Introduction:

Cement machinery and equipment such as rotary kilns, vertical roller mills, and ball mills need to undergo NDT testing. The core reason is that many mechanical defects left over from welding and casting are difficult to detect with the naked eye at the beginning, but may expand rapidly over time. These equipment have been operating under harsh conditions of high temperature, high pressure, continuous rotation, and medium corrosion for a long time. Key parts such as the cylinder, tires, support wheels, vrm grinding roller, vrm rocker arm, ball mill head trunnion and welded joints are prone to hidden defects such as microcracks, wall thickness reduction, and fatigue damage due to factors such as thermal stress, friction, and corrosion. NDT testing can accurately detect these defects through ultrasonic, magnetic powder, penetration, and radiation technologies testing without destroying the structure of the equipment. It can not only warn of hidden dangers in advance and avoid catastrophic accidents, but also extend the life of the equipment and reduce maintenance costs. Today, customers from Europe Belgium came to Tongli to conduct a series of flaw detection and dimensional inspections on their customized cement and compound fertilizer equipment. We will use their process to introduce the factory acceptance test process of cement machinery in detail. Caution: this article is very very long, will take you approximately 3 hours to read through.

What is non-destructive testing's definition

Nondestructive testing (NDT) is a way to check materials, parts, and systems without breaking or damaging them. It helps keep things safe, reliable, and working well in many industries like construction, manufacturing, energy, and aerospace. NDT uses methods such as X-rays, sound waves, and magnetic tools to find problems early, stop failures, and make sure equipment lasts longer. Now the next question is who is able to do the NDT test? Can a random person do the NDT test? The answer is no, the person who perform the NDT has to be well tranied or certified, for example, Tongli's inspection staff is certified by CE and United State ASNT(the american society for non destructive testing)

What is ASNT: The American Society For Non-destructive Testing?

ASNT stands for the American Society for Nondestructive Testing. It is a professional organization that supports people and companies who work with nondestructive testing (NDT). NDT is the process of inspecting materials or equipment without damaging them. ASNT was founded in 1941 and is one of the most respected groups in the NDT industry. It sets international standards for NDT methods, testing procedures, and certification of NDT professionals. This helps ensure safety and quality in industries like cement, oil and gas, aerospace, construction, manufacturing, and power generation. ASNT also provides training, organizes events and conferences, publishes research and technical papers, and offers certifications like the ASNT Level I, II, and III. These certifications prove that an NDT technician has the skills and knowledge to do the job correctly. So now we have a understanding of who ASNT is, notice that all our TONGLI quality inspector are ASNT level II and level III certified!

What is intertek?

Intertek Group plc is a British multinational company headquartered in London, England, with a rich history spanning over 130 years, originally tracing its roots back to pioneering businesses in testing and certification, including one started by Thomas Edison. Today, Intertek is a global leader in providing Total Quality Assurance (TQA) solutions, which encompass Assurance, Testing, Inspection, and Certification (ATIC) services to a vast array of industries worldwide. With a network of over 1,000 laboratories and offices and more than 44,000 employees in over 100 countries, Intertek helps businesses ensure their products, processes, and systems meet rigorous quality, safety, sustainability, and performance standards, thereby mitigating risk, improving efficiency, and building trust for consumers and brands globally. So in breif Intertek provides non-destructive testing (NDT), materials testing and welding services, what is worth noting is Tongli is also Intertek certified!

What is a rotary kiln factory acceptance test FAT?

A Rotary Kiln Factory Acceptance Test (FAT) is a test done at the manufacturer’s workshop before the kiln is shipped to the customer. It checks if the equipment is made correctly and works as expected, during the FAT:

- The kiln parts are checked for size, materials, and quality.

- Motors, gears, bearings, and seals are tested.

- The rotation, alignment, and balance may be checked.

- Control systems and safety features are inspected.

The customer or a third-party inspector often watches the test. After the FAT, a report is made. If the kiln passes, it can be packed and shipped to the site. This test helps avoid problems during installation and saves time later.

What are the main types of non-destructive testing?

Electromagnetic Testing (ET)

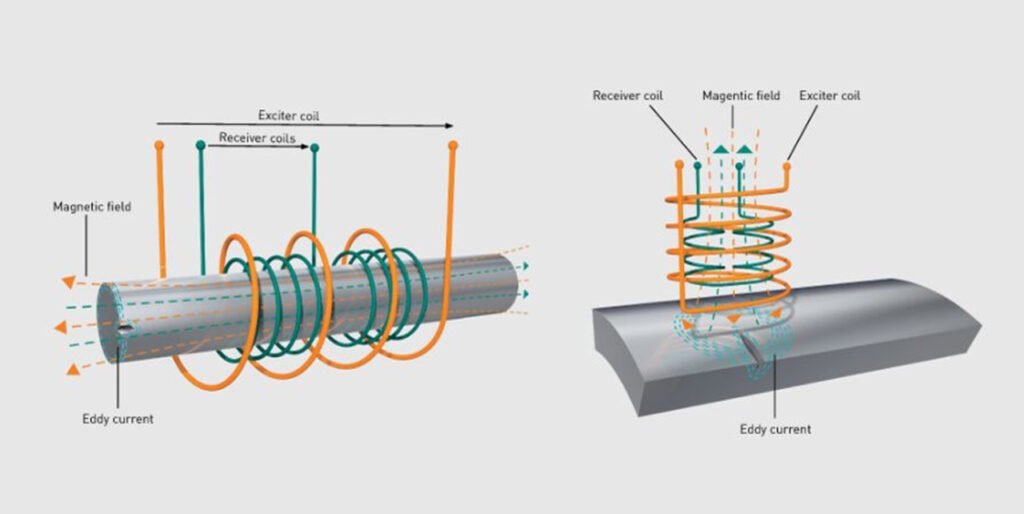

Electromagnetic Testing (ET) is a non-destructive testing technology based on the principle of electromagnetics. It applies an electromagnetic field to the material being tested and analyzes the changes in the electromagnetic response of the material due to internal defects, structural changes, or differences in physical properties to determine whether the material has defects or abnormalities. The core principle is to use phenomena such as electromagnetic induction, eddy current effect, and changes in magnetic permeability: when the electromagnetic field is applied through coils, probes, etc. and interacts with the object being tested, if there are defects or structural differences such as cracks, corrosion, inclusions, thickness changes, etc. in the object, it will interfere with the distribution of the electromagnetic field and produce eddy current disturbances, magnetic field leakage, impedance changes, etc. These changes can be captured by special instruments and converted into analyzable signal current, voltage, and magnetic field strength, thereby achieving the location, qualitative and even quantitative evaluation of defects.

What are the primary objectives of ET in rotary kiln industrial applications?

- Evaluate thinning of cylinder wall thickness and local corrosion/wear: The support ring (riding ring) of the rotary kiln is fixed to the cylinder by welding or riveting. After long-term stress, problems such as loose connection and cracking of welds may occur, resulting in relative sliding of the support ring and the cylinder, aggravating local wear.

- Detect defects in welded joints: The rotary kiln cylinder is usually welded by multiple sections of steel plates. The welded joints (circumferential seams and longitudinal seams) are stress concentration areas, which are prone to defects such as incomplete penetration, slag inclusions, pores, and welding cracks. These defects may expand rapidly under high temperature and rotational stress.

- Detect thermal fatigue cracks on the surface and near the surface of the cylinder: Under the alternating effects of high temperature (usually 300-1000℃) and periodic cooling, the rotary kiln cylinder will produce alternating stress due to thermal expansion and contraction, resulting in thermal fatigue cracks on the surface and near the surface (mostly axial or circumferential distribution), especially at the two ends of the cylinder (feed end, discharge end) and the contact area of the support wheel.

What are the primary method of ET?

- Eddy Current Testing (ECT): It detects defects by detecting the changes in eddy currents induced by alternating magnetic fields in conductive materials. It is suitable for surface and near-surface defect detection of metal pipes, plates, fasteners, etc. It is widely used in aerospace, automobile manufacturing, pipeline detection and other fields.

- Magnetic Particle Testing (MPT): Although it is often classified separately, it is essentially based on the electromagnetic principle - by magnetizing ferromagnetic materials, a leakage magnetic field is generated at the defects, and magnetic powder is adsorbed to form visible traces. It is mainly used to detect surface and near-surface cracks of ferromagnetic materials.

- Magnetic Flux Leakage (MFL): For ferromagnetic materials, corrosion and pits are judged by detecting the magnetic field leaked at the defects after magnetization. It is commonly used in the detection of oil and gas pipelines and storage tanks.

- Remote Field Eddy Current Testing: It is suitable for inner wall defect detection of thick-walled pipelines (such as power station boiler tubes). It can penetrate thicker pipe walls to achieve deep detection.

What are the 5 adventages of Electromagnetic Testing?

Non-contact detection:

No need to come into direct contact with the object to be detected, especially suitable for high temperature, high pressure, toxic or inaccessible environments (such as rotary kiln cylinder, high temperature pipeline, etc.), avoiding damage to the workpiece surface and reducing safety risks during the detection process.

High sensitivity to surface and near-surface defects:

It can accurately detect tiny cracks, pores, slag inclusions and other defects on the surface and near the surface of metal materials. For example, eddy current detection can identify micron-level cracks, and magnetic particle detection can intuitively display opening defects. It is suitable for fields such as aerospace and automobiles that require extremely high precision of parts.

Fast detection speed and automation:

With the help of probe scanning or automated equipment, large-area workpieces (such as pipes and plates) can be quickly detected, and the data can be recorded and analyzed in real time, which is suitable for online quality control of production lines and improves detection efficiency.

Applicable to a variety of materials and working conditions:

It can detect not only ferromagnetic materials (such as carbon steel and alloy steel), but also non-ferromagnetic metals (such as aluminum, copper, and austenitic stainless steel); at the same time, it can work in complex environments such as humidity and oil pollution, and has strong adaptability.

Can evaluate material properties:

In addition to detecting defects, it can also analyze the material's electrical conductivity, magnetic permeability, hardness, heat treatment status, etc. through electromagnetic signals, providing multi-dimensional data for material quality assessment (such as judging the purity of metal materials or the uniformity of heat treatment).

What are the 5 limitations of Electromagnetic Testing in NDT

Limited ability to detect deep defects:

The penetration depth of electromagnetic signals is affected by material properties (such as conductivity, magnetic permeability) and detection frequency. Usually, it can only effectively detect surface and near-surface defects (generally no more than a few millimeters in depth), and has low sensitivity to deep defects in thick-walled workpieces (such as cracks inside thick steel plates).

Limited by materials and workpiece shapes:

Electromagnetic detection cannot be used for non-conductive materials (such as plastics and ceramics);

Workpieces with complex shapes (such as special-shaped parts, parts with deep holes or grooves) are prone to detection blind areas due to uneven magnetic field distribution, affecting the accuracy of defect identification.

Susceptible to interference factors:

Factors such as workpiece surface roughness, coating thickness, temperature changes, and surrounding magnetic fields (such as electromagnetic interference in the environment) may interfere with the detection signal, resulting in misjudgment or missed detection. It is necessary to pre-treat the workpiece surface in advance (such as removing thick coatings) and optimize the detection environment.

High skill requirements for operators:

The interpretation of the test results depends on the analysis experience of electromagnetic signals. The signal characteristics of different types of defects (such as cracks and pores) may be similar. If the operator is inexperienced, it may lead to misjudgment of defects or incorrect grade assessment.

It is difficult to accurately quantify defect size:

Although the defect position can be located, it is difficult to accurately quantify the depth, length and other dimensions of the defect. It usually needs to be further verified in combination with other detection methods (such as ultrasonic detection), especially for complex morphological defects, the quantitative accuracy is limited.

What is the basic working principle of Electromagnetic Testing

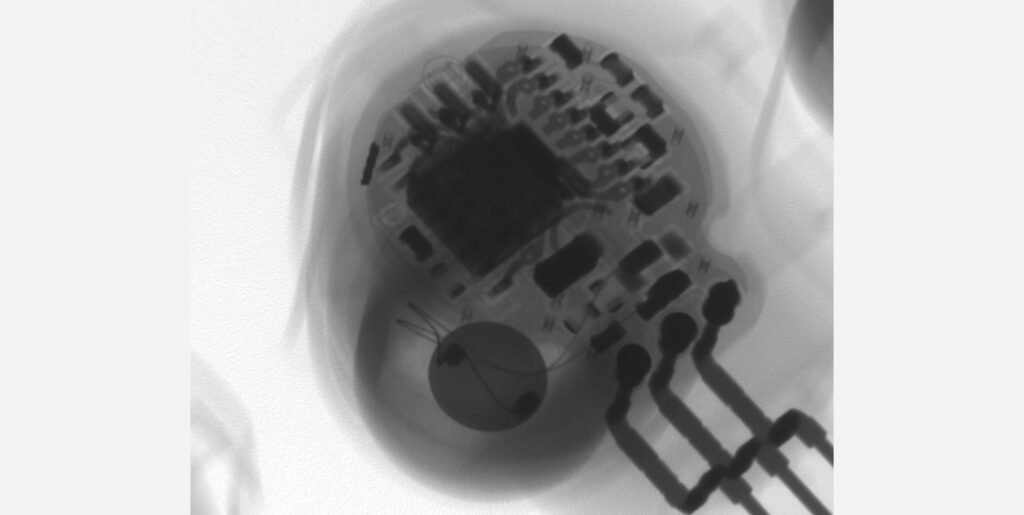

Electromagnetic induction and the interaction between electromagnetic fields and materials: alternating current (AC) is applied to a coil to generate a changing electromagnetic field. Technicians place an eddy current probe with a coil around the material, or a handheld probe on the material. The electromagnetic field can directly penetrate the material. If the object is a conductive material, the alternating electromagnetic field will induce eddy currents inside it, and defects in the material (such as cracks, wall thickness changes) will interfere with the distribution of eddy currents, causing the impedance or induced voltage of the detection coil to change; for ferromagnetic materials, a uniform magnetic field will be formed inside after magnetization. If there are surface or near-surface defects, the magnetic resistance at the defects will increase, causing part of the magnetic field to leak and form a leakage magnetic field, which can be captured by magnetic powder adsorption or sensors. Skilled operators can determine the presence and characteristics of discontinuities, such as cracks, corrosion, or inclusions.

What is Eddy Currents in ET?

Eddy current refers to the closed loop current generated inside a conductor when it is in a changing electromagnetic field. The formation of this current originates from the phenomenon of electromagnetic induction: according to Faraday's law of electromagnetic induction, the changing magnetic field will induce an electromotive force in the conductor, which in turn drives the free electrons to move in a directional manner, forming a circular current similar to a vortex in water, hence the name "eddy current". These currents are strongest on the surface of the material, gradually weaken as they go deeper, and eventually become too weak to be used. Surface defects have the greatest interference with these currents.

The size and distribution of eddy currents are related to many factors, including the intensity and frequency of the electromagnetic field, the conductivity and magnetic permeability of the conductor, and the shape and size of the conductor. For example, in metal materials, the presence of eddy currents will generate Joule heat (eddy current loss), which is used in scenes such as induction cooker heating; at the same time, the distribution of eddy currents will change due to defects (such as cracks, inclusions) or structural changes in the conductor, and changes in materials (such as thickness or conductivity) will affect the interaction of the magnetic field, which will be displayed on the test instrument. The results can be displayed in many ways, but the most common is the impedance plane display. This process helps identify problems in materials without causing any damage.

3 Factors that affect the depth at which eddy currents penetrate a material

- Electrical conductivity of materials: The higher the electrical conductivity of the material (good conductors such as copper and aluminum), the faster the eddy current decays and the shallower the penetration depth. This is because high electrical conductivity leads to stronger eddy current induction, and the anti-magnetic field generated by the eddy current weakens the penetration ability of the original magnetic field. For example, the electrical conductivity of copper is much higher than that of carbon steel, and its eddy current penetration depth is significantly less than that of carbon steel.

- Magnetic permeability of materials: For ferromagnetic materials (such as iron and carbon steel), higher magnetic permeability will enhance the concentration effect of the magnetic field, causing the eddy current to concentrate more on the surface of the material, thereby reducing the penetration depth. The magnetic permeability of non-ferromagnetic materials (such as stainless steel and aluminum) is close to that of air, and the eddy current penetration depth is relatively greater.

- Frequency of excitation current: The higher the frequency of the excitation current, the faster the alternating electromagnetic field changes, the more significant the skin effect of the eddy current (i.e., the current is concentrated on the surface of the material), and the shallower the penetration depth. For example, high-frequency eddy current testing is suitable for detecting small surface defects, while low-frequency testing can be used to detect deeper defects (but the sensitivity will be reduced).

5 Electromagnetic Testing Techniques Used in NDT

Electromagnetic Testing (ET) has many techniques to detect and measure flaws in materials. These techniques can be characterized by how the eddy currents cut into the material.

Pulsed Eddy Current Testing (PECT)

Pulsed Eddy Current Testing is an advanced variation of standard eddy current testing. Instead of using a continuous AC current, PECT uses a short burst (pulse) of direct current (DC) to magnetize the material. When the current stops, eddy currents are created in the test object. These eddy currents decay over time, and their decay rate is measured and analyzed to determine the condition of the material. PECT is very effective for detecting corrosion, especially in situations where insulation, coatings, or even concrete covers the surface. It can inspect thick materials and detect wall loss or thinning underneath surface layers—making it ideal for inspecting pipelines, tanks, or structural components without removing insulation. This reduces downtime and saves costs in industrial maintenance.

Remote Field Testing (RFT)

Remote Field Testing is a special electromagnetic method mainly used to inspect the inside and outside of ferromagnetic tubing, such as carbon steel heat exchanger and boiler tubes. A probe with a transmitter and receiver coil is inserted into the tube. The transmitter emits a low-frequency magnetic field that travels through the tube wall and returns to the receiver after passing through both the inner and outer surfaces. Because the magnetic field travels through the material twice, RFT is very sensitive to defects on both surfaces. It is especially effective for detecting wall loss, corrosion, and pitting. This method is commonly used in power plants, refineries, and petrochemical facilities for in-service inspection of tubes without needing to remove them from the system.

Electromagnetic Acoustic Transducer (EMAT)

EMAT is an advanced ultrasonic testing method that generates sound waves in conductive materials without direct contact. It works by using electromagnetic fields to create ultrasonic waves directly within the test material, instead of sending them through a separate transducer and couplant (gel or water). This allows inspections to be done on rough, dirty, hot, or painted surfaces. Because EMAT does not require surface preparation, it’s ideal for use in environments where conventional ultrasonic testing (UT) is difficult or impractical. Common applications include measuring wall thickness, detecting corrosion under coatings, and inspecting welds or hot steel in pipelines or structural components. EMAT is especially useful in automated or high-temperature settings, like in steel mills or power plants.

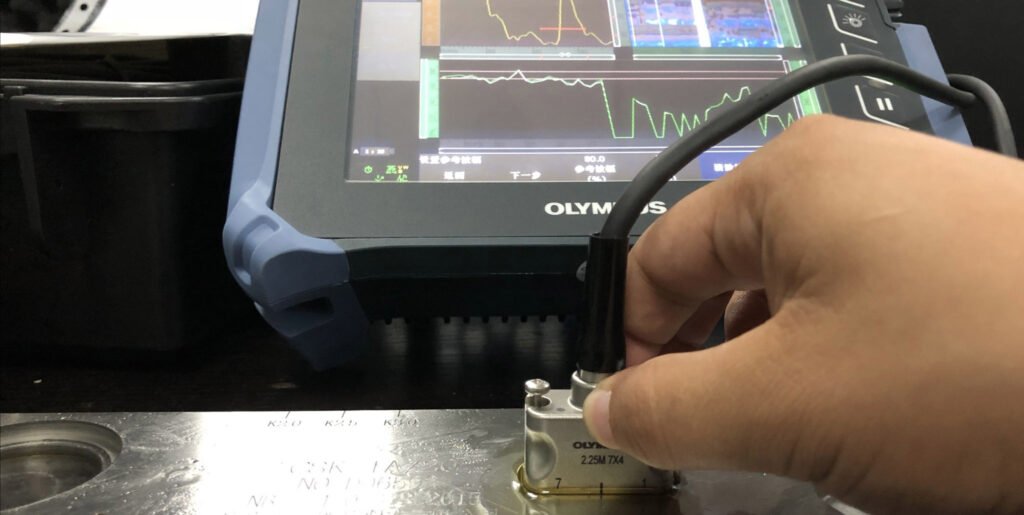

Eddy Current Testing (ECT)

Eddy Current Testing is one of the most widely used electromagnetic NDT techniques, especially for inspecting conductive materials like aluminum, copper, and steel. It uses a probe with coils that generate an alternating magnetic field. When this probe is placed near a conductive surface, it induces circulating electric currents—called eddy currents—inside the material. If there is a flaw such as a crack, corrosion, or other discontinuity near the surface, it will disrupt the flow of these eddy currents. The change in current flow is detected by the same probe and interpreted to locate and possibly size the defect. ECT is ideal for surface and near-surface inspection, such as aircraft parts, heat exchanger tubes, or welds. It offers immediate results, high sensitivity, and does not require couplants or special surface preparation.

Alternating Current Field Measurement (ACFM)

ACFM is a non-contact electromagnetic testing method used to detect and size surface-breaking cracks in metal structures. It works by applying an alternating current (AC) through a probe, which creates a magnetic field on the surface of the material. In areas without defects, this magnetic field is uniform. However, when there’s a crack or defect, the field becomes distorted. Sensors in the probe measure this disturbance to identify and size the crack accurately. One of the key advantages of ACFM is that it does not require the surface to be cleaned or stripped of coatings like paint or rust. This makes it especially useful for inspecting offshore oil platforms, pipelines, welded joints, and other painted or corroded surfaces. It also provides digital records, which are helpful for documentation and comparison in future inspections.

ET in the Real World – Cement Plant Equipment

Rotary kilns, vertical roller mills, and ball mills are core machines in cement production, handling intense heat, high loads, and continuous operation. Over time, these machines are exposed to wear, thermal stress, material build-up, and structural fatigue. To keep the plant running safely and efficiently, non-destructive testing (NDT) is widely used to monitor their condition without dismantling the entire system.

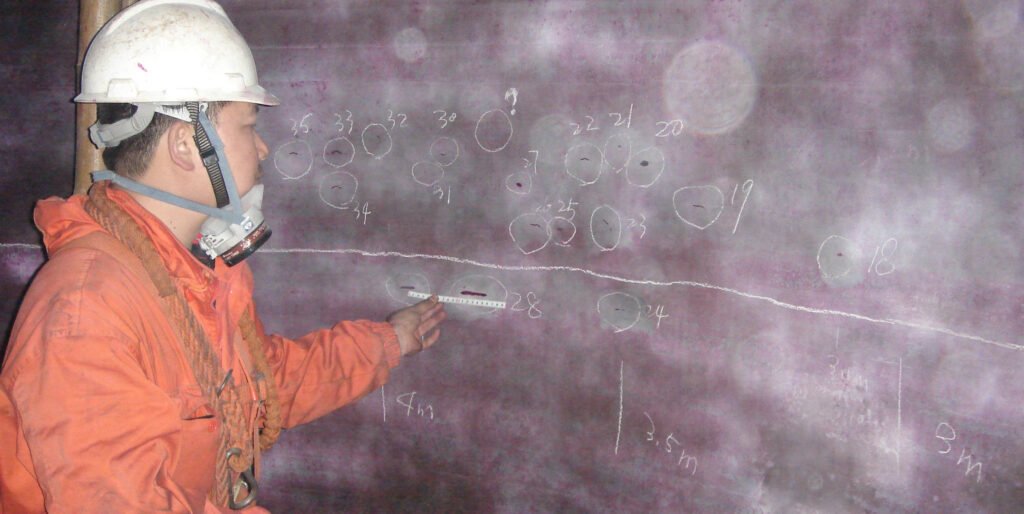

For example, during a planned shutdown, technicians perform ultrasonic testing (UT) and magnetic particle inspection (MPI) on rotary kiln shells and tires to detect surface or subsurface cracks. Eddy current testing (ECT) or ACFM might be used to evaluate cracks near weld seams or high-stress areas. Similarly, vertical roller mill rollers and table liners are checked using ultrasonic thickness measurement and vibration analysis to assess wear and mechanical integrity.

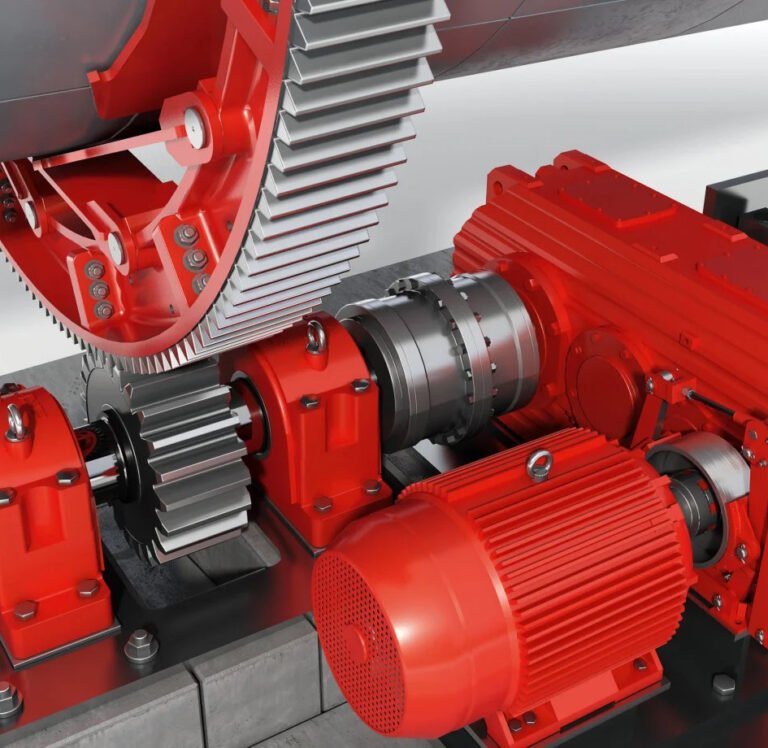

Ball mills, which grind clinker and other materials, are also subject to gear wear and shell deformation. NDT methods such as dye penetrant testing (DPT) or laser alignment checks are applied to spot cracks in trunnions, pinions, and mill liners. These inspection results help maintenance teams schedule timely repairs or part replacements—reducing the risk of catastrophic failure, avoiding unplanned downtime, and keeping cement production on track.

Magnetic Particle Testing (MT)

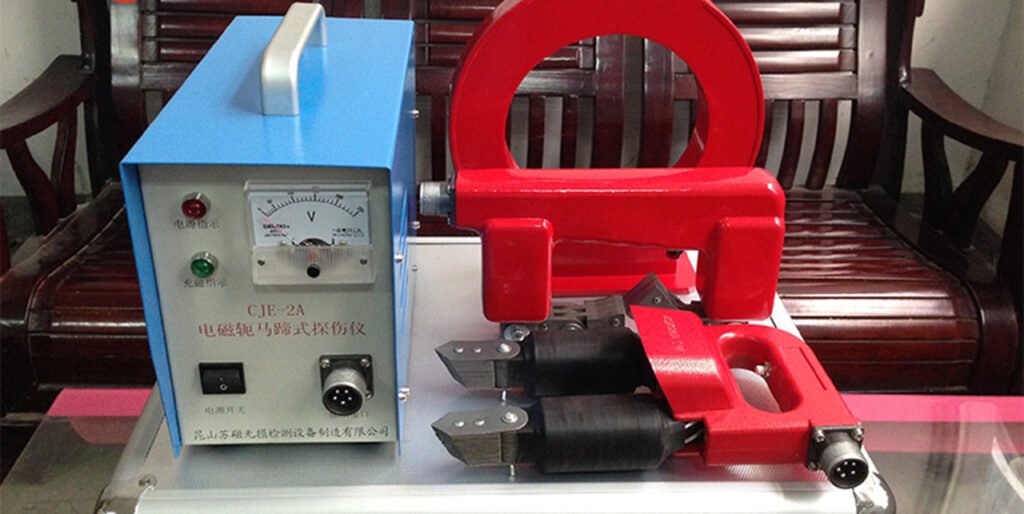

Magnetic Particle Testing (MPT) for cement equipment is a non-destructive testing technology for surface and near-surface defects of carbon steel and alloy steel parts commonly used in cement production. It is used to detect discontinuities on the surface and near-surface of ferromagnetic materials. The principle is to apply a magnetic field to the inspected part through a coil, so that the defects, cracks, pores, and unfused surfaces on the surface and near-surface of the material will generate leakage magnetic fields. These leakage magnetic fields will interfere with the magnetic field and generate leakage magnetic fields. Ferromagnetic particles are attracted by these leakage magnetic fields to form visible discontinuity traces, thereby intuitively displaying the location, shape and size of the defects. This technology has the advantages of simple operation, fast detection speed, and high sensitivity (micron-level cracks can be detected). It is widely used in the detection of key components of cement equipment, such as rotary kiln cylinder welds, support wheels and wheel belt surfaces, reducer gears, couplings, etc. It is especially suitable for quickly locating hidden dangers that may affect the safe operation of equipment in harsh environments such as high temperature and dust, ensuring the continuity and reliability of cement production.

9 Advantages of Magnetic Particle Testing

Fast and relatively simple:

This process does not require complex signal conversion and analysis. After the magnetic field is established through the yoke, coil and other equipment, dry magnetic powder or wet magnetic suspension is applied (the particle size of the magnetic powder is usually 5-50μm, and the magnetic field strength needs to be matched). The magnetic traces at the defect can be formed within seconds to minutes. Its operation process complies with ASNT SNT-TC-1A and other standard specifications. The skill threshold for operators is lower than that of ultrasonic or radiographic testing. It is especially suitable for online sampling of batch components (such as bolts and shaft parts). The single-piece inspection cycle can be controlled within 10 minutes.

Economical and efficient:

The initial investment of magnetic particle testing equipment (such as portable magnetic yoke, black light, magnetic powder) is only 1/10-1/5 of that of radiographic testing equipment, and the cost of consumables (magnetic powder, carrier liquid) is low. Compared with ultrasonic testing, which requires coupling agent, and radiographic testing, which requires protective facilities, MT has extremely low auxiliary costs. It is particularly suitable for large-scale surveys of large structures (such as bridge bearings and pressure vessel welds). The unit inspection area cost is only 60%-70% of that of penetration testing.

Easy to operate and high detection efficiency:

No complicated pretreatment is required (only thick coating or oil stains on the surface need to be removed), the magnetic field can be quickly established through yokes, coils and other equipment, and detection can be achieved with dry magnetic powder or wet magnetic suspension. The detection time of a single weld or small component is usually completed within a few minutes. At the same time, magnetic traces can be directly observed with the naked eye without relying on complex signal analysis, which is suitable for rapid on-site screening, especially for complex environments with high dust and limited space such as cement plants.

Versatility:

Applicable to all ferromagnetic materials (iron, cobalt, nickel and their alloys, such as 45# steel, 20CrMnTi), regardless of the shape (plate, pipe, special-shaped parts) or size (from bolts with a diameter of 2mm to pipes with a length of tens of meters). By adjusting the magnetization method (axial magnetization, circumferential magnetization, composite magnetization), defects in different directions can be covered, such as circumferential magnetization for detecting radial cracks in the annular seam of the rotary kiln shell, and axial magnetization for detecting transverse cracks in the longitudinal weld.

Instant results:

After the magnetic trace is formed, it can be directly observed by naked eyes (visible light magnetic powder) or black light (fluorescent magnetic powder), without waiting for film development like X-ray detection, or waveform analysis like ultrasonic detection. The test results can be recorded in real time (photographing, recording), and the determination of defects can be completed on site, especially in emergency maintenance scenarios (such as equipment shutdown and maintenance), it can quickly decide whether to release or return for repair, greatly shortening the downtime.

Quantitative insights:

The length, width, and stacking density of the magnetic trace can be used to preliminarily determine the size and severity of the defect. For example, the length of the magnetic trace usually coincides with the actual length of the defect (error ≤10%), and the density of the magnetic trace reflects the leakage magnetic field strength (indirectly related to the depth of the defect). Combined with the comparison of standard test blocks (such as type A test blocks), the defects can be graded (such as the defect acceptance level in ISO 9712), providing a quantitative basis for quality assessment.

Highly sensitive to surface and near-surface defects:

Can accurately detect tiny cracks, unfused, pores and other defects on the surface and near-surface (usually ≤1mm deep) of ferromagnetic materials, and can even identify micron-level open cracks. The principle is that the leakage magnetic field at the defect has a strong adsorption to the magnetic powder, and the magnetic traces formed can directly reflect the defect shape, which is especially suitable for detecting fatigue cracks in stress concentration areas (such as heat-affected zones of welded joints and near machining tool marks), which is crucial for cement equipment that bears alternating loads (such as rotary kiln wheel belts and crusher spindles).

Defect display is intuitive and low cost:

The magnetic traces formed by the magnetic powder are highly consistent with the defect shape, and the location, direction and approximate size of the defect can be directly determined, providing a clear basis for subsequent maintenance (such as determining the scope of repair welding). In addition, the equipment investment (such as portable yoke, magnetic powder) and consumables costs are much lower than X-ray detection and ultrasonic detection, which is suitable for large-scale, normalized equipment inspections.

Surface and near-surface inspection:

Magnetic particle testing (MT) is based on the principle that a leakage magnetic field is generated at a defect after the ferromagnetic material is magnetized. It has extremely high sensitivity to surface and slight sub-surface defects (usually ≤1mm in depth). The intensity of the leakage magnetic field is positively correlated with the defect opening and depth, and can accurately capture micron-level cracks (such as hydrogen-induced cracks in the heat-affected zone of welding and fatigue cracks at the root of gear teeth). In particular, the detection rate of linear defects (such as cold working cracks and quenching cracks) is significantly higher than other surface inspection methods. This is because the gradient of the leakage magnetic field generated by linear defects is more obvious, and the adsorption force on magnetic powder is stronger.

10 Limitations of Magnetic Particle Testing

Only applicable to ferromagnetic materials:

Its detection principle relies on the leakage magnetic field generated after the material is magnetized, so it cannot be used for non-ferromagnetic materials (such as austenitic stainless steel pipes and aluminum alloy parts in cement equipment), which limits the scope of application.

Weak detection ability for deep defects and non-surface opening defects:

The leakage magnetic field intensity decays sharply with the increase of defect depth, and it can usually only effectively detect surface and near-surface defects with a depth of ≤1mm. It is difficult to identify defects deeply buried inside the material (such as cracks in the center of thick steel plates) or closed defects (such as unopened rolling cracks), and it is necessary to combine ultrasonic testing and other technologies for supplementary verification.

Poor environmental adaptability:

High temperature (>60℃) will cause the wet magnetic suspension to evaporate and the magnetic powder to aggregate; high humidity (relative humidity>85%) will cause the dry magnetic powder to absorb moisture and agglomerate, reducing fluidity; dusty environment (such as cement plant area) will contaminate the magnetic powder and interfere with magnetic trace identification. In addition, a strong magnetic field environment (such as an electromagnet nearby) will superimpose the external magnetic field, resulting in pseudo magnetic traces. Therefore, it is necessary to conduct detection in an area with an environmental magnetic field of ≤0.5mT, which increases the restrictions on on-site operations.

Requires mandatory demagnetization:

After magnetization, ferromagnetic materials will have residual magnetism (especially high magnetic permeability materials, such as electrical pure iron). Residual magnetism may cause chip adsorption in subsequent processing, affect precision assembly (such as bearing installation), or interfere with instrument readings (such as nearby magnetic sensors). According to the API 5L standard, the residual magnetism of the workpiece after detection must be ≤2mT (20 Gauss), and a demagnetization coil or demagnetization machine must be used for demagnetization. This step will increase the detection time by 10%-20%, and large components (such as 10,000-ton hydraulic press beams) require customized special demagnetization equipment, which is costly.

Limited by the shape of the workpiece and the direction of the magnetic field:

Complex geometric shapes (such as curved surfaces, edges and corners, and near deep holes) are prone to magnetic field distortion, which may cover real defects or form pseudo-magnetic traces; at the same time, the sensitivity of defect detection is closely related to the direction of the magnetic field (such as longitudinal cracks must be perpendicular to the direction of the magnetic field to produce obvious leakage magnetic fields). If the direction of the magnetic field is parallel to the direction of the defect, it may lead to missed detection. Therefore, multi-directional magnetization (such as cross yoke) is required to cover defects with different directions.

Greatly affected by environmental factors:

When there is a thick coating, rust, or oil on the surface of the workpiece, it will hinder the effective interaction between the magnetic powder and the leakage magnetic field, resulting in blurred magnetic traces; a humid environment may cause the magnetic powder to agglomerate, affecting the detection accuracy, so the detection surface needs to be pre-treated, which increases the operation steps.

Limited to ferromagnetic materials:

The core principle of magnetic particle detection is to use the leakage magnetic field at the defect to adsorb magnetic powder, and only ferromagnetic materials (such as iron, cobalt, nickel, and their alloys) can be effectively magnetized and generate a stable magnetic field. For non-ferromagnetic materials (such as austenitic stainless steel, aluminum alloy, and copper alloy), their relative magnetic permeability is close to 1 (equivalent to air), and they cannot form a leakage magnetic field sufficient to adsorb magnetic powder, so they are completely unsuitable. For example, 304 stainless steel pipe welds in cement equipment cannot be tested with magnetic particle detection, and penetration detection or eddy current detection must be used instead.

Strict surface treatment requirements:

The surface of the test object must be cleaned of contaminants such as oil, rust, oxide scale, and thick coating (thickness exceeding 50μm will significantly attenuate the leakage magnetic field), otherwise it will hinder the contact between magnetic powder and leakage magnetic field, resulting in missed defects. According to the ASME V standard, the surface roughness must be ≤Ra 25μm, and there must be no covering impurities. In actual operation, pre-treatment steps such as grinding and solvent cleaning are often required, which will increase the total detection time by 30%-50%. Especially for equipment that has been running for a long time (such as rotary kiln cylinders), special tools are required to clean the high-temperature oxide layer on the surface, further increasing the operating cost.

Significant depth limitation:

The effective detection depth of magnetic particle testing depends on the magnetic permeability of the material and the defect morphology. It can usually only reliably detect surface and near-surface defects with a depth of ≤1mm. This is because the leakage magnetic field strength decays exponentially with the increase of defect depth - when the defect depth exceeds 10% of the material thickness or is greater than 1mm, the leakage magnetic field is too weak to absorb magnetic powder to form identifiable magnetic traces. For example, for a 20mm thick carbon steel flange, magnetic particle testing is difficult to detect internal cracks less than 3mm from the surface, and ultrasonic testing is required for additional verification.

Health and safety risks:

Dry magnetic powder (especially micron-level ferromagnetic powder) is easily inhaled into the respiratory tract, and long-term contact may cause pneumoconiosis, so a dust mask must be worn; fluorescent agents (such as rhodamine B) in fluorescent magnetic powder are potentially irritating and must be cleaned in time after contact with the skin; the strong magnetic field (>0.5T) of the magnetizing equipment may interfere with medical implants such as pacemakers, and warning signs must be set up in the operating area, all of which increase the complexity of safety management.

How does Magnetic Particle Testing Work?

To understand how magnetic particle testing works, it helps to know some basic magnetism. We all know that magnets attract certain metals, such as iron, nickel, and cobalt, but not others, such as aluminum or copper. Magnets come in different shapes and sizes and have different strengths. In fact, the earth itself is a giant magnet.

In magnetic particle testing, a magnetic field is first applied to the metal part being inspected. Technicians typically use a device like a yoke, coil, or probe to magnetize the part. This magnetic field can be generated using either alternating current (AC) or direct current (DC). AC is good for detecting surface defects, while DC is better for finding defects below the surface.

Once the metal part is magnetized, magnetic particles are sprinkled on its surface. The magnetic particles can be dry or mixed in a liquid to form a magnetic suspension. If there are cracks, pores, or other defects on the metal surface, these areas will interrupt the magnetic field, forming a "leakage field." The magnetic particles are attracted to these leakage areas and accumulate at the location of the defect, forming a visible indication.

Experienced inspectors can determine the approximate location, direction and size of defects by observing the shape and position of these magnetic particles. Magnetic particle testing is a very effective method, commonly used to detect surface or near-surface defects in welds, castings, forgings and other key parts, especially for ferromagnetic materials.

How Magnetic Fields Reveal Material Defects: Principle Analysis in Magnetic Particle Testing

In magnetic particle testing (MT), the magnetic field is not only an external energy source, but also has important interactions with the internal structure of the material being tested. When there are discontinuities such as cracks, pores or inclusions in the magnetized material, the originally uniformly flowing magnetic field will be "interrupted" and leak out from the defect. This phenomenon is called magnetic flux leakage. You can imagine the magnetic flux as a flowing stream, and the defects inside the material are like stones in the stream. Water (magnetic flux) bypasses the stone and creates turbulence; similarly, the magnetic field will "leak" from the crack or void when it encounters it, forming a local magnetic anomaly. To show these anomalies, technicians will sprinkle a layer of ferromagnetic powder (either dry powder or wet powder suspended in liquid) on the surface of the magnetized material. When the magnetic flux leaks at the defect, the powder will be attracted and accumulate above the defect, forming a visible indication. This process is like the experiment we did as children, where we sprinkled iron filings around a magnet and they would align along the magnetic lines of force, except that here, the iron powder is attracted by the "abnormal magnetic field". This phenomenon can be divided into two key parts:

- Flux Leakage: When the magnetic field encounters a discontinuity in the material (such as a crack), it leaks from there, forming a local area of enhanced magnetic field.

- Particle Attraction: Ferromagnetic particles are automatically attracted to these abnormal areas, forming a "visual mark" of defects on the surface.

3 Types of Materials in MT

In magnetic testing, the response characteristics of materials to magnetic fields are derived from the electromagnetic structure inside their atoms: atoms are composed of positively charged nuclei and electrons orbiting the nucleus. The orbital motion and spin motion of electrons jointly generate magnetic moments, and the overall magnetic nature of the material is the collective behavior of atomic magnetic moments under the action of an external magnetic field. According to the arrangement of atomic magnetic moments and the intensity of the response to the external magnetic field, materials can be divided into three categories:

Diamagnetic materials:

The magnetic moments generated by the electron spin and orbital motion inside its atoms are completely offset, and the overall magnetic moment is zero. When exposed to an external magnetic field, a weak magnetic moment opposite to the external magnetic field is induced, showing an extremely weak repulsive force (the magnetic susceptibility χ is negative, usually in the order of -10⁻⁶~-10⁻⁹). After the external magnetic field is removed, the induced magnetic moment disappears immediately, and there is no residual magnetism. For example, copper, gold, bismuth, etc., their diamagnetism originates from the Lorentz force effect of electron orbital motion in an external magnetic field. This property makes it a shielding material in high-precision magnetic field measurement.

Paramagnetic materials:

Atoms have an inherent magnetic moment that is not offset (such as the presence of unpaired electrons), but thermal motion causes the magnetic moment to be disordered, and the overall magnetism is weak. Under the action of an external magnetic field, the magnetic moment will be slightly oriented along the direction of the magnetic field, showing a weak attraction (the magnetic susceptibility χ is positive, usually in the order of 10⁻⁶~10⁻³), but the magnetization intensity is much lower than that of ferromagnetic materials. After the external magnetic field is removed, thermal motion restores the magnetic moment to disorder, and there is no remanence. For example, the paramagnetism of aluminum, platinum and some austenitic stainless steels (such as 304) is mainly contributed by the spin magnetic moment of unpaired electrons, and is often used in precision devices that require weak magnetic response.

Ferromagnetic materials:

There are "magnetic domains" formed by the parallel arrangement of atomic magnetic moments inside. In the absence of an external magnetic field, the magnetic domains are randomly oriented and the overall magnetism is not obvious; under the action of an external magnetic field, the magnetic domains will expand and rotate along the direction of the magnetic field, generating extremely strong magnetization intensity (magnetic susceptibility χ can reach 10³~10⁶), showing a strong attraction. If the external magnetic field is strong enough, the material can reach magnetic saturation and retain significant remanence (i.e., "permanent magnetic characteristics") after the external magnetic field is removed. This is due to the irreversible reorganization of the magnetic domain structure. Iron, cobalt, nickel, and most carbon steels and alloy steels belong to this category. Their strong magnetism makes them the core materials of magnetic devices such as motors and permanent magnets, and they are also the main applicable objects of non-destructive testing technologies such as magnetic particle testing.

4 Types of Magnetic Fields in MT

Circular Magnetization

Circular magnetization is to pass current directly into the workpiece (such as shaft parts) or through the central conductor (such as the inner wall of the pipe) to make the magnetic field circumferentially distributed along the workpiece to form circular magnetic lines of force. Its core advantage is that it can efficiently detect longitudinal discontinuities (i.e., the direction of the defect is parallel to the axis of the workpiece, such as axial cracks and longitudinal lack of fusion), because such defects will vertically cut the circular magnetic lines of force and produce a strong leakage magnetic field. In cement machinery, it is often used to detect the circumferential welds of the rotary kiln shell (current needs to be passed through the central conductor, and the magnetic field surrounds the weld), which can accurately detect longitudinal cracks in the weld; it is also suitable for the detection of ball mill main shafts, and can identify axial fatigue cracks on the shaft surface caused by long-term heavy loads.

Longitudinal Magnetization

Longitudinal magnetization places the workpiece in a coil or uses a yoke to bridge the workpiece surface, so that the magnetic field is distributed along the length of the workpiece (the magnetic field lines are parallel to the axis). It is mainly used to detect transverse discontinuities (the defect direction is perpendicular to the workpiece axis, such as circumferential cracks and transverse pores). Such defects will vertically cut the longitudinal magnetic field lines, forming a significant leakage magnetic field.

In cement machinery, the yoke method is widely used in the detection of vertical mill roller journals, which can detect circumferential cracks caused by friction; when detecting the outer surface of the rotary kiln wheel belt, longitudinal magnetization can effectively identify transverse fatigue cracks caused by the contact between the wheel belt and the supporting wheel, ensuring the safety of the supporting components.

Alternating Current (AC)

AC magnetization uses alternating current to generate a magnetic field. Its magnetic field energy is concentrated on the surface of the workpiece (the skin effect is significant). The surface magnetic field intensity is high but the penetration depth is shallow (usually ≤1mm). The detection sensitivity of surface defects (such as open cracks and mechanical scratches) is extremely high. The dynamic change of AC magnetic field can also enhance the fluidity of magnetic powder and make the magnetic trace clearer.

In cement machinery inspection, it is often used for surface crack detection of ball mill liner bolts - bolts are prone to surface fatigue cracks due to frequent vibration, and AC magnetization combined with dry magnetic powder can quickly locate them; it is also suitable for vertical mill reducer gear tooth surface inspection, and can identify fine surface cracks caused by meshing wear.

Circular Magnetization

DC magnetization generates a constant magnetic field through direct current. Its magnetic field has a large penetration depth (up to several millimeters) and can effectively detect near-surface discontinuities (such as subcutaneous pores and near-surface unfused). In practical applications, it is often used in conjunction with wet magnetic suspension (magnetic powder suspended in liquid). The liquid carrier can make it easier for magnetic powder to penetrate into tiny defects and improve the visibility of magnetic traces. In cement machinery, it is suitable for detecting near-surface defects of rotary kiln support wheels. Support wheels bear the weight of the kiln body for a long time, and subcutaneous cracks are easily generated near the surface due to contact stress. DC magnetization can accurately identify them. When inspecting the hub of the large gear of the ball mill, near-surface inclusions or shrinkage holes formed during the casting process can be found to avoid fractures caused by stress concentration.

3 Particle Types in MT

In magnetic particle inspection, the type of magnetic powder needs to be selected according to the surface state of the inspection object, defect sensitivity requirements and environmental conditions, mainly including the following three categories:

Visible magnetic powder (Visible Particles)

Visible magnetic powder is usually black (iron oxide-based), red or gray (chromium oxide-based) and other high-contrast pigment-colored particles. The magnetic traces can be directly observed by the naked eye without special light sources. According to the application form, it can be divided into dry visible magnetic powder and wet visible magnetic powder: Dry visible magnetic powder particles are coarse (usually 50-150μm) and have good fluidity. They are suitable for the inspection of rough surfaces (such as castings and forgings). Their loose state can quickly fill surface defects to form clear magnetic traces; in cement machinery, they are often used for on-site inspection of rough surfaces such as ball mill liners, and are easy to operate and portable.

Fluorescent magnetic powder (Fluorescent Particles)

Fluorescent magnetic powder is a magnetic particle coated with fluorescent dyes (such as fluorescein and rhodamine) on the surface, usually suspended in water or oil-based carriers to form a wet magnetic suspension. During the inspection, it is necessary to cooperate with ultraviolet light (UV-A, wavelength 320-400nm) irradiation. The magnetic powder will emit strong fluorescence (such as yellow-green, orange-red), and the recognition sensitivity of tiny defects (such as microcracks, pinholes) is much higher than that of visible magnetic powder (which can detect surface defects ≤0.1mm). In the inspection of precision parts of cement machinery, such as the root of the rotary kiln transmission gear and the surface of the piston rod of the vertical mill hydraulic cylinder, fluorescent magnetic powder can accurately detect fine cracks caused by fatigue or corrosion, and is especially suitable for use in dark sites or workshop environments.

Dual-Use Particles

Dual-Use magnetic powder is a special particle with dual coatings of visible pigments and fluorescent dyes. The detection mode can be flexibly switched according to the detection needs: under natural light, more obvious defects can be identified through visible colors, and under ultraviolet irradiation, fluorescence can enhance the detection ability of tiny defects. This kind of magnetic powder reduces the operation steps of changing the type of magnetic powder and improves the detection efficiency.

In the comprehensive inspection of cement machinery (such as large-area rough inspection and key-part fine inspection of the rotary kiln cylinder), dual-purpose magnetic powder can take into account both efficiency and sensitivity and adapt to complex inspection scenarios.

3 Magnetic Particle Testing Techniques Used in NDT

Magnetic particle testing (MT) applies magnetic fields in different ways and optimizes the defect display effect. It can be divided into three categories: contact detection, coil detection and portable detection. Each type of technology is designed for specific scenarios and workpiece shapes, and each has its own focus in industrial inspection:

Contact Testing

Contact testing applies a magnetic field by direct contact between the probe and the workpiece surface. The magnetic field is highly concentrated and suitable for precise detection of local areas. The core technologies include:

- Yoke Testing: Use a handheld yoke (U-shaped or horseshoe-shaped electromagnet) to bridge the surface of the workpiece, and form a longitudinal magnetic field through the two poles of the yoke. Its advantage is that it does not require power to penetrate the workpiece, has strong adaptability to irregular-shaped parts (such as special-shaped flanges and complex castings), and the direction of the magnetic field can be flexibly changed by adjusting the yoke placement angle. In cement machinery, it is often used for local detection of vertical mill disc supports, which can quickly locate cracks caused by stress concentration; during on-site maintenance, it is also very convenient to detect curved surfaces such as the shoulder of the rotary kiln support wheel.

- Prod Testing: Two conductive contacts (copper or steel) are contacted to the workpiece surface. After current is passed, a circumferential magnetic field is formed between the contacts (magnetic lines surround the current path), which is suitable for circumferential magnetization of local areas (such as the heat-affected zone of welds). Its magnetic field strength can be adjusted by current, and the detection efficiency of local repair welding area of small workpieces or large equipment is extremely high. For example, the detection of local welds of the flange of the feed port of a ball mill can accurately detect tiny cracks caused by welding stress.

Coil Testing

Coil testing places the workpiece inside the coil and uses the magnetic field generated by the coil to achieve overall magnetization. It is suitable for batch detection of regular-shaped workpieces, mainly including:

- Circular Coil Testing: Place cylindrical workpieces (such as shafts, rods, and tubes) coaxially into the circular coil, and the coil is energized to generate a longitudinal magnetic field, which can efficiently detect transverse defects (such as circumferential cracks) on the surface of the workpiece. Its magnetic field has good uniformity and is suitable for batch detection of standard parts. For example, for cylindrical parts such as conveyor rollers and hydraulic piston rods in cement machinery, it can realize automated assembly line detection to ensure consistency in defect detection.

- Solenoid Coil Testing: The solenoid is composed of long straight coils, and the magnetic field covers a wider range, which is suitable for the overall magnetization of large cylindrical workpieces or components (such as long shafts and large pipelines). Compared with toroidal coils, its magnetic field has a greater penetration depth and can detect near-surface defects. For example, when the support shaft of a rotary kiln is inspected as a whole, near-surface inclusions or cracks caused by forging defects inside the shaft can be found.

Portable Testing

Portable testing uses miniaturized magnetic yokes, coils or battery-powered equipment, which is designed for on-site in-situ testing. Its core feature is strong flexibility and is not restricted by the site. The equipment usually weighs 5-15kg and can be carried to high altitudes, narrow spaces or outdoor operations, such as online inspection of the rotary kiln cylinder of a cement plant (without disassembly) and on-site sampling of vertical mill racks. Portable equipment combined with dry magnetic powder or spray-type wet magnetic suspension can quickly complete large-area scanning, which is especially suitable for regular equipment inspections and sudden fault troubleshooting. It is indispensable in ensuring the safe operation of large equipment (such as key components of a 10,000-ton cement production line).

Example: Magnetic Testing in the cement industry

In the cement industry, magnetic particle testing (MT) is often used in conjunction with penetrant testing (PT) to cover the defect detection needs of key equipment of different materials and ensure production continuity and safety.

- For example, in large-scale cement production lines, the rotary kiln is the core calcining equipment, and the circumferential weld joints of its cylinder (carbon steel material) need to be checked for surface and near-surface welding cracks through magnetic particle testing - the weld is longitudinally magnetized using the magnetic yoke method, which can accurately identify fine cracks caused by high temperature stress; and for the austenitic stainless steel temperature measuring sleeve (non-ferromagnetic material) on the kiln body, penetrant testing is required for supplementary inspection to ensure that there are no open defects.

- In the inspection of ball mills, magnetic particle testing is mostly used for the journal surface of the main shaft (forged steel material), and a circumferential magnetic field is generated by the contact method to find axial fatigue cracks caused by long-term heavy loads;

- While the roller bearing seat (cast iron material) of the cement clinker vertical roller mill is combined with magnetic particle testing and penetrant testing, the former locates near-surface casting defects, and the latter checks surface pores. This "MT+PT" combination solution not only covers the key hidden dangers of a large number of ferromagnetic components in cement equipment, but also makes up for the limitations of magnetic particle testing for non-ferromagnetic materials. It strictly follows the cement industry equipment safety standards (such as GB/T 30574), avoids downtime accidents caused by equipment defects from the root, and ensures the stable operation of the production line.

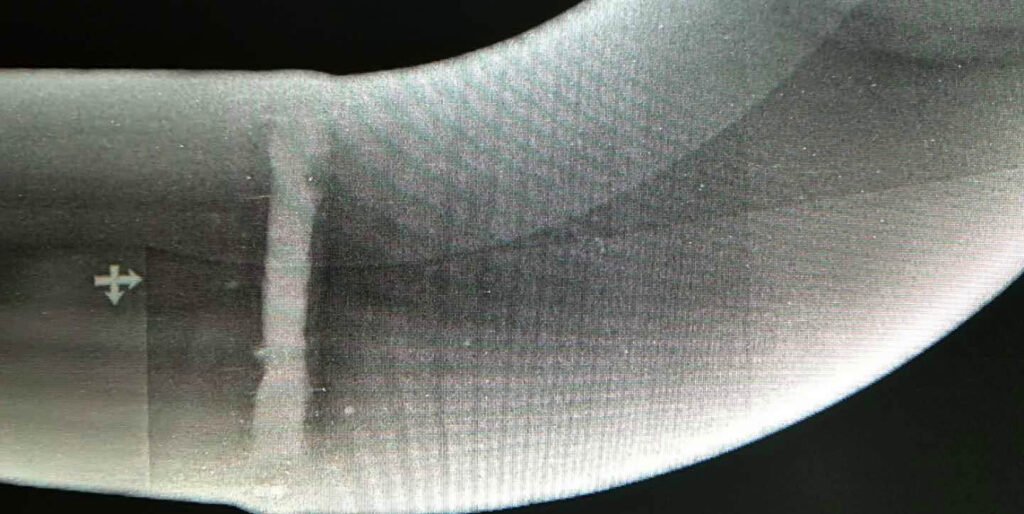

Liquid Dye Penetrant Testing (DPI)

Liquid penetrant testing (PT) is a non-destructive testing method based on capillary action. It mainly uses specially formulated liquids to detect open defects on the surface of materials such as cracks, pores, pinholes, etc. It is suitable for almost all non-porous materials such as metals, ceramics, plastics, etc., especially for non-ferromagnetic materials that cannot be covered by magnetic particle testing, such as austenitic stainless steel and aluminum alloy. It has an irreplaceable role. The process involves applying the penetrant liquid to the surface of the test part, allowing it to penetrate into any surface-damaging defects, and then using a developer to absorb the penetrant liquid to form a visible discontinuity indication.

What is the primary objectives of PT in industrial applications

- Detect surface opening defects: Accurately identify open defects such as cracks, pores, pinholes, looseness, and incomplete penetration on the surface of the workpiece. These defects may become stress concentration points or medium leakage channels, affecting the safe operation of the equipment.

- Ensure the integrity of materials and components: By discovering potential defects, ensure that raw materials, semi-finished products and finished products will not fail due to the expansion of initial defects during subsequent processing, assembly or service. It is especially suitable for industrial parts that bear loads, high temperatures or corrosive environments (such as the surface of vertical mill rollers in cement machinery and the welds of rotary kilns).

- Verify manufacturing and processing quality: In the production link (such as casting, forging, welding, and heat treatment), check whether the process meets the standards, and promptly remove unqualified products to avoid defects from being transmitted with the production process, reducing the subsequent rework or scrapping costs.

- Support maintenance of in-service equipment: Regularly inspect the operating industrial equipment, and detect surface defects caused by fatigue, corrosion, wear, etc. at an early stage, provide a basis for maintenance decisions, and prevent production interruptions or safety accidents caused by sudden failures.

12 Advantages and Liquid Dye Penetrant Testing in NDT

- Widely Applicable Materials: Unrestricted by the material's magnetic properties, it can inspect all non-porous materials (metals, ceramics, plastics, etc.). It is particularly suitable for non-ferromagnetic materials (such as austenitic stainless steel, aluminum alloys, and copper alloys) that are not accessible with magnetic particle testing.

- Economical and Effective: Penetrant testing (PT) requires no complex or expensive equipment, is easy to operate, and is cost-effective.

- Widely Applicable Materials: Unrestricted by the material's magnetic properties, it can inspect all non-porous materials (metals, ceramics, plastics, etc.). It is particularly suitable for non-ferromagnetic materials that magnetic particle testing cannot reach (such as austenitic stainless steel, aluminum alloys, and copper alloys).

- High Sensitivity for Detecting Open Surface Defects: It can effectively identify fine surface cracks, pinholes, porosity, and incomplete weld penetration. Even cracks as small as microns in width can be clearly revealed through the coloring trace.

- Easy to Use and Low Equipment Cost: It does not require complex equipment. The core consumables are a coloring penetrant, a cleaning agent, and a developer (mostly in spray cans). It is highly portable and suitable for on-site inspections (such as field pipeline welds and spot checks of large equipment).

- Intuitive test results: defects are displayed as colored marks (usually red) that contrast sharply with the background. No special light source is required (natural light can be observed), and the inspector can directly determine the position, shape and size of the defect by naked eyes.

- Not limited by the shape of the workpiece: For parts with complex geometric shapes (such as curved surfaces, grooves, threads), the penetrant can penetrate all accessible surface defects through capillary action, and the detection range covers the entire surface of the workpiece.

- Clear defect indication: After the penetration process is completed, the defects are usually visible to the naked eye, which is convenient for direct interpretation and recording.

- Strong complementarity with other NDT methods: It is often used in conjunction with magnetic particle testing (MT), the former covers non-ferromagnetic materials, and the latter covers ferromagnetic materials, together to achieve comprehensive detection of surface defects of workpieces of different materials to meet diversified industrial needs.

- Portability: Penetrant testing (PT) equipment and materials are usually portable and can be used for on-site testing in various environments, including field conditions.

- Sensitivity to tiny defects: Penetrant testing (PT) can detect tiny surface defects that are not visible to the naked eye, including fine cracks, pores and other tiny defects.

- Batch inspection capability: Penetrant testing (PT) can efficiently inspect large numbers of parts in a single operation. By covering all accessible surfaces in one go, it is ideal for inspecting batches of small parts simultaneously. Sensitivity to small defects: Penetrant testing (PT) can detect small surface defects that are invisible to the naked eye, including hairline cracks, pores, and other microscopic defects.

9 Limitations of Liquid Dye Penetrant Testing in NDT

- Surface testing: PT can only detect open discontinuities on the surface. It is not effective for detecting defects below the surface.

- Unable to quantify defect size: Although it can display the surface morphology and location of defects, it is difficult to accurately measure quantitative parameters such as the depth and length of defects, and further evaluation is required in combination with other testing methods (such as ultrasonic testing).

- Affected by environmental factors: High temperature environment will cause the penetrant to evaporate too quickly, and low temperature environment will reduce the fluidity of the penetrant and affect the penetration effect; in addition, strong light or dust at the testing site may interfere with the observation of defect display and reduce the accuracy of interpretation.

- Limited by material porosity: It is not suitable for porous materials (such as wood, foam plastics, and some ceramics) because the penetrant will be absorbed by the pores of the material itself, resulting in serious background interference and inability to distinguish defects from the pores of the material itself.

- Health and safety issues: Some liquid penetrants, emulsifiers, and developers may cause skin irritation or other health problems. Appropriate safety precautions must be taken, including the use of personal protective equipment (PPE). Since the chemicals used in PT may cause harm to the environment and health, the handling and disposal of these chemicals also need to be carefully managed.

- High requirements for accessibility of defect locations: The penetrant needs to directly contact the defect opening. For deep holes, the bottom of narrow slits, or hidden surfaces of complex structures (such as deep grooves inside parts), if the penetrant cannot reach them, the defects in this area cannot be detected.

- Cleaning and condition requirements: Careful surface cleaning must be performed before and after testing to avoid contaminating the test results. Environmental factors such as high temperature or strong winds will have an adverse effect on the application and effectiveness of penetrants, so it is necessary to control environmental conditions to obtain accurate results.

- Potential impact of chemical reagents: Penetrants, cleaning agents, etc. are mostly organic solvents or chemical preparations, which may corrode or swell certain sensitive materials (such as some plastics and rubbers), and attention should be paid to the health protection and environmental protection of operators.

- Dependence on surface cleanliness: Oil stains, rust, oxide scale, coatings, etc. on the surface of the workpiece will hinder the penetration of the penetrant into the defects, and strict pretreatment (such as cleaning and polishing) is required, otherwise it is easy to cause missed detection and increase the preparation cost and time before testing.

How does Liquid Penetrant Testing Works? the working principle and mechanism

In breif: Liquid penetrant testing is based on capillary action. First, clean the surface of the workpiece, apply the penetrant to make it penetrate into the open defect; after removing the excess penetrant on the surface, apply the developer, and absorb the penetrant in the defect through reverse capillary action, forming an obvious trace. It can detect defects such as cracks on the surface of non-porous materials. It is easy to operate, the results are intuitive, and it is suitable for a variety of materials. following is the detail in steps:

What are the Steps in the Liquid Dye Penetrant Testing Process

- Surface pretreatment: Oil, scale, etc. need to be thoroughly removed, and the roughness usually needs to be ≤Ra 25μm, otherwise the pollutants will block the defects. For the rusted surface of cement equipment, mechanical grinding and solvent cleaning are often used to ensure that the penetrant can contact the defect opening.

- Application of penetrant: The penetrant needs to cover the entire surface, and the dwell time (penetration time) is set according to the size of the defect, generally 5-30 minutes. High-viscosity penetrants are suitable for rough surfaces, while low-viscosity ones are more permeable to fine cracks and can penetrate cracks as wide as 0.5μm.

- Removal of excess penetrant: The water-washable type needs to control the water pressure (≤0.2MPa) to avoid washing away the penetrant in the defect; the solvent-based type is wiped unidirectionally with a liquid-soaked cloth to prevent secondary contamination. The key is to retain the penetrant in the defect, relying on the capillary binding effect.

- Application of developer: The developer "sucks out" the penetrant in the defect through capillary action, and the dwell time is usually 5-10 minutes. Dry developer is suitable for rough surfaces, while wet developer can enhance the display of tiny defects, and the traces formed are 10-50 times larger than the actual defects.

- Detection and observation: The coloring method is observed under natural light of ≥500lux, and the fluorescence method needs to be observed under ultraviolet light (365nm). The fluorescence intensity in the dark is ≥1000μW/cm², and 0.1mm surface cracks can be identified.

- Post-processing: Residual developer and penetrant need to be removed to avoid corrosion of the workpiece. For food-grade equipment, it needs to be cleaned with a special solvent to meet hygiene standards.

Liquid Interaction with Materials mechanism:

Surface Tension

Surface tension is a phenomenon in which surface molecules on a liquid are attracted by molecules within it more strongly than by molecules outside it (air). This creates a tension along the surface that causes it to contract, causing the surface to exhibit properties similar to those of a stretched elastic film. The surface tension coefficient (unit: N/m) is used to express this tension. For example, the surface tension of water at 20°C is approximately 0.073 N/m. In penetrant testing, too low a surface tension can lead to excessive diffusion of the penetrant, while too high a surface tension can hinder penetration into tiny defects. Therefore, additives are needed to control the penetrant's surface tension, ensuring that it wets the workpiece surface and penetrates micron-sized cracks.

Capillary Action

Capillary action is the phenomenon by which liquids spontaneously rise or penetrate into confined spaces (such as microcracks and capillaries) due to the synergistic effect of surface tension and adhesion. This action is present throughout the core process of penetrant testing:

- Penetration Phase: Penetrants penetrate cracks wider than 0.1μm due to capillary forces. The penetration depth is inversely proportional to the crack width and the liquid viscosity.

- Development Phase: The developer "draws" the penetrant from the crack to the surface through reverse capillary forces, creating a magnified defect trace. This is driven by the affinity between the developer and penetrant and the surface tension difference.

- The efficiency of capillary action directly determines the sensitivity of micron-sized defect detection and is the core mechanism by which penetrant testing can identify micron-sized cracks.

Wetting Ability/Action

Wettability is the ability of a liquid to spread on a solid surface. It is determined by both the liquid's surface tension and the liquid-solid interfacial tension. It is often measured by the contact angle (the angle between the liquid and the solid surface): a contact angle of less than 90° indicates good wetting (e.g., penetrant spreading on a clean metal surface), while a contact angle of greater than 90° indicates poor wetting (e.g., penetrant clumping and droplet formation on an oily surface). During penetrant testing, the contact angle of the penetrant on the workpiece surface must be less than 30° to ensure it fully covers and penetrates all open defects. Therefore, surface pretreatment (removing oil, scale, and other impurities) is key to improving wetting.

4 PT Processing Methods explained:

Water-Washable Method:

The penetrant is pre-mixed with an emulsifier (such as a fatty acid soap). Excess penetrant can be removed directly from the surface by rinsing with water. The rinsing pressure should be controlled between 0.1-0.3 MPa (to avoid over-rinsing and loss of penetrant within defects). The water temperature should be 38±3°C. This method has a simple process (penetration → rinsing → imaging) and is suitable for batch inspection of workpieces with rough surfaces (such as castings). However, it is slightly less sensitive for fine defects (<0.5μm wide) because the emulsifier may prematurely penetrate into small cracks.

Post-Emulsification Oleophilic Method:

The penetrant does not contain an emulsifier. After penetration, an oil-based emulsifier (such as a mixture of mineral oil and surfactant) is applied. The emulsification time should be strictly controlled between 10-60 seconds (adjusted according to the surface roughness of the workpiece), followed by a water rinse. Its emulsifier only binds to the surface penetrant and does not penetrate defects. Its detection rate for cracks as small as 0.2μm is over 30% higher than Method A, making it suitable for high-precision inspections (such as aerospace parts). However, it is highly sensitive to operating time.

Solvent Removal:

Excess penetrant is removed by wiping with a volatile solvent (such as ethanol or acetone). The solvent evaporation rate should be ≤ 2g/min (at 25°C) to avoid surface residue from excessive drying. This method does not require a water source and is suitable for localized on-site inspections (such as spot checks of cement kiln shell welds). However, the risk of secondary contamination of fine defects by the solvent is high, so a one-way wiping method should be used (avoiding reciprocating wiping).

Post-emulsification hydrophilic method:

Similar to Method B, but using a water-based emulsifier (containing a nonionic surfactant). After penetration, a pre-rinse at 30-50°C is performed (removing 60%-70% of the surface penetrant). Then, an emulsifier is applied to remove residual penetrant through a "detergency" action (a decontamination mechanism). The emulsifier concentration should be controlled between 5% and 10% (mass fraction), and the treatment time is 5-15 minutes. This method is 40% more efficient than Method B in removing excess penetrant from workpieces with complex geometries (such as around the oil hole of a vertical mill bearing seat), while also minimizing the impact of oil-based residue on subsequent processes.

3 Penetrant Types and Sensitivity Classifications for Liquid Penetrant Testing (PT)

The type of penetrant directly determines defect detection capabilities. Key differences lie in fluorescence characteristics, visibility, and sensitivity levels. Specific technical parameters and application scenarios are as follows:

Fluorescent penetrant (Type 1):

Contains fluorescent dyes (such as rhodamine B, sodium fluorescein), emits yellow-green fluorescence of 510-550nm under ultraviolet light (UV-A) with a wavelength of 320-400nm, and the fluorescence intensity must be ≥2000μW/cm² (380mm from the light source). Its sensitivity covers Level ½ to Level 4 (according to ISO 3452 standard):

- Level ½: can detect cracks with a width of ≥5μm, suitable for general industrial parts;

- Level 4: can identify micro cracks with a width of ≥0.5μm, used for key aerospace parts (such as turbine blade tenons).

- The signal-to-noise ratio of the fluorescent signal (defect fluorescence intensity / background fluorescence intensity) must be ≥3:1 to ensure that tiny traces can be identified. It is the preferred type for high-precision detection.

Colored penetrant (Type 2):

Contains red/purple dyes (such as Sudan red, azo dyes), visible under natural light (≥500lux), fixed sensitivity at Level 1, and can detect cracks ≥20μm wide. Its contrast (color difference between dye and developer background) must be ≥70% (CIE color difference value). Although its sensitivity is lower than that of the fluorescent type, it does not require a special light source and is suitable for rapid on-site inspections (such as the casting surface of cement machinery).

Dual-purpose penetrant (Type 3):

Contains both fluorescent dyes and colored dyes, which appear red under white light and fluorescent under ultraviolet light, but its sensitivity is lower than that of a single type: equivalent to Level 1 (cracks ≥30μm wide) in white light mode, and up to Level 2 (cracks ≥10μm wide) in fluorescent mode. Because it can adapt to different lighting environments without changing the penetrant, it is often used in complex sites (such as day/night alternating inspections), but a compromise in sensitivity must be accepted.

Sensitivity classification application principles:

- Level 1 (Type 2/3): Applicable to non-critical parts (such as automobile chassis bolts, cement equipment protective covers), with low detection cost and high efficiency;

- Level 2 and above (Type 1): Used for parts that bear alternating loads or high pressure (such as aircraft engine blades, high-pressure pipeline welds), among which Level 4 can meet the requirements of nuclear industry-level defect detection.

- Although Type 2/3 is called "low sensitivity", its detection ability is still much higher than visual inspection (visual inspection can only identify defects with a width of ≥100μm), which can cover the quality control needs of most industrial scenarios.

Liquid Penetrant Testing (PT) Removers and Emulsifiers Why it is needed?

Answer: Penetrant removal is a key step in the PT process. After the dwell time, the excess penetrant is removed from the surface using the appropriate solvent of emulsifier for the PT processing method used. The selection of removers and emulsifiers must match the penetrant type and treatment method (Method A-D). Their chemical composition and operating parameters directly affect the accuracy of defect detection.

Solvent Removers:

The main ingredients are petroleum fractions (such as kerosene derivatives), chlorinated solvents (such as 1,1,1-trichloroethane, which has been gradually replaced by environmentally friendly solvents) or water-based solvents (containing surfactants). The boiling point is usually 60-150℃, and the volatilization rate is controlled at 0.5-2g/min (25℃) to avoid excessive drying and causing penetrant residue. When used in Method C (solvent removal method), it is necessary to wipe in one direction with a lint-free cloth dipped in solvent, and the amount of solvent used per 100cm² wiping area is ≤5mL to prevent excessive solvent from penetrating into defects. Environmentally friendly solvents (such as limonene derivatives) must comply with the VOC limit of ≤50g/L (EU REACH standard) and are suitable for on-site random inspections (such as bolts for wind power equipment), but cracks with a width of less than 1μm may be missed due to solvent intrusion.

Lipophilic Emulsifiers: