Tubular(Pipe) reactor granulation technology is a revolutionary process in the modern fertilizer industry, efficiently coupling the acid-base neutralization reaction with the granulation process. Since its introduction in the 1970s, this highly efficient and compact acid-base reaction unit has become a core technology in the modern fertilizer industry, particularly in the production of ammonium phosphate, ammonium sulfate, and NPK compound fertilizers. By confining the vigorous neutralization reaction between acid and ammonia within the tube, this technology leverages the reaction heat to evaporate water, generating a high-temperature melt that is directly used for granulation. This significantly reduces energy consumption and improves production efficiency and product quality. This article systematically explains the technology's operating principles, historical evolution, core process configurations (single or double pipe reactors, with or without a pre-neutralizer), its significant advantages over traditional granulation technologies (such as pre-neutralizer processes and steam granulation), and its specific applications in the production of ammonium phosphate, ammonium sulfate, and NPK compound fertilizers. This article also provides an in-depth analysis of the technology's capabilities in addressing raw material flexibility, energy integration, and environmental challenges, and explores its challenges and future development trends.

What is a pipe reactor

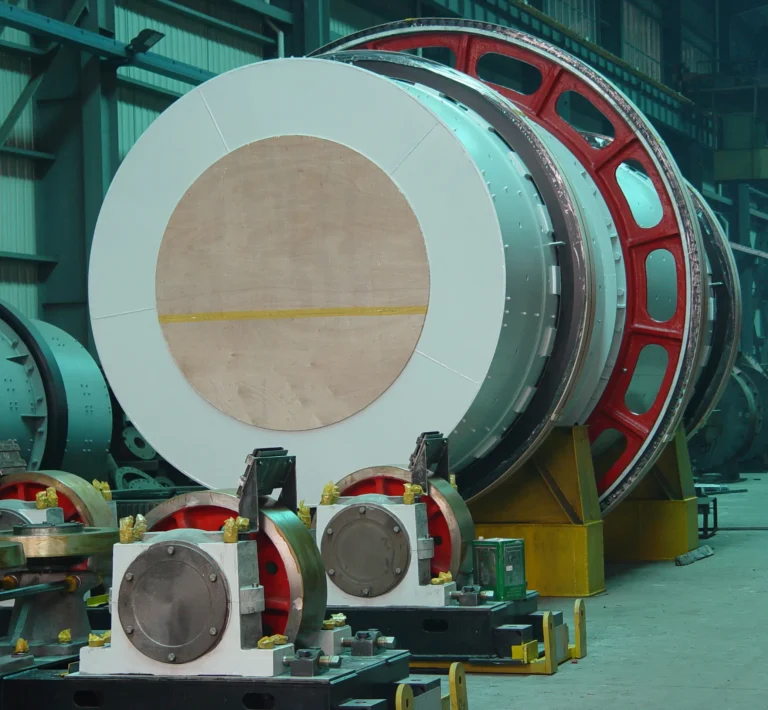

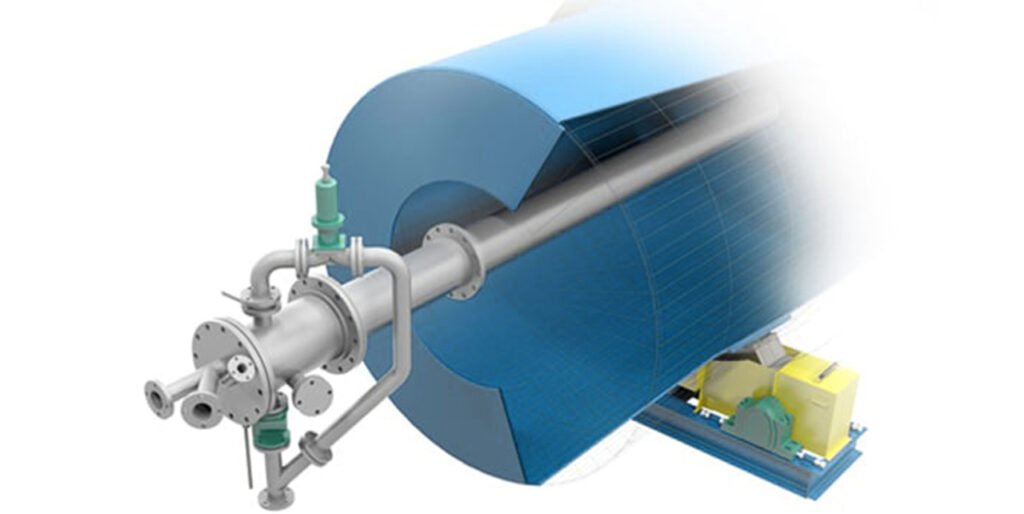

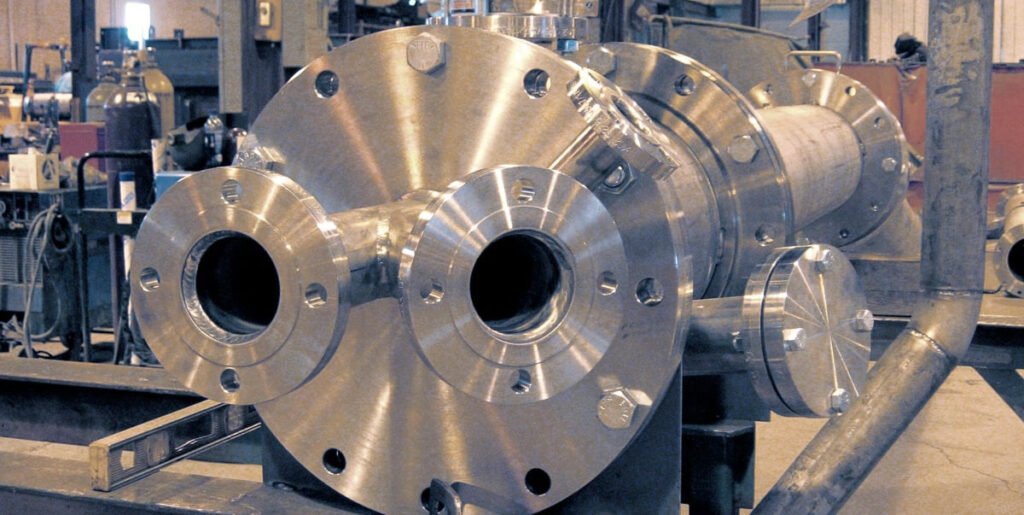

A pipe reactor, also known as a pipe cross-flow granulation reactor, is an acid-base reaction vessel that can be combined with a granulation drum for the production of certain fertilizer products. Originally developed for the production of ammonium phosphate fertilizers, it can add significant value to operations under the right circumstances. By utilizing the heat of reaction as the primary drying method, pipe reactors have been shown to significantly reduce plant energy costs, thereby alleviating the burden on dryers. Also known in the industry as a pipe cross-flow reactor, it is a revolutionary continuous flow reactor. Its core concept is to replace the traditional, bulky, and complexly temperature-controlled tank neutralizer with a section of high-performance, corrosion-resistant piping. Originally developed for the production of ammonium phosphate fertilizers, this technology is now widely used in the production of monoammonium phosphate (MAP), diammonium phosphate (DAP), ammonium sulfate (AS), and various NPK compound fertilizers. The key to its success lies in confining the violent exothermic reaction to a small space, enabling efficient control and utilization of reaction energy and products. This reactor is distinct from the traditional tank pre-neutralizer commonly used to react large quantities of ammonia with phosphoric acid. A pipeline reactor essentially consists of a length of corrosion-resistant pipe (approximately 5-15 meters long). Phosphoric acid, ammonia, and often water are added simultaneously to one end of the pipe through a tee-like pipe structure, hence the name "tee reactor." The reaction between the acid and ammonia is quite violent, building up pressure within the unit. This causes a superheated mixture of ammonium phosphate slurry ("melt") and water vapor to be forcefully discharged from the other end of the pipe, located within the granulator . By varying the structure and orientation of the pipe discharge port, the "melt" can be evenly distributed over the tumbling material bed within the granulator.

Basic composition

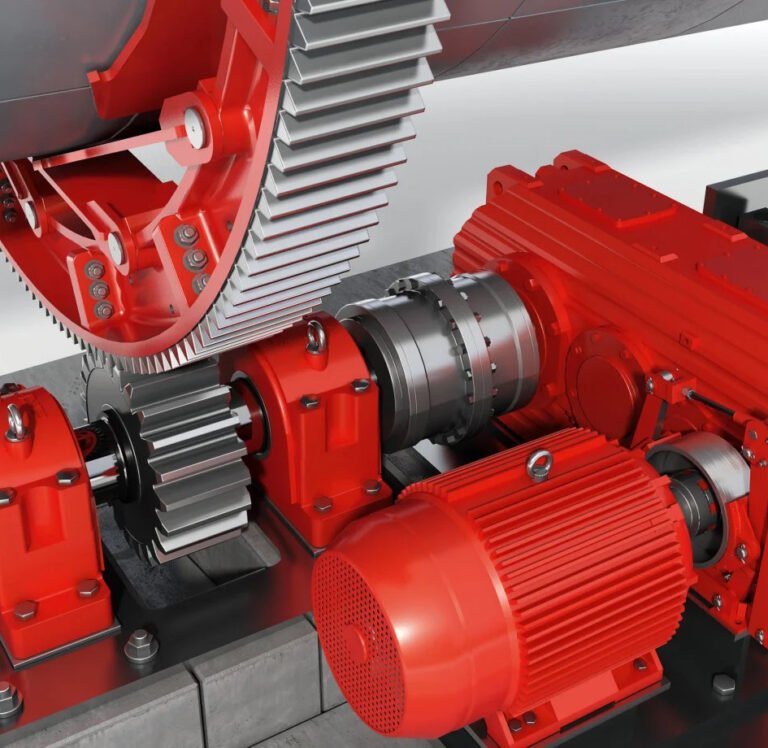

The pipe reactor is a pressure-resistant pipe system with pressure relief valve, bursting disc, raw material inlet and drain valve , which can be directly integrated into the pelletizer.

Core Features

Its core function is to neutralize phosphoric acid and/or sulfuric acid with ammonia. pipe reactor granulators offer significant energy savings because they facilitate the mixing of the acid and ammonia, which leads to a chemical reaction and heat generation. This heat dissipates the initial moisture, creating a hot melt in the pelletizer and aiding the pelletizing process.

Product

The high-temperature and high-pressure fluid produced by the reaction, which can be ammonium phosphate slurry ("melt") or ammonium sulfate "melt" depending on the raw materials, is directly sprayed into the granulator.

Organic applications

Innovative organic-based fertilizer production adds value. In addition to eliminating odors, the pipeline reactor provides customizable nutrient fortification. Feedstock rates can be adjusted to control nutrient levels. In organic environments, the pipeline reactor can be integrated into the granulation drum or agitator (paddle mixer).

Working principle and process

The workflow of the tubular reactor is an efficient unit operation that integrates reaction, evaporation and granulation.

- Feed and instantaneous reaction : Phosphoric acid and/or sulfuric acid enter from one side of the pipeline, while gaseous or liquid ammonia is injected through a specific structure (such as a tee or cross). The two achieve instantaneous and intense mixing and reaction in the pipeline.

- Energy Release and Evaporation : This neutralization reaction is highly exothermic, instantly releasing a large amount of heat, creating a high temperature (typically 125-165°C) and high pressure (2-5.5 kg/cm²) environment inside the reactor. This reaction heat is directly used to evaporate the water contained in the feed liquid and the wash recovery liquid.

- Melt Formation and Granulation : The hot, fluid melt or slurry generated by the reaction is sprayed out from the reactor end in atomized or streaked form and evenly distributed onto the rotating solid material bed within the granulator. To optimize the final product's nutrient profile and granulation quality, a portion of the ammonia gas is injected directly into the granulator's solid bed via a uniquely designed ammonia distributor. The melt acts as a high-quality liquid binder, cooling and solidifying on the granule surface, causing the fine powder particles to grow into hard, uniform finished granules.

- Subsequent Processing and Closed-Loop Control : The resulting wet granules undergo drying, screening, cooling, and coating (to prevent caking) to yield the final product. The screened fines and crushed large granules are returned to the granulator as feedstock, forming a highly efficient closed-loop granulation system. Precise feedstock control technology maintains a low feedstock ratio, thereby increasing the overall system's production capacity.

Main technical configuration

Depending on production requirements and raw material characteristics, tubular reactor systems can be configured in the following ways:

- Single-tube reactor system : This is the most basic and common configuration. The reactor is installed directly inside the granulator, where all liquid phase reactions are completed. This system has a simple structure and low investment cost.

- Dual-Tube Reactor System : This system uses a tubular reactor in the granulator and a dryer. "The DPR operates almost inversely to the GPR, as it is designed to produce solids rather than slurries . The heat generated by the DPR is used very efficiently to dry the material, contributing so much that in some plants the dryer runs entirely on this heat." This significantly improves system capacity and thermal energy efficiency.

- Tubular reactor system with pre-neutralizer : In this configuration, a tubular reactor is connected in series with a conventional pre-neutralizer. The advantage: "The pre-neutralizer promotes the initial neutralization reaction between phosphoric acid and ammonia... Using a pre-neutralizer reduces the amount of steam released from the tubular reactor within the granulator." This improves process stability and product consistency.

- Tubular Reactor System without Pre-Neutralizer : The feedstock enters the tubular reactor directly. This "eliminates the need for a pre-neutralizer, reducing system complexity and maintenance requirements... and reducing the system footprint." This results in a more compact and cost-effective solution.

| Configuration plan | Process Description | Key Benefits | Applicable Scenarios |

| Single tube reactor system | All liquid raw materials are reacted in a tubular reactor inside the granulator. | The system is simple, with low investment and maintenance costs and a small footprint. | The raw material combination is relatively fixed, and the pursuit of low investment and stable operation of standard product production. |

| Double tube reactor system | A tubular reactor is installed in each of the granulator and dryer. The second reactor mainly produces solid products. | Greatly improve the total production capacity of the system; use the reaction heat in the dryer to directly dry the material, with significant energy saving effect. | Factories with high production capacity requirements, the need to maximize the use of reaction heat energy, and the pursuit of production flexibility. |

| System with pre-neutralizer | The tubular reactor is connected in series with a pre-neutralization tank to carry out a two-stage reaction. | The process is more stable and the product composition is more uniform; the amount of steam entering the granulator can be reduced. | Complex production with high production capacity, multiple formulations and extremely high requirements for product consistency. |

| Systems without pre-neutralizer | All raw materials directly enter a single tubular reactor to complete the entire reaction. | The process is simple, the number of equipment is small, the capital and operating costs are low, and the layout is compact. | Factories with limited space, simpler raw material combinations, and a focus on cost-effectiveness. |

Advantages of Pipeline Reactors

The primary advantage of a pipeline reactor over a traditional pre-neutralizer is that it eliminates the need for a pre-neutralizer slurry pump and piping system, allowing a much more concentrated slurry to be delivered directly to the pelletizer. Consequently, the heat of the chemical reaction can be used more efficiently to evaporate unwanted process water than with a traditional pre-neutralizer. TVA modified the three-way reactor to accept an additional sulfuric acid stream via a second pipeline inlet located opposite the phosphoric acid inlet, giving the unit a "cross" configuration, hence the name "Pipeline Cross Reactor" (PCR) . Using PCR technology, a variety of phosphoric acid/sulfuric acid mixtures can be reacted with ammonia. This technology is particularly useful in NPK pelletizing plants, providing a wider selection of raw materials, improving pelletizing results and optimizing overall production costs. Furthermore, since the sulfuric acid does not come into direct contact with potassium chloride (MOP) that may be present in the formulation, the problem of ammonium chloride fumes is eliminated. Generally, the mixture discharged from the PCR does not require further reaction with ammonia in the pelletizer. However, in some cases, the reaction level in the PCR can be modified (reduced) to minimize ammonia evolution or improve pelletizing characteristics when the "melt" combines with solids in the pelletizer. DAP and MAP plants utilize a variety of pipe reactor types (and their materials of construction); sometimes, tubular reactors are combined with traditional tank pre-neutralizers. Perhaps one of the greatest advantages of using tubular reactor technology in the NPK industry is its ability to efficiently utilize a wider variety of raw materials, such as larger quantities of dilute acid and scrubbing liquids. This increased flexibility in raw material selection often reduces production costs while also providing a means to handle certain problematic materials, such as excess scrubbing liquids. However, it's important to note that this technology isn't suitable for all situations. Therefore, its potential should be carefully evaluated on a case-by-case basis.

Energy efficiency

Tubular reactors "have been proven to significantly reduce plant energy costs by utilizing reaction heat as the primary drying method, reducing the burden on the dryer." This translates directly into lower fuel consumption and operating costs. The high-quality heat generated during the reaction is directly used to evaporate the water, reducing fuel consumption in the subsequent drying process. Industrial practice has shown that plants using this technology can significantly reduce dryer fuel requirements.

High quality of finished products

The fertilizer granules produced by this technology have the following characteristics:

- High hardness : The compressive strength of the particles can usually reach 2-3.5 kg/cm², which is strong enough to withstand transportation and mechanical fertilization.

- Low moisture content : The moisture content of the product can be stably controlled below 1.0%-1.5%.

- Uniform particle size : The proportion of target particles of 1-4mm easily reaches more than 90%, or even as high as 99%.

- Good sphericity and less dust : The ammonium sulfate particles it produces are "round and have significantly less dust than products produced by compression granulation," making them easier to apply mechanically.

Raw material flexibility

The tubular reactor is capable of processing a wide range of feedstock combinations, including dilute phosphoric acid, concentrated phosphoric acid, and sulfuric acid. Concentrated or diluted phosphoric acid, sulfuric acid, and nitrogen-containing solutions from various sources can all be effectively processed. It can operate with a combination of dilute or concentrated phosphoric acid and bulk sulfuric acid, or with sulfuric acid alone, avoiding the erosion and corrosion issues traditionally associated with such feedstocks. This flexibility allows manufacturers to select the most economical feedstock combination at any given time based on market prices and to recycle waste streams such as scrubbing liquids generated during the production process for reuse as feedstock.

Environmentally friendly

Combined with an efficient scrubbing system, the tubular reactor process can achieve ultra-low emissions and zero wastewater. According to reports, emissions from plants using tubular reactors contain "ammonia levels of 21-34 ppm (guaranteed value <50), suspended particulate matter of 30-40 ppm (<50), and fluoride of 1.4-2.0 ppm (<10)." Furthermore, a "double-mole scrubbing system maximizes the removal of ammonia and fluoride from plant exhaust gases." The scrubbing liquid can be fully recycled or concentrated and reused through evaporation technology, achieving "zero liquid emissions under normal conditions. "

| pollutants | Guaranteed emission values | Typical measured values |

| Ammonia (NH₃) | < 50 ppm | 21 - 34 ppm |

| Suspended particulate matter (SPM) | < 50 ppm | 30 - 40 ppm |

| Fluoride (F) | < 10 ppm | 1.4 - 2.0 ppm |

Low operating and investment costs

Because the reactor itself is compact and the high reaction heat reduces the size of subsequent equipment, the capacity requirements of the entire granulation circuit are reduced, thus saving capital expenditure and operating expenditure. The technology also includes a "precision control recovery" system that "automatically controls the recovery rate by adjusting the amount of product transferred to the recovery stream," thereby "minimizing the recovery rate and producing a product with a more similar size," further improving production efficiency.

- Capital expenditure : The compact equipment reduces plant space requirements; high reaction efficiency reduces the size of drying, screening and conveying equipment in the granulation circuit.

- Operating expenses : Significant energy savings and consumption reductions; low return ratio and stable operation reduce maintenance needs and downtime.

Industrial Application Cases

Coromandel Fertilizers Ltd. of India

is using X-PR tubular reactor technology in a 250,000-ton annual NPK unit at its egypt plant . The plant successfully produces high-quality NPK 20-20-0 and NPK 14-35-14 using diluted phosphoric acid (26% P₂O₅) and sulfuric acid. Using diluted phosphoric acid and sulfuric acid as the primary raw materials, the line not only achieved its designed capacity (exceeding 115% of the guaranteed value), but also exceeded all product quality specifications, including nutrient content, moisture content, and particle size.

Double-tube reactor technology

This technology boasts over 30 years of successful operation. In one particular 2,000 MTPD plant, “due to the high process flexibility , over 200 different grades of products were successfully produced in a single year,” demonstrating its robust capabilities for high-variety production.

Ammonium sulfate granulation

Utilizing a pipe reactor to produce ammonium sulfate granules, the product is “delivered in the form of round granules, which produce significantly less dust than products produced by compression granulation. The rounded product also provides better breakability upon application。”

Supporting environmental protection technology

In order to achieve truly clean production, tubular reactor systems are usually equipped with advanced environmental protection technologies:

- Washing system : The multi-stage washing system (including pre-scrubber, venturi scrubber and tail gas scrubber) can effectively recover ammonia, dust and fluoride.

- Liquid treatment : For washing liquid that cannot be fully reused, atmospheric evaporation technology has been developed to concentrate the wastewater through the evaporation plate, and the concentrated liquid is returned to the granulation process, ultimately achieving zero liquid discharge.

- Recycling control : Through weighing conveyors and automatic feedback, the return ratio of the granulation process is precisely controlled to ensure stable product quality and maximize production capacity.

Conclusion

Through decades of global industrial practice and continuous innovation, pipe reactor granulation plant technology has evolved from a groundbreaking concept into a mature, reliable, and efficient standard in fertilizer manufacturing. Through sophisticated engineering, it integrates chemical reactions, energy management, and granulation processes, delivering exceptional performance in energy efficiency, product quality, production flexibility, and environmental protection . Whether used for the production of ammonium phosphate, ammonium sulfate, or complex NPK formulations, for new projects or upgrades to existing facilities, tubular reactor technology remains one of the most valuable strategic options for fertilizer producers facing fierce market competition and increasingly stringent environmental regulations.