What Is a Vertical Mill Grinding Roller Tyre and Grinding table liner?

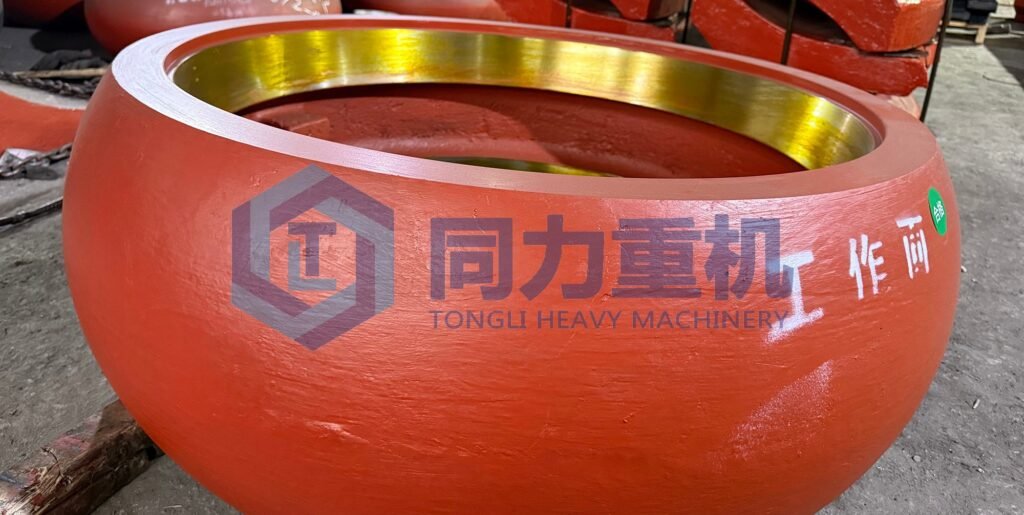

A Vertical Mill Grinding Roller Tyre (also called a roller sleeve or roller liner) is the replaceable wear-resistant outer ring mounted on the grinding roller of a vertical roller mill (VRM). It is the primary component that directly contacts the grinding table and the material bed during operation. Its main function is to apply grinding pressure onto the material layer, crushing and grinding raw materials such as clinker, slag, coal, or limestone through compression and shear force. Because it is exposed to continuous high pressure, high temperature, and severe abrasion, it is manufactured from advanced wear-resistant materials such as high-chromium cast iron, hardfaced alloy steel, or ceramic-reinforced metal matrix composites (MMC). The tyre must maintain precise geometry and surface profile to ensure stable grinding efficiency and proper material bed formation. A Grinding Table Liner (also called a table segment or table plate liner) is the replaceable wear-resistant lining installed on the surface of the grinding table in a Vertical Roller Mill (VRM). typically designed in segmented pieces for easier replacement and maintenance. Depending on mill design and application, they can have different structural profiles, such as flat type (flat grinding track), bowl type (concave profile), or tire-track type (grooved or track-guided design). Bowl-type liners help stabilize the material bed and improve grinding efficiency in high-capacity mills, while flat types are simpler and often used in smaller or coal mills. In this introduction we will show you what is the manufacturing process of grinding roller tyre and vrm grinding table liner step by step.

Casting Process of Vertical Roller Mill Grinding Roller Tyres

Pattern and Mold Preparation

Manual resin sand molding is a critical auxiliary process in the casting of high-chromium cast iron roller sleeves for vertical roller mills. It is mainly used to form the non-working surfaces of the roller sleeve and auxiliary structures—such as gating and riser systems, venting channels, and positioning pads—in coordination with the overall chilled mold centrifugal casting process, ensuring complete mold formation and defect-free castings. Before molding, the molding area is thoroughly cleaned to eliminate debris, loose sand, and other contaminants. High-strength resin sand—prepared by mixing base sand, resin binder, and hardener according to a predetermined ratio—is then manually filled layer by layer into the sand box, conforming closely to the sand core tooling matched to the chilled mold. Each layer is compacted manually to ensure uniform sand density and to prevent looseness or delamination. During molding, the locations of gates, risers, and venting channels are accurately reserved. The gating and riser system must be sized to match the subsequent pouring flow rate, while the venting channels must remain unobstructed to prevent defects such as gas porosity or misruns during pouring. At the same time, strict control is maintained over mold thickness and external profile to conform to the design dimensions. The sand mold surface is manually dressed to remove burrs and protrusions, ensuring a smooth surface and clearly defined contours. After molding is completed, the sand mold is left to stand for a specified curing period to allow the resin sand to fully harden and achieve the required strength, thereby preventing mold collapse, sand drop-off, or damage during mold assembly and pouring operations.

Drawing Confirmation

Based on the customer’s technical requirements, vertical roller mill model, and actual operating conditions—including but not limited to Loesche LM series, Gebr. Pfeiffer MVR series, FLSmidth OK™ Mill, Polysius RM, Ube, Atox, and Chinese domestic models such as HRM, TRM, ZGM, and MLS, ZGM(MPS) Medium Speed Coal Mill—our engineering department prepares the finished drawing for the high-chromium cast iron roller sleeve. Regardless of brand or mill type, as long as the approved technical drawing is provided or the dimension is taken by on-site measurement, the roller sleeve can be designed, manufactured, and inspected strictly in accordance with the drawing requirements. The drawing shall clearly define the complete geometry and technical specifications, including inner diameter, outer diameter, height, wall thickness, mating and fitting dimensions, machining allowances, heat treatment requirements, hardness range, non-destructive testing (NDT) standards, and dimensional tolerances. The drawing must be jointly reviewed, checked, and formally approved by design engineers, process engineers, and relevant responsible personnel to ensure that all dimensions, technical parameters, and performance requirements are accurate and consistent. Once approved, the drawing serves as the sole and authoritative basis for chilled mold design, centrifugal casting production, machining operations, and final inspection of the high-chromium roller sleeve.

Chilled Mold Structural Design Based on the Approved Drawing

After final drawing approval, the mold engineer or casting process engineer carries out the chilled mold design for centrifugal casting. The chilled mold is a critical tooling component for the centrifugal forming of high-chromium cast iron roller sleeves. The design must strictly follow the roller sleeve geometry while considering the solidification shrinkage characteristics of high-chromium cast iron to determine the mold cavity dimensions, wall thickness, and structural configuration. In addition, parameters of the centrifugal casting machine—such as rotational speed range and clamping method—must be considered to ensure proper compatibility between the chilled mold and the casting equipment.

Shrinkage Allowance and Machining Allowance Calculation

High-chromium cast iron undergoes volumetric shrinkage during solidification and cooling. Therefore, appropriate casting shrinkage allowances must be incorporated into the mold design based on material characteristics. At the same time, sufficient machining allowances shall be reserved on the outer diameter, inner diameter, and end faces to meet subsequent machining requirements. Accurate calculation of shrinkage and machining allowances is essential to prevent dimensional deviations and to ensure that the final machined roller sleeve fully complies with drawing specifications.

Strength and Safety Verification of the Chilled Mold

During operation, the chilled mold rotates at high speed and is subjected to significant centrifugal forces and thermal stresses. Engineers must perform strength, stiffness, and stability checks on the mold shell, flanges, and positioning structures to ensure that no deformation, cracking, or abnormal vibration occurs at the rated rotational speed. A properly designed structure with adequate safety factors is a fundamental requirement for stable production and for ensuring the safety of both personnel and equipment.

Cooling System and Process Design

To ensure uniform microstructure and stable wear resistance of the high-chromium cast iron, the chilled mold must be equipped with a properly designed cooling system or temperature-control structure. By regulating the cooling rate and optimizing the solidification sequence, the density and wear resistance of the roller sleeve working surface can be significantly improved. At the same time, the design should consider the convenience of coating application, demolding, cleaning, and repeated use of the mold, thereby improving overall production efficiency.

Mold Inspection and Acceptance

After cold molding is completed, the mold enters the inspection and acceptance phase. Led by the company's Quality Inspection Department, and in conjunction with the Technical Department and Process Department, a comprehensive inspection is conducted. Only after passing the inspection can the mold be put into use. The acceptance process and content are as follows:

- 1. Dimensional Inspection: Compare with the design drawings to comprehensively inspect the internal cavity dimensions, external diameter dimensions, height, wall thickness, positioning dimensions, and geometric tolerances of the cold mold, ensuring that all dimensional parameters meet the design standards and are within acceptable limits;

- 2. Surface Quality Inspection: Visually inspect the surface and internal cavity of the cold mold using a magnifying glass to check for defects such as cracks, porosity, sand holes, inclusions, burrs, and tool marks, ensuring the surface finish meets standards;

- 3. Performance Inspection: Perform hardness testing and metallographic analysis on the cold mold material to confirm that its heat resistance, wear resistance, and strength meet the usage requirements;

- 4. Assembly Inspection: Assemble the cold mold with the centrifugal casting machine, testing the positioning accuracy, clamping reliability, and sealing performance to ensure good compatibility;

- 5. Acceptance Confirmation: After all inspection items pass the test, the Quality Inspection Department, Technical Department, and Process Department shall sign and confirm the acceptance of the mold and issue a mold acceptance certificate. The cold mold shall then be officially put into storage for use. If any non-conforming items are found during the inspection, the processing workshop shall rework and repair them. After the repair, the mold shall be re-inspected until it passes the test. It is strictly forbidden to put non-conforming molds into the roller sleeve casting process.

Sand casting vs resin sand casting

Conventional sand casting typically uses green sand or simple bonded sand molds, which are cost-effective and flexible for large sizes, but offer relatively lower mold strength, poorer surface finish, and less dimensional accuracy. For high-chromium cast iron grinding rollers, this can result in higher risks of sand inclusion, porosity, uneven cooling, and inconsistent carbide distribution, all of which directly affect wear resistance and service life. Additional machining allowance is usually required, and quality consistency can vary from batch to batch. Resin sand casting, by contrast, uses chemically bonded sand with much higher mold strength, rigidity, and thermal stability. This allows better control of mold geometry and cooling conditions, resulting in improved dimensional accuracy, smoother surface finish, and more stable solidification behavior. For high-chromium VRM grinding rollers, resin sand casting helps achieve a denser microstructure, more uniform carbide distribution, reduced internal defects, and more consistent hardness across the working surface. Although resin sand casting has higher material and process costs, it is generally preferred for high-performance VRM grinding rollers where wear resistance, reliability, and long service life are critical, especially for demanding applications in cement, slag, and mineral grinding.

Dimensional accuracy for large-size roller tyres

For large-size vertical roller mill (VRM) roller tyres, the casting process has a direct and very visible impact on dimensional accuracy, mainly because of the component’s large diameter, high mass, and sensitivity to uneven shrinkage. With conventional sand casting, the mold strength is relatively low, so deformation of the mold cavity can occur during mold assembly, pouring, and solidification. For large roller tyres, this often leads to ovality, wall-thickness deviation, and axial runout. In addition, uneven compaction of sand and less precise control of shrinkage allowance make it difficult to consistently hold tight tolerances. As a result, larger machining allowances are required, material utilization is lower, and there is a higher risk that final dimensions may drift close to or beyond tolerance limits after machining. In resin sand casting, the chemically bonded sand provides much higher rigidity and dimensional stability, even for large-diameter and heavy-section roller tyres. The mold cavity is less prone to deformation under the metallostatic pressure of molten high-chromium iron, and shrinkage behavior can be predicted and controlled more accurately. This significantly improves roundness, concentricity, and wall-thickness uniformity, allowing tighter as-cast tolerances and reduced machining allowance. For large-size VRM roller tyres, this translates into better fit with the hub or shaft, more stable operation in the mill, and lower overall manufacturing risk.

Mold Assembly and Preparation for Pouring

- After the resin sand mold has fully cured and passed inspection, the process proceeds to the mold assembly stage. The quality of mold assembly directly affects the dimensional accuracy and forming quality of the roller sleeve casting.

- Before assembly, the chilled mold (already inspected and approved for use) and the resin sand mold are thoroughly cleaned to remove loose sand, debris, and burrs. The inner cavity of the chilled mold and the mold cavity of the resin sand mold are carefully checked to ensure there is no damage, deformation, or surface defects.

- According to the specified production process, the chilled mold and resin sand mold are then precisely aligned and assembled. Their relative positions are adjusted to ensure accurate positioning, tight contact, and proper concentricity, with no misalignment or excessive gaps. During assembly, sealing materials—such as sealing compound or sealing sand—are applied at the joint interface between the chilled mold and the sand mold to prevent molten metal leakage during pouring.

- At the same time, the pouring cup and riser sleeves are installed. The gating and riser system must align smoothly with the pouring channels of both the sand mold and the chilled mold. Riser locations are positioned to correspond precisely to the thermal hot spots of the casting, facilitating effective feeding and gas evacuation during solidification.

- After mold assembly is completed, a self-inspection is carried out on the overall setup to confirm that there are no assembly defects, that sealing is reliable, and that positioning accuracy meets process requirements. The assembled mold unit is then transferred to the pouring area and arranged in an orderly manner to await molten metal pouring. Dedicated personnel are assigned to monitor the molds to prevent impact or displacement. Meanwhile, pouring-area equipment and tools—such as ladles and metal transfer channels—are checked to ensure full readiness, guaranteeing a smooth transition to the pouring operation.

Melting and Alloy Control

Melting and alloy control is a core upstream process in the production of high-chromium cast iron grinding roller tyres and liners for vertical roller mills. This process directly determines the fundamental material properties, wear resistance, and internal quality of the casting, and therefore must be executed in strict accordance with predefined process specifications with full-process precision control. Before melting, thorough raw-material preparation is carried out. Qualified high-chromium cast iron base materials—such as pig iron and steel scrap—together with alloying materials including ferrochromium, ferromanganese, ferromolybdenum, ferrovanadium, and others are selected according to the performance requirements of the roller tyre or liner. Oil, rust, and surface contaminants are removed from all raw materials to prevent contamination of the molten metal. At the same time, the melting equipment is inspected to ensure stable operation and the accuracy and reliability of temperature-measurement and temperature-control systems. During melting, the base metal charge is first introduced into the furnace and heated gradually until fully molten. Once complete melting is achieved, alloying materials are added in batches and at a controlled rate according to the predetermined composition design. The alloy-addition sequence follows the principle of “low-melting-point alloys first, high-melting-point alloys later” to minimize oxidation and alloy burn-off, ensuring that all alloying elements dissolve uniformly into the molten metal. Throughout the melting process, the molten metal temperature is continuously monitored and controlled within the range of 1500 °C to 1550 °C. Mechanical or electromagnetic stirring is applied to eliminate chemical segregation, remove dissolved gases and non-metallic inclusions, and improve melt cleanliness. Based on real-time melting conditions, alloy additions are fine-tuned to ensure that the final molten high-chromium iron exhibits uniform composition, sufficient purity, and no obvious metallurgical defects, thereby providing a stable foundation for subsequent pouring and final roller tyre or liner performance.

Chemical composition control

Chemical composition control runs through the entire melting process and is a key factor in ensuring that high-chromium cast iron VRM grinding roller tyres and liners meet requirements for wear resistance, hardness, toughness, and metallographic structure. A closed-loop control system of “pre-setting, in-process monitoring, and post-verification” is established. Before melting, the engineering department defines the target chemical composition based on actual operating conditions of the roller tyre or liner, such as abrasive wear, impact loading, and elevated temperature exposure. Control ranges are specified for key elements including chromium, carbon, manganese, molybdenum, vanadium, silicon, phosphorus, and sulfur. Chromium content—being the core element for high-chromium cast iron—is typically controlled within 12–20%, while carbon is controlled within 2.8–3.8%. Harmful elements such as phosphorus and sulfur are strictly limited to below 0.05% to avoid degradation of toughness and wear resistance. During melting, molten metal samples are taken at approximately 30-minute intervals and analyzed using a spectrometer. The measured results are compared in real time with the preset composition targets. If any element is found to be out of range, immediate corrective actions are taken: alloying materials are added if content is insufficient, or dilution with base metal and adjustment of melting parameters is performed if content is excessive. This ensures that the chemical composition remains within the qualified range throughout the process.

Pouring and Solidification

Once the molten metal—high-chromium cast iron that has completed charge preparation, melting, and chemical composition inspection—has been confirmed as qualified, the pouring operation is initiated. During pouring, process parameters are strictly controlled to ensure stable mold filling. The molten metal is poured into the assembled chilled mold and resin sand mold, where it begins to fill the cavity and subsequently solidifies, forming the roller sleeve. Dedicated personnel continuously monitor the filling behavior to ensure smooth and complete solidification without interruption.

Controlled pouring temperature

The pouring temperature is strictly controlled within the range of 1480 °C to 1520 °C. The pouring rate is adjusted according to the roller sleeve size and wall thickness, maintaining a steady and uniform flow. Excessive pouring speed is avoided to prevent splashing and turbulence, which can lead to gas porosity and slag inclusions, while excessively slow pouring is prevented to avoid misruns and cold shuts. Throughout the pouring process, operators closely observe the gating and riser system to promptly identify and address issues such as blockage or molten metal leakage, ensuring stable and continuous metal flow.

Avoiding shrinkage, porosity, and cracks

After pouring is completed, the molten metal begins controlled solidification within the chilled mold and sand mold, followed by a regulated cooling stage. Cooling is carried out strictly in accordance with a predefined cooling curve, and rapid or forced cooling methods—such as water spraying or air blowing—are strictly prohibited. This controlled cooling prevents excessive internal stress, cracking, and deformation of the roller sleeve while promoting a uniform metallographic structure of the high-chromium cast iron. During the cooling process, the temperature of both the casting and the mold assembly is continuously monitored, and the cooling rate is adjusted as needed. The total cooling duration is determined based on the roller sleeve dimensions, including diameter and wall thickness, and typically ranges from 24 to 72 hours. Mold opening is only permitted after the casting temperature has dropped below 300 °C and the roller sleeve has fully solidified, ensuring dimensional stability and meeting subsequent heat-treatment and wear-resistance requirements.

Chemical analysis samples using germany thermo spectrum machine

After pouring, chemical analysis samples are taken from each production batch of roller tyres or liners and tested in a laboratory. A formal chemical composition inspection report is issued to confirm full compliance with design specifications. If any batch fails to meet chemical composition requirements, it is clearly identified and isolated, and further actions—such as rework, remelting, or scrapping—are determined based on the severity of deviation. Non-conforming castings are strictly prohibited from entering subsequent production processes.

Furnace types (electric arc / induction furnace)

In the melting process of high-chromium cast iron grinding roller tyres and liners for vertical roller mills, electric arc furnaces (EAF) and induction furnaces are the two primary furnace types employed. Each furnace type has its own suitable application scenarios and may be selected flexibly based on production scale, roller size, and material requirements, with the shared objective of achieving efficient melting, uniform alloy distribution, and precise temperature control.

Electric arc furnaces

Electric arc furnaces are mainly used for large-scale and high-volume production. Their key advantages include high melting power, rapid temperature rise, and large melting capacity, enabling them to meet the molten metal demand of large-size VRM roller tyres with large diameters and thick sections. By adjusting electrode positioning and power input, melting temperature and holding time can be accurately controlled, facilitating effective removal of inclusions and gases and improving molten metal purity. Electric arc furnaces are well suited to high-chromium cast iron with complex alloy systems and strict composition control requirements, although they typically involve higher energy consumption and longer startup preparation times.

Induction furnaces

Induction furnaces, commonly medium-frequency induction furnaces, are more suitable for small- to medium-batch production with multiple roller specifications. Their advantages include fast startup, relatively lower energy consumption, and strong electromagnetic stirring during melting, which significantly reduces chemical segregation and ensures uniform alloy distribution. Induction furnaces offer high temperature-control precision, compact layout, and operational flexibility, making them ideal for frequent specification changes in roller tyre or liner production. However, their melting capacity is limited, making them less suitable for extremely large roller tyres.

Heat Treatment Process for Grinding Roller Tyres

The heat treatment process is a core element of our proprietary know-how and represents the decisive factor in achieving the final performance of high-chromium cast iron grinding roller tyres and liners for vertical roller mills. While many casting manufacturers are capable of producing high-chromium components with the correct chemical composition and basic casting quality, heat treatment is the true “heart” of performance, directly determining wear resistance, toughness, fatigue behavior, and long-term service stability. This approach is consistent with industry leaders such as Magotteaux and Vega Industries, whose heat treatment technologies and thermal cycles are likewise treated as confidential intellectual property. Although the chemical composition of high-chromium cast iron can be specified and verified, the precise heat treatment curve—including heating rates, holding temperatures, soaking times, cooling methods, and intermediate treatments—plays a decisive role in controlling carbide morphology, matrix structure, residual stress distribution, and overall mechanical performance. For this reason, while we fully guarantee that all delivered grinding roller tyres meet or exceed the agreed technical specifications, hardness requirements, and service-life expectations, the detailed heat treatment parameters and curves are not disclosed to clients. This confidentiality ensures the protection of our proprietary process know-how and safeguards the consistent quality and performance of our products under demanding operating conditions.

Why Vertical roller mill grinding table liner and tyre needs heat treatment?

Improve Hardness:

Although high-chromium cast iron contains a large amount of alloying elements such as chromium and carbon after casting and cooling, its internal microstructure is not ideal, resulting in low and uneven hardness. Through standardized heat treatment involving quenching and high-temperature tempering, the internal structure of the material can be fully transformed, forming a high-hardness martensitic matrix and a large amount of hard carbides. This significantly improves the overall hardness of the roller sleeves and liners, achieving the required high hardness level. Without heat treatment, the casting hardness will be far below the design standard, the surface will be soft, and it will be unable to withstand the pressure and grinding of materials, quickly resulting in indentations, deformation, and collapse.

Enhance Wear Resistance:

Wear resistance is the most crucial performance characteristic of vertical mill rollers and liners, and it directly depends on the material's hardness and microstructure. Heat treatment allows the abundant chromium carbides in high-chromium cast iron to be evenly and continuously distributed in the matrix, forming a very strong wear-resistant skeleton, maintaining stable wear resistance under long-term scouring, pressure, and grinding of materials. Untreated castings have coarse, unevenly distributed carbides, a soft matrix, and extremely poor wear resistance. In actual operation, the wear rate will accelerate exponentially, significantly shortening the service life and failing to meet the requirements for long-term stable operation of vertical mills. If you are also interested in What causes wear and tear on the grinding rollers of a vertical roller mill? Click here.

Reducing Internal Stress:

Roller sleeves and liners are thick castings. During the cooling process from high temperature to room temperature after pouring, the surface and internal cooling rates are inconsistent, generating significant internal stress. If this stress is not eliminated, the castings are prone to deformation, cracking, and chipping during storage, processing, or operation. The preheating, holding, and slow cooling processes in heat treatment can effectively release and eliminate residual internal stress, stabilize dimensions, and ensure that the castings do not crack or deform during machining and long-term use. Without heat treatment, the internal stress persists, leading to dimensional deviations after machining or, in severe cases, sudden breakage during use, causing equipment downtime and safety hazards.

Direct Consequences of Not Performing Heat Treatment for VRM tyre and liner:

If the high-chromium cast iron roller sleeves and liners of a vertical mill are not heat-treated, the following serious problems will occur:

- Insufficient hardness, resulting in a soft surface that is extremely prone to wear;

- Poor wear resistance, leading to a very short service life and frequent replacements;

- High internal stress, causing easy deformation, cracking, and spalling;

- Substandard metallographic structure, resulting in substandard overall performance and inability to meet the operating requirements of the vertical mill.

Typical processes:

Normalizing

Normalizing is the first preparatory heat-treatment step for grinding roller tyres and liners. Its primary purpose is to homogenize the microstructure, refine grain size, relieve a portion of the casting stresses, and prepare the metallurgical structure for subsequent quenching. The casting is heated to 950 °C–1000 °C and held for a sufficient time to ensure uniform temperature throughout the component and complete austenitization. It is then allowed to cool naturally in air. Normalizing improves the coarse as-cast structure, reduces carbide networks, segregation, and porosity, and promotes a more uniform chemical composition and microstructure. If the normalizing step is omitted, the casting retains a coarse and inhomogeneous structure, which can directly result in insufficient hardness after quenching, increased risk of cracking, and unstable wear resistance in service.

Quenching

Quenching is the critical heat-treatment process for increasing the hardness and wear resistance of grinding roller tyres and liners and directly determines whether the product can meet service requirements. After normalizing, the casting is reheated to 980 °C–1050 °C and held long enough to allow carbon and chromium to fully dissolve into the austenitic matrix. Rapid cooling is then applied, typically by oil quenching or forced air cooling. Through rapid cooling, the matrix transforms into high-hardness martensite, accompanied by the precipitation of a large amount of hard chromium carbides. This process significantly increases the working surface hardness, typically to above HRC 60. Without quenching, the material exhibits very low hardness and a weak microstructure, leading to rapid wear, surface collapse, and deformation under grinding and impact loads, making it completely unsuitable for vertical roller mill operating conditions.

Tempering

Tempering is an essential process for stabilizing dimensions, relieving internal stresses, and achieving an optimal balance between hardness and toughness. This step is mandatory and cannot be omitted. After quenching, the casting contains high residual stresses and exhibits high brittleness, making it highly susceptible to cracking. The quenched component is reheated to 250 °C–350 °C, held for an extended period, and then slowly cooled. Tempering relieves quenching stresses, stabilizes the microstructure, reduces brittleness to an appropriate level, and preserves high hardness and wear resistance. Insufficient tempering results in excessive residual stress, edge chipping, and fracture, while over-tempering leads to a reduction in hardness and deterioration of wear resistance. Only through properly controlled tempering can grinding roller tyres and liners achieve the required combination of high hardness, high wear resistance, impact resistance, and crack resistance.

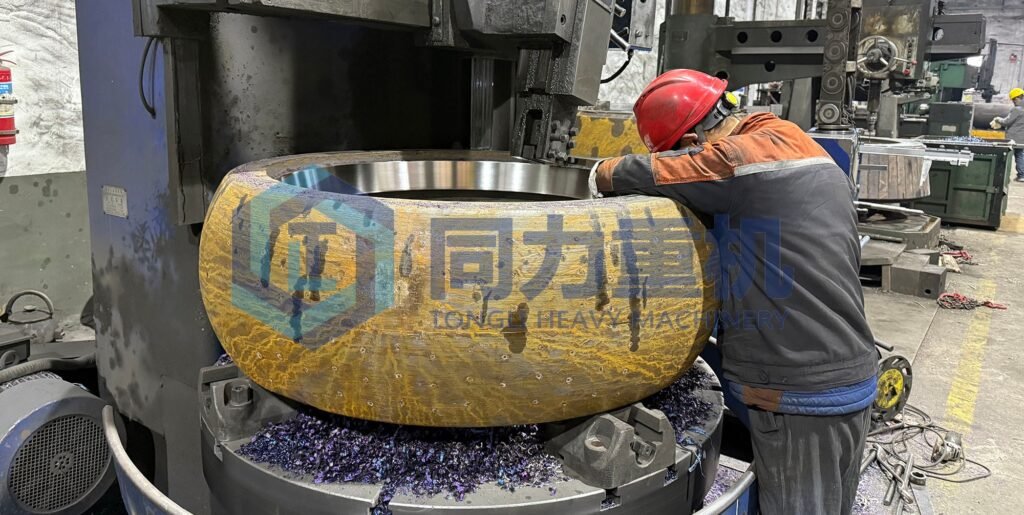

Machining Process of Grinding Roller Tyres and grinding table liner

machining is the final critical stage that transforms a qualified heat-treated casting into a precision functional component. While melting, casting, and heat treatment determine the metallurgical performance, machining determines dimensional accuracy, geometric precision, assembly fit, and operational stability inside the mill. This process applies to all major VRM brands and models, including Loesche LM series, Gebr. Pfeiffer MVR series, Polysius, FLSmidth OK Mill, HRM, TRM, MLS and other similar designs. Regardless of model, machining is executed strictly according to the OEM-approved drawing. Poor machining can compromise even the best metallurgical quality; therefore, this stage requires strict process control and advanced CNC equipment.

Rough Machining After Heat Treatment

After completing the full heat treatment cycle — typically normalizing, quenching and tempering — the casting undergoes dimensional verification before entering the machining stage. Heat treatment may cause minor distortion, scale formation, or dimensional variation due to thermal stress relief. Therefore, rough machining is first performed to remove oxide scale, correct slight deformation, and establish accurate reference surfaces for subsequent precision operations. Because high-chromium cast iron reaches hardness levels above 58–65 HRC after quenching and tempering, machining requires heavy-duty CNC lathes and specialized cutting tools designed for high-hardness materials. Cutting parameters must be carefully controlled to avoid surface cracking or tool damage.

Precision Machining of the Inner Bore and Mounting Surfaces

The most critical machined area of a grinding roller tyre is the inner bore. This surface directly determines the fit between the tyre and the roller hub or shaft. CNC precision turning ensures accurate inner diameter, correct interference or transition fit, and proper roundness and cylindricity. Tight control of concentricity between the inner bore and reference faces is essential to prevent imbalance and uneven load distribution during mill operation. The side faces and mounting surfaces are also precisely machined to ensure axial positioning accuracy and parallelism. These surfaces must meet strict flatness and perpendicularity requirements so that clamping forces are evenly distributed. Any deviation at this stage can lead to vibration, misalignment, or premature bearing wear in high-load VRM conditions. Depending on the specific design — whether Loesche LM, MVR, HRM or other configurations — additional machining may include bolt holes, counterbores, positioning shoulders or keyways. All such features are executed strictly according to the approved technical drawings.

Outer Grinding Surface Considerations

A key technical principle in VRM wear part manufacturing is that the outer grinding surface of high-chromium roller tyres and table liners is generally not fully machined. The working surface is intentionally left in its optimized as-cast condition. There are important reasons for this approach. The outer surface hardness typically exceeds 60 HRC, making full machining both difficult and unnecessary. More importantly, the as-cast surface preserves the dense wear-resistant microstructure formed during solidification and heat treatment. Excessive machining could remove this beneficial layer and reduce service life. Instead of full turning, the outer surface undergoes controlled finishing operations such as riser removal, surface cleaning, local defect grinding, and non-destructive testing. Minor correction may be performed if required, but large-scale material removal is avoided. During initial mill operation, the grinding bed itself creates a natural running-in process that ensures proper surface adaptation.

Dimensional Accuracy and Geometric Control

For large-size roller tyres and table liners, which may exceed two or even three meters in diameter, dimensional accuracy is critical. Machining must ensure precise concentricity between the inner bore and the outer working surface, controlled axial runout, and stable geometric symmetry. Even small deviations can result in uneven grinding pressure, increased vibration, and accelerated wear. Therefore, large-capacity CNC lathes, precision measurement systems, and strict inspection protocols are applied throughout the machining process. Dimensional verification is performed after each key operation to maintain compliance with drawing tolerances.

Surface Finish Requirements

The required surface finish varies depending on function. The inner bore and mounting faces require controlled roughness to guarantee proper fit and load transmission. These surfaces are machined to achieve consistent and stable contact conditions. In contrast, the outer grinding surface does not require a polished finish. An excessively smooth surface would not improve performance and may even reduce initial material grip. The as-cast condition, when free of defects and within dimensional tolerance, provides optimal wear performance under actual grinding conditions.

Final Inspection and Quality Assurance

Before delivery, each grinding roller tyre and table liner undergoes comprehensive inspection. Dimensional accuracy, geometric tolerances, hardness distribution, and non-destructive testing results are verified against technical specifications. Only components meeting all drawing and performance requirements are approved for shipment. So in terms of what are the inspection steps we carry out before we ship our vertical roller mill tyre and liner please check our previous article here: "What are the inspection steps of a Greb.Pfeiffer MVR PMS vertical roller mill grinding roller tyre and liner."

Common Manufacturing Defects and How to Avoid Them

Grinding roller tyres and grinding table liners operate under extremely high compressive loads, abrasive wear, and cyclic thermal stress. Due to their large size, high chromium alloy composition, and complex heat treatment requirements, manufacturing defects can significantly affect service life and operational reliability.

Casting Cracks

Casting cracks are among the most serious defects in high-chromium VRM wear parts. These cracks may appear as surface cracks, internal shrinkage cracks, or delayed cracks after heat treatment. The primary causes include excessive thermal stress during solidification, improper cooling rate, uneven wall thickness design, and residual stress accumulation during quenching. Large roller tyres and table liners are particularly susceptible due to their thick sections and significant temperature gradients between the chilled working surface and the sand-molded inner section. If cooling is too rapid or uncontrolled, internal tensile stress can exceed the material’s strength, resulting in crack formation. Prevention begins at the casting design stage. Optimized gating and riser systems must ensure directional solidification and adequate feeding to eliminate shrinkage stress. Controlled cooling curves — typically 24 to 72 hours depending on size — are essential to prevent thermal shock. During heat treatment, gradual heating and controlled quenching procedures must be applied to minimize stress concentration. In addition, proper tempering is mandatory to relieve quenching stress and stabilize the structure. Non-destructive testing such as magnetic particle inspection and ultrasonic testing is used to detect cracks before machining.

Uneven Hardness Distribution

Uneven hardness is a critical quality issue that directly impacts wear performance. It typically manifests as localized soft spots, excessive hardness gradients between working and non-working areas, or inconsistent hardness across the circumference. The root causes are usually linked to improper alloy control, insufficient austenitizing during quenching, temperature deviation inside the furnace, or inadequate quenching intensity. For high-chromium cast iron, proper dissolution of chromium and carbon into austenite during heating is essential to form a martensitic matrix with uniformly distributed carbides after quenching. To prevent hardness variation, chemical composition must be tightly controlled throughout melting. Real-time spectrometer analysis ensures chromium, carbon, molybdenum, and other alloying elements remain within design limits. During heat treatment, furnace temperature uniformity must be verified using calibrated thermocouples. Adequate soaking time is required to ensure full austenitization, especially for thick-section components. After quenching and tempering, hardness mapping across multiple zones of the casting confirms uniform mechanical properties before approval.

Excessive Wear Rate

Excessive wear in service is often not immediately visible during manufacturing, but it is typically rooted in metallurgical or heat treatment deficiencies. If carbide distribution is non-uniform, if the matrix contains excessive retained austenite, or if hardness does not meet the specified range (generally ≥ 60 HRC for VRM working surfaces), wear resistance will be significantly reduced. Another contributing factor may be over-machining of the outer grinding surface. Removing too much material can eliminate the dense wear-resistant layer formed during solidification and heat treatment, exposing a less optimal microstructure. Prevention requires a holistic approach: precise alloy proportioning, controlled solidification to form dense carbides, optimized quenching parameters, and properly balanced tempering to retain hardness while reducing brittleness. Microstructural examination is recommended to verify that the matrix consists predominantly of martensite with evenly distributed chromium carbides. Field performance feedback should also be incorporated into process refinement. After a grinding roller tyre is worn, replacement of the new tyre is necessary, for more detail about How to Replace Grinding Roller Tyres Click here.

Poor Machining Accuracy

Machining inaccuracies primarily affect assembly stability and mill operation rather than wear resistance directly. Typical issues include incorrect inner bore dimensions, poor concentricity between inner bore and outer surface, excessive runout, or improper flatness of mounting faces. Because VRM grinding rollers operate under high pressure and rotational load, even minor geometric deviations can cause vibration, uneven grinding pressure, accelerated bearing wear, or bolt loosening. To avoid such problems, machining must be conducted on heavy-duty CNC vertical or horizontal lathes capable of handling large diameters and high hardness materials. Precise datum establishment during rough machining is critical. Concentricity and roundness must be continuously monitored throughout machining, and final inspection should include full geometric tolerance verification using calibrated measuring equipment. Strict adherence to the OEM drawing is essential for compatibility with brands such as Loesche, Gebr. Pfeiffer, FLSmidth, Polysius, HRM, TRM, and similar systems.

How Manufacturing Quality Affects Roller Tyre Service Life

Casting Quality → Direct Impact on Structural Failures and Early Spalling

In field cases, roller tyres with internal shrinkage cavities or carbide segregation typically show surface spalling within the first 2,000–4,000 operating hours. In contrast, dense and properly solidified castings often operate 8,000–12,000 hours before major wear intervention. The reason is measurable: ultrasonic testing on prematurely failed tyres often reveals internal discontinuities beneath spalled zones. These hidden voids act as stress concentrators under grinding pressure (which can exceed 100–120 bar hydraulic loading in cement VRMs). Once micro-cracks initiate, surface material begins to detach. Plants often report that tyres with poor casting quality require early hardfacing repair, increasing unplanned downtime. In contrast, high-density castings exhibit uniform, gradual wear rather than chunk breakage. Operational proof:

- Higher scrap rate during NDT = higher risk of early failure

- Early surface flaking = typical symptom of casting discontinuity

Heat Treatment Quality → Measurable Differences in Wear Rate

Hardness alone does not define wear life. Field comparisons show that two tyres both tested at 60–62 HRC can have very different service durations. In cement grinding:

- Poorly stabilized microstructure → 1.5–2.0 mm wear per 1,000 hours

- Properly heat-treated structure → 0.8–1.2 mm wear per 1,000 hours

Over a 10,000-hour cycle, this difference can equal 8–10 mm of additional usable thickness — often translating to one extra year of service in some plants. Improper heat treatment typically results in:

- Edge chipping near high-pressure zones

- Uneven wear bands across the circumference

- Sudden hardness drop after several thousand hours

Plants monitor these issues through periodic hardness checks and profile measurements. Stable hardness over time correlates directly with controlled quenching and tempering.

Machining Accuracy → Directly Reflected in Mill Vibration Data

This is one of the most immediately visible impacts. When inner bore machining lacks concentricity or roundness control, the installed roller develops radial runout. In operation, this appears in:

- Increased mill vibration amplitude (often +1.0–2.5 mm/s higher than baseline)

- Uneven grinding pressure distribution

- Localized high wear zones

Cement plants routinely track vibration trends. After replacing inaccurately machined tyres with precision-machined components, vibration levels often decrease measurably within days of operation. Improved concentricity leads to:

- More stable hydraulic pressure fluctuation

- Reduced bearing load oscillation

- Smoother mill sound profile

These are observable parameters, not theoretical outcomes.

Overall Manufacturing Quality → Maintenance Frequency and Downtime

From a maintenance perspective, the difference becomes financial, Poor manufacturing quality typically leads to:

- Earlier hardfacing campaigns

- Higher risk of unexpected stoppage

- More frequent inspection shutdowns

High manufacturing quality results in:

- Predictable wear intervals

- Longer time between major overhauls

- Reduced spare parts consumption

In cement plants running 24/7 production, even one avoided unplanned shutdown can offset the entire cost difference between suppliers.

What are the Heat treatment standards for cement and mining VRM applications?

ASTM A532/A532M-10 (2019) – ASTM International Standard (Most Widely Applied)

ASTM A532/A532M is the most commonly adopted international standard for the production of wear-resistant cast irons, including high-chromium cast iron, used in vertical roller mill (VRM) roller tyres and liners in the global cement and mining industries. It clearly specifies requirements for melting practice, chemical composition, heat treatment procedures, and mechanical properties. This standard fully aligns with the wear demands of VRM applications and is one of the primary standards followed for export products.

Melting and Alloy Control Requirements

The standard specifies that high-chromium cast iron must be produced using compliant melting processes, such as electric arc furnaces (EAF) or induction furnaces. The chromium content must exceed 4%, and the alloy must be fully melted as a dedicated heat rather than produced by simple ladle alloy additions to conventional cast iron. Chromium content is categorized into grades such as 11–13%, 15–18%, and 23–28%. For VRM roller tyres and liners, the 12–20% chromium range—consistent with the previously described production process—is generally preferred. Carbon content is typically controlled within 2.3–3.6%, while harmful elements such as phosphorus and sulfur must not exceed 0.05%, fully consistent with the chemical control parameters described earlier. The standard also requires real-time chemical composition monitoring during melting to ensure uniform alloy distribution and to prevent segregation.

Heat Treatment Requirements

ASTM A532 explicitly mandates that high-chromium cast iron castings must undergo heat treatment and prohibits use in the as-cast condition. Approved heat treatment combinations include “as-cast + stress-relief annealing” or “quenching + stress-relief tempering,” depending on performance requirements for VRM roller tyres and liners. Heat treatment parameters must be adjusted according to section thickness. Typical process ranges include:

- Normalizing: 950 °C–1000 °C

- Quenching: 980 °C–1050 °C

- Tempering: 250 °C–350 °C

These parameters are highly consistent with the heat treatment process previously described. Post-treatment hardness must fall within 50–72 HRC depending on grade classification. For VRM roller working surfaces, hardness is generally required to be ≥60 HRC to ensure sufficient wear resistance. The standard further requires that residual stresses be properly relieved after heat treatment to prevent cracking or deformation during high-speed VRM operation.

Applicability to VRM Components

ASTM A532 classifies high-chromium cast iron into multiple grades. Grades such as I-A, I-B, and I-C (chromium 11–28%) are specifically intended for mining and milling wear components and are highly suitable for VRM roller tyres and liners. With hardness ranges of 50–70 HRC, these grades fully match the severe wear conditions of cement and mining vertical roller mills.

ISO 20431:2023 – International Organization for Standardization (General Heat Treatment Standard)

ISO 20431:2023 is a general international heat treatment quality management standard. Although not limited specifically to high-chromium cast iron, it clearly covers wear-resistant castings, including VRM roller tyres and liners. It serves as an effective complement to ASTM A532 and is applicable to VRM manufacturers worldwide. The standard emphasizes quality management systems for heat treatment facilities. It requires complete documentation of melting and heat treatment parameters, including temperature records, holding times, and cooling rates—fully consistent with the previously described real-time monitoring and full-process documentation requirements. It also specifies control standards for quenching media (such as quenching oil) to ensure uniform cooling and prevent quench cracking. Typical heat treatment flow sequences—normalizing, quenching, tempering—are clearly defined, and the importance of preheating and controlled slow cooling for stress relief and dimensional stability is emphasized. These requirements directly support dimensional accuracy and reliability of VRM roller tyres and liners. ISO 20431 can be used in conjunction with ASTM A532. Its focus on heat treatment process control and traceability perfectly aligns with the cement and mining industries’ demand for high reliability and extended service life, especially in large-scale VRM system production.

Other Major International Standards (Regional Applications)

In addition to ASTM and ISO standards, various regional standards are applied in VRM production and trade. These standards are fully compatible with the melting and heat treatment processes described previously.

Germany – DIN 1695

This standard specifies melting processes and heat treatment parameters for high-chromium cast iron. It recommends quenching temperatures of 980 °C–1050 °C and tempering temperatures of 220 °C–300 °C, with hardness requirements ≥60 HRC. It emphasizes the compositional uniformity advantages of induction furnace melting and is suitable for small- to medium-batch VRM roller production.

United Kingdom – BS 4844

This standard is technically similar to ASTM A532, with particular emphasis on chemical composition tolerances and post-heat-treatment microstructure. It requires a martensitic matrix with uniformly distributed carbides to ensure stable wear performance in VRM components.

France – NFA 32-401

This standard defines melting parameters for both electric arc and induction furnaces. It requires post-heat-treatment hardness testing and residual stress evaluation and prohibits the use of castings with cracks, distortion, or other structural defects. It is particularly suited for high-load cement VRM applications.

What Are The Materials Used in Vrm Grinding Roller Tire Manufacturing?

High-Chromium Cast Iron

High-chromium cast iron is a traditional and widely applied material for VRM grinding roller tires, typically containing 18–30% chromium. Its microstructure is dominated by hard M7C3 carbides distributed within a martensitic or austenitic matrix, delivering hardness levels around HRC 58–65. This material provides excellent resistance to abrasive wear, especially in clinker and slag grinding. However, due to its relatively lower toughness compared with steel-based solutions, it performs best in stable operating conditions with controlled impact loads.

Cast Steel with Hardfacing

Cast steel with hardfacing consists of a tough alloy steel base combined with a high-wear-resistant overlay layer applied through welding. The steel substrate ensures high structural strength and impact resistance, while the hardfacing layer—typically enriched with chromium, molybdenum, or complex carbides—protects the working surface against abrasion. This solution offers a balanced combination of toughness and wear resistance and allows for on-site rebuilding through re-welding, making it suitable for mills with higher vibration or variable operating conditions.

Primary Ceramic Composite Technology (Integral MMC, Magotteaux Equivalent)

Primary ceramic composite refers to an integral casting process in which ceramic reinforcements are incorporated during the initial casting stage, forming a strong metallurgical bond between the ceramic phase and the metal matrix. In international terminology, this is generally classified as Metal Matrix Composite (MMC) technology, and a well-known equivalent is Magotteaux’s TiC reinforced systems such as Xwin® or Neox®. In this process, titanium carbide (TiC) inserts or ceramic elements are integrated into the casting so that they become structurally bonded with the alloy body. The result is a synergistic material combining the ultra-high hardness of ceramics with the load-bearing strength of metal, significantly extending wear life in highly abrasive VRM applications.

Secondary Ceramic Composite – Indian Vega AIA engineering Process

Secondary ceramic composite typically involves embedding pre-formed ceramic or TiC inserts into a metallic base through a secondary casting, infiltration, or anchoring method after the main body is prepared. In the international market, this is commonly referred to as TiC insert reinforced alloy casting, and Indian manufacturers such as Vega Industries promote similar solutions under TiC insert or ceramic composite roller technologies. Although the bonding mechanism may differ from fully integral MMC casting, this structure still greatly enhances abrasion resistance compared with traditional high-chrome materials. It is widely used in cement and mineral grinding where extended service life and controlled wear patterns are critical. For more details about the difference between these two type of ceramic composite grinding roller tyre check out our previous article: "Ceramic VRM Tyre Composite Technology: Magotteaux Vs Vega Industries"

For more detailed information about Greb.Pfeiffer PMS MVR Grinding table liner material please check out our previous article: Vertical Roller Mill Grinding Table Liner: Steel Casting vs Ceramic vs High Chrome Wear-Resistant Cast Iron