What is a paper pulping machine?

A drum pulper is a continuous paper pulping and coarse screening machine used in recycled fiber processing lines & Paper mill. It integrates pulping and rough screening also known as trommel in a single unit, especially suitable for processing unsorted or unpicked waste paper such as old newspapers (ONP), industrial paperboard, old corrugated containers (OCC), and mixed waste paper. Operating at a high pulp consistency of approximately 14–22%, the drum pulper enables efficient fiber disintegration while minimizing water consumption and energy demand. Inside the paper pulper machine rotating drum, waste paper is gently soaked, lifted, and tumbled, allowing fibers to separate through friction and mild mechanical action. This pulping principle ensures maximum retention of fiber physical characteristics, while preventing excessive shredding of contaminants such as plastics, films, wires, and textiles. As a result, impurities remain largely intact and can be effectively removed through integrated coarse screening, producing a clean accept pulp with high quality and stability. From both an economic and environmental perspective, Paper machine pulper deliver significant benefits by expanding the recovery and utilization of secondary fibers, reducing solid waste and environmental pollution, lowering energy consumption, and supporting the localization and modernization of papermaking equipment. Due to their continuous operation, high-consistency capability, and superior contaminant handling performance, pulping machine have become a preferred pulping solution for modern recycled paper and paperboard mills worldwide.

What is the working principle and mechamism of a pulping machine?

The working principle of a pulping machine is based on continuous, high-consistency, gentle fiber separation rather than intensive mechanical cutting. Waste paper is processed at a relatively high consistency—typically 14–22%—which allows fibers to separate primarily through hydration, friction, and gravity, instead of strong shear forces. This approach minimizes fiber damage and preserves key physical properties such as fiber length, tensile strength, and tear resistance. Unlike conventional low-consistency pulpers, the drum pulper relies on time, motion, and controlled chemistry to achieve effective defiberization while keeping contaminants intact.

Wetting, Impregnation, and Fiber Swelling of pulping machine

After waste paper and process water enter the drum, the first stage of the working principle is thorough wetting and chemical impregnation. Under controlled temperature conditions (typically 45–60 °C) and residence time (15–25 minutes), water penetrates the paper structure, allowing fibers to swell and loosen. When deinking pulp is produced, chemicals such as hydrogen peroxide, sodium silicate, and surfactants are added to promote ink detachment and dispersion. For ordinary recycled pulp, alkaline agents are used to maintain a suitable pH range of about 8.5–10.5. This chemical environment supports fiber liberation without aggressive mechanical action.

Gentle Fiber Separation by Lifting and Falling Motion

The core pulping mechanism of a pulping machine is the repeated lifting and dropping motion of the waste paper mass. As the drum rotates at a stable low speed (around 13–15 r/min), internal motion elements continuously raise the paper mixture to a certain height and allow it to fall freely.

- During this process, fibers are separated by:

- Mutual friction between fibers

- Impact caused by gravity-driven falling

- Mild hydraulic shear from water movement

This washing-machine-like action enables fibers to dissociate gradually, while contaminants such as plastics, films, textiles, wires, and stones remain largely unbroken. This is a key advantage of the drum pulper’s working principle and the reason it is particularly suitable for unsorted or unpicked waste paper.

Pulping machine Controlled Forward Movement and Residence Time

The pulping machine operates with a slight inclination, allowing the pulp to move forward naturally as pulping progresses. This inclined rotation ensures a stable residence time for fiber separation without the need for internal conveying mechanisms. By carefully matching rotation speed, inclination, pulp consistency, and temperature, the drum pulper achieves uniform pulping quality across a wide range of raw materials such as OCC, ONP, and mixed waste paper, each with its own optimized consistency window.

Pulping machine Integrated Dilution and Coarse Screening Principle

Once fiber separation is achieved, the pulp enters the screening stage of the working process. Here, dilution water is introduced, reducing pulp consistency to approximately 3–5%, which is suitable for screening and downstream processing. At this stage:

- Acceptable fibers pass through the screen openings and are collected as usable pulp

- Light and heavy contaminants are continuously flushed, backwashed, or conveyed toward the reject outlet

- Impurities are discharged without being shredded, ensuring low fiber loss

This integrated pulping-and-screening principle allows the drum pulper to combine defiberizing, pre-deinking, and coarse screening into a single continuous operation.

High Fiber Yield and Low Contaminant Breakdown inside pulping machine

Because the pulping machine relies on gentle mechanical action instead of cutting or tearing, fiber loss is extremely low. In industrial operation, fiber retention rates can exceed 98%, even when processing highly contaminated waste paper streams. At the same time, contaminants remain in large, recognizable forms, which significantly reduces the load on downstream cleaning, screening, and refining equipment, improving overall system efficiency.

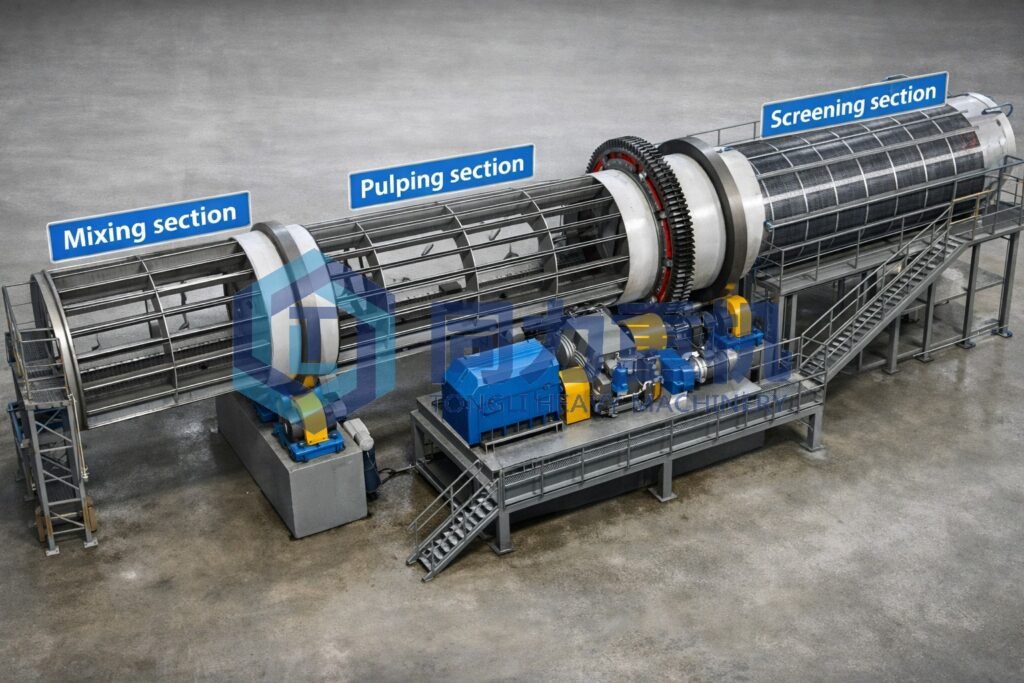

What are the feeding mixing pulping screening zone of paper pulper machine?

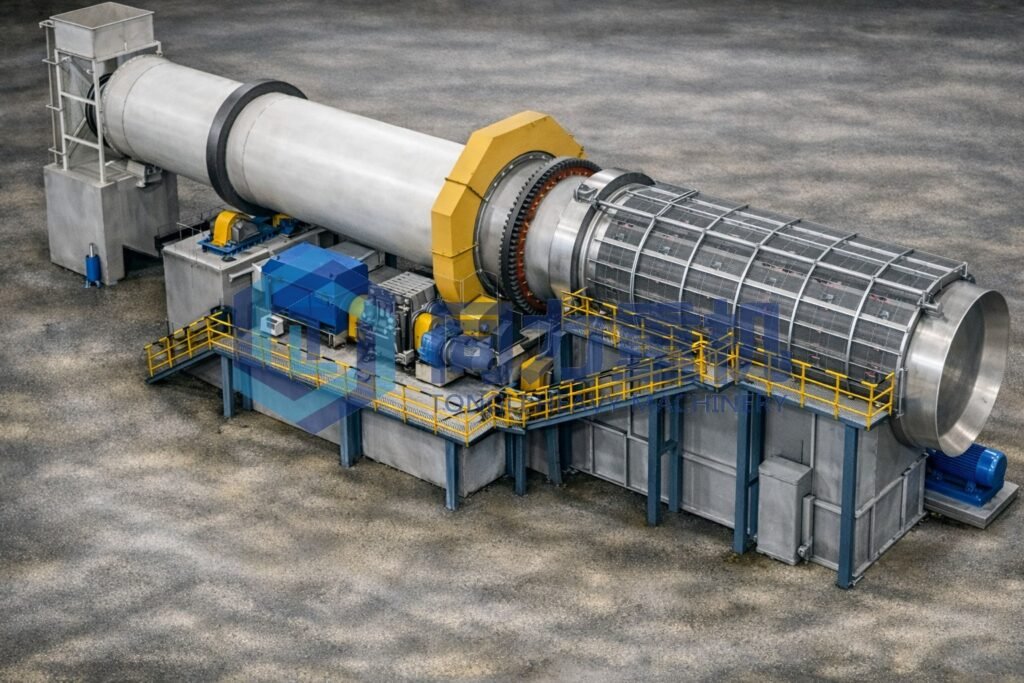

The rotary drum pulping machine is composed of feeding, mixing, pulping, screening and rejection zones as well as core structures including cylindrical drum, support roller system and drive system, with the drum running at 13-15 r/min at an inclined angle of 1°-1.5°; waste paper is fed with metered water and chemicals into the machine, with pulping consistency controlled at 8%-12% for OCC, 13%-18% for ONP and 10%-14% for mixed waste paper at 45℃-60℃, the pulp mixture is lifted and dropped by internal baffles in the pulping zone to realize gentle fiber dissociation through friction and impact while keeping impurities intact, then the pulp is diluted to 3%-5% consistency by flushing water in the screening zone, qualified pulp passes through 6-10 mm aperture sieve plates and is sent to subsequent processes, and large impurities are discharged from the rejection zone; the common TL2500 model has a processing capacity of 70-140 t/d and a fiber retention rate of over 98%, integrating pulping, pre-deinking and coarse screening to minimize fiber damage and reduce the load of subsequent equipment. So now let's introduce the following parts one by one:

Feeding Zone

The feeding zone is the material entry end of the rotary drum paper pulper machine, equipped with a quantitative screw feeder and a metered water/chemical adding device to realize closed and uniform feeding of recycled waste paper (OCC, ONP, mixed waste paper) and auxiliary materials, with the feeding speed matched to the drum’s processing capacity (e.g., 70-140 t/d for ZDG2500 model) to avoid material accumulation or insufficient feeding; the zone is designed with a sealed feeding hopper to prevent pulp splashing and odor leakage, and the mixed feeding of dry waste paper and process water is initially completed here, forming a primary pulp mixture with a preliminary consistency of 5%-7% before entering the subsequent zone.

Mixing zone

Adjacent to the feeding zone, the mixing zone is the core area for uniform blending of waste paper, process water and functional chemicals, with an internal spiral guide plate to accelerate material mixing and axial movement; for deinking pulp production, hydrogen peroxide (0.5%-1.2% based on oven-dry pulp), sodium silicate (2%-3%) and non-ionic deinking agents (0.1%-0.3%) are accurately metered and added here, while alkaline agents are added for ordinary pulp to adjust the mixture’s pH to 8.5-10.5, and the zone controls the initial mixing temperature at 40℃-45℃, with a material residence time of 3-5 minutes to ensure full contact between chemicals and waste paper fibers, laying the foundation for subsequent pulping; the consistency of the pulp mixture is adjusted to the standard pulping range (8%-18% according to paper type) in this zone through precise water control.

Pulping Zone

The pulping zone accounts for 60%-70% of the total drum length, with evenly distributed stainless steel wear-resistant baffles (height 0.8-1.2m) inside, and the drum runs at a stable speed of 13-15 r/min with an inclined angle of 1°-1.5° (adjustable by pulp viscosity); driven by the rotating baffles, the pulp mixture is continuously lifted to a certain height and dropped by gravity, realizing gentle fiber dissociation through mutual friction, impact and mild hydraulic shear between materials, without breaking hard impurities such as plastics and metal scraps; the zone maintains a constant pulping temperature of 45℃-60℃ and a material residence time of 15-25 minutes, with strict consistency control (8%-12% for OCC, 13%-18% for ONP, 10%-14% for mixed waste paper), ensuring the fiber dissociation rate reaches over 95% while maximizing the retention of fiber physical properties (tensile strength, tearing strength).

Screening Trommel Zone

Located in the middle and rear section of the drum, the screening zone is integrated with the pulping zone and accounts for about 20%-25% of the total drum length, with a detachable stainless steel sieve plate (aperture 6-10 mm) as the core component, and a high-pressure flushing water pipe installed on the outer side of the sieve plate to prevent sieve hole blockage (flushing water pressure 0.2-0.3 MPa); the pulp mixture flowing into this zone is diluted to a consistency of 3%-5% by flushing water (flushing water to pulp volume ratio 1:2), and the qualified fiber pulp with a fiber length of more than 0.2 mm passes through the sieve plate under the action of gravity and drum rotation, and is pumped to the subsequent cleaning and refining process by a pulp pump; the screening efficiency of this zone is over 90%, and the sieve plate is designed with a modular structure for easy replacement and maintenance, adapting to the screening requirements of different types of waste paper pulp.

Rejection Zone

As the tail end of the rotary drum pulper (also called impurity discharge zone), the rejection zone accounts for about 5%-10% of the total drum length, with a conical structure design to facilitate the collection and discharge of impurities, and an adjustable discharge gate to control the impurity discharge speed; the large undissolved impurities (plastics, fabrics, metal scraps, large paper blocks) that cannot pass through the screening zone sieve plate move forward to this zone along with the drum’s inclination and rotation, and are discharged out of the drum through the discharge gate under the action of gravity, with the impurity discharge rate matching the drum’s processing capacity to avoid impurity accumulation inside the drum; the zone is equipped with a small amount of spray water (0.1-0.2 m³/t pulp) to wash the attached fiber pulp on the impurities, improving the overall fiber retention rate of the equipment to more than 98%.

What are the parts of a paper pulper machine?

The rotary drum pulper is primarily made up of a cylindrical drum, riding ring, girth gear, trommel machine functional sections including pulping and screening zones, a drum drive unit, a support device, and a feeding and discharging system; the drum is the main body with internal baffles for fiber dissociation, the drive unit powers the drum’s rotation, the support device bears the drum’s load and ensures stable operation, the feeding system delivers waste paper and auxiliary materials into the machine uniformly.

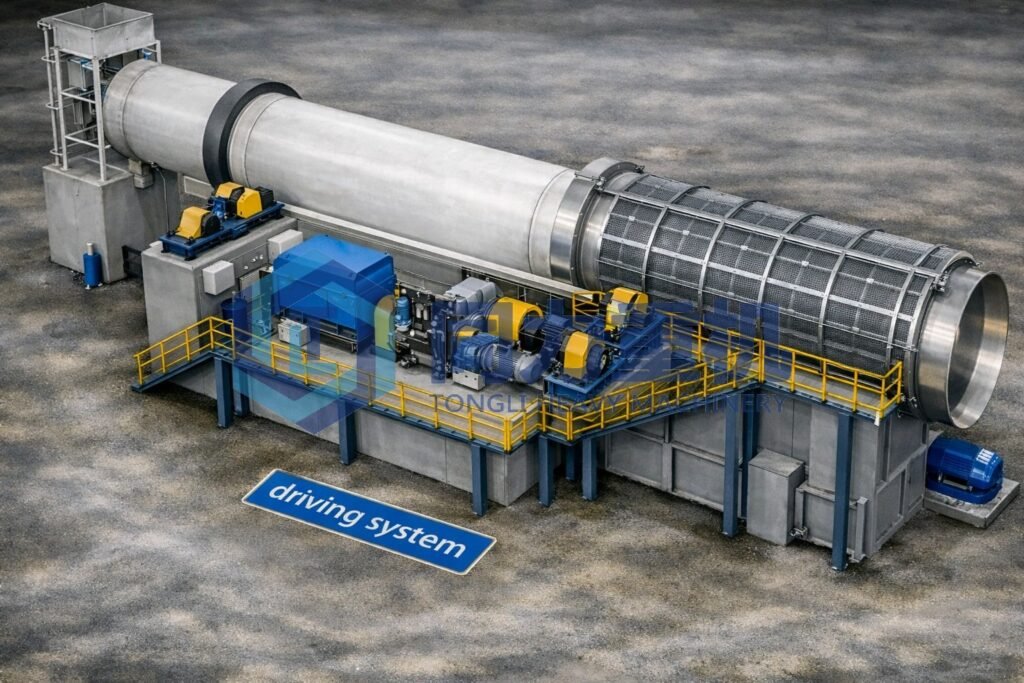

Paper Pulper Machine Drive system

The drive system is the power source of the paper pulper machine, composed of a variable frequency speed-regulating motor, a reducer (hard tooth surface cylindrical gear reducer, transmission efficiency over 95%), a driving gear ring and a pinion; the motor power is matched to the drum model (e.g., 75-110 kW for ZDG2500 model), and the variable frequency control system realizes stepless speed regulation of the drum (10-18 r/min) to adapt to the pulping requirements of different types of waste paper; the driving gear ring is welded on the middle part of the drum outer wall, and the pinion is connected to the reducer output shaft and meshed with the gear ring (modulus 16-20, pressure angle 20°) to transmit power, with a lubrication system installed at the meshing part to reduce gear wear; the drive system is equipped with an overload protection device (torque limiter), which automatically cuts off the power when the drum is overloaded (over 120% of the rated torque) to protect the motor and reducer from damage, and the whole system has a high operation stability with a failure rate of less than 0.5% per year.

Paper Pulper Machine Drum Shell

The shell is the main body of the rotary drum pulper, a horizontal cylindrical pressure vessel made of Q345 carbon steel with a thickness of 12-20 mm (according to model size), and the inner wall is fully lined with 15-20 mm thick wear-resistant rubber (Shore hardness 60-70 HS) to reduce material wear on the drum and extend the service life (service life of rubber lining over 3 years); the total length-diameter ratio of the drum is 3:1 to 5:1 (e.g., Φ2500×10000 mm for ZDG2500 model), and it is designed with a sectional structure for easy transportation and on-site assembly; the drum is inclined at 1°-1.5° to the horizontal plane, which is the power for the axial movement of the pulp mixture and impurities, and the inner wall is equipped with different types of guide plates and baffles according to the functional division of each zone, realizing the integrated operation of mixing, pulping, screening and impurity discharge in the drum.

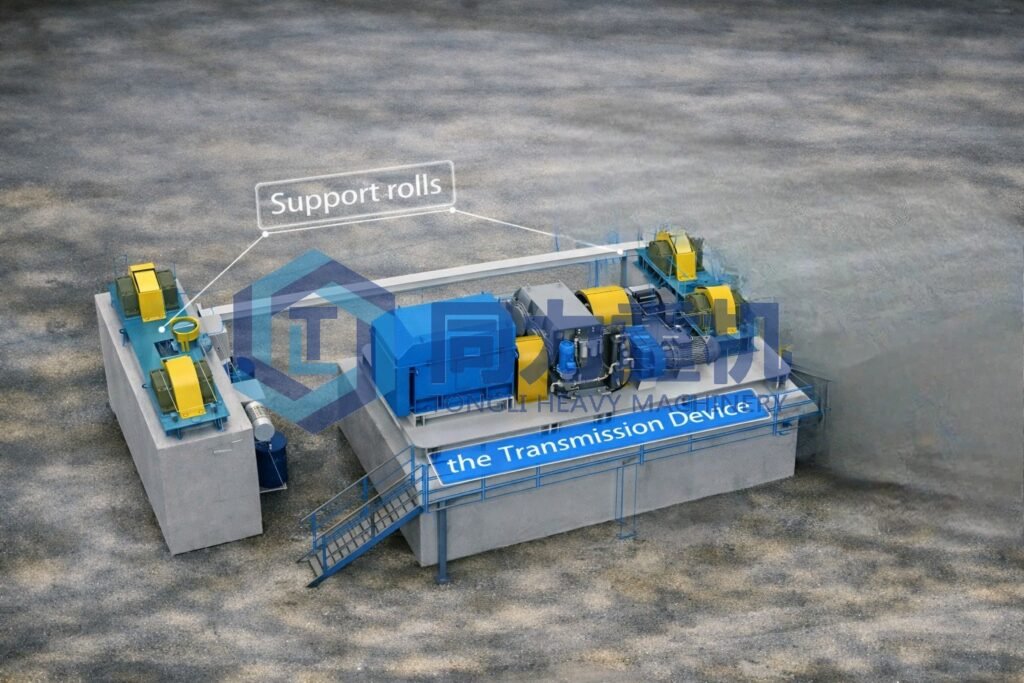

Paper pulper machine Support Roller System

The support roller system is the load-bearing and running support component of the rotary drum pulper, composed of 2-4 sets of upper and lower support roller pairs (made of 42CrMo alloy steel, quenched and tempered to HRC 45-50), a roller frame, a thrust roller and a centering adjustment device; each support roller pair bears 25%-50% of the total weight of the drum (including the weight of the drum itself and the internal material, up to 50-100 t for large models), and the thrust roller limits the axial displacement of the drum (control within ±5 mm) to prevent the drum from sliding during operation; the centering adjustment device can realize the micro-adjustment of the support roller angle (0°-2°) to correct the drum’s running deviation in real time, ensuring the drum runs stably at 13-15 r/min without abnormal vibration (vibration amplitude control within 0.1 mm).

Riding Ring

The riding ring (also known as the rolling ring) is a core load-bearing and force-transmitting component of the rotary drum pulper, which is closely matched with the support roller system and bears the entire static weight of the cylindrical drum and the dynamic load generated during the drum's rotation, ensuring the stable and concentric operation of the drum without axial deviation. It is mainly made of high-strength alloy structural steel 42CrMo (for forging type) or cast steel ZG35CrMo (for casting type), both of which have excellent fatigue resistance and wear resistance suitable for heavy-duty long-term operation. Its processing technology includes integral forging/casting first, followed by normalizing and tempering heat treatment to eliminate internal stress and improve the comprehensive mechanical properties of the base material; then rough machining of the inner and outer circular surfaces is carried out to meet the preliminary dimensional requirements, and finish machining is performed to ensure the flatness of the contact surface with the support roller and the coaxiality with the drum; the outer working surface is further subjected to surface quenching and tempering treatment to reach a hardness of HRC45-50, enhancing surface wear resistance; finally, it is fixedly connected with the drum body by welding or high-strength bolt groups, with strict control of assembly coaxiality to avoid abnormal vibration during operation.

Paper mill machine Girth Gear

The girth gear is fixedly installed on the middle upper part of the Paper mill machine drum body and meshes with the small pinion connected to the reducer output shaft to transmit the power of the drive motor to the drum body and drive the drum to rotate at a set speed. It is mainly made of high-quality alloy cast steel ZG42CrMo (the mainstream material for large-size girth gears) or forged steel 40CrNiMoA (for high-precision transmission requirements), which balances high bending strength of the tooth root, good toughness of the base material and wear resistance of the tooth surface. Its processing technology is sophisticated: integral casting/forging is first carried out, followed by overall quenching and tempering heat treatment to ensure the base hardness of HB260-300 and eliminate casting/forging internal stress; the tooth profile is processed by rough hobbing/gear shaping first, then finish hobbing or grinding to ensure the tooth profile accuracy (modulus 16-20, pressure angle 20° for conventional models) and reasonable meshing clearance with the pinion; the tooth surface is subjected to carburizing and quenching or medium-frequency induction hardening treatment to make the tooth surface hardness reach HRC50-55, while the tooth core remains good toughness to prevent tooth surface pitting, wear and tooth root fracture; before assembly, dynamic balance detection and meshing precision test are carried out, and it is connected with the drum body by welding or flange connection, with a special lubrication oil station configured for the meshing part to reduce tooth surface wear during operation.

Paper Pulper Trommel Machine

The trommel machine is fully made of corrosion-resistant stainless steel to adapt to the pulper’s internal working environment (45°C-60°C, pH 8.5-10.5, and contact with chemical agents such as hydrogen peroxide and sodium silicate). For general pulping scenarios, 304 stainless steel (with a thickness of 3-5mm) is adopted, which has excellent acid and alkali resistance, anti-scaling performance, and moderate wear resistance. For pulping scenarios with strong chemical corrosion (such as high-concentration deinking agents), 316L stainless steel (with a thickness of 4-6mm) is selected to further improve corrosion resistance. The reinforcing ribs and fixing seats are made of the same material as the sieve plates to ensure consistent thermal expansion and contraction performance and avoid structural loosening caused by material mismatch. The processing technology of the trommel machine is sophisticated: the sieve plates are processed by precision laser cutting (to ensure the accuracy of sieve hole diameter and position, with a hole position deviation of less than ±0.1mm), then bending forming (to fit the drum’s radian), followed by surface polishing (to remove burrs on the sieve hole edges and plate surface), and finally integral quenching and tempering heat treatment (to improve the material’s hardness and toughness, with a base hardness of HB200-230).

20 adventages of a paper pulper machine

1. Optimized Standard Drum Diameter for Maximum Pulp Drop Height

The Paper machine is designed with a standardized drum diameter, under which the pulp discharge direction is precisely controlled between 11:15 and 11:30 o’clock. This optimized falling angle creates the maximum vertical drop height, allowing the pulp mat to fully loosen and separate during each rotation cycle. As a result, fiber wetting and dispersion efficiency are significantly improved without applying destructive mechanical force.

2. Non-Rotor, Low-Shear Design Achieving ~50% Energy Savings

Unlike conventional high-speed rotor pulpers, the paper production machine does not rely on violent agitation, cutting, or shear forces. Energy is consumed only for rotating the drum itself, eliminating unnecessary power losses from turbulent mixing. This design results in approximately 50% lower energy consumption, with a typical specific energy demand of only 15–25 kWh/t, depending on raw material quality and operating conditions.

3. Gentle Fiber Separation Preserving Fiber Length and Strength

Pulping occurs through controlled lifting, free falling, and mild friction under high-consistency conditions. There is no cutting edge, no impact rotor, and no aggressive shear zone, ensuring that fibers remain long, intact, and mechanically strong. This directly improves final paper strength properties and increases usable fiber yield.

4. Extremely Low Fiber Loss Due to Non-Destructive Impurity Handling

Because impurities are not shredded or torn, contaminants such as plastics, foils, strings, and hot-melt adhesives remain intact. This prevents fibers from being trapped and lost within broken contaminants, resulting in minimal fiber loss and higher pulp yield, especially when processing highly contaminated recycled paper.

5. High-Capacity Continuous Operation up to 1500 TPD

The paper recycling machine is engineered for large-scale continuous production, with single-unit capacities reaching up to 3000 tons per day. Its long residence time and uniform pulp movement enable stable high-throughput operation without compromising pulp quality or energy efficiency.

6. Exceptional Adaptability to All Grades of Recycled Paper

The paper mill machine is suitable for writing & printing paper, newsprint, kraft paper, and even low BF grades (14, 16, 18 BF). It performs reliably with highly contaminated recycled paper, reducing dependence on strict raw-material sorting and improving raw-material flexibility for paper mills.

7. Replaceable Pulping Bars with ERP-Controlled Optimization

The paper pulper machine is equipped with replaceable pulping bars, allowing wear parts to be renewed quickly without major downtime. Combined with the DCS system, operating parameters can be optimized in real time to maintain stable pulping performance, adapt to raw-material variations, and extend component service life.

8. Special Internal Geometry for Stable and Uniform Pulp Movement

The internal structure features specially shaped lifters arranged in an alternating pattern, ensuring smooth lifting and controlled cascading of the pulp. The slightly inclined drum allows the pulp to move slowly and evenly toward the screening zone, preventing surges, dead zones, or uneven residence time.

9. High-Consistency Operation Improving Fiber Wetting Efficiency

At high consistency, waste paper undergoes gentle friction rather than violent motion. This promotes rapid fiber wetting and separation while maintaining fiber integrity, leading to higher pulp yield and better fiber dispersion compared with low-consistency systems.

10. Superior Pulp Quality with Excellent Fiber Dispersion

The pulper produces pulp with uniform fiber distribution, low shive content, and minimal fines generation. The resulting pulp is well suited for high-quality recycled paper grades requiring strength, cleanliness, and formation stability.

11. Effective Removal of Light and Heavy Contaminants

The rotary drum pulper efficiently separates light contaminants (plastics, foils, films) and heavy contaminants (stones, metals) without breaking them down. This significantly improves the efficiency of downstream screening and cleaning systems and reduces overall system wear.

12. Efficient Deinking Performance under High-Consistency Conditions

Due to high consistency, extended residence time, and enhanced chemical effectiveness, ink particles detach more easily from fiber surfaces. Steam and chemicals are utilized more efficiently, resulting in improved deinking performance and cleaner pulp for higher-grade recycled paper production.

13. Reliable Continuous Reject Discharge without Screen Plugging

The integrated screening and reject discharge system is designed to resist plugging and allow continuous operation. High reject-removal efficiency reduces interruptions and minimizes load on downstream cleaning equipment.

14. Integrated Pulping and Screening Reducing System Cost

By combining pulping and primary screening in a single machine, the rotary drum pulper reduces the number of downstream units required. This leads to lower capital investment, reduced installation complexity, and simplified plant layout.

15. Low Maintenance Design with Minimal Wear Parts

The mechanical structure is simple, robust, and stable, with very few wear components. The single, efficient drive system minimizes spare-part requirements and ensures extremely low maintenance cost over the equipment lifecycle.

16. Paper machine pulper Tire-Free Drive System(Optional)

The drive system of the Paper machine pulper can use either friction drive or girth gear drive which does not rely on tire-based friction drive, eliminating risks of slippage, uneven wear, or frequent replacement. Power transmission is more direct and reliable, improving long-term operational stability.

17. Single-Drum, Non-Blocking Design for Maximum Availability

The single-drum configuration avoids internal accumulation and dead zones. As a result, the pulper offers exceptionally high availability and long uninterrupted operating periods, ideal for continuous production lines.

18. Environmentally Friendly Operation with Recyclable Rejects

Since contaminants are removed intact, they can be sorted and recycled, reducing landfill volume and environmental impact. This supports sustainable recycling practices and lowers waste-handling costs.

19. Proven Mechanical Reliability with Long Industrial Track Record

The paper production machine design has been extensively proven in industrial applications worldwide. Its mechanical strength and operational stability make it suitable for harsh operating conditions and long service life. By the way we have been OEM for some of the well renowned internation company in the paper industry for decades, therefore quality is guaranteed.

20. Universal Solution for Modern Recycled Fiber Processing Lines

With low energy consumption, high pulp quality, strong impurity tolerance, and minimal maintenance, the paper recycling machine represents one of the most comprehensive and future-proof solutions for recycled paper pulping systems.

What are the features of a paper pulper machine?

Efficient High-Consistency Pulping up to 20% Stock Consistency

The rotary drum pulper is specifically designed for efficient pulping at stock consistencies up to 20%, enabling effective fiber liberation under high-consistency conditions. At this level, fibers are separated through controlled lifting, falling, and gentle friction rather than aggressive mechanical forces. This ensures thorough disintegration of waste paper while avoiding fiber damage and excessive fines generation, even when processing highly contaminated recovered paper.

Gentle and Effective Separation of Fibers and Contaminants

Fiber separation and contaminant handling occur simultaneously in a non-destructive, low-shear environment. Because the system operates without a rotor, contaminants are not crushed or fragmented. Instead, fibers are gradually released while impurities remain largely intact, enabling efficient downstream removal. This approach minimizes fiber entrapment in rejects and significantly improves usable fiber recovery.

Consistently High Quality for Board and Packaging Paper Grades

Thanks to the machine’s gentle pulping technology, the strength-related properties of fibers are fully preserved, which is especially critical for board and packaging paper production. Even under high-consistency operation, fiber length, bonding potential, and structural integrity remain intact, ensuring that final paper quality is maintained at a consistently high level despite the use of lower-grade or more contaminated raw materials.

Rapid Consistency Reduction via Bundled Water Jet Dilution

An additional bundled water jet system enables immediate and controlled dilution of the pulp suspension from approximately 20% pulping consistency down to 10–12% screening consistency. This rapid dilution is critical for effective screening performance and occurs without interrupting the continuous process. As a result, fiber loss and flake content in the accepts are significantly reduced, while overall process stability is improved.

Reduced Fiber Loss, Flake Content, and Chemical Consumption

Operating at high consistency during pulping improves fiber-to-fiber interaction and wetting efficiency, which in turn reduces the formation of flakes and unpulped fragments. Once diluted for screening, fibers are already well separated, leading to clean accepts with minimal fiber loss. In addition, high-consistency pulping reduces specific energy consumption and chemical dosage, as chemicals act more effectively at higher concentrations.

Rotor-Free Pulping Section with Special Lifting Bars

In the pulping section, specially designed lifting bars raise the pulp suspension and allow it to fall back onto the drum body in a controlled manner. This repeated lifting-and-dropping action replaces the function of conventional rotors without introducing crushing or cutting forces. As a result, contaminants are not broken down, and fibers are separated efficiently through gravity and controlled mechanical motion.

Optimized Screening Efficiency Below 10% Stock Consistency

Operational experience and extensive trials have demonstrated that screening is most efficient at stock consistencies below 10%. To reach this optimal condition as quickly as possible, one or two shower pipes may be installed in the first half of the screening section, depending on drum size and production capacity. This ensures stable screening conditions early in the process and maximizes separation efficiency.

Early-Stage Screening with Perforated Drum Body

In the screening section, the fiber suspension is handled using the same gentle lifting principle and dropped onto the perforated drum surface. Process water from spray pipes enters the drum through the perforations, allowing fibers to pass through while contaminants remain outside. This enables effective washing of fibers away from the rejects, achieving clean separation already at the pulping stage.

Clean Separation Without Damaging Contaminants

Because contaminants are not subjected to cutting, grinding, or impact forces, they retain their original size and structure. This allows for clean, early separation without producing secondary fines or micro-contaminants. Intact rejects are easier to handle, discharge, and recycle, while downstream cleaning systems benefit from reduced load and wear.

Resource-Saving and Energy-Efficient Process Concept

The absence of a high-speed rotor and the reliance on gravity-assisted motion result in an extremely resource-efficient pulping process. Energy is used almost exclusively for drum rotation, avoiding unnecessary power losses from turbulent mixing. Water, chemicals, and energy are all utilized more effectively, contributing to lower operating costs and improved sustainability.

Gentle Separation of Fibers and Rejects in the Screening Section

Both fibers and rejects are handled carefully throughout the screening zone. Water introduced via shower pipes penetrates the screening area and efficiently washes fibers away from the reject stream. This gentle washing action further reduces fiber loss while ensuring that rejects are discharged cleanly and efficiently.

Constant Accept Quality Due to Absence of Wear Parts

The machine design features no internal wear parts subject to rapid degradation, such as rotors or cutting elements. This ensures that pulping and screening performance remains consistent over time, delivering stable accept quality throughout long operating periods without frequent adjustments or component replacement.

Lower Production Costs and Reduced Downtime

The simple, robust mechanical design and low wear rate result in minimal maintenance requirements and fewer unplanned shutdowns. Reduced spare-part consumption, shorter maintenance intervals, and high operational availability collectively lead to lower total production costs and improved plant profitability.

FAQ: Frequently Asked Questions about Paper Pulper Machine:

Rotary Drum Pulpers operate at 14%-18% consistency via a rotating baffled drum that gently lifts and drops material, tearing and shearing fibers to preserve their integrity while keeping large impurities intact for simple removal, featuring low energy consumption, minimal wear parts, and reduced downstream processing needs but requiring more floor space and performing poorly with hard-to-disperse materials like wet-strength paper; Hydrapulpers use a high-speed rotor in a vat to create intense hydraulic shear at 3%-5% consistency, delivering powerful pulping ideal for OCC and mixed waste streams, with a compact footprint, lower upfront cost, and broader raw material adaptability, yet they consume more energy, risk shattering impurities which increases downstream equipment wear, and may degrade fiber quality due to their aggressive mechanical forces, making Rotary Drum Pulpers the better choice for high-quality pulp production with controlled contamination and Hydrapulpers suitable for cost-sensitive, space-constrained operations prioritizing throughput and versatility.

Paper pulper machines process a diverse range of paper and paper-based materials, including virgin pulp feedstocks like wood pulp sheets and pulp logs for primary paper production, and all grades of waste paper such as old corrugated containers (OCC), old newsprint (ONP), mixed office waste (MOW) with printed and unprinted white paper, kraft paper, and tissue paper, as well as specialty papers like coated paper, lightweight offset paper, and even some wet-strength papers (with specialized pulper designs like high-shear hydrapulpers). They also handle paper scraps, trim waste, and reject materials from paper mills for on-site recycling, with rotary drum pulpers excelling at gentle processing of waste paper to preserve fiber quality and hydrapulpers tackling more challenging waste paper types with heavy contamination or tough fibers, while both can process paper combined with minor non-paper contaminants (e.g., staples, tape) that are later removed via downstream cleaning equipment.

High consistency pulping is a pulping process that operates at a fiber consistency of 14% to 30% (far above the 3% to 5% of low consistency pulping), using mechanical forces like gentle tearing, shearing, and kneading—rather than intense hydraulic shear—to separate fiber bundles without aggressive cutting or fraying, and it is critical because this low-shear, high-consistency action preserves fiber length, strength, and structural integrity, resulting in higher-quality pulp with better paper formation, tensile strength, and burst resistance for premium paper products; it also minimizes fiber fines generation, reduces energy consumption compared to low consistency processes by eliminating excess water handling and pumping, keeps large non-paper impurities (e.g., plastics, wood debris, metal) intact and easily removable in downstream processing (lowering equipment wear and contamination risks), and is highly efficient for recycling waste paper as it gently disperses fiber networks without damaging valuable fibers, making it ideal for rotary drum pulpers and specialized high-consistency refiners that prioritize pulp quality over sheer throughput, while also supporting more sustainable paper production by maximizing fiber reuse and reducing the need for virgin pulp inputs.

Rotary drum pulpers (RDP) at 14%-18% consistency use 15-35 kWh/ton dry pulp, with motor power 150-300 kW for 5-10 t/h throughput and 50% lower energy than intermittent high-consistency hydrapulpers; standard low-consistency hydrapulpers (3%-5% consistency) consume 30-80 kWh/ton dry pulp, powered by 100-200 kW motors for 3-5 t/h capacity; high-consistency hydrapulpers (10%-12% consistency) range 25-50 kWh/ton dry pulp, balancing energy use and pulping intensity; batch pulpers (intermittent) are less efficient at 40-90 kWh/ton dry pulp. Key variables include raw material (OCC/MOW vs. wet-strength paper), consistency (higher = lower energy), rotor design (advanced rotors cut use by ~30%), and system integration (RDPs reduce downstream energy via better impurity retention). Typical baselines: RDPs 15-35 kWh/ton, hydrapulpers 30-80 kWh/ton, with RDPs 30%-50% more energy-efficient than conventional hydrapulpers for equivalent throughput.

Small lab/mini pulpers for testing at 0.01–0.5 t/h, mid-sized industrial units (standard low-consistency hydrapulpers) for small to medium mills at 1–10 t/h, and large-scale production pulpers (rotary drum pulpers, high-capacity hydrapulpers) for major paper recycling and manufacturing facilities at 10–50+ t/h; rotary drum pulpers, optimized for high-consistency continuous operation, typically range from 5–40 t/h for standard models and can reach 50+ t/h with custom large-drum designs, while low-consistency hydrapulpers are available in both batch (0.5–5 t/h per unit, often modularly stacked for higher total capacity) and continuous versions (3–25 t/h), with high-consistency hydrapulpers falling in the 2–15 t/h range; capacity is also influenced by raw material type—processing clean OCC yields maximum rated capacity, while contaminated or tough materials like wet-strength paper reduce throughput by 10–30%—and operational parameters such as pulp consistency, rotor speed (for hydrapulpers), and drum rotation rate (for RDPs), with modular setups (multiple pulpers in parallel) easily scaling total plant capacity to 100+ t/h for large industrial operations.

The typical service life of a paper pulper machine is notably long, with the main drum body and structural frame lasting between 20 and 30 years. This durability is attributed to the machine’s robust construction, which utilizes heavy-gauge steel for the drum and reinforced materials for the frame, designed to withstand the consistent mechanical demands of pulping operations. Core wear components, including internal baffles, drum liners, and discharge screens, have a shorter operational lifespan, ranging from 5 to 12 years. The exact longevity of these parts is influenced by the abrasiveness of the raw materials being processed; highly contaminated materials with grit or hard impurities reduce the service life of liners and baffles to the lower end of the range, while clean waste paper and less abrasive feedstocks extend their life to the upper end. The drive system components, such as gears, motors, and bearings, typically last between 8 and 15 years when maintained properly. Regular scheduled lubrication, routine part inspections, and timely adjustments to the drive system prevent premature wear and ensure consistent performance. Seals and gaskets, which are critical for preventing pulp leaks and maintaining operational efficiency, require more frequent replacement, usually every 2 to 4 years, as they are exposed to moisture, pulp residue, and mild chemical agents over time. The rotary drum pulper’s long overall service life is also a result of its low-shear, gentle operating principle, which minimizes mechanical stress on structural parts compared to more aggressive pulping machines. Well-maintained units often exceed the typical 20 to 30 year lifespan, and minor retrofits such as liner replacement, baffle upgrades, or drive system enhancements can further extend the machine’s functional life without the need for full replacement, making it a cost-effective and reliable asset for paper recycling facilities.

Paper pulper machine pricing is primarily driven by production capacity—larger throughput models (10–50+ t/h) command far higher costs than small lab/mini units (0.01–0.5 t/h) or mid-sized 1–10 t/h industrial pulpers, as higher capacity requires bigger structural components and more powerful drive systems. Construction materials are a key factor, with abrasion-resistant stainless steel for wear parts like liners, rotors and baffles pushing prices up compared to standard steel, since premium materials deliver better durability for abrasive raw materials. Brand reputation also impacts pricing, with established international manufacturers like Metso Andritz, known for robust build quality and reliable after-sales support pricing their pulpers higher than regional or lesser-known brands, which often offer more budget-friendly upfront costs. Machine type further shapes pricing, with rotary drum pulpers typically more expensive than standard low-consistency hydrapulpers due to their heavy-gauge steel drum construction and precision rotating components, while high-consistency hydrapulpers fall at a mid-range price point between the two. Basic, non-customized standard models are consistently more affordable, with any customization—such as tailored designs for specific raw materials or integrated impurity separation—adding to the overall cost.

Choose the right paper pulper for a paper mill by prioritizing core operational and production requirements, starting with pulp quality and end product—opt for rotary drum pulpers for high-quality pulp needs (e.g., tissue, fine paper) that demand preserved fiber length/strength, and low/high-consistency hydrapulpers for cost-effective, high-throughput production (e.g., corrugated board, packaging paper) where fiber quality is secondary to throughput. Production capacity is critical: match the pulper’s rated t/h dry pulp output to your mill’s total production volume, with rotary drum pulpers ideal for 5–50+ t/h continuous operation and hydrapulpers offering flexible batch/continuous options for 0.5–25 t/h (easily scaled with modular setups for higher total capacity). Evaluate raw material type and contamination level: rotary drum pulpers excel with clean to moderately contaminated waste paper (OCC, ONP) and keep large impurities intact for easy removal, while hydrapulpers handle heavily contaminated, tough feedstocks (e.g., wet-strength paper, mixed waste) via aggressive shear. Consider facility constraints: hydrapulpers have a compact footprint for space-limited mills, while rotary drum pulpers require more floor space but deliver lower long-term energy and maintenance costs. Factor in build materials and durability—select abrasion-resistant steel components if processing gritty, abrasive raw materials to extend wear part life and reduce downtime. Align with budget and total cost of ownership (TCO): hydrapulpers have lower upfront costs, while rotary drum pulpers offer better TCO via lower energy consumption (15–35 kWh/ton vs. 30–80 kWh/ton for hydrapulpers) and longer structural service life (20–30 years). Choose a reputable brand with regional after-sales support, as reliable maintenance and spare part availability minimize operational disruptions. Finally, verify scalability: opt for modular pulper designs if your mill plans to expand production capacity, to avoid full machine replacement down the line.

What are the 5 types of paper pulpers?

1. Drum Pulper

A drum pulper is a pulping device used in recycled fiber processing that separates waste paper into individual fibers through gentle, high-consistency operation. By using a slowly rotating drum instead of a high-speed rotor, it maximally preserves the physical properties of the fibers while avoiding aggressive cutting or shear. Contaminants such as plastics, foils, and hot-melt adhesives are minimally disintegrated and remain largely intact, allowing them to be efficiently removed at an early stage. As a result, the drum pulper produces high-quality accept pulp with low fiber loss, making it especially suitable for board, packaging, and other recycled paper grades.

2. Broke pulper

A broke pulper is a pulping machine mainly used for repulping broke paper and various types of waste paper generated during paper production, such as trim waste, off-spec sheets, and damaged rolls. It is typically installed close to the paper machine to enable fast recycling of fibers back into the process. The pulping rotor is installed horizontally, allowing heavy contaminants to settle at the bottom of the tank, which reduces residue carryover and helps prevent screen hole clogging. This design ensures stable operation, low fiber loss, and reliable reuse of valuable fibers.

3. High consistency (HC) pulper

A high consistency (HC) pulper is a pulping machine designed to operate at stock consistencies typically between 12% and 18%, and in some applications up to 20%, to achieve efficient fiber separation with reduced water usage. The high-consistency hydraulic pulper is mainly used for deinking waste paper and for aluminum–plastic separation in liquid packaging materials such as Tetra Pak. It commonly features a tower-shaped tub with a spiral rotor, providing strong fiber separation capability while preventing excessive disintegration of impurities. By operating at high consistency, the HC pulper saves energy and chemicals, delivers stable pulp quality, and, thanks to its compact structure, is easy to operate and maintain.

4. D-type pulper

A D-type pulper is a conventional low-consistency pulping device mainly used for pulping OCC, various pulp boards, damaged paper, and mixed waste paper. It features a D-shaped tub combined with a high-speed rotor, providing strong pulping capability through intense hydraulic circulation and mechanical shear. With its wide range of applications, simple structure, and easy operation and maintenance, the D-type pulper has become one of the commonly used solutions for OCC pulping. However, the strong rotor action can also break contaminants into smaller pieces and shorten fibers, which may increase the load on downstream screening and cleaning systems.

5. Medium consistency (MC) pulper

A medium consistency (MC) pulper is a pulping machine designed to operate at stock consistencies typically between 8% and 15%, providing an effective balance between pulping efficiency, energy consumption, and fiber quality. It is mainly used for pulping various commercial pulp boards, including softwood and hardwood fibers, and is considered one of the most ideal pulping solutions for virgin fiber processing. By operating at higher consistency than low-consistency pulpers, the MC pulper reduces water usage and energy demand while offering gentler fiber treatment and more stable pulp quality for downstream screening and cleaning processes.

Can These Pulp Lines Use a Rotary Drum Pulper?

1. i-OCC (Improved Old Corrugated Containers)

One of the best applications, Rotary drum pulpers are ideally suited for i-OCC lines because they handle high contamination levels (plastics, strings, tapes, hot-melt adhesives) without breaking them down. The gentle, high-consistency pulping preserves fiber strength and enables early removal of intact contaminants, resulting in high pulp yield, low fiber loss, and reduced load on downstream cleaning systems.

What is i-OCC(Drum Pulping System?

An i-OCC drum pulping system is an advanced recycled fiber stock preparation system specifically designed for old corrugated containers (OCC). It is engineered to achieve high fiber yield, stable pulp quality, high operational reliability, and low energy consumption, while efficiently handling contaminants commonly found in OCC furnish. The system emphasizes simplified process flow, gentle pulping, and effective reject removal, making it a preferred solution for modern corrugated and linerboard production.

High-Yield, Low-Energy Stock Preparation Concept

The i-OCC drum pulping system is based on a high-consistency, gentle pulping philosophy, which maximizes fiber recovery while minimizing fiber damage and losses. By reducing the number of intermediate stock chests, the system can save approximately 20% of plant floor space, while simplifying operation and reducing capital investment. Group start/stop logic further improves operational convenience and system stability.

Drum Pulper as the Core of the System

After bale breaking, waste paper is fed evenly into the rotary drum pulper, where it is subjected to minimal impact and gentle rubbing action. This allows rapid water absorption and efficient fiber separation without aggressive mechanical forces. Fibers are fully disintegrated through friction and cascading motion, while contaminants remain largely intact. In the screening section of the drum pulper, shower pipes dilute the stock from high pulping consistency to approximately 3–5%, which is optimal for screening. Accept pulp passes through the perforated drum holes, while light contaminants such as plastics are discharged from the reject end.

Efficient Removal of Heavy Contaminants

Stock collected in the bottom vat of the drum pulper is pumped to a two-stage high-density (HD) cleaner system.

- Accept from the first stage is sent to the dump tower.

- Reject is collected in a settling tank and further treated in the second stage.

- Accept from the second stage is returned to the pulper, while heavy contaminants such as sand and stones are discharged to a sand separator for removal.

This configuration ensures efficient removal of heavy debris while minimizing fiber losses.

Multi-Stage Screening and Reject Handling

After the dump tower, stock enters the coarse screening system. Rejects from the first screening stage are sent to the second stage via an eco-jet mixer, reducing energy consumption and maintenance requirements. Rejects from the second stage are further treated by a float purger and reject separator, where light impurities are collected for downstream treatment. Accepted stock proceeds to the fractionation system, where short fibers are thickened and sent to the storage tower, while long fibers continue through additional cleaning stages.

Advanced Long Fiber Cleaning and Fine Screening

Long fibers are processed through a four-stage low-consistency (LC) cleaner system, where centrifugal force removes remaining light contaminants. In the fine screening stage, high-efficiency screen baskets provide excellent stickies removal, high throughput, and low energy consumption.The final fine screening stage includes under-rotor dilution, which prevents reject thickening inside the screen basket and ensures complete removal of residual impurities. Accepts from all fine screening stages are combined and sent to the long fiber disc thickener.

Long Fiber Dispersion and Refining

The thickened long fiber mat is discharged using a knock-off shower and conveyed through a screw press, plug screw, shredding screw, and heating screw before entering the disperser for further treatment. The dispersed stock is then stored in the long fiber storage tower and subsequently refined using a double disc refiner, delivering stable beating performance, low energy consumption, and consistent pulp quality.

Comprehensive Reject Handling and Environmental Benefits

The i-OCC drum pulping system is designed not only for efficient stock preparation but also for effective reject sorting and handling. Typical OCC and mixed waste paper contain fibers, ash, and various rejects such as plastics, wires, metals, sand, glass, and stickies. The system aims to:

- Maximize fiber retention (typical fiber loss ≤ 2.8%)

- Minimize debris losses (≤ 6.5%)

- Retain a controlled amount of ash

- Remove as many rejects as possible, with stickies removal efficiency ≥ 90%

Proper reject separation and treatment improve environmental performance while also generating economic benefits through higher yield and lower disposal costs.

2. Kraft Liner & Test Liner

For kraft liner and test liner production—especially when based on recycled fibers—the rotary drum pulper provides stable pulp quality, excellent fiber preservation, and efficient contaminant separation. This is particularly beneficial for packaging grades where strength and cleanliness are critical. Drum pulpers are commonly used as the main pulping unit in modern linerboard mills.

What is Kraft Liner & Test Liner

Kraft Liner is made primarily from virgin wood fibers using the kraft pulping process, which gives it high strength, good tear resistance, and excellent burst performance. Because of its superior mechanical properties and clean surface, it is commonly used for outer liners of corrugated boxes where strength, durability, and print quality are critical, especially for heavy-duty or export packaging. Test Liner (also called recycled linerboard) is produced mainly from recycled fibers, typically OCC and mixed waste paper. It has slightly lower strength compared to kraft liner but offers significant cost and environmental advantages. Test liner is widely used for inner or outer liners in standard corrugated packaging where ultra-high strength is not required. It is commonly graded (Testliner 1, 2, 3) based on fiber quality and strength performance.

Corrugated Paper (Medium & Liner Grades)

Yes, Highly suitable, Corrugated paper production relies heavily on OCC-based pulp. Rotary drum pulpers support large capacities, continuous operation, and low energy consumption, making them well suited for high-throughput corrugating medium and linerboard lines.

What is Corrugated Paper (Medium & Liner Grades) pulping Production line

A corrugated paper production line is a complete manufacturing system that converts recycled waste paper and old corrugated containers (OCC) into high-strength corrugated paper used for cartons and packaging. The corrugated paper structure is composed of multiple paper layers, typically two layers of testliner bonded to a wavy corrugated medium known as fluting, which is formed by pressing paper into wave shapes. Common fluting types include A, B, C, E, and F, each providing different thicknesses and compressive strengths to meet various packaging requirements. This layered structure gives corrugated paper excellent strength, cushioning, and compression resistance, making it widely used for carton boxes and protective packaging. Because recycled fibers are the primary raw material, corrugated paper is recyclable and environmentally friendly, aligning with sustainable resource utilization. Our company’s rotary drum pulper equipment for corrugated paper production lines has been successfully applied in hundreds of projects worldwide, and we also supply complete OCC stock preparation systems for paper mills.

Coated Board Paper

Conditionally suitable (depending on furnish design), Rotary drum pulpers are suitable for base layer and middle layer pulping where recycled fibers are used. Their ability to deliver clean, well-dispersed pulp with low contaminant content is advantageous. However, top layers requiring high brightness or surface quality often rely on virgin pulp prepared in MC or HC pulpers.

What is Coated Board Paper pulping line?

A coated board paper production line is a complete system used to manufacture coated white board paper with a smooth, durable, and erasable surface. The paper is coated with a functional layer that allows easy writing and erasing with whiteboard markers and provides water- and stain-resistant performance. It is widely used for portable whiteboards and dry-erase applications. The line includes stock preparation and approach flow systems, supported by complete pulping solutions and turnkey paper mill services. The core equipment is a coated board paper machine with automatic control, high speed, and high output, designed for large-scale production. It uses a three- or four-layer coating process with an air-knife system for uniform coating, followed by double-layer hot air drying and calendering to ensure a smooth, flat surface and good writing performance. Typically based on a Fourdrinier paper machine, the line uses waste paper and wood pulp as raw materials and produces white board paper with a 4600 mm trim width, 350 m/min operating speed, 80–160 gsm basis weight, and 200 t/d capacity. We provide one-stop solutions, supplying pulping, screening, cleaning, refining, papermaking equipment, and spare parts to meet complete project needs.

i-CTMP (Improved Chemi-Thermo-Mechanical Pulp)

Limited / indirect application, CTMP production itself requires specialized refiners and chemical-thermal treatment, not drum pulpers. However, a rotary drum pulper can be used downstream for repulping CTMP-based broke or for handling CTMP-containing recycled streams, not for primary CTMP manufacture.

What is i-CTMP (Improved Chemi-Thermo-Mechanical Pulp) production line?

An i-CTMP (Integrated Chemical Thermo-Mechanical Pulping) production line is a modern pulping system designed to convert wood chips into high-yield pulp with excellent bulk, strength, and optical properties, while maintaining low capital and operating costs. In this process, raw wood chips are first fed into a chip receiving bin, washed to remove sand and dirt, and mechanically dewatered to control moisture. The cleaned chips are then pre-steamed and moisturized, after which a plug screw feeder forms a stable chip plug to seal high-pressure saturated steam inside the pre-heating tube, where the chips are thermally softened. The softened chips are discharged into an equalizing bin and then fed into a thermal shredder system, where they are shredded and kneaded into uniform, hair-like fiber shreds. During this stage, chemicals can be added as required. The shredded fibers have a large specific surface area and uniform size, allowing efficient and controlled chemical treatment. The fiber shreds are then conveyed to a cyclone separator to recover part of the steam before entering the high-consistency (HC) tower, where chemical reactions are completed under controlled retention time. After the HC tower, the pulp is diluted, washed, and dewatered to remove spent chemicals and impurities. It is then treated in a latency chest to eliminate fiber latency and refined in a low-consistency refiner to achieve the target freeness and pulp quality. The refined pulp is screened through pressure screens to remove shives and fiber bundles, with accepts thickened by a gravity disc thickener and sent to a storage tower for papermaking use. The i-CTMP production line is highly flexible and suitable for small to large capacities ranging from 100 to over 500 t/d. It offers high yield from wood resources, lower investment costs, and strong adaptability to different pulp requirements. Hardwood i-CTMP pulp provides higher bulk and improved optical properties, and when combined with chemical pulp (CP), it delivers synergistic benefits such as better bulk, tensile strength, and brightness, making it ideal for a wide range of paper grades.

i-VSP (Improved Virgin Short Pulp)

Generally not used as the main pulper, Virgin short fiber pulp (hardwood pulp) is typically slushed in MC pulpers or HC pulpers for precise fiber control. Rotary drum pulpers are not the primary choice for virgin pulp slushing, but may be used for repulping mixed or recycled streams that contain virgin fibers.

What is i-VSP (Improved Virgin Short Pulp) production line?

An i-VSP (Integrated Virgin Stock Preparation) production line is a complete virgin pulp stock preparation and tissue paper manufacturing system designed for high-quality tissue grades such as facial tissue, napkin, roll tissue, handkerchief paper, paper towel, sanitary paper, napkin/pad base paper, and cotton tissue packing paper. The system covers the entire process from stock preparation to paper making and packing, with a design that optimizes the function of each section to ensure smooth operation, high efficiency, and stable product quality.

- In the virgin pulp pulping system, pulp bales are first conveyed to an automatic de-wiring machine, where bale wires are cut and removed. The pulp then enters a middle-consistency pulper, where mechanical and hydraulic forces generated by the rotor fully slush the bales to a uniform consistency. The pulp is discharged by pump to a dump tower, where fibers are well swollen. The pulping process can be configured as batch or continuous. Before refining, the stock passes through high-density cleaning and magnetic separation to remove heavy and hard contaminants and protect refiner plates. After refining to the required beating degree, the pulp is sent to the final storage tower.

- During the mixing and approach flow, different furnishes are automatically dosed into the mixing chest according to preset recipes. The mixed pulp then passes through a mixing refiner, machine chest, fan pump, and screen before reaching the headbox of the tissue machine. In the i-VSP system, long fiber, short fiber, and broke are processed separately, which significantly improves system efficiency, reduces energy consumption, and ensures good bulk and strength properties of the final tissue paper.

The i-VSP production line features intelligent pulping control and high-efficiency pulping equipment, achieving up to 30% reduction in pulping energy consumption. Key technologies include a new S-type middle-consistency rotor, bale breaker design inside the pulper vat, and a fully automated control system with group start/stop, self-diagnosis, and multiple sensors. Pulping level, feeding amount, and pulper motor speed are automatically controlled via frequency converters, minimizing mis-operation, reducing system failures, and ensuring stable, high-quality tissue production.

Tissue Paper

Selective application only, Rotary drum pulpers are rarely used as the main pulper in tissue lines due to space, response time, and furnish requirements. However, they may be applied in recycled tissue lines or for repulping highly contaminated tissue broke, where gentle fiber treatment and contaminant removal are important.

What is Tissue Paper production line?

A tissue paper production line is an integrated system used to manufacture products such as facial tissue, toilet paper, napkins, and paper towels with high efficiency and consistent quality. It features separate processing of long fibers, short fibers, and waste paper, which preserves fiber strength, improves bonding, and reduces dust and fuzz. The line adopts energy-saving pulpers, low-power double disc refiners, and low-pulse pressure screens for efficient and intelligent stock preparation. Using Crescent Former technology, the tissue machine can run at speeds of up to 1700 m/min and produce paper with a basis weight of 18–35 g/m². An energy-optimized system, including a Yankee dryer heat recovery unit, reduces steam consumption by about 23%, while intelligent basis-weight control ensures stable and uniform paper quality.

Why Choose tongli as the paper pulper machine manufacturer?

Tongli is a specialized manufacturer of large rotary drum equipment, with long-term focus on the design, fabrication, and quality control of heavy-duty rotating machinery. This specialization gives us a deep technical understanding of paper pulper machine structures, drive systems, welding integrity, dimensional accuracy, and long-life operation—all of which are critical to the performance and reliability of rotary drum pulpers. We operate under a fully certified management system, holding ISO 9001 (Quality Management), ISO 14001 (Environmental Management), and ISO 45001 (Occupational Health & Safety) certifications. These systems ensure consistent manufacturing quality, strict process control, and safe, compliant production across all projects. For many years, Tongli has served as an OEM manufacturing partner for internationally recognized companies like Metso and Andritz, producing paper pulper machine main machines for large industrial projects. Through long-term cooperation with global clients, we have accumulated extensive experience in meeting international technical standards, inspection requirements, and factory acceptance criteria. It is important to note that Tongli focuses exclusively on supplying the core paper pulper machine—the rotary drum paper pulper mach ine and its primary mechanical systems. By concentrating on what we do best, we ensure high structural reliability, precise manufacturing, and stable long-term performance, providing our partners with a solid, dependable foundation for complete pulping lines.