinding systems, the contact area, grinding force, and stress load increase significantly, and large-section castings face greater risks of thermal imbalance and internal defects during solidification. In such cases, a two-stage composite casting process is more appropriate. By separately casting the TiC-reinforced wear layer and the high-toughness alloy steel core, the properties of each layer can be independently controlled. The high-volume TiC outer layer provides superior abrasion resistance with hardness up to HRC 62–68, while the tough inner substrate improves impact resistance and reduces the risk of cracking or spalling under heavy load, better meeting the structural and performance requirements of large-diameter roller tyres. For roller tyres near the 2.5 m range, process selection should be based on actual operating conditions. Moderate abrasion and cost-sensitive projects may favor the single-pour process, whereas high wear severity and reliability requirements justify adopting the two-stage composite solution to balance durability and lifecycle cost.

What Is the Expected Service Life Difference Between the Two Technologies?

In direct technical comparison under equivalent operating conditions, a two-stage TiC composite roller tyre generally provides a longer service life than a single-pour (gradient) TiC composite roller tyre. In cement grinding applications, a single-pour TiC composite typically achieves about 1.2–2 times the service life of conventional high-chromium cast iron. A two-stage TiC composite, due to its higher TiC volume fraction and distinct bi-layer structure consisting of a highly wear-resistant outer layer and a high-toughness alloy steel core, typically delivers a further 10~20% increase in service life over the Magotteaux TiC alloy composite process. In high-wear applications such as slag grinding, the total wear life of a two-stage composite can reach roughly 2 times that of high-chromium cast iron, while single-pour composites generally fall within the lower end of that range. Therefore, as a definitive comparison, the two-stage TiC composite technology provides measurably longer uninterrupted operating life, whereas the single-pour composite offers slightly shorter wear life but retains advantages in manufacturing cost and repairability.

| Material | Typical Bond Work Index (kWh/t) | Magotteaux One-Shot TiC Composite (hrs) | Vega Two-Stage TiC Composite (hrs) | High-Chromium Cast Iron (hrs) | Cast Steel + Hardfacing (hrs) |

| Limestone | 10–14 | 16,000–20,000 | 18,000–22,000 | 12,000–15,000 | 9,000–12,000 (per campaign) |

| Gypsum | 8–12 | 18,000–22,000 | 20,000–24,000 | 14,000–17,000 | 10,000–13,000 (per campaign) |

| Clinker | 14–18 | 12,000–16,000 | 15,000–20,000 | 8,000–10,000 | 6,000–9,000 (per campaign) |

| High-SiO₂ Raw Meal | 16–22 | 9,000–13,000 | 13,000–17,000 | 6,000–8,000 | 5,000–7,000 (per campaign) |

| Phosphate Rock | 15–20 | 10,000–14,000 | 14,000–18,000 | 7,000–9,000 | 5,000–8,000 (per campaign) |

| Granulated Blast Furnace Slag (GBFS) | 18–23 | 8,000–12,000 | 12,000–16,000 | 5,000–7,000 | 4,000–6,000 (per campaign) |

| GGBFS | 20–25 | 7,000–11,000 | 11,000–15,000 | 4,000–6,000 | 3,500–5,500 (per campaign) |

| Steel Slag | 20–26 | 7,000–10,000 | 11,000–15,000 | 4,000–6,000 | 3,500–5,000 (per campaign) |

Which Composite Process Is More Stable Under High Vibration Conditions?

Under high vibration conditions, the vega AIA engineering two-stage TiC composite process is more structurally stable than the Magotteaux single-pour (gradient) composite process. The two-stage design features a clearly defined high-toughness alloy steel core that is independently optimized for impact resistance and fatigue strength, while the high-volume TiC wear layer provides surface hardness. This deliberate separation of functions allows the inner substrate to absorb cyclic stresses more effectively, reducing the risk of crack initiation and propagation under sustained vibration and fluctuating grinding loads. In large vertical roller mills operating with unstable feed size distribution or high grinding pressure, this structure offers better resistance to spalling and edge chipping.

Which Materials Are Suitable for Magotteaux One-Shot Ceramic Composite and Vega Two-Stage TiC Composite VRM Roller Sleeves and why?

Applicable Difficult Materials:

- Quartz Sand

- Spodumene / Lithium Ore

- Slag

- Bauxite

- Coke

- Fluorite / Calcium Fluoride

- Pebbles

- Pyrophyllite

- Coal Gangue

- Corundum

- Talc / Related Soft Silicate Minerals

- Manganese Ore Powder

Why These Materials Require Ceramic Composite Roller Sleeves?

Most of the above materials are classified as high-abrasion or high-hardness minerals, which create severe wear in vertical roller mills. Materials such as quartz sand, corundum, bauxite, and manganese ore contain high levels of silica (SiO₂) or aluminum oxide (Al₂O₃), both of which are extremely abrasive. During grinding, sharp mineral particles continuously cut and micro-plough the roller surface, leading to rapid material loss if conventional high-chromium cast iron or hardfacing layers are used. In addition, materials like slag, pebbles, and coal gangue present a combination of abrasion plus impact stress. Their density and irregular particle size distribution generate cyclic loading on the roller surface. Under such conditions, traditional metal materials may suffer from surface cracking, spalling, or uneven wear. Lithium ore (spodumene), fluorite, and manganese ore often produce hard angular fragments during grinding. These fragments embed into the roller surface and intensify three-body abrasion, accelerating wear rates. Meanwhile, even relatively softer layered minerals like pyrophyllite or talc can create fine abrasive dust, which continuously polishes and thins metallic surfaces over time.

How Should Cement Plants Choose Between Integral and Two-Stage TiC Roller Tyres?

From a VRM cement grinding plant operational perspective, cast steel roller tyres with wear-resistant hardfacing are often considered more economical and practical. The primary advantage lies in maintenance strategy: instead of removing and replacing the entire roller tyre, rebuilding can be performed in situ inside the mill through on-line hardfacing. This eliminates the need for dismantling, lifting, and reinstallation of heavy components, significantly reducing maintenance downtime, crane costs, and labor intensity. As a result, total maintenance expenditure is lower, and production interruption is minimized. For standard cement raw meal and clinker grinding applications, where wear rates are predictable and manageable, cast steel plus periodic hardfacing provides a cost-effective and flexible long-term solution. In contrast, one-shot TiC composite roller tyres (such as Magotteaux’s integral composite technology) and two-stage TiC composite roller tyres (such as Vega’s bi-layer TiC composite design) are more commonly applied in extremely abrasive mineral grinding applications rather than conventional cement raw materials. These include minerals such as pyrophyllite, bauxite, spodumene, manganese ore fines, and quartz sand, where material hardness and silica content are high and the Bond Work Index typically exceeds 25–29 kWh/t, or in certain coal grinding systems where abrasive mineral contamination is significant. Under such severe wear conditions, the service life of traditional cast steel with hardfacing may become too short, making high-volume TiC-reinforced composite structures technically and economically justified. In summary, for most cement plants, cast steel with hardfacing remains the preferred solution due to its maintenance flexibility and lower lifecycle cost, while integral and two-stage TiC composites are better suited to high-hardness, high-abrasion mineral processing environments.

What Factors Affect the Total Cost of Ownership of TiC Composite Rollers?

The total cost of ownership (TCO) of TiC composite roller tyres is determined not only by the initial procurement price but by the combined effect of service life, downtime cost, maintenance strategy, and operational stability over the entire campaign cycle.

- The first major factor is service life under actual operating load. Higher TiC volume fraction and optimized composite structure generally extend wear life, directly reducing replacement frequency. Longer campaign duration lowers the number of shutdowns required over several years, which significantly impacts lifecycle economics.

- The second critical factor is downtime cost per replacement event. In large vertical roller mills, roller change-out may require mill stoppage, lifting operations, reassembly, and recommissioning. Lost production during shutdown often represents the largest single cost component, frequently exceeding the material cost of the roller itself. Technologies that extend uninterrupted operating hours therefore reduce indirect production losses.

- The third factor is repairability and rebuild strategy. Some TiC composite structures are more compatible with hardfacing repair, while high-volume TiC layers may be more crack-sensitive during welding. If refurbishment is difficult or limited, full replacement may be required, increasing long-term capital expenditure.

- Another important element is structural reliability under vibration and impact loading. Crack resistance, metallurgical bonding strength, and core toughness affect the risk of premature failure such as spalling or structural fracture. Unexpected failure dramatically increases total ownership cost due to emergency downtime.

- Manufacturing quality and defect rate also influence TCO. Large-section composite castings require precise control of solidification and bonding; internal defects, interfacial discontinuities, or uneven TiC distribution can shorten service life and negate theoretical wear advantages.

Is Higher Ceramic Content Always Better in VRM Roller Tyres?

For vertical roller mill (VRM) roller tyres, a higher ceramic content is not inherently better. The fundamental reason is that VRM roller tyres must simultaneously achieve wear resistance, toughness, and metallurgical bonding strength. Excessive ceramic content disrupts the balance among these three properties, potentially reducing overall service life and operational reliability while increasing production cost and failure risk.

Ceramic Content Is Not Proportional to Performance

For vertical roller mill (VRM) roller tyres, a higher ceramic content does not automatically result in better performance. The roller tyre must simultaneously satisfy requirements for wear resistance, toughness, and metallurgical bonding strength. Excessive ceramic addition disrupts the balance among these three critical properties, potentially reducing overall service life, structural reliability, and economic efficiency while increasing the risk of premature failure.

Role of TiC as the Primary Wear-Resistant Phase

Titanium carbide (TiC) is the most commonly used ceramic reinforcement phase in composite VRM roller tyres. With a Mohs hardness of approximately 9–9.5, TiC significantly enhances abrasion resistance. However, ceramics are inherently brittle and exhibit limited fracture toughness. In addition, their wettability and interfacial bonding compatibility with metallic matrices are naturally constrained. When the TiC volume fraction is maintained within a typical range of 30%–50%, particles can be uniformly dispersed throughout the metal matrix. In this balanced configuration, TiC provides effective resistance to abrasive wear, while the ductile metallic substrate absorbs operational impact and cyclic stresses, maintaining structural integrity and preventing spalling or cracking. This range reflects the commonly adopted ceramic fraction in mainstream composite casting technologies.

Mechanical and Structural Risks of Excessive Ceramic Content

When ceramic content exceeds approximately 50%, several negative effects may emerge. The overall toughness of the roller tyre decreases significantly due to the increased proportion of brittle phases, making it more susceptible to crack initiation and propagation under high grinding pressure and vibration. Excessive ceramic concentration may also impair metallurgical bonding and matrix infiltration, leading to porosity, weak interfaces, or delamination. Detached ceramic particles can further intensify wear between the roller and grinding table, accelerating damage rather than improving durability.

Manufacturing, Machining, and Repair Challenges

Higher ceramic content substantially increases manufacturing complexity and cost. High-performance TiC particles are expensive, and elevated fractions raise raw material expenses. Large composite castings with excessive ceramic content are more prone to uneven heat dissipation, shrinkage stress, and interfacial defects, which may increase rejection rates. Furthermore, extremely high hardness complicates post-casting machining and finishing. In-service repair becomes more difficult, as high-ceramic structures are more susceptible to cracking during welding, often limiting refurbishment options and necessitating complete replacement.

Matching Ceramic Content to Roller Diameter and Operating Load

Ceramic volume fraction must also correspond to roller diameter and operational stress conditions. Large-diameter roller tyres, especially those exceeding 2.5 meters and operating under high grinding forces, demand greater core toughness to withstand elevated mechanical stress. In moderate-abrasion applications, excessive ceramic reinforcement represents over-engineering and does not provide proportional lifecycle value, leading to unnecessary cost escalation.

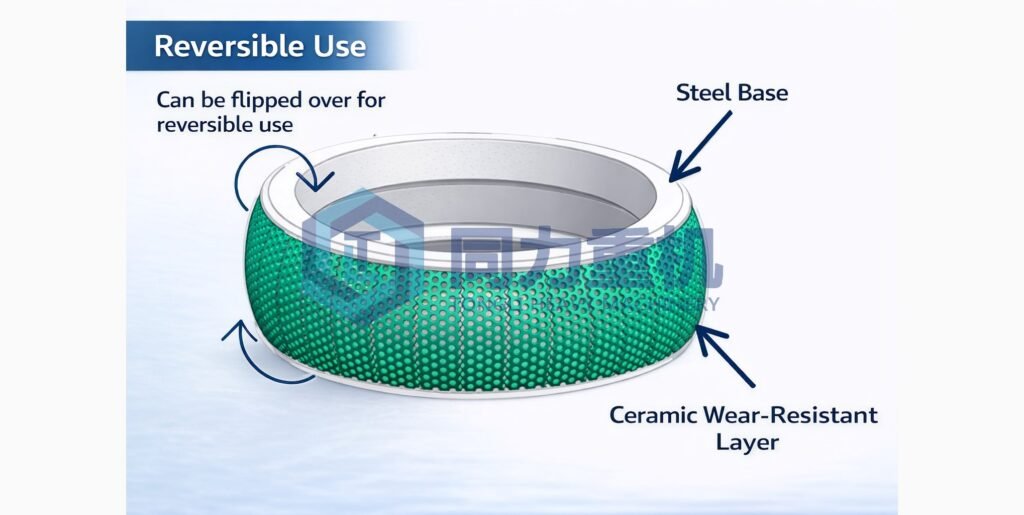

Does One-Shot MMC Casting Provide Lower Maintenance Frequency?

One-shot MMC (Metal Matrix Composite) casting generally provides lower maintenance frequency, primarily because the ceramic reinforcement (such as TiC) is integrally bonded into the metal matrix during a single casting process. This creates a fully metallurgical composite structure with no mechanical interfaces or secondary bonding zones. As a result, the working layer exhibits extremely high wear resistance, stable hardness distribution, and strong impact resistance. In real operating conditions, this typically leads to longer continuous service cycles and fewer shutdowns for repair or surfacing. However, when discussing ceramic composite roller tyres, it is essential to clarify an important limitation. Although ceramic-reinforced tyres often provide a longer wear life compared to traditional high-chromium cast iron or hardfaced cast steel, they are generally non-repairable. The ceramic phase cannot be re-welded, resurfaced, or rebuilt once it is worn out or damaged. Unlike conventional hardfacing rollers that can be repeatedly rebuilt through welding, ceramic composite tyres are essentially a one-time wear component. Even if the roller tyre is designed to be reversible (flippable for use on both sides), once the ceramic working layer is exhausted or fractured, the entire tyre must be replaced as a whole unit. There is no practical on-site refurbishment solution. This means that while maintenance frequency may be lower during operation, the replacement cost at end-of-life is significantly higher compared to rebuildable designs.

FAQ: Frequently Asked Questions about Ceramic Metal Composite Grinding Roller/ Table Liners

Single-stage TiC composite casting (such as the process used by Magotteaux) adopts a one-shot pouring method in which TiC particles and a tough alloy matrix solidify simultaneously during a single casting operation, forming a functionally graded composite structure. The process is relatively straightforward, manufacturing cost is lower, and it provides a balanced combination of baseline wear resistance and toughness, making it suitable for medium- to lower-load operating conditions. In contrast, the dual-stage TiC reinforced composite process (such as the technology promoted by Vega Industries) utilizes two independent casting stages: first forming a high-TiC-content, ultra-high-hardness wear-resistant outer layer, followed by pouring a high-toughness metallic substrate to create a clearly defined layered structure. This configuration delivers superior abrasion resistance and impact toughness, but involves greater process complexity and higher manufacturing cost, making it more suitable for high-abrasion, high-load applications—particularly for roller diameters above 2.5 meters.

The choice ultimately depends on operating load conditions and cost-performance balance: integral MMC features uniformly distributed TiC particles throughout the entire roller tyre matrix, providing process continuity, high overall structural integrity, and no interfacial bonding defects; it is well suited for medium-to-low abrasion and moderate load conditions, offering balanced wear resistance, reasonable cost, and relatively straightforward maintenance management. In contrast, insert-type TiC composite incorporates high-TiC-content wear blocks embedded into the roller working surface, delivering more aggressive wear resistance and allowing targeted reinforcement of high-wear zones; it is better suited for high-abrasion, high-load applications—particularly large-diameter roller tyres above 2.5 m—but involves greater manufacturing complexity, higher cost, and requires careful control of bonding stability at the insert interfaces over long-term operation.

A 2.5-meter diameter is widely regarded as the critical threshold for composite casting of VRM grinding roller tyres, representing a combined inflection point in casting process capability, material performance, structural mechanics, and equipment matching. Once the diameter exceeds 2.5 m, molten metal filling behavior and solidification control become significantly more challenging, increasing the risk of shrinkage cavities, porosity, segregation, and inadequate bonding within the composite layer. The casting’s self-weight and centrifugal forces rise sharply, placing greater demands on mold rigidity, gating system design, and heat-treatment fixtures. At the same time, during operation, bending stress and contact fatigue stress in the roller shell increase nonlinearly, making it more difficult to maintain an optimal balance between wear resistance and toughness. Large-diameter tyres above 2.5 m are typically installed on heavy-duty VRMs operating under higher grinding pressure and more severe abrasive conditions, where bonding strength, anti-spalling performance, and structural uniformity of the composite layer become critical quality bottlenecks. In contrast, diameters at or below 2.5 m remain within the maturity range of current composite casting technologies—including one-shot MMC systems such as those associated with Magotteaux

One-shot TiC composite (integral MMC) can be applied to large-diameter VRM rollers, but its suitability decreases as diameter and load increase—particularly beyond the widely recognized ~2.5 m threshold. In large castings, molten metal filling control, TiC distribution uniformity, and solidification stress management become significantly more difficult, which can affect composite layer consistency and internal soundness. While one-shot systems such as those used by Magotteaux offer good structural continuity and balanced wear–toughness performance, in very large rollers operating under high grinding pressure and severe abrasion, maintaining uniform reinforcement and long-term fatigue resistance becomes more challenging. Therefore, one-shot TiC composite is technically feasible for large diameters, but for extreme-duty, heavy-load VRMs (especially >2.5 m), process capability, quality control level, and operating conditions must be carefully evaluated before selection.

For large-scale VRM roller tyres with diameters exceeding 2.5 meters, the Two-Stage TiC Insert Process is often preferred because ultra-large composite castings are prone to uneven solidification, interfacial bonding defects, and instability in wear-layer performance when produced through integral composite casting. The two-stage approach allows the roller shell substrate to be cast and heat-treated independently to ensure structural integrity and mechanical reliability, followed by precise embedding of high-hardness TiC inserts to reinforce the working surface. This method effectively mitigates risks associated with internal stress, distortion, and casting defects inherent in single-pour large-diameter composite castings, while enabling localized ultra-high wear resistance in high-abrasion zones. As a result, it enhances service life and operational stability, significantly reduces rejection rates for oversized castings, and lowers overall lifecycle cost—making it the most stable and cost-effective reinforcement solution for VRM roller tyres above 2.5 meters in diameter.

In TiC composite roller tyres, the essential difference between metallurgical bonding and mechanical insert bonding lies in the bonding mechanism and interface integrity. Metallurgical bonding is achieved during a single casting operation, where the TiC reinforcing phase—either formed in situ or pre-added—is integrated into the molten alloy and solidifies simultaneously with the metallic matrix. Through atomic diffusion and interfacial reaction, a continuous metallurgical bond is formed without stratification or distinct physical boundaries; the interface is diffusion-bonded, with no inherent weak plane. In contrast, mechanical insert bonding belongs to a two-stage casting process: pre-fabricated TiC or ceramic blocks are first positioned, and molten base metal is subsequently poured to secure them through solidification shrinkage, mechanical interlocking, anchoring geometry, and limited local fusion. A clear physical interface remains between the insert and substrate, meaning the structure is not fully metallurgically integrated. Consequently, the two approaches differ significantly in interface bonding mechanism, stress transfer mode, and long-term resistance to spalling or delamination under cyclic grinding loads.

First, thermal gradient stress becomes severe in thick-section castings. During solidification and cooling, the surface cools much faster than the core, creating significant temperature differentials. This can generate high internal tensile stresses, increasing the risk of hot cracking, solidification cracking, or delayed stress cracking after shakeout.

Second, CTE mismatch stress (coefficient of thermal expansion mismatch) between the TiC reinforcement and the metallic matrix is amplified in large components. TiC has a much lower thermal expansion coefficient than the iron or steel matrix; during cooling from casting or heat treatment temperatures, differential contraction can produce localized interfacial stress, potentially initiating microcracks within the composite layer if stress relief is insufficient.

Third, residual stress accumulation becomes more difficult to control as diameter increases (particularly beyond ~2.5 m). Large mass castings retain heat longer, making uniform heat treatment challenging. Non-uniform quenching or tempering can lead to distortion, hardness variation, and tensile residual stress concentration in the wear layer.

Fourth, operational thermal cycling stress is more critical in large VRMs. Under heavy grinding pressure, frictional heat combined with cyclic loading may exacerbate pre-existing residual stresses, increasing the long-term risk of spalling or fatigue cracking in the composite zone.

Yes—under thick-section conditions, a Two-Stage TiC composite process can significantly reduce shrinkage and cracking risk compared with large integral MMC castings. The key reason is that the roller substrate is cast and heat-treated independently as a conventional alloy steel or ductile iron structure, allowing optimized feeding design, riser efficiency, and solidification control without the complexity of simultaneously managing a high-TiC composite melt. This reduces the likelihood of shrinkage cavities, porosity, and solidification cracking in heavy sections. The TiC wear layer or inserts are then integrated in a controlled secondary step, which minimizes large-volume composite solidification stresses and limits coefficient-of-thermal-expansion (CTE) mismatch effects to localized regions rather than the entire cross-section. As a result, internal residual stress accumulation, distortion, and thermal cracking risk are generally lower in very thick or large-diameter components—particularly above ~2.5 m—provided that insert anchoring design and interfacial bonding quality are properly engineered.

The distribution of TiC alloy composite within a VRM grinding roller directly determines wear uniformity, stress transfer behavior, and ultimately service life. When TiC particles are uniformly dispersed throughout the working layer (as in integral MMC structures), the contact surface maintains consistent hardness and abrasion resistance across the grinding track, reducing localized wear bands and minimizing differential profile loss. This promotes stable grinding pressure distribution, lowers vibration, and slows fatigue crack initiation. In contrast, if TiC distribution is uneven—such as clustering, segregation during solidification, or hardness gradients—localized over-hard zones can generate stress concentration while under-reinforced zones wear faster, leading to profile distortion and accelerated overall wear. For insert-type or locally reinforced designs, targeted TiC placement in high-wear zones (typically the outer grinding track) can significantly extend wear life under severe abrasion; however, the transition zones between reinforced and non-reinforced areas must be carefully engineered to prevent stress discontinuity or spalling. In large-diameter rollers, maintaining controlled TiC distribution becomes more critical because load and contact pressure increase nonlinearly with size.

The common failure modes of integral (one-shot MMC) TiC rollers and insert-type TiC rollers differ primarily due to their bonding structure and stress distribution characteristics. For integral TiC composite rollers, typical failure modes include:

1. Gradual wear-out of the composite layer, where the TiC-reinforced zone is uniformly consumed until the matrix is exposed and wear rate accelerates.

2. Thermal or solidification-related cracking, particularly in large-diameter castings where residual stress or CTE (coefficient of thermal expansion) mismatch between TiC and the metal matrix induces microcracks.

3. Fatigue cracking within the composite layer, usually initiating from casting defects (porosity, segregation) rather than from interfaces, since no distinct insert boundary exists.

Failure in integral structures is generally progressive and predictable, rarely involving sudden material detachment.

For insert-type TiC rollers, the most common failure modes include:

1. Insert debonding or pull-out, caused by insufficient anchoring strength or long-term cyclic shear stress at the insert–matrix interface.

2. Edge spalling at insert boundaries, where stress concentration occurs due to stiffness mismatch between ultra-hard inserts and the tougher substrate.

3. Localized differential wear, if insert distribution is uneven or transition zones are not well engineered.

4. In severe cases, interface cracking propagation, which may lead to partial detachment of reinforced segments.

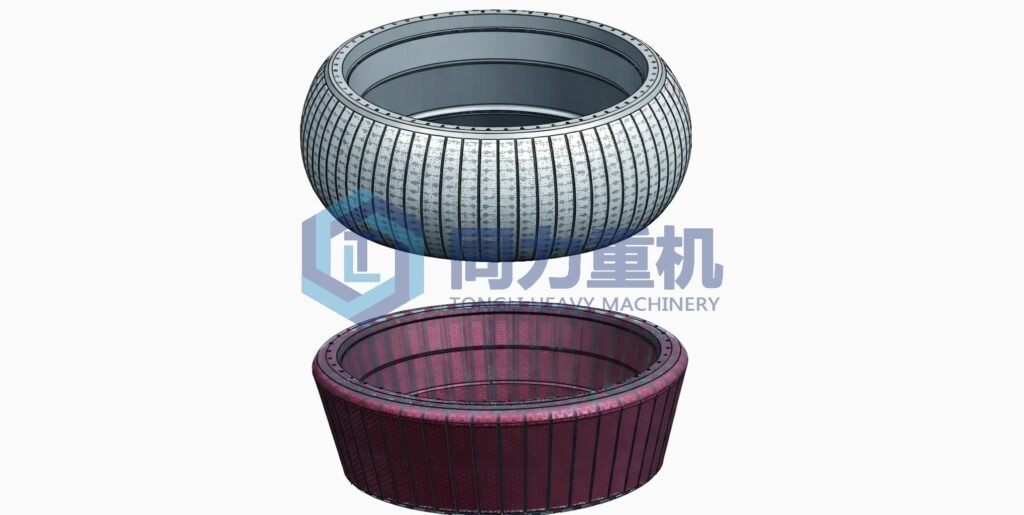

A ceramic composite lining vertical roller mill (VRM) grinding roller tyre is typically manufactured either through an integral MMC casting process or a two-stage insert process: in the integral method, TiC or ceramic-reinforced phases are formed in situ or pre-added into the molten alloy during a single controlled pouring operation, where the ceramic phase and metal matrix solidify simultaneously to create a metallurgically bonded, wear-resistant working layer over a tough core structure; strict control of melt chemistry, temperature, mold design, and cooling rate ensures uniform ceramic distribution and minimizes segregation or porosity, followed by heat treatment to optimize hardness–toughness balance and final precision machining of mounting surfaces. In the insert-type process, the roller substrate is first cast and heat-treated as a high-strength alloy steel or ductile iron body, after which pre-fabricated high-hardness ceramic or TiC inserts are accurately positioned in the wear zone and secured through secondary casting or metallurgical anchoring, creating a reinforced working surface with localized ultra-high abrasion resistance before final machining and dynamic balance verification.

Yes, vertical roller mill (VRM) grinding tables (grinding discs) can also be manufactured using metal–ceramic composite structures with TiC reinforcement, although this is less common than for roller tyres. In such designs, a TiC-reinforced wear layer is either integrally cast as a metal matrix composite (MMC) or locally reinforced through insert-type ceramic blocks embedded in the table surface. The purpose is to improve abrasion resistance in high-wear zones, particularly when grinding highly abrasive materials such as slag, quartz sand, manganese ore, or certain non-metallic minerals. However, because the grinding table experiences different stress distribution compared to rollers—more compressive loading and less bending stress—the economic justification for full-surface TiC composite reinforcement depends on mill size, feed abrasiveness, and maintenance strategy. In many cement applications, hardfacing welding remains more common for tables due to repair flexibility, whereas TiC composite solutions are typically selected for severe-duty or mineral grinding environments.

To replace a TiC-reinforced composite segmented roller tyre liner in a vertical roller mill, shut down and isolate the mill, lift the roller assembly into the maintenance position, remove the clamping ring and fastening bolts, and take out the worn segments. Clean and inspect the mounting surfaces for damage or deformation, then position the new TiC composite segments correctly on the roller body. Tighten the bolts evenly to the specified torque to ensure uniform load distribution and proper seating. After reassembly, check alignment and perform a slow trial rotation before restarting the mill. Since TiC composite liners cannot be repaired or hardfaced, replacement is the only maintenance method once the wear layer is consumed.

Inspection of a TiC-reinforced metal–ceramic composite VRM grinding roller liner tyre includes dimensional measurement (outer diameter, width, profile wear depth, and mounting tolerances), surface and cross-section hardness testing (usually Rockwell or Brinell to verify wear layer consistency), and microstructural or compositional analysis using spectrometry to confirm alloy chemistry and TiC content. Additional checks may include ultrasonic or dye penetrant testing for internal defects or surface cracks, ensuring the composite layer integrity and bonding quality meet design specifications before or during service.

High Chrome refers to high-chromium white cast iron (typically 18–30% Cr) produced by conventional casting. It offers high hardness (commonly 58–65 HRC) and good abrasion resistance due to the presence of hard chromium carbides (M7C3). It is widely used in cement and mining applications for grinding media and mill liners where wear resistance is important but extreme impact resistance is not the primary requirement. In-situ TiC ceramic composite casting

SinterCast is a TiC-reinforced metal matrix composite or controlled-solidification casting technology that improves carbide distribution and microstructural uniformity compared to standard high-chrome castings. The process enhances wear resistance and structural consistency, reducing porosity and segregation, making it suitable for more demanding abrasion conditions.

V-Cast is a more advanced composite casting solution, often associated with ceramic or TiC-reinforced technology, where ultra-hard wear phases are integrated into or embedded within the metallic matrix. This product line targets severe-duty applications such as large VRM grinding rollers and tables operating under high load and high abrasion, offering extended service life compared to conventional high-chrome materials.

Why our Tongli’s Ceramic TiC Composite Casting Vertical Grinding Roller Tyre Comparable to Magotteaux and Vega and even better?

Superior Crack Resistance – Impact Toughness AK > 7 J

Tongli’s ceramic TiC composite vertical grinding roller tyre demonstrates outstanding crack resistance, with impact toughness (AK value) exceeding 7 Joules, which is above the general domestic benchmark for high-chromium cast iron. Through a proprietary casting stress-relief and micro-crack elimination process, residual internal stresses generated during solidification are effectively minimized. This significantly reduces the risk of crack initiation and propagation during operation, especially under cyclic loading and high grinding pressure conditions typical in vertical roller mills.

Strong Metallurgical Bonding – Anti-Spalling Performance

Tongli utilizes a mature metallurgical bonding casting process to ensure effective fusion between the molten metal matrix and the ceramic alloy preform (TiC reinforcement phase). Unlike mechanical embedding methods, this metallurgical integration creates a stable interfacial bonding structure, reducing the risk of ceramic phase detachment or spalling during operation. As a result, the ceramic reinforcement remains firmly anchored within the working layer, allowing the wear-resistant phase to perform at its full potential and ensuring stable long-term operation.

Enhanced Wear Resistance – Ceramic Roller Tyre Hardness HRC 57–62

Through a specialized heat treatment process, Tongli ensures that the ceramic composite roller tyre achieves a working hardness of HRC 57–62 while maintaining structural toughness. This optimized hardness range provides strong resistance against abrasive wear from high-silica and high-alumina materials, without compromising crack resistance. Compared with conventional high-chromium cast iron products in the same category, Tongli’s ceramic composite liner and roller tyre offer improved wear stability, reduced profile deformation, and extended service life under demanding grinding conditions.

How does Tongli help customers reduce procurement costs through recycling used roller tyres and liners?

Tongli supports customers in reducing re-purchase costs by collecting and recycling used metal-ceramic VRM roller tyres and liners manufactured with one-piece casting technology, consisting of a high-chromium cast iron substrate and a ceramic wear-resistant layer. After the components reach the end of their service life, Tongli recovers the worn parts and reuses the valuable high-chromium alloy material through controlled remelting and material optimization processes. By crediting the residual material value back to the customer, Tongli can help reduce the cost of new replacement roller tyres and liners by approximately 15%, while also lowering overall lifecycle cost and promoting sustainable manufacturing practices.

5 Reasons to Choose a Ceramic TiC-Reinforced Composite Vertical Roller Mill Grinding Roller Tyre

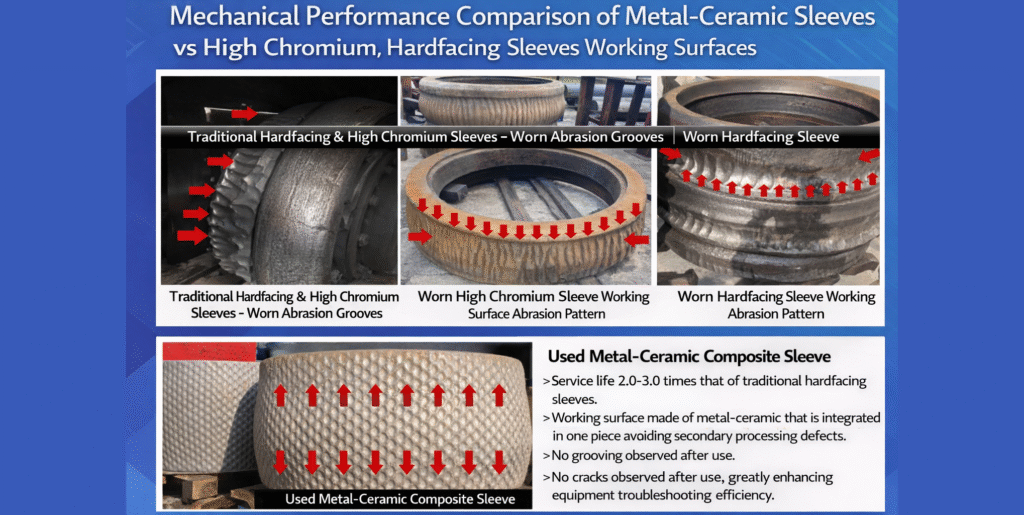

Ceramic composite roller tyres offer a service life that is 2.0–3.0 times longer than conventional hardfacing or high-chromium roller tyres

Traditional hardfaced overlays and high-chromium cast iron rollers typically exhibit a hardness of approximately 650 HV, whereas the ceramic alloy reinforcement phase achieves a microhardness range of 1850–2100 HV. This substantial increase in hardness significantly enhances resistance to abrasive wear. As a result, the advanced ceramic composite material delivers two to three times the operational lifespan of conventional materials. The extended single-service cycle helps enterprises reduce downtime, disassembly frequency, labor requirements, consumable usage, spare parts consumption, and overall maintenance costs.

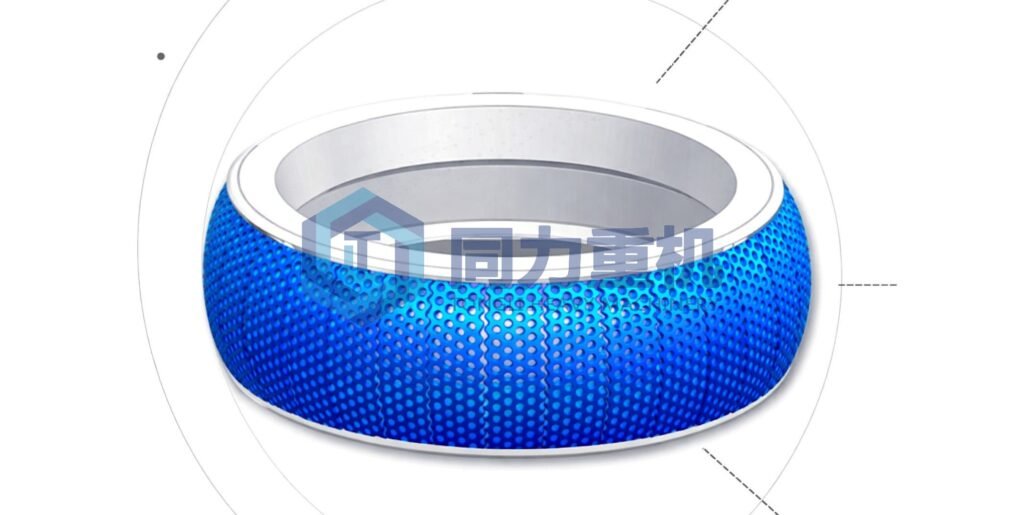

optimized surface design can increase hourly production capacity by approximately 7%.

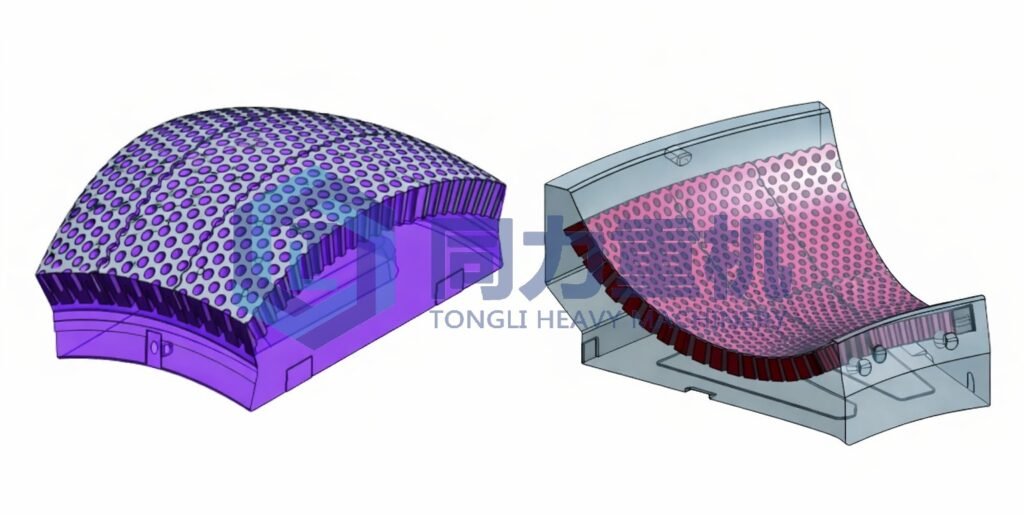

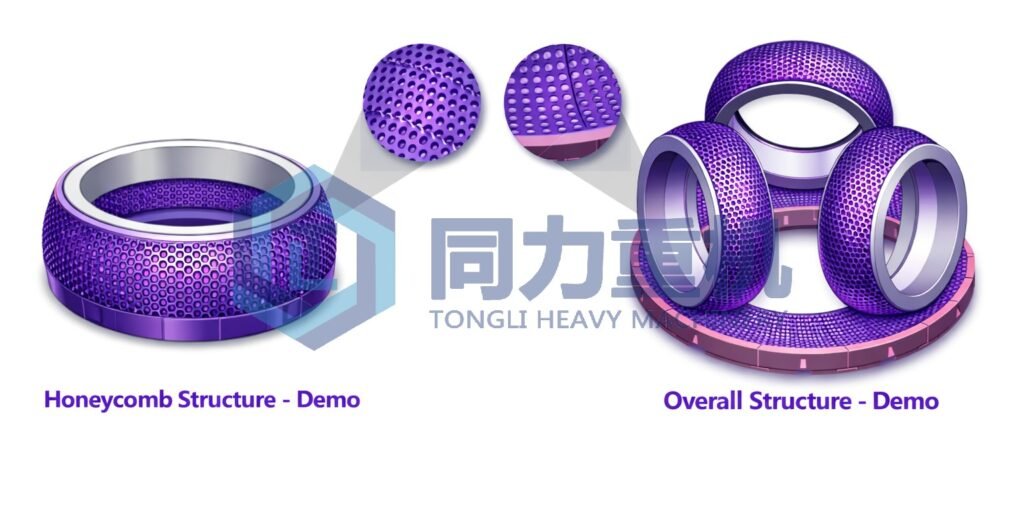

The ceramic composite roller tyre features a honeycomb-structured grinding surface, which increases the effective grinding contact area and improves material interlocking. This engineered surface geometry enhances the gripping force between the roller and the feed material, resulting in more stable mill output and improved grinding efficiency. Under identical operating conditions, the optimized surface design can increase hourly production capacity by approximately 7%. In contrast, conventional high-chromium roller tyres and hardfaced composite rollers typically have relatively smoother working surfaces, leading to weaker material engagement during the grinding process. The enhanced interlocking effect of the ceramic composite roller not only improves comminution efficiency but also stabilizes bed formation within the vertical roller mill, contributing to higher throughput and more consistent operational performance.

Improved grinding area stability, reducing mill power consumption by 10% kWh/t

The ceramic composite roller tyre and liner are engineered with a highly wear-resistant ceramic working layer that maintains the stability of the grinding profile throughout the entire service life. Due to its superior abrasion resistance and structural integrity, the grinding curve and effective contact area remain consistent even in the later stages of wear. This ensures stable mill output over time and enables a measurable reduction in specific power consumption of approximately 10% kWh per ton. By maintaining a stable grinding geometry, the mill operates more efficiently and avoids the progressive energy increase typically seen with conventional materials.

In contrast, traditional hardfaced overlays and high-chromium cast iron roller tyres tend to experience uneven wear after extended operation. Surface deformation such as grooves, ploughing marks, and localized depressions reduces the effective grinding area and disrupts material bed stability. These irregularities increase vibration levels, raise main motor current, and ultimately lead to higher energy consumption per ton of product.

After wear, the ceramic composite roller tyre continues to deliver stable performance. Its service life is 2.0–3.0 times longer than conventional hardfaced or high-chromium rollers. The working zone consists of a metal-ceramic composite structure that can be reversed once during its lifecycle, allowing dual-side utilization. Only one reversal is required throughout the entire service period. Even in the advanced wear stage, mill output does not decrease, no ploughing grooves are formed, vertical mill vibration does not increase, and the main motor current remains stable—ensuring that overall power consumption does not rise over time.

Ceramic composite roller tyres offer an extended single-service lifespan

Ceramic composite roller tyres offer an extended single-service lifespan, enabling enterprises to optimize maintenance scheduling and avoid peak production interruptions. Due to their superior wear resistance and structural stability, spare part degradation is significantly reduced, ensuring consistent mill output over long operating cycles. The grinding capacity remains stable without the frequent performance decline commonly associated with conventional materials, allowing production planning to be more predictable and efficient.

In contrast, traditional hardfaced or high-chromium roller tyres experience faster wear, which can lead to insufficient mill output, reduced hourly capacity, and unplanned shutdowns. These interruptions often require maintenance stoppages, component disassembly, spare part replacement, additional labor, and may even cause delivery delays. The cumulative effect of these factors increases operational expenditure.

By extending maintenance intervals, reducing unplanned downtime, and stabilizing production efficiency, ceramic composite roller tyres can help enterprises lower total annual operating costs by up to 30%, particularly in high-capacity continuous production environments. Of course the cost is the biggest concern of the owner therefore we are going to elaborate more here:

Ceramic VRM Roller Tyre vs Hardfacing: Real Cost Saving Data from ZGM95G & HRM2800S Mills

Case 1 – ZGM95G Vertical Mill (24,000 Operating Hours)

- Industry: Thermal Power Generation

- Application: Hardfaced Roller Tyres – Operating Data from a Coal-Fired Power Plant

For a ZGM95G vertical mill operating approximately 24,000 hours, the conventional hardfaced roller tyre solution resulted in the following cost structure:

- Hardfacing application cost: approximately USD 170,000

- Three major maintenance and inspection cycles: approximately USD 270,000

- Energy consumption savings achieved after optimization: approximately USD 150,000

By improving wear stability, reducing maintenance frequency, and lowering power consumption, the total cost reduction per single mill unit was approximately USD 250,000. For a power generation unit operating five identical mills, the total cost savings reached approximately USD 1,250,000 per unit set. This case demonstrates that extended wear life and stable grinding performance significantly reduce maintenance expenditure and energy cost in long-cycle continuous operation environments.

Case 2 – HRM2800S Vertical Mill (1-Year Operation)

- Industry: Thermal Power Generation

- Application: Hardfaced Roller Tyres – Operating Data from a Coal-Fired Power Plant

For an HRM2800S vertical mill operating over a one-year period, the conventional hardfaced roller tyre solution showed the following annual cost profile:

- Hardfacing and application cost: approximately USD 380,000

- Three maintenance service interventions: approximately USD 90,000

- Energy consumption savings achieved after wear optimization: approximately USD 350,000

The total annual cost reduction per mill was approximately USD 300,000. Over a three-year operating period, the cumulative cost savings reached approximately USD 900,000 per mill. This case highlights how improved wear resistance, reduced downtime, and stabilized grinding efficiency directly contribute to long-term operational savings in high-capacity thermal power plant applications.

Six Advantages of Metal-Ceramic Composite Roller Liners as Replacements for Cast Welded Roller Liners

1. The service life can be extended by 2–3 times.

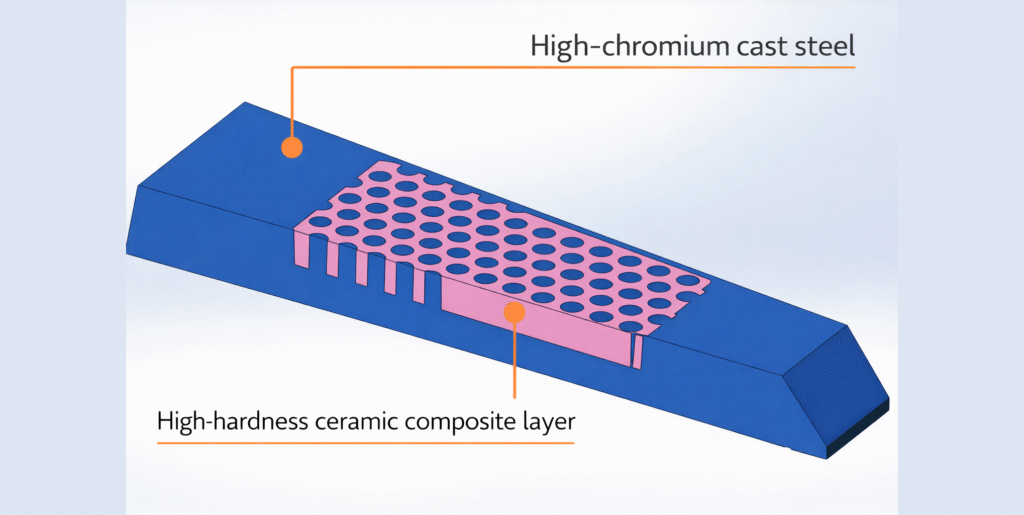

In pulverized coal or raw coal applications, the maximum hardness of certain hard inclusions can reach approximately 1800 HV, while conventional high-chromium cast iron typically has a Vickers hardness of around 700 HV. ZTA (Zirconia-Toughened Alumina) ceramic particles, with a particle size range of 1–3 mm, are incorporated onto the surface of high-chromium grinding rollers or liners using a composite casting process. Through this metal–ceramic composite casting technology, a reinforced composite layer with a thickness exceeding 70 mm is formed. The ceramic phase achieves a hardness of approximately 2100 HV, which is significantly higher than that of conventional high-chromium cast iron. As a result, the overall wear resistance is substantially improved, and the service life reaches 2–3 times that of traditional high-chromium cast iron components.

2. Improvement of Late-Stage Mill Output and Pulverizing Efficiency

ZTA metal–ceramic composite roller sleeves and liners feature a specially engineered honeycomb-structured ceramic grinding layer, which increases the friction coefficient between the grinding surface and the material bed. During operation, this structure helps maintain the original surface profile and smooth geometry of the roller sleeve and liner over an extended service period. As a result, improved contact and stable matching between the grinding roller and liner are maintained, ensuring more consistent mill output throughout the lifecycle. Particularly in the later stages of operation, when conventional high-chromium components typically suffer from significant wear and reduced performance, this composite structure can improve grinding efficiency by more than 15%.

3. Energy Saving and Emission Reduction (Vertical Roller Mill Power Consumption Reduced by 1 kWh/t)

The ZTA metal–ceramic composite material adopts a specially engineered negative-pressure infiltration composite casting process, which ensures that the wear profile of the roller and liner working surfaces remains smooth throughout the entire service life. This stable wear curve maintains sufficient effective grinding area, allowing mill output to remain consistently stable over long operating periods. Even in the later stages of wear, the mill can sustain normal production capacity, thereby effectively reducing specific energy consumption. Field application data indicate that, compared with conventional high-chromium roller sleeves, metal–ceramic composite roller sleeves reduce coal mill power consumption by approximately 1 kWh per ton of coal—equivalent to saving 1 kWh of electricity per ton processed. Assuming 7,000 annual operating hours for a 1000 MW power generation unit, each mill can save approximately 500,000 kWh of electricity per year. Based on typical industrial electricity rates, this corresponds to an annual cost saving of approximately USD 20,000–22,000 per mill, depending on the local electricity tariff.

4. Reduced Maintenance Frequency, Lower Operating Costs, and Enhanced Equipment Reliability

The adoption of ZTA metal–ceramic composite roller sleeves and liners helps stabilize coal mill operating current and reduce overall energy consumption, while simultaneously minimizing wear on auxiliary components such as oil seals, bearings, and other transmission parts. Ventilation resistance and vibration levels are significantly reduced, particularly during the later stages of service life. This improvement enhances mill operational stability and ensures more consistent output capacity and coal fineness control. Due to the substantial increase in wear resistance of the working surface, shutdown frequency is greatly reduced. In many applications, mills can achieve synchronized major overhauls once every two years, significantly lowering maintenance workload and reducing total production and maintenance costs. Through a patented composite process, the exceptional wear resistance of ceramic materials is integrally combined with the mechanical strength and toughness of a steel substrate. This structure provides a highly wear-resistant grinding surface while maintaining the impact resistance and structural toughness of metallic materials. The ceramic particles are firmly anchored and resistant to cracking or spalling, ensuring safe and reliable long-term equipment operation.

5. Direct Economic Benefits Increased by More Than 30%

In 300 MW, 600 MW, and 1000 MW thermal power generation units, metal–ceramic composite grinding rollers and liners can operate for a full service cycle of approximately 20,000 hours without the need for hardfacing rebuild or intermediate maintenance. Compared with conventional high-chromium cast iron rollers and liners, direct operating costs can be reduced by more than 30%. These cost reductions result from eliminated hardfacing expenses, reduced downtime losses, lower labor input, and decreased spare part consumption. The overall economic return is therefore highly significant over a complete operating cycle. In summary, the adoption of ZTA metal–ceramic composite roller sleeves and liners overcomes the limitations of traditional manufacturing technologies. It extends service life, improves economic performance, and enhances operational safety and reliability. Guided by a customer-oriented and integrity-based approach, we provide mature and proven metal–ceramic composite roller and liner solutions.

6. Recyclable and Re-Manufacturable Design

Used ceramic composite grinding rollers and liners can be reprocessed through a secondary composite re-manufacturing procedure, enabling cyclic reuse. This approach addresses the traditional limitation that ceramic composite grinding components cannot be reused after wear. Through controlled refurbishment and re-composite manufacturing, customers can benefit from reduced replacement costs and preferential pricing for repeat orders, further lowering long-term lifecycle expenses while supporting sustainable resource utilization.

When to replace a Ceramic Vertical Roller Mill Roller Sleeve? Key Inspection Standards and Wear Indicators

At Tongli’s practical operating experience, waiting until the roller sleeve is “completely worn out” is not realistic. In most plants, the production manager will first notice a rise in specific power consumption (kWh/t) or overall energy usage. Once unit power consumption increases abnormally, it is a strong signal that the ceramic roller sleeve may be approaching its wear limit and should be inspected immediately. Replacement decisions should be based on measurable wear data, structural integrity, and mill operating performance not simply on elapsed time. For what casues grinding roller wear please check out our previous article: What causes wear and tear on the grinding rollers of a vertical roller mill? But below is a summary of 6 possible causes:

1. Excessive Wear Thickness

If the remaining ceramic layer thickness falls below one-third of the original design thickness, the wear margin is no longer safe. If localized wear exposes the metallic substrate, replacement is mandatory. If unilateral wear exceeds the OEM limit (typically ≥8–15 mm depending on mill model), continued operation may cause imbalance and vibration issues.

2. Large-Scale Structural Failure

Immediate replacement is required if there is:

- Extensive ceramic spalling, corner breakage, or fragmentation

- Debonding, hollowing, or loosening between ceramic and metal substrate

- Cracked weld seams, failed clamping plates, or bolt damage that cannot be effectively repaired

These defects compromise structural safety and may result in catastrophic failure if ignored.

3. Significant Decline in Operating Performance

If the mill shows:

- Substantially increased vibration and unstable operation

- Persistent failure to meet product fineness or output targets

- Abnormally high main motor current or a clear rise in energy consumption