Designed for high-capacity, high-accuracy performance, the Tongli Accu-BB-Blend System represents state of art technology in multi-feed fertilizer blending.

Traditional declining weight blending systems typically place large storage bins directly on load cells and refill them continuously during operation. While widely used, this configuration often suffers from weight signal instability caused by material impact during refilling, fluctuating material levels, structural deflection, and delayed system response—especially in continuous bulk blending applications with frequent formula changes. The TONGLI Accu-BB-Blend System overcomes these limitations through a refined declining weight architecture that integrates a dedicated intermediate weigh hopper beneath an automated refill (surge) bin. By decoupling weighing from refilling, the system maintains a stable, low-mass weighing environment where material flow is measured solely by controlled weight loss over time. Refill cycles are executed rapidly and independently, with weighing signals temporarily isolated to eliminate disturbances. This optimized configuration delivers a significantly smoother weight curve, faster control response, and highly repeatable flow-rate calculations. In continuous BB fertilizer blending operations, the Accu-BB-Blend System routinely achieves ratio accuracy within ±0.2–0.3%, even under varying material densities and flow characteristics. The smaller weighing mass also allows for rapid proportional adjustment, making the system especially effective for multi-component blends and frequent recipe changes. Combined with high-resolution HMB/Toledo/Suncells NTEP load cells, variable-speed discharge devices, and PLC-based closed-loop control, the Accu-BB-Blend System provides superior stability, precision, and long-term reliability compared with conventional declining weight systems on the market. The result is a blending solution engineered for modern bulk blending plants that demand consistent quality, reduced material giveaway, and dependable performance under continuous operation.

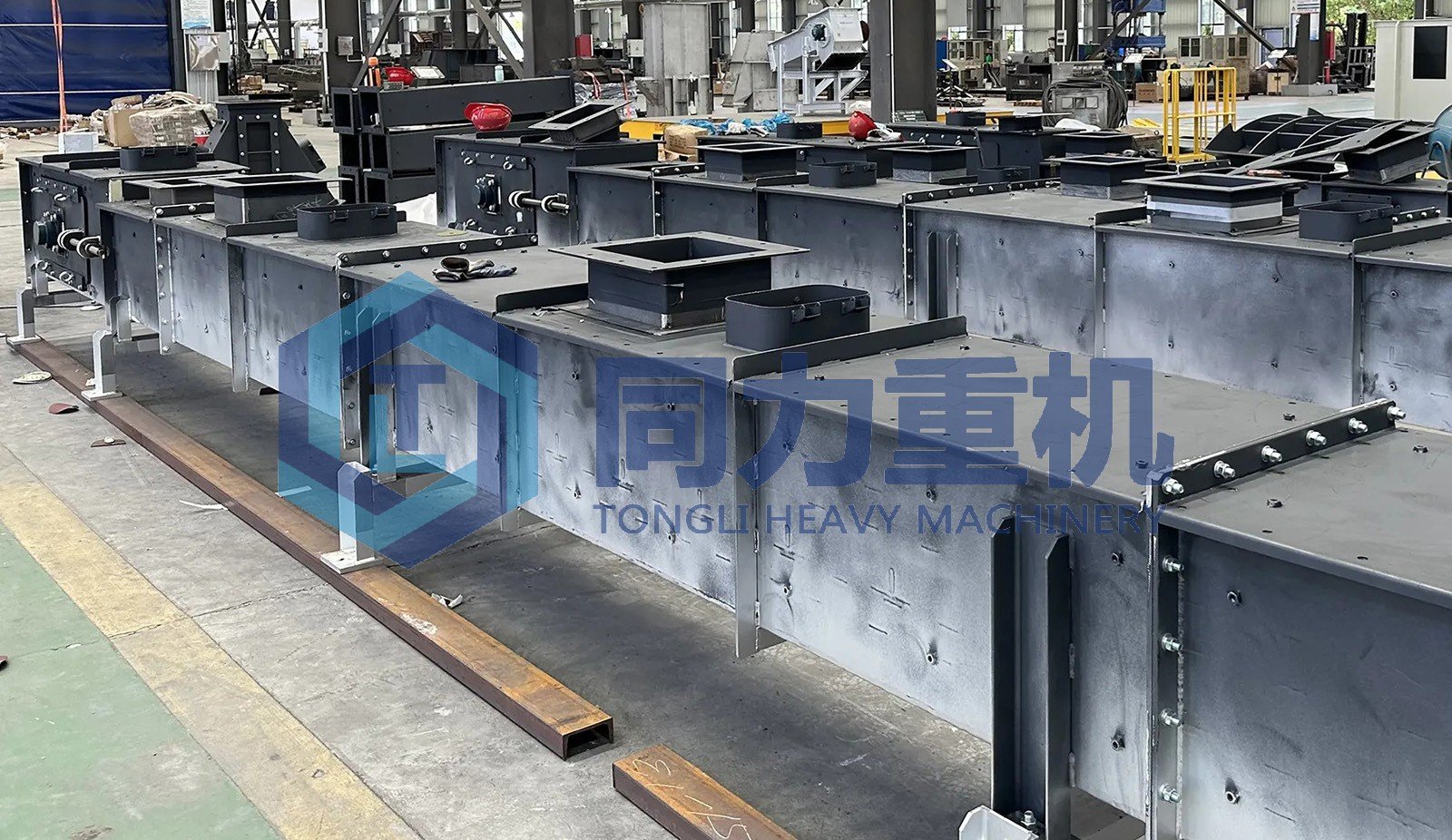

Declining Weigh Blender Fertilizer Plant Equipment List

Measures material flow by combining a weighing load cell installed under the belt with a speed sensor that monitors belt velocity. The system calculates the material throughput based on belt load and belt speed, providing continuous feeding and basic metering control for bulk materials.

Measures material flow accurately by monitoring the continuous reduction in hopper weight, ensuring precise proportioning of each raw material according to the set formula.

Homogenizes multiple fertilizer components through gentle tumbling action, producing a uniform and consistent blend without damaging granules.

Automatically weighs and fills fertilizer into 25 kg or 50 kg bags with high accuracy and consistent output.

Designed for filling 500–2,000 kg bulk bags, enabling efficient handling and shipment of large fertilizer volumes.

Transports materials horizontally between process stages in a stable and continuous manner, suitable for high-capacity fertilizer handling.

Vertically lifts bulk fertilizer materials from ground level to higher points in the process line with minimal material degradation.

Moves materials in enclosed troughs, preventing spillage and dust while ensuring steady feeding to downstream equipment.

Declining Weigh Blender ADVANTAGES

The TONGLI Declining Weight Blending System achieves ±2‰weighing accuracy (up to 99.8%), comparable to leading international brands such as AGI and Sackett-Waconia. Using NTEP-certified HBM or METTLER TOLEDO load cells and high-speed PLC weight-loss algorithms, the system automatically compensates for flow variation, vibration, and refill interference, ensuring precise nutrient ratios, stable blending quality, and reduced material giveaway.

The TONGLI Accu-BB-Blend Declining Weight System is a true continuous blending solution, simultaneously feeding, weighing, and blending all components in real time—eliminating batch delays and conventional mixer limitations. Using precision rotary valves, flat wire chain feeders, and metering augers, the system accurately handles capacities from ounces per minute to tons per hour, with variable-speed control and real-time weight-loss feedback to maintain a consistent formulation. Stainless steel construction ensures corrosion resistance, easy cleaning, and long service life

The TONGLI Declining Weight (DW) Blending System maintains accurate blend ratios by measuring actual weight loss in real time, rather than relying on fixed volume or flow assumptions. When bulk density, particle size, or flow characteristics change, the system automatically corrects feed rates without operator intervention, eliminating density-related errors, reducing off-spec product, and ensuring consistent fertilizer quality throughout continuous production.

The TONGLI continuous weighing fertilizer blender features a modular hopper design that allows true add-on expansion as production demand grows. A 3-hopper system typically provides 40–50 tons of live capacity, expandable to 60–80 tons by adding one hopper, while a 5-hopper configuration can reach 100–120 tons of total capacity. Each hopper operates as an independent module, enabling easy on-site expansion without major structural modification, giving customers flexible, step-by-step investment and efficient long-term scalability.

The TONGLI Declining Weight (DW) Blending System supports multiple mixing configurations to match different budgets, layouts, and long-term operating goals. Rotary drum mixers provide the most robust solution for high-duty continuous operation and allow future integration of coating, biological, or trace additive systems. Screw mixers offer a compact, cost-effective option for moderate capacities, while vertical (tower-type) mixers maximize throughput where floor space is limited. For entry-level installations, a simplified integrated mixing zone can be used, providing basic blending and additive incorporation with minimal investment while preserving upgrade flexibility.

The TONGLI Declining Weight (DW) Blending System supports flexible liquid impregnation solutions using positive displacement pumps, adaptable to different mixing configurations. With a rotary drum mixer, liquids such as coatings, binders, or biological additives can be applied directly during continuous mixing. For screw mixers or alternative layouts, liquid or powdered additives can be introduced via a dedicated conditioning or mixing bin upstream of bagging, ensuring effective treatment without altering the core DW feeding system. This modular approach allows practical selection based on budget, layout, and future upgrade needs.

TONGLI DW Blending Systems can be equipped with dedicated micro hoppers and precision screw feeders for accurate dosing of micronutrients and low-inclusion additives such as trace elements, premixes, pigments, enzymes, or powders. Controlled directly by the PLC and synchronized with the main declining weight system, micro ingredients are proportionally introduced into the mixer or conditioning zone without disturbing primary material flow. This capability enables high-value functional products, including pesticide–fertilizer blends, allowing integrated nutrient and crop-protection application that reduces field operations, improves utilization efficiency, and creates strong product differentiation with higher market value.

TONGLI Declining Weight Blending Systems support both bulk and bagged output, including FIBC big bags (1 ton) as well as 50 kg and 25 kg packaging. Blended material can discharge directly to packaging or via a surge hopper for stable, continuous feeding. Heavy-duty net or gross weigh scales are used for ton bags, while electronic bagging scales with fast/slow feed control ensure speed and accuracy for smaller bags. Fully synchronized with the DW system, packaging can switch between bulk and bagged formats without interrupting continuous blending, allowing one Accu-BB-Blend line to serve bulk, warehouse, and retail markets efficiently.

FERTILIZER DECLINING WEIGHT BLENDING PLANT WORKING PRINCIPLE:

Raw Material Loading

Common bulk fertilizer materials such as MAP, DAP, urea, ammonium sulfate, potassium chloride (MOP), and compound granular fertilizers (e.g. 15-15-15) are delivered to the plant by bulk truck or jumbo bags. Each material is identified by product type, particle size range, and bulk density to ensure compatibility with the metering system and to prevent cross-contamination during blending.

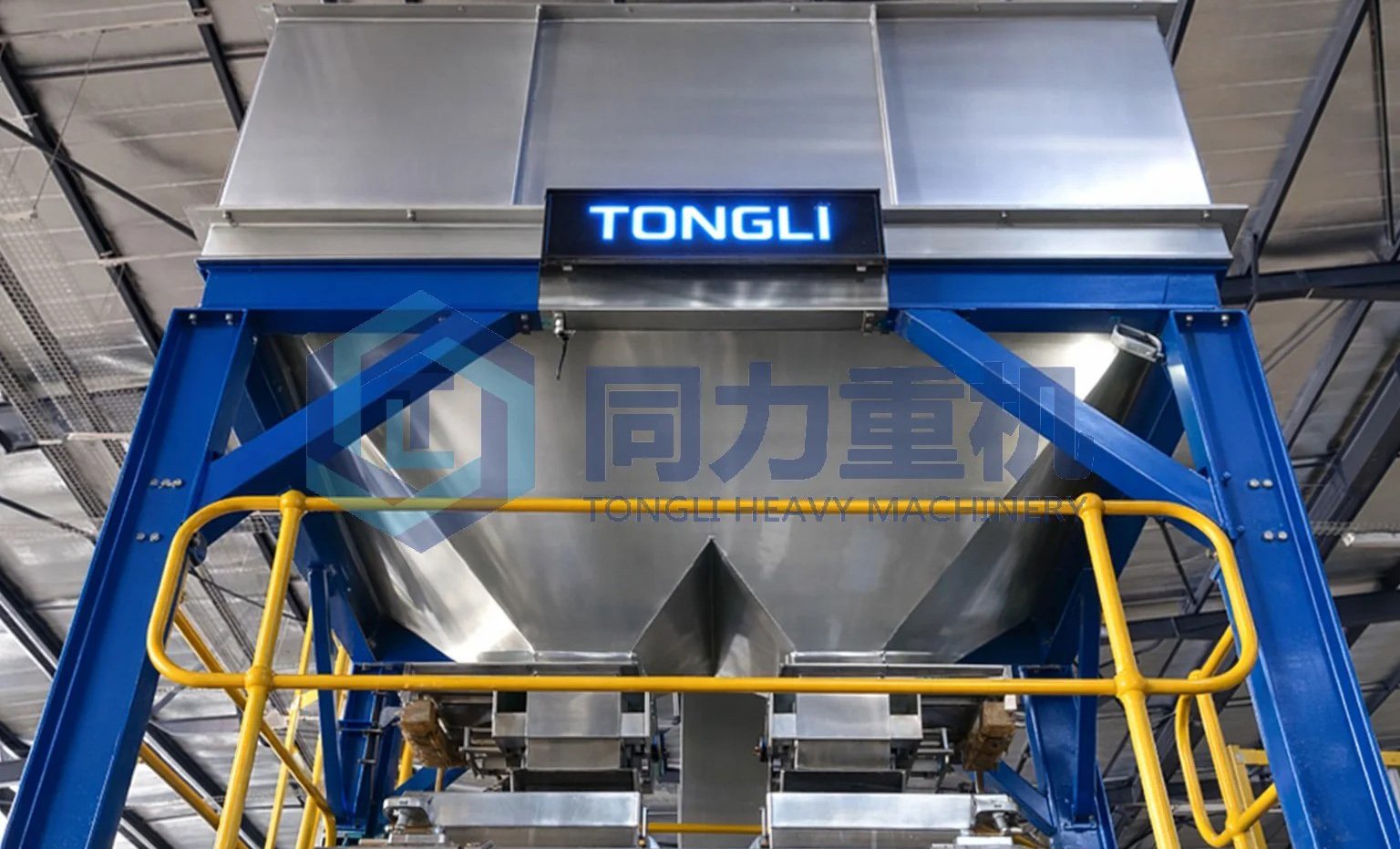

Stainless Steel Storage & Surge Bins

Raw materials are stored in individual stainless steel storage bins, typically fabricated from SS304 for standard fertilizers or SS316 for corrosive materials. These bins act as surge bins, providing a stable material head above the weighing system. Bin geometry, internal liners, and optional vibrators or air pads are designed to promote uniform mass flow and eliminate bridging or rat-holing.

Automated Charging into Intermediate Weigh Hoppers

Material is discharged from the surge bin into a dedicated intermediate weigh hopper mounted on 3 or 4 high-precision load cells. Charging is controlled by fast-acting pneumatic gates or rotary valves. Refill occurs only when the hopper weight reaches a preset low limit, and weighing signals are isolated during refill to maintain high measurement stability.

Real-Time Weight-Loss Measurement (Declining Weight Principle)

Once charging is complete, the weigh hopper discharges continuously. The system calculates mass flow rate based on the real-time reduction in hopper weight, rather than volumetric assumptions. This method ensures accurate dosing even when bulk density, particle shape, moisture content, or flow characteristics change.

Closed-Loop Proportional Feeding Control

Each weigh hopper is equipped with a precision discharge device—such as a rotary valve, flat wire chain feeder, or metering screw—driven by a variable-frequency motor. A PLC continuously compares actual weight-loss rate with the target setpoint and automatically adjusts feeder speed to maintain the programmed formulation ratio.

Simultaneous Multi-Component Discharge

All raw materials are discharged simultaneously and proportionally by the belt weigher feeder according to the recipe (e.g. N-P-K ratio). This true continuous operation eliminates batch cycling, reduces segregation, and maintains a stable nutrient composition throughout the entire production run.

Continuous Mixing (Rotary Drum / Screw / Integrated Mixing Zone)

All raw materials are discharged simultaneously and proportionally according to the recipe (e.g. N-P-K ratio). This true continuous operation eliminates batch cycling, reduces segregation, and maintains a stable nutrient composition throughout the entire production run.

Micronutrient & Liquid Additive Integration (Optional)

Trace elements, powdered additives, or liquids such as coatings and biological agents are added via dedicated micro hoppers, screw feeders, or positive-displacement pumps. Dosing is synchronized with the main DW system to ensure proportional addition. Additives can be introduced directly into the mixer or a downstream conditioning hopper.

Surge Hopper & Flow Stabilization

Before packaging or bulk dispatch, blended material may pass through a surge hopper to decouple blending from packaging. This ensures stable, continuous feeding to downstream equipment and prevents interruptions caused by bag changes or operator handling.

Bagging or Bulk Load-Out

Finished fertilizer is discharged to FIBC big bag packing (1,000 kg) or 25 / 50 kg bagging systems using electronic or mechanical scales with fast/slow feed control. The packaging system is fully synchronized with the declining weight blender, allowing continuous operation without stopping the blending process.

VIDEO

WHY CHOOSE US

Premium Quality Compare to Other Chinese Supplier

CFO

We bought 2 line and installed this year

CEO

Comparable to US quality

CEO

We usually don't give compliment, but this line is not bad

CEO

FAQ: Frequently Asked Question about Declining weight blending system.

A screw mixer fertilizer declining weight blending system is used to accurately weigh, blend, and package bulk blending (BB) fertilizer. The system typically consists of 4–5 SS304 stainless steel weigh hoppers, each with a capacity of 5–12 tons. Hoppers continuously discharge material by weight into a drag chain scraper conveyor installed below. As the materials move forward, a screw mixer provides thorough and uniform mixing before the final discharge. After blending, the finished fertilizer can be discharged directly into one-ton big bags (FIBC) or into 25 kg and 50 kg bagging machines. The entire process is controlled by a Siemens PLC-based control system with a touchscreen interface, making operation simple and intuitive, even for operators with minimal technical experience. Depending on the fertilizer formula, a 10-ton batch can typically be completed in about 5 minutes. Field operating data shows that total blending deviation is usually kept within ±0.2% (2‰) of the target weight.

The TONGLI Declining Weight (DW) Blending System is a true continuous, multi-feed fertilizer blending solution achieving typical weighing accuracy of ±0.3–0.5% (up to 99.5%), using NTEP-certified HBM or METTLER TOLEDO load cells and real-time weight-loss control algorithms. It simultaneously feeds, weighs, and blends up to 10 materials via mesh chain feeders, rotary valves, and metering augers, covering dosing ranges from tens of kg/h to 25 t/h per hopper. Hopper sizes range from 6 to 30 tons, with modular add-on design allowing capacity expansion from ~40 tons to over 120 tons without PLC replacement. The system automatically compensates for density, flow, vibration, and refill disturbances through PLC-controlled closed-loop adjustment, ensuring stable nutrient ratios and batch-to-batch consistency. Built with double-welded SS304 hoppers, heavy-duty stainless or carbon steel frames, ABB VFDs, Siemens/LEC PLC control, optional micro-nutrient bins, liquid impregnation, multiple mixer options, and support for ton bags or 25/50 kg bags, the DW system delivers high throughput, durability, easy maintenance, and long-term scalability for modern fertilizer blending plants.

A Declining Weight (DW) fertilizer blending line typically consists of material storage hoppers (carbon steel or SS304) for urea, MAP, MOP, micronutrients or pesticides, equipped with anti-bridging devices for stable flow; declining weight feeders with NTEP-certified load cells that meter each ingredient by real-time weight loss, achieving ±0.2–0.5% dosing accuracy; conveying equipment such as belt conveyors, bucket elevators, screw or drag chain conveyors for controlled material transfer; mixing equipment including screw mixers or rotary drum mixers to ensure homogeneous blending within 3–5 minutes; optional screening machines (vibrating, rotary, or trommel) to remove oversize and fines; finished product bagging systems for 25 kg, 50 kg, or FIBC ton bags with automatic weighing and sealing; and a PLC-based control system with HMI that centrally manages ratios, feeding, mixing, data logging, and fully automated operation.

A Declining Weight (DW) blending system works by measuring each ingredient based on real-time weight loss from individual hoppers. Each raw material is stored in a dedicated hopper and discharged through controlled feeders, while high-precision load cells continuously monitor the hopper’s decreasing weight. The PLC calculates the actual discharge rate from the weight-loss signal and automatically adjusts or stops the feeder when the preset target weight or ratio is reached. All ingredients are metered with this same declining-weight principle, then discharged to a mixer or directly to packaging, ensuring precise proportions and a uniform fertilizer blend.

Declining Weight (DW) fertilizer blending systems use three main mixing mechanisms: rotary drum mixing, screw mixer mixing, and tower (gravity) mixing. Rotary drum mixers use a rotating drum with internal lifting flights to gently tumble materials, providing uniform blending and low segregation for granular fertilizers. Screw mixer systems use single or twin screw shafts to convey and mix materials, offering good accuracy, compact layout, and efficient operation. Tower mixing systems rely on gravity, with materials weighed at the top and mixed during downward discharge, delivering high efficiency, minimal segregation, and stable blending quality for large-capacity fertilizer plants. These DW systems can be configured as continuous or batch blending lines, depending on the operating mode and production requirements.

Underground feeding places hoppers and feeders in a pit below grade, offering excellent dust control, space efficiency, gravity-assisted material flow, and cleaner operation, but it requires higher civil construction cost, more complex installation, and reduced flexibility for future modifications, but lower operational cost overall therefore we recommand underground feeding.

Above-ground feeding positions hoppers above the system, allowing easier installation, lower upfront cost, better accessibility for maintenance, and greater flexibility for expansion, while requiring more vertical space and careful dust control. The optimal solution should balance plant layout, budget, environmental control, and long-term expansion plans.

A screw mixer declining weight blending system is preferred when true continuous blending, high formulation accuracy, and a compact plant layout are required, and most importantly when your budget is low. It is especially suitable for DW systems handling powders or granular fertilizers where precise nutrient ratios are critical, floor height or space is limited, and fast, uniform mixing is needed. Screw mixers offer lower energy consumption, easier maintenance, and greater flexibility for adding or adjusting feeders compared to rotary drum mixers. Rotary drum mixers are generally chosen only when extremely large bulk throughput is required and mixing accuracy or response speed is less critical.

A rotary drum continuous declining weight blending system is preferred for high-capacity bulk blending of granular fertilizers where gentle handling is required. Multiple materials are continuously metered by declining weight feeders and fed into a rotating drum, where mixing occurs by tumbling as the drum rotates on rollers. This mixing method minimizes granule breakage and dust generation, making it ideal for coarse, heavy, or mixed-size fertilizers and plants with very high throughput requirements. While it requires more space, higher energy input, and periodic maintenance of bearings and drive components, the rotary drum system integrates well with DW feeding for accurate proportioning and is best suited for large-scale continuous fertilizer blending lines where volume and granule integrity are prioritized over ultra-fine mixing precision.

A tower auger declining weight blending system is a vertical fertilizer blending solution that uses gravity and vertical auger mixing in combination with declining weight feeders. Raw materials are metered accurately at the top of the tower by DW feeders and then move downward through enclosed chutes or vertical augers, where mixing occurs as the material flows by gravity. This vertical, continuous process provides stable blending, good dust control, efficient use of floor space, and accurate formulation, making tower auger systems well suited for high-capacity fertilizer plants with limited footprint and a preference for gravity-assisted material handling.

A Declining Weight (DW) blending system is suitable for a wide range of granular and powdered fertilizer materials. Common materials include granular urea (46-0-0), ammonium nitrate (34-0-0), DAP (18-46-0), MAP (11-52-0), and potassium chloride, typically with particle sizes of 5–10 mm. Powdered materials such as ammonium sulfate (21-0-0-24S), triple superphosphate (0-46-0), and micronutrients (boron, zinc, copper compounds) in the 1–3 mm range can also be accurately dosed using declining weight feeders. The system can handle coarse amendments like gypsum, lime, dolomite, and rock phosphate, as well as dried organic pellets or compost up to about 10 mm, provided materials are properly dried, screened, and free-flowing to ensure stable, continuous feeding and accurate proportioning.

For reliable operation of a Declining Weight (DW) blending system, raw materials must be dry and free-flowing. Powdered fertilizers such as TSP, ammonium sulfate, and micronutrients should typically have moisture content below 2%. Granular fertilizers including urea, DAP, MAP, KCl, and ammonium nitrate can generally tolerate up to 3% moisture. Coarse or organic materials such as gypsum, lime, rock phosphate, or dried compost pellets should be kept below 5% moisture, with particle sizes usually not exceeding 10–15 mm. Staying within these limits ensures stable feeding, accurate dosing, uniform blending, and minimal risk of clogging or downtime.

Pesticide–fertilizer blends produced by a Declining Weight (DW) blending system are value-added products that combine nutrient supply and pest control in a single application. Using precise declining weight feeders, fertilizers such as urea, DAP, MAP, KCl, or ammonium sulfate are continuously and uniformly blended with powdered, granular, or coated pesticides, ensuring even distribution without hot spots. Pesticides are typically added through dedicated small screw or vibratory feeders directly into the main mixer, or optionally after pre-blending for very low inclusion rates. Suitable additives include insecticides, fungicides, herbicides, and biopesticides, provided they are dry, free-flowing, and within size limits (≈1–3 mm for powders, ≤10 mm for granules, moisture ≤2–3%). This DW process minimizes dust, improves safety, maintains product quality, and allows fertilizer producers to differentiate their products with integrated crop nutrition and protection.

Well-known Declining Weight (DW) blending system manufacturers include AGI Fertilizer Systems (formerly Yargus, founded 1968, USA), Sackett-Waconia (roots dating to 1897/1959, USA), Doyle Equipment Manufacturing (founded 1951, USA), and Adams Fertilizer Equipment (founded 1966, USA), all recognized for high-accuracy, continuous fertilizer blending systems widely used in commercial plants. Bagtech (South Africa) is a key supplier of fertilizer packaging equipment often integrated with DW blending lines. In China, Tongli Heavy Machinery (founded 1958) is a major DW blending system manufacturer, known for robust construction, ±0.2–0.5% accuracy systems, and large-scale continuous blending solutions supplied to international fertilizer producers, including global brands such as Yara and BASF.

The cost of a declining weight fertilizer blending line depends on capacity, materials of construction, automation level, and system configuration. A high-specification line with stainless steel hoppers, conveyors, and packing machines, designed for about 100–120 t/h, typically costs USD 500,000–750,000. A lower-specification system using carbon steel components can reduce the investment to around USD 350,000–500,000, but with lower corrosion resistance and higher long-term maintenance. Extremely low-priced systems (around USD 150,000) often lack accurate weighing, durable materials, and reliable controls, and are generally unsuitable for operations requiring U.S.-level quality, accuracy, and long-term reliability.

When investing in a fertilizer bulk blending (BB) plant, the most critical considerations are annual production volume, blend formulations, required blending and bagging capacity, and target hourly efficiency, as these factors define both the technical design and the long-term economics of the project. First, the planned annual output—typically based on 4,800 or 7,200 operating hours per year—directly determines equipment size, capital expenditure, and whether the plant prioritizes high hourly throughput or continuous, reliability-focused operation. Second, the types of blends to be produced (NPK, secondary nutrients, micronutrients, specialty formulations) dictate raw-material compatibility, hopper quantity and layout, process flow selection (batch vs. continuous), and the required weighing accuracy and automation level. Third, blending and bagging capacity should be intentionally designed 15–30% above nominal demand to absorb seasonal peaks, maintenance downtime, and future growth while maintaining stable mass-flow control and weighing precision. Finally, the target blending speed must balance throughput with blend quality: excessive speed reduces residence time and increases segregation risk, while undersizing creates bottlenecks and limits annual output. A properly engineered declining weight blending system aligns these parameters to deliver reliable accuracy, operational flexibility, and a lower unit cost per ton over the plant’s lifecycle.

Accuracy in a professional BB fertilizer plant must be controlled at three levels: blend ratio accuracy, batch weight accuracy, and bag weight accuracy, because small deviations compound and directly affect regulatory compliance, product quality, and customer trust. At the ingredient level, blend ratio accuracy should typically be ±0.3–0.5% per nutrient, with high-end declining weight or loss-in-weight systems achieving up to ±0.25%, far outperforming volumetric systems that usually remain around ±1.0%. This precision is essential because errors accumulate across multiple bins, potentially pushing final N-P-K values outside contract or regulatory limits. At the batch level, total batch weight accuracy should be ±0.25–0.5%, ensuring consistent nutrient delivery per tonne and avoiding cumulative over- or under-supply during truck or big-bag loading. For bagging, tolerances are even tighter due to legal metrology standards: ±0.2–0.3% for 25–50 kg bags and ±0.25% for 500–1,000 kg big bags. Achieving these targets depends on stable mass flow, high-resolution load cells, fast feeder response, PLC-based real-time correction, and properly designed two-stage filling systems—making declining weight blending systems the preferred choice for high-accuracy, commercial fertilizer operations.

almost every country with a regulated fertilizer market enforces rules on bulk-blend (BB) fertilizer uniformity, and these regulations should be reviewed before finalizing the plant design and equipment selection. In most jurisdictions, compliance is verified through random sampling and laboratory nutrient analysis, with allowable deviations typically in the range of ±0.3–0.5% per declared major nutrient (N, P₂O₅, K₂O) or within legally defined tolerance bands tied to the product label. Some regions apply absolute tolerances (e.g., ±0.5 units of NPK), while others use relative percentage tolerances, and repeat non-compliance can lead to rejected loads, forced relabeling, fines, or loss of sales permits.

From practical plant experience, uniformity compliance is not achieved in the mixer alone—it is determined upstream by weighing precision, feeder stability, and mass-flow control. Declining-weight or loss-in-weight systems with ±0.25–0.5% ingredient accuracy, fast PLC correction, and properly sized mixers are typically required to meet modern uniformity standards consistently. Low-precision volumetric systems may pass visually but often fail laboratory testing, especially when blending materials with large bulk-density differences, wide particle-size distributions, or hygroscopic behavior. Regulatory inspectors are particularly strict on BB fertilizers because segregation can occur during conveying, truck loading, and transport, so plants must demonstrate not only initial accuracy but repeatability over multiple samples and loads.

In markets with stricter enforcement—such as North America, the EU, and parts of Latin America—uniformity requirements effectively dictate the technology level: manual or semi-manual blending is rarely acceptable for commercial-scale operations. Confirming these regulations at the feasibility stage is therefore a data-driven investment decision that directly affects blender type, weighing system class, automation level, CAPEX, operating cost, and long-term market access. For a deeper technical explanation of the factors influencing uniformity, see our article “What affects fertilizer blending plant product uniformity?”—and to maintain uniformity in practice, the next step is ensuring blending and weighing precision, which we detail below.

DECLINE N WEIGHT BLENDING PLANT TECHNICAL SPECIFICATION

| No. | Tag / SR No. | Equipment | Model / Technical Specification | Qty |

| 1 | L101 | Ingredient Feed Conveyor | 100–120 t/h feed; | 1 |

| 2 | L102 | Mixing Spiral Conveyor | Height 4,600 mm; Capacity 100–120 t/h; | 1 |

| 3 | L103 | Finished Product Elevator | Height: 12,500 mm; | 1 |

| 4 | W101 | Decline Weighing / Feed Scale – Line 1 | Belt weigh feeder, Length 1,500 mm; | 1 |

| 5 | W102 | Decline Weighing / Feed Scale – Line 2 | Belt weigh feeder, Length 1,500 mm; | 1 |

| 6 | W103 | Decline Weighing / Feed Scale – Line 3 | Belt weigh feeder, Length 1,500 mm; | 1 |

| 7 | W104 | Decline Weighing / Feed Scale – Line 4 | Belt weigh feeder, Length 1,500 mm; | 1 |

| 8 | W105 | Decline Weighing / Feed Scale – Line 5 | Belt weigh feeder, Length 1,500 mm; | 1 |

| 9 | W106 A/B/C | Bagging Scale Stations (Net Bagging / Packaging System) | Servo controlled packaging scale; >1,000 bags/hour at 25/40/50 kg; 30–40 bags/hour at 1,000 kg bulk; automatic bag clamp & discharge chutes | 3 |

| 10 | — | Central Electrical Control & PLC System | Main PLC panel with HMI, weigh feeder interface, blend logic control, safety interlocks, network communications (for recipe entry & supervision) | 1 |