A shuttle conveyor system is a type of reversible conveyor designed for precise unloading and flexible material distribution at multiple points. Our shuttle conveyor uses a trolley that moves back and forth along a track, combined with the reverse movement of the belt, to achieve efficient, automated handling. Shuttle conveyors are widely used in bulk material industries such as fertilizers, grains, and mining to improve storage efficiency and automation. This shuttle conveyor belt system typically consists of a mobile belt conveyor, track system, drive unit, control panel, and auxiliary components, forming a complete material distribution solution. The core function of our reversible conveyor is to move back and forth along a track and achieve bidirectional unloading through a shuttle conveyor, precisely distributing materials to multiple silos or storage areas-greatly enhancing operational flexibility. Functionally, the shuttle conveyor acts as a mobile silo distribution device. It can connect in series with a main belt conveyor or operate independently as a unit that moves above linearly arranged silos to achieve multi-point, quantitative, and directional unloading. Reversing shuttle conveyors are ideal for building straight, continuous piles or supplying multiple fixed discharge points. Structurally similar to a trough belt conveyor, the shuttle conveyor features a moving trolley that enables the belt to travel in both directions along the track. Depending on the configuration, the shuttle conveyor system can perform single-side, double-side, or center unloading, making it adaptable to a variety of industrial material handling needs and ensuring reliable, automated performance.

What is a reversible shuttle conveyor?

A reversible shuttle conveyor is a belt conveyor system designed to move materials forward and backward. This design allows for precise distribution of materials to different locations from a single conveying system. Shuttle carriages move back and forth along the length of the conveyor belt, transporting materials to multiple unloading points. This back-and-forth motion makes shuttle conveyors particularly useful for applications requiring the storage of materials in different stacks or bins without the need for multiple systems. Through a specially designed traveling mechanism and reversing device, it meets the needs of multi-point unloading and flexible warehousing in industrial production. The combination of reversible operation and mobile functionality improves the efficiency and accuracy of material distribution. This design overcomes the limitations of stationary conveying systems in material distribution, providing a more flexible and mobile solution for industrial production. Technically, reversible shuttle conveyors possess core functions such as bidirectional conveying capability, mobile operation, and fixed-point unloading. They can complete material conveying tasks at different locations and in different directions according to production needs.

Difference from stationary belt conveyor systems

Compared to traditional fixed belt conveyor systems, reversible shuttle conveyors offer significant advantages. Traditional fixed belt conveyors typically only allow unidirectional material transport from start to finish. If unloading at multiple points is required, multiple conveyors must be connected in series or equipped with multiple unloaders, increasing system complexity, floor space, investment costs, and operating and maintenance expenses. In contrast, reversible shuttle conveyors can precisely distribute materials across a series of silos using a single mobile device, saving space and simplifying operations. In terms of application areas, reversible shuttle conveyors are widely used in mining, metallurgy, power, chemical, coal, and building materials industries. In these industries, the storage and distribution of raw materials, semi-finished products, or finished products are crucial links in the production process. An efficient material distribution system can improve overall production efficiency and reduce operating costs. Especially in situations requiring the classification and storage of multiple materials or proportional batching, reversible shuttle conveyors offer greater flexibility and precision.

| Feature | Reversible Shuttle Conveyor | Fixed Belt Conveyor + Multiple Dischargers | Simple Discharge Trolley |

| Discharge Flexibility | High, can move to any position for discharge | Low, can only discharge at fixed points | Medium, movable but with limited functions |

| Equipment Complexity | Medium-high | High (requires multiple sets of equipment) | Low |

| Space Utilization | High | Low | Medium |

| Investment Cost | High long-term returns | High | Low |

| Maintenance Cost | Medium | High | Medium-low |

| Distribution Accuracy | High | Medium | Low |

Working principle and composition of reversible shuttle conveyor

Its core operating mechanism, based on its mobility and reversible conveying capabilities, enables efficient material placement at multiple target points within a limited space. Through the synergy of a sophisticated mechanical structure and an intelligent control system, it completes the entire process from material reception to precise delivery.

Working mechanism

The core operating mode of a reversible shuttle conveyor is bidirectional conveying and mobile positioning. Under normal operating conditions, the conveyor moves along the track system to the designated position, and then activates the conveyor belt to run in either the forward or reverse direction according to unloading requirements, accurately delivering the material to the target hopper. This flexible operating mechanism allows it to replace multiple fixed conveyors, simplifying the material distribution system. Compared to conventional conveying equipment, the reversible shuttle conveyor can complete the change of unloading direction without stopping the preceding conveyor. This feature ensures the continuity and efficiency of the material conveying process, avoiding production interruptions caused by changing unloading points. This advantage is particularly pronounced in silo distribution environments, where the shuttle conveyor can sequentially distribute material to multiple silos, improving the utilization rate of storage space and work efficiency.

System Composition

The mechanical structure of a reversible shuttle conveyor mainly consists of the following key parts:

- Chassis Structure: The foundational load-bearing platform of the entire system, typically constructed from welded steel, possessing sufficient strength and rigidity to withstand belt tension, material loads, and various dynamic forces. Chassis design must comprehensively consider equipment stability and material utilization. Common structural forms include plate-beam and truss types. Plate-beam structures offer better rigidity and are suitable for heavy-duty conditions; truss structures are lighter and suitable for applications with strict requirements on movement inertia. Various mounting interfaces are provided on the chassis for fixing components such as rollers, idlers, and drive units.

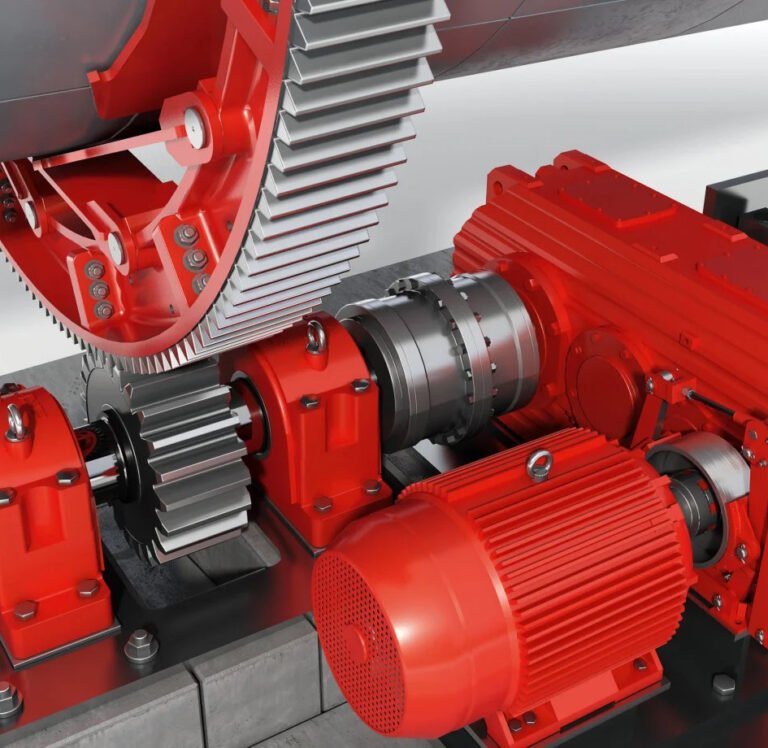

- Drive Unit: Comprising a belt drive system and a walking drive system. The belt drive system provides power for the belt movement, typically using an electric roller or a combination of a geared motor and transmission roller. Electric rollers are compact and easy to install, suitable for space-constrained applications; separate drives offer easier maintenance and a wider power range. The walking drive system is responsible for the trolley's movement along the track, typically consisting of an electric motor, reducer, chain drive, and wheels. To ensure smooth trolley start-stop and accurate positioning, the walking drive system often employs frequency converter control for smooth speed adjustment. In applications requiring precise positioning, the system is also equipped with encoders or absolute sensors to provide real-time feedback on the trolley's position.

- Conveying System: This is the part that directly contacts the material, including the conveyor belt, idler rollers, drums, and cleaning devices. The conveyor belt, as the material carrier, must be selected considering material characteristics (such as abrasiveness, humidity, acidity/alkalinity) and the ambient temperature. Ordinary rubber conveyor belts are generally suitable for materials with temperatures not exceeding 60℃, while heat-resistant rubber belts (up to 120℃) are required for high-temperature materials. Idler rollers support the conveyor belt and maintain its trough shape; their spacing and dynamic balance directly affect operating resistance and stability. Drums include drive drums and redirecting drums; the former provides power, and the latter changes the belt direction. The cleaning device removes material adhering to the belt, preventing spillage and deviation.

- Unloading Device: This is a key component for directional material diversion, typically employing a gate valve or flap valve structure. By adjusting the valve opening or angle, the flow direction and flow rate of the material can be controlled. For applications requiring precise batching, the unloading device can be equipped with electric or hydraulic actuators for remote automatic control. The shape and angle of the chute design directly affect the smoothness of material flow and its anti-clogging performance. For materials prone to adhesion, the inside of the chute is often lined with wear-resistant or non-stick plates to extend its service life and reduce maintenance requirements.

| Component Category | Core Component | Function | Technical Features |

| Main Structure | Frame | Bear the entire system | Steel structure welding, requiring high strength and rigidity |

| Track and traveling wheels | Support and guidance | Steel rails laid, traveling wheels with flanges to prevent derailment | |

| Drive System | Belt drive | Drive the conveyor belt | Electric drum or separate drive, reversible operation |

| Traveling drive | Drive the trolley movement | Motor + reducer + chain drive, frequency conversion control | |

| Material Conveying System | Conveyor belt | Carry and transport materials | Rubber composite material, optional heat/oil/acid and alkali resistance |

| Idler group | Support the conveyor belt | Trough/parallel arrangement to reduce running resistance | |

| Drum | Direction change and tensioning | Drive drum/direction change drum, high-strength design | |

| Discharge System | Discharge hopper | Collect and guide materials | Wear-resistant lining, anti-blocking design |

| Gate valve/flap valve | Control material flow direction | Electric/hydraulic actuation, remote control | |

| Chute | Guide materials into the bin | Optimized angle to reduce impact and dust | |

| Auxiliary System | Dust removal system | Control dust diffusion | Dry/wet dust removal, environmental protection requirements |

| Electrical control | Coordinate system operation | PLC control, automated operation |

Product Types and Technical Specifications

Reversible rubber shuttle conveyors, based on their structural characteristics and application requirements, can be categorized into several types, each with its specific applicable scenarios and technological advantages.

From a structural design perspective, reversible shuttle conveyors are mainly divided into three types: single-unit, two-section trailer, and three-section trailer. The single-unit type has a simple structure and good rigidity, suitable for shorter lengths (6-9 meters). Two-section trailers (12-18 meters) and three-section trailers (21-30 meters) use articulated connections, better adapting to track unevenness and foundation settlement, making them particularly suitable for long-distance conveying scenarios. For specific needs, manufacturers can even provide customized designs up to 60 meters in length.

Conveying capacity is the core performance indicator of a reversible shuttle conveyor, directly affecting the efficiency of the entire material handling system. Depending on the model and configuration, the conveying capacity of reversible shuttle conveyors ranges widely, from a few tons per hour to thousands of tons per hour. For example, heavy-duty reversible shuttle conveyors can handle various materials with a capacity of 1600-2500 kg/m³, including fertilizers, ores, coal, cement, lime, solid waste, etc., meeting the needs of most industrial scenarios.

| Parameter Type | Parameter Range | Application Scenario |

| Conveying Length | 6–30 m (standard type), up to 60 m | Selected according to warehouse scale and layout |

| Conveying Capacity | 50–1000 t/h, up to 2000 t/h | Selected according to material characteristics and handling requirements |

| Power Range | 2.2–220 kW | Determined based on load and conveying speed |

| Applicable Materials | Ore, coal, cement, lime, solid waste, etc. | Various bulk material handling |

| Conveying Distance | Up to 1000 m | Medium- to long-distance material conveying |

In addition to standard models, reversible shuttle conveyors also offer customized designs to meet specific working conditions. For example, users can choose different types of mobile power supply devices, including overhead cables, sliding contact lines, cable reels, and cable chains. For applications requiring explosion protection, explosion-proof motors and electrical components can be used; for corrosive environments, stainless steel or special surface treatments can be selected. Tailor-made solutions are provided to users.

Advantages of reversible shuttle conveyors

As a key piece of equipment in the modern material handling field, the widespread application of reversible shuttle conveyors is backed by a series of technological advantages and performance characteristics.

Precise Material Placement and Position Control

This system enables precise material placement, accurately unloading specified types and quantities of material into target hoppers. This advantage is primarily due to its position control technology. Traditional limit switches provide only limited position signals, while modern scale positioning technology can detect the absolute position of the trolley in real time with an accuracy of ±5mm and a resolution of 2mm. This continuous, high-precision position detection capability ensures that the trolley stops precisely at the designated unloading point in each hopper.

Precise material placement is crucial for ensuring product quality. Taking the steel industry as an example, ironmaking systems require precise mixing of different ores, and the accuracy of hopper placement directly affects the quality of the steel. Traditional unloading methods, due to inaccurate positioning, are prone to hopper mixing accidents, directly affecting the stability of raw material composition and causing quality defects. The high-precision positioning unloading trolley system effectively avoids these problems, ensuring the accuracy of raw material proportions.

Furthermore, the system's real-time position monitoring function allows control room operators to monitor the precise position and operating status of the trolley at any time. Compared to traditional methods, this not only reduces reliance on on-site personnel but also improves the ability to respond to abnormal situations. In the event of vehicle loss of control or other abnormal situations, the system can immediately identify and take corrective measures to avoid the problem of "vehicle location loss".

Efficient Space Utilization and Layout Flexibility

A single shuttle conveyor can serve multiple storage bins, reducing floor space requirements and simplifying your material handling setup. Compared to traditional multi-belt conveyor systems, a single mobile unit can cover the entire storage area, reducing equipment footprint. This feature is particularly advantageous in space-constrained renovation projects. The system's incoming conveyor axis can be coaxial with or perpendicular to the storage bins, allowing for a simpler and more rational process layout. Because reversible distribution belt conveyors can operate in reverse, their length is shorter, typically about half the required fabric length for the storage bin plus 2-3 meters, resulting in lower equipment investment. Compared to ordinary unloading trolleys, reciprocating belt unloading systems occupy less space, reducing civil engineering costs; however, the entire machine is subject to belt tension, requiring high frame strength.

Strong Material Delivery Capacity

Through the organic combination of continuous movement and bidirectional unloading, the system can quickly complete the material distribution operation of a series of silos, significantly shortening material delivery time. For multiple raw materials requiring mixing, the system can sequentially feed materials into designated silos according to preset proportions, laying the foundation for subsequent precise batching. This flexible material delivery capability allows the system to maximize the utilization of silo or storage yard volume and is widely used in industries such as fertilizer, cement, metallurgy, power, and mining.

Wide Material Adaptability

The system can handle bulk materials with various properties. Based on the material characteristics, the system can be divided into light-duty and heavy-duty types. Light-duty systems are suitable for materials with a bulk density <1600kg/m³, with a suitable belt width of 500-1400mm; heavy-duty systems are suitable for materials with a bulk density ≥1600kg/m³, with a suitable belt width of 800-1400mm. For special materials, specialized designs are available, such as a single-sided unloading chute designed for sticky, wet powdery materials (fine ore, concentrate), with a chute inclination angle of up to 60° to prevent material adhesion and blockage. The system also has strong adaptability to ambient temperature, generally operating in environments ranging from -10℃ to +40℃. The temperature of the conveyed material can reach up to 120℃ (heat-resistant rubber belt) depending on the conveyor belt material.

Environmental Performance

The system can be equipped with a sealed material guide chute, dust removal system, and chute sealing device to effectively control dust diffusion during loading and unloading. For applications with strict environmental requirements, a fully enclosed design can be adopted to completely isolate materials from the surrounding environment. These environmental protection measures not only reduce material loss but also improve the working environment.

Industry Applications of Reversible Shuttle Conveyors

Reversible shuttle conveyors have found applications in numerous industrial sectors. These industries typically involve large throughput, diverse material types, and centralized warehousing facilities, placing high demands on material delivery efficiency and flexibility. Analyzing the specific applications of conveyors in various industries provides a more comprehensive understanding of their practical value and selection considerations.

Coal and Mining Industry

In the processing of coal, metallic, and non-metallic minerals, raw ore, concentrates, and intermediate products typically require separate storage or blending. Reciprocating belt conveyor unloading trolley systems move along ore bin tracks, unloading minerals of different qualities or types into designated bins, achieving refined storage management. In this field, systems often face challenges such as high abrasiveness, large particle size, and high moisture content; therefore, heavy-duty designs are frequently adopted, equipped with wear-resistant components and anti-clogging devices to ensure reliable operation under harsh conditions.

Power Industry

Especially in thermal power plants, reversible shuttle conveyors are another important application. In coal-fired power plants, the system is often used for coal bunker distribution, distributing raw coal from the coal conveying system to each boiler bunker as needed. This application places extremely high demands on system reliability and safety, as any interruption in fuel supply can affect power generation capacity. Therefore, unloading trolley systems used in power plants are typically equipped with redundant drives, fault self-diagnosis, and fire-fighting facilities to ensure continuous and stable operation. Meanwhile, considering the risk of coal dust explosions, the system must also meet strict explosion-proof requirements, employing explosion-proof electrical components and explosion suppression measures.

Chemical and Building Materials Industries

In fertilizer plants, cement plants, glass factories, and plastic processing plants, various raw materials and semi-finished products need to be stored separately and precisely proportioned. Reversible shuttle conveyors, through flexible material distribution schemes and programmable control, can meet the stringent requirements of these industries for batch management and formula execution. In these applications, material characteristics may cover a wide range, from fine powder to large lumps, and from room temperature to high temperature. The system design needs to be specifically optimized for specific material characteristics, such as anti-sticking, moisture-proofing, and anti-static properties.

Metallurgical Industry

The metallurgical industry has complex production processes and a wide variety of materials. From sintered ore and coke to pellets and limestone, various raw materials need to undergo storage and distribution. In integrated iron and steel enterprises, reversible shuttle conveyors can be used for material distribution on blast furnace troughs, precisely distributing different raw materials into each silo according to the blast furnace process requirements. This application typically requires a system with high-precision positioning and weighing/proportioning capabilities to ensure the stability of the furnace charge composition. Materials used in the metallurgical industry are characterized by high specific gravity, uneven particle size, and high abrasiveness; therefore, the system must adopt a heavy-duty or integral heavy-duty design, equipped with wear-resistant measures and overload protection.

Different application scenarios have different requirements for system configuration. Light-duty unloading vehicles are suitable for materials with low bulk density, such as some agricultural products and light chemical raw materials; heavy-duty unloading vehicles are suitable for heavy materials such as ores and coal. Single-sided unloading designs are typically used for silo lines arranged along walls, while double-sided unloading designs are used for silo lines arranged in the middle. When selecting a system, material characteristics, process requirements, and site conditions must be considered to choose the most suitable configuration.

Selection Guidelines and Technical Specifications

Selecting a reversible shuttle conveyor requires comprehensive consideration of multiple factors, including process requirements, material characteristics, site conditions, and investment budget.

Material Property Analysis

Different materials possess different physical and chemical properties, directly impacting system design and configuration. Bulk density determines whether the system falls into the light- or heavy-duty category—materials with a bulk density less than 1600 kg/m³ can be processed using light-duty equipment, while materials with a density greater than or equal to this value require heavy-duty equipment.

- Particle size distribution: Affects chute and funnel design. Excessively large particles may cause blockages, requiring increased cross-sectional area or special measures.

- Abrasiveness: Highly abrasive materials require wear-resistant materials for contact parts, such as manganese steel plates or ceramic liners.

- Moisture content and viscosity: Affect material flowability and unloading performance. Highly viscous materials require increased chute angle or the installation of vibrators.

In addition, the chemical properties of materials, such as acidity, alkalinity, temperature, and explosiveness, are also important bases for material selection and explosion-proof design.

Process Parameter Determination

- Conveying capacity: Usually expressed in tons per hour (t/h), it determines the system's bandwidth, belt speed, and power configuration.

- Number and layout of service hoppers: Affects track length and drive selection.

- Material placement method: (continuous or fixed-point) determines the control strategy and positioning accuracy requirements.

- Equipment operating schedule: (daily operating time, load rate) relates to the equipment's lifespan design and safety factor selection.

Key Technical Specifications

- Bandwidth: This is the basic size of the system, commonly available in specifications such as 500, 650, 800, 1000, 1200, and 1400 mm.

- Belt Speed: Affects conveying capacity and operational stability, generally not exceeding 2.5 m/s.

- Drive Power: Depends on multiple factors such as conveying capacity, lifting height, and operating resistance, and needs to be determined through detailed calculations.

- Equipment Weight: Related to civil engineering foundation design and track support requirements, and should be provided to relevant professionals in the early stages.

Configuration Options

- Belt drive: Options include an electric roller or an external drive unit; the former is more compact, while the latter is easier to maintain.

- Travel guidance: Options include track-guided and trackless (e.g., laser or magnetic) guidance; most fixed installation systems use track guidance.

- Unloading device: Options include gate valves or flap valves, driven electrically, pneumatically, or hydraulically.

- Control level: Options range from basic manual operation to fully automatic intelligent control, with tiered options available.

| Selection Factors | Consideration Parameters | Common Options |

| Material Properties | Bulk Density | Light (<1600kg/m³), Heavy (≥1600kg/m³) |

| Particle Size | Fine powder, Granules, Lumps (maximum lump size) | |

| Humidity and Viscosity | Dry, Moist, Sticky (affects chute angle) | |

| Abrasiveness | Low, Medium, High (determines wear protection measures) | |

| Special Characteristics | Temperature, Acidity/Alkalinity, Explosiveness | |

| Process Requirements | Conveying Capacity | t/h (determines basic specifications) |

| Number of Service Bins | pcs (affects track length) | |

| Material Distribution Method | Continuous distribution, Fixed-point distribution | |

| Equipment Duty Cycle | Continuous operation, Intermittent operation | |

| Technical Specifications | Belt Width | 500-1400mm (light-duty); 800-1400mm (heavy-duty) |

| Belt Speed | ≤2.5m/s | |

| Drive Power | kW (determined by calculation) | |

| Equipment Weight | tons (varies with specifications) | |

| Configuration Options | Belt Drive | Electric drum, External drive unit |

| Travel Guidance | Rail-guided, Trackless guidance | |

| Discharge Device | Gate valve, Flap valve | |

| Control Level | Manual, Semi-automatic, Fully automatic |

Conclusion

A shuttle conveyor system and singulation conveyor are essential components in npk compound fertilizer production line or BB bulk blending fertilizer plant. Our reversible conveyor design combines bidirectional conveying with mobile functionality, allowing shuttle conveyors to deliver materials to multiple points. This systems widely used in metallurgy, power generation, ports, mining, and chemicals, where flexibility and accuracy are key to productivity. The singulator conveyor and shuttle conveyor together can replace multiple fixed conveyors, simplifying layout. Structurally, the shuttle conveyor system includes a belt conveyor, traveling trolley, power unit, and control system, all working collaboratively to ensure precise positioning and stable performance. Technical parameters typically range from 6–60 meters in conveying length and 50–2000 t/h in capacity, meeting the needs of diverse industrial applications. With its automated controls and system compatibility, the reversible conveyor integrates seamlessly into advanced material handling networks. So if you need a shuttle conveyor or what we call a back and forth movable conveyor belt, let me know.