What is a bowl-type grinding roller in a vertical roller mill?

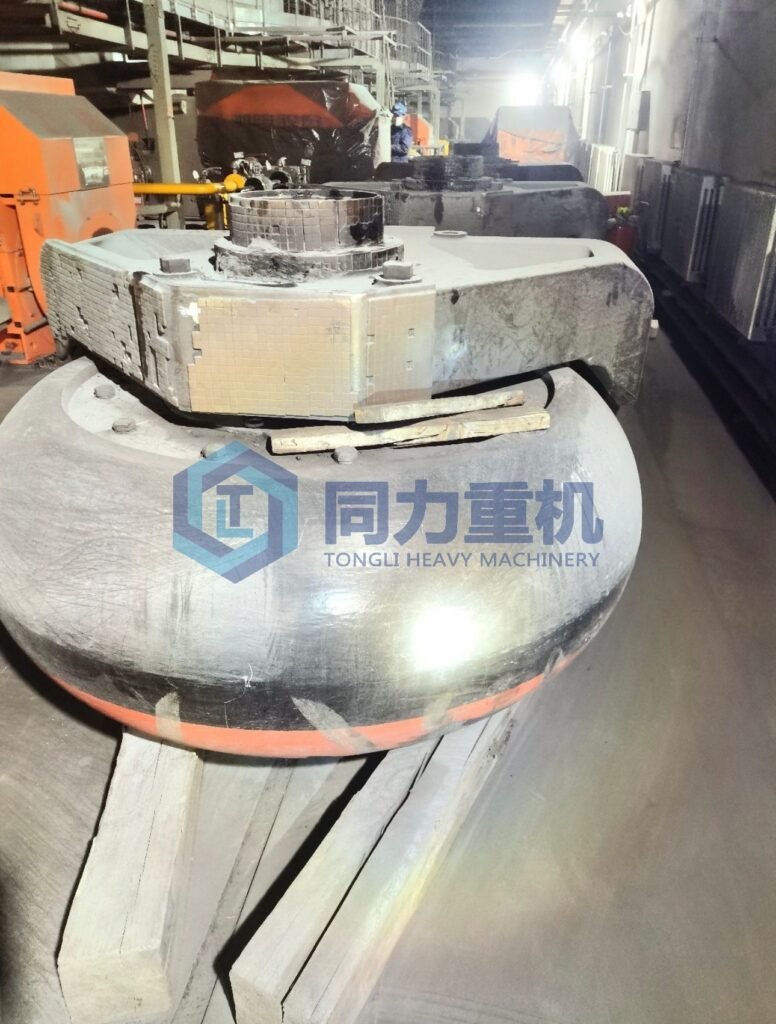

In a vertical roller mill, the bowl-type grinding roller Tyre or liner/sleeve features a curved roller body designed to match an annular-grooved grinding table. The curvature of the roller working surface is precisely aligned with the groove profile of the table liner, allowing the roller and grinding table to form surface contact rather than line contact during operation. This design reduces peak contact stress by approximately 15%–20%, effectively minimizing localized wear. By adjusting the roller-to-table clearance, the bowl-type roller structure enables stable control of the material bed thickness within the range of 30–80 mm. Under cement raw meal and clinker grinding conditions, this configuration delivers an 8%–12% improvement in grinding efficiency compared with conical roller designs. The roller tyre is typically manufactured from high-chromium cast iron (Cr15–Cr20) or Ni-Hard cast iron or ceramic composite grains providing excellent impact resistance and abrasive wear performance. With a service life of 8,000–12,000 operating hours, the bowl-type grinding roller is a core grinding component for high-capacity vertical roller mills.

Bowl type grinding roller liner manufactuer

As an OEM manufacturer specializing in vertical roller mill (VRM wear parts), we design and produce bowl type grinding roller sleeve liners engineered to meet the demanding operating conditions of cement, ggbfs, coal, slag, limestone and mineral grinding applications. Our vrm gridning roller tyre liners are fully compatible with leading VRM company, including Loesche LM, FLSmidth ATOX, UBE, Gebr. Pfeiffer MPS, with magotteaux comparable quality, providing a reliable and cost-effective alternative to original branded components. Manufactured using ceramic composite materials, high chromium cast iron, and hardfaced steel surfaces, our bowl type roller sleeve liners deliver excellent wear resistance, impact strength, and service life stability under high-pressure grinding conditions. By combining advanced material technology with precision manufacturing and strict quality control, we ensure dimensional accuracy, consistent performance, and seamless installation across a wide range of bowl-type VRM configurations.

We provide an alternative to original branded vertical roller mill grinding roller sleeve liner spare parts.

The attached table lists the vertical roller mill models that our bowl-type grinding roller sleeve liners are compatible with.

| Brand / OEM | Mill Series | Typical Models Using Bowl-Type Grinding Rollers | Main Applications |

| Loesche (Germany) | LM Series | LM 17.3–28.3 (coal); LM 35.2–45.2 (raw); LM 46.2–63.3 (cement) | Coal, raw meal, clinker |

| FLSmidth | ATOX® Series | ATOX 17.5–22.5 (coal); ATOX 25–33 (raw); ATOX 37.5–57.5 (cement) | Coal, raw, cement |

| Gebr. Pfeiffer (Germany) | MPS Series | MPS 140–200 (coal); MPS 225–265 (coal/petcoke); MPS 280–4250 (raw) | Coal, petcoke, raw meal |

| UBE Machinery (Japan) | UM Series | UM 20–28 (coal); UM 30–38 (raw); UM 42–60 (cement) | Coal, raw, clinker |

| CITIC Heavy Industries | LG / LGM / LMZ Series | LG 25–40 (raw); LGM 42–60 (cement); LMZ coal mills | Cement, raw, coal |

| Sinoma / Hefei Cement Research Institute | HRM Series | HRM 1700–2200 (coal); HRM 2400–3400 (raw); HRM 3700–5600 (cement) | Coal, raw, cement |

| Sinoma / Tianjin Cement Industry Design & Research Institute (TJCI) | TRM Series | TRM 21–28 (coal); TRM 31–38 (raw); TRM 42–56 (cement) | Coal, raw, cement |

| Shanghai Electric / Shanghai Heavy | ZGM Series | ZGM 95–113 (coal); ZGM 123–133 (large coal mills) | Coal, power plants |

| NHI (Northern Heavy Industries) | MLS / MPS-type | MLS 2619–3626; MPS-type coal mills | Coal, raw |

Loesche LM Series Grinding Roller Tyre Liner - Full Ceramic without insert/composite grain on roller surface

Our vertical roller mill grinding liner/tyre is adaptable to Loesche LM series mills, including LM 17.3, LM 20.3, LM 24.3, LM 28.3, and LM 30.3 for coal and petcoke grinding; LM 35.2, LM 38.2, LM 41.2, LM 41.45 and LM 45.2 for cement raw meal grinding; LM 46.2+2, LM 48.4, LM 53.3+3, and LM 56.3+4 for cement clinker grinding; and LM 60.4+6 and LM 63.3+6 for high-capacity cement grinding applications. (Note: owner provide drawing)

Gebr. Pfeiffer MPS Series Vertical Roller Mill Tyre- Bowl Type High Chromium Cast Iron

Our high chromium cast iron vertical roller mill grinding liner/tyre is adaptable to Gebr. Pfeiffer MPS series mills, including MPS 140, MPS 160, MPS 180, and MPS 200 for coal grinding; MPS 225, MPS 250, and MPS 265 for coal and petcoke grinding; MPS 280, MPS 3070, and MPS 3150 for cement raw meal grinding; and MPS 3450, MPS 3750, and MPS 4250 for high-capacity cement raw milling applications. (Note: owner provide drawing)

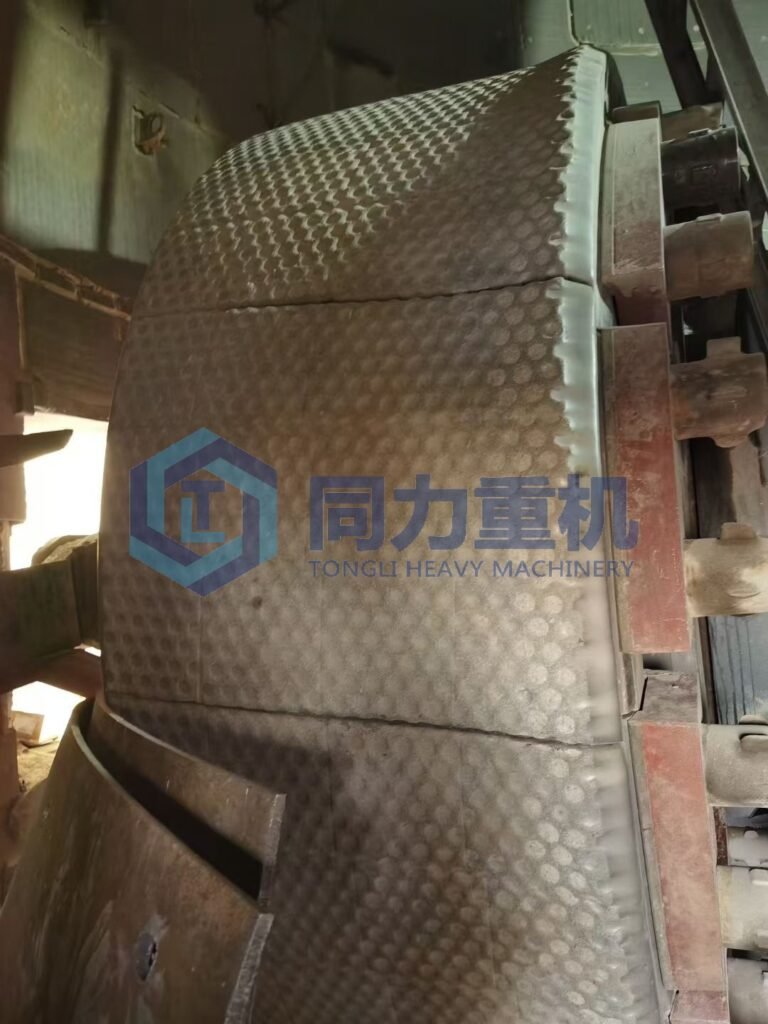

FLSmidth Atox Series and Ok Mill - Segmented Hi-chrome Wear & Ceramic Bowl Type Grinding Roller Tyre

We have done Hi-chrome wear segment and ceramic wear segment grinding roller liner, including ATOX 17.5, ATOX 20, and ATOX 22.5 for coal grinding; ATOX 25, ATOX 27.5, ATOX 30, and ATOX 33 for cement raw meal grinding; ATOX 37.5, ATOX 42.5, ATOX 45, and ATOX 50 for cement clinker grinding; and ATOX 55 and ATOX 57.5 for large-capacity cement grinding applications. (Note: owner provide drawing)

UBE UM Series Bowl Type Vertical roller mill Grinding Roller Assembly Liner tyre

Our VRM grinding liner/tyre is adaptable to UBE UM bowl-type series mills, including UM 20, UM 24, and UM 28 for coal grinding; UM 30, UM 34, and UM 38 for cement raw meal grinding; UM 42, UM 46, UM 50, and UM 56 for cement clinker grinding; and UM 60 for large-capacity cement grinding applications. Other models are UM14.20D×2, UM38.4, UM46.4×2, UM46.4SN, UM50.4, UM50.470×2, UM35.3, UM56.4(Note: owner provide drawing)

Supply HRM Series (Sinoma / Hefei Cement Research Institute)Ceramic composite grain Vertical roller Mill Grinding Roller Liner

Our vertical roller mill grinding liner/tyre is adaptable to the HRM series bowl-type mills, including HRM 1700, HRM 1800, HRM 1900, HRM 2000, HRM 2100, and HRM 2200 for coal grinding; HRM 2400, HRM 2500, HRM 2600, HRM 2800, HRM 3000, HRM 3200, and HRM 3400 for cement raw meal grinding; and HRM 3700, HRM 4000, HRM 4300, HRM 4600, HRM 4800, HRM 5000, HRM 5200, and HRM 5600 for cement grinding applications.

TRM Series (Sinoma / Tianjin Cement Industry Design & Research Institute (TJCI)) Vertical Roller Mill Grinding Roller Supplier

Our vertical roller mill grinding liner/tyre is adaptable to the TRM series bowl-type mills, including TRM 21, TRM 23, TRM 25, and TRM 28 for coal grinding; TRM 31, TRM 33, TRM 35, and TRM 38 for cement raw meal grinding; and TRM 42, TRM 45, TRM 48, TRM 50, TRM 53, and TRM 56 for cement grinding applications.

LGM / LG / LMZ Series (CITIC Heavy Industries) VRM Grinding Roller Tyre Spare Parts OEM Manufacturer

Our vertical roller mill grinding liner/tyre is adaptable to CITIC Heavy Industries (CITIC HIC) bowl-type vertical mills, including LG 25, LG 28, LG 30, LG 32, LG 35, and LG 40 for cement raw meal grinding; LGM 42, LGM 45, LGM 4521, LGM 48, LGM 50, LGM 53, LGM 56, and LGM 60 for cement grinding applications; and LMZ series coal mills, covering commonly supplied LMZ bowl-type coal mill models used in cement plants and power stations.

ZGM Series (Beijing Power Equipment Group) Coal Pulverizer Vertical Coal Mill Grinding roller Sleeve Bowl Tyre

Our vertical roller mill grinding liner/tyre is adaptable to the ZGM series bowl-type mills, including ZGM 95, ZGM 98, ZGM 100, ZGM 105, ZGM 108, ZGM 110, and ZGM 113 for coal grinding; and ZGM 123, ZGM 130, and ZGM 133 for high-capacity coal grinding applications.

NHI (Northern Heavy Industries) Vertical Roller Tyre bowl type coal mill Grinding Roller Spare Parts Manufacturer.

Our vertical roller mill grinding liner/tyre is adaptable to MLS series MPS-type coal mills, including MLS 2619, MLS 2723, MLS 2825, MLS 3026, MLS 3126, MLS 3226, MLS 3426, and MLS 3626, which are widely used for coal grinding applications in cement plants and power stations.

Shanghai Electric SHMP Pulverizing & Special Equipment Co., Ltd. Medium speed coal mill HP Bowl Mill

We have developed Hi-chrome wear segment and ceramic wear segment grinding roller liners for Shanghai Heavy Machinery (Shangzhong) bowl-type medium-speed coal mills (HP series), covering the full range from small- and medium-sized to large-capacity coal mills. For coal grinding, the applicable models include HP 17.5, HP 20, HP 22.5, HP 25, HP 27.5, HP 30, HP 33, and HP 37.5. For large-capacity coal grinding, the models include HP 42.5, HP 45, HP 50, HP 55, and HP 57.5. These grinding roller liners, made from a combination of high-chrome and ceramic wear-resistant materials, are designed to handle coal of varying hardness and moisture content, ensuring stable mill operation, efficient grinding performance, and extended roller service life.

How does a bowl-type grinding roller differ from a conical or flat roller design?

The bowl-type grinding roller (also referred to as a tyre-type roller) differs fundamentally from conical and flat roller designs in terms of contact mechanics and stress distribution. Featuring a radius-curved working surface, the bowl-type roller forms full surface contact with the matching annular-grooved grinding table, increasing the effective contact area by 15%~20% compared with conical rollers. This configuration reduces maximum contact stress by more than 25%, ensuring more uniform force transmission to the material bed and significantly lowering the risk of localized over-grinding or material bypass during operation. By contrast, conical grinding rollers operate under a line-contact mechanism, where contact stresses are highly concentrated. While this makes them suitable for high-hardness material comminution, it is typically accompanied by higher specific energy consumption. Flat grinding rollers, although also providing surface contact, rely on a planar interface; their large contact area often leads to uneven edge wear and reduced liner utilization efficiency. The bowl-type roller overcomes these limitations through its curvature-matched design between the roller surface and the table liner profile, enabling stable material bed formation and controlled grinding conditions. In addition, the roller tyre can be reversed for secondary use, extending overall service life by approximately 30%. These characteristics make bowl-type grinding rollers particularly well suited for large-scale cement raw meal and clinker grinding applications.

What VRM models are compatible with bowl-type grinding roller sleeves?

Vertical roller mill models compatible with bowl-type grinding roller sleeves (tyre-type roller sleeves) are primarily those designed with annular-grooved grinding tables. Mainstream applicable models include:

- The Loesche LM series (such as LM28.3D, LM35.3D, and LM46.4D), featuring roller diameters ranging from φ1200 to φ1800 mm, single-roller loading capacities of 120–200 t, and grinding table groove depths of 80–120 mm. The corresponding bowl-type roller sleeves are designed with curvature radii of R800–R1200 mm, ensuring full surface contact with the table liner.

- The FLSmidth OK series (e.g., OK46 and OK53) employs bimetal hardfaced bowl-type roller sleeves with surface hardness of HRC 58–62. These rollers are optimized for grinding table peripheral speeds of 12–15 m/s and stable material bed thicknesses of 30–50 mm, delivering consistent wear performance under high-throughput conditions.

- The Anhui Conch Kawasaki CK series (such as CK450 and CK500) utilizes bowl-type roller sleeves with a roller-to-table clearance controlled within 5–8 mm. The sleeves support reversible operation, achieving a single-set service life of 8,000–10,000 operating hours.

- In addition, domestic Chinese VRM designs—including the CITIC Heavy Industries LGM series and TONGLI ZJTL Series are widely equipped with bowl-type roller sleeves. These models typically feature outer sleeve diameters of φ1500–φ1700 mm, accommodate feed particle sizes up to ≤50 mm, and support production capacities of 150–300 t/h.

Are bowl-type grinding roller tyres interchangeable between different mill models?

No, Bowl-type grinding roller tyres are not interchangeable between different vertical roller mill models. The primary limitation lies in the requirement that the roller tyre curvature radius, end-face geometry, and mounting reference surfaces must be precisely matched to the annular groove profile of the corresponding grinding table liner. This geometric compatibility is essential to maintain uniform material bed thickness and proper stress distribution during grinding. Other reason are as follows:

1. Geometry Matching Between Roller Tyre and Grinding Table

Bowl-type grinding roller tyres cannot be directly interchanged across different vertical roller mill models. The fundamental constraint lies in the strict geometric matching requirement between the roller tyre curvature radius, end-face dimensions, and mounting reference surfaces and the annular groove profile of the grinding table liner. This precise matching is essential to ensure uniform material bed thickness and balanced stress distribution during the grinding process.

2. Influence of Curvature Radius on Grinding Performance

Each VRM model is designed with a specific bowl-type roller curvature radius corresponding to its grinding table groove geometry. For example, the Loesche LM56.4 utilizes a bowl-type roller tyre with a curvature radius of R320 mm, whereas the FLSmidth VRM4500 employs a grinding table groove profile with a radius of R280 mm. These differences, although seemingly minor, result in significant deviations in contact mechanics.

3. Performance and Wear Risks of Forced Interchangeability

If a bowl-type grinding roller tyre designed for one mill model is forcibly installed on another:

- Grinding efficiency may decrease by more than 30%

- Wear rates of both the roller tyre and table liner can increase by 2–3 times

- Material bed stability deteriorates, leading to uneven grinding and potential material bypass

4. Impact on Bearing Load and Mechanical Reliability

Improper roller geometry also causes the roller bearing load distribution to deviate from the original design parameters. This can lead to:

- Abnormal bearing temperature rise

- Accelerated fatigue damage

- Premature bearing failure and unplanned shutdown

Such failures significantly increase maintenance costs and operational risk. Therefore to ensure optimal grinding efficiency, wear performance, and mechanical reliability, bowl-type grinding roller tyres must be custom-designed and manufactured for the specific VRM model and grinding table configuration, rather than treated as interchangeable spare parts.

What materials are best for bowl-type grinding roller tyres and liners?

There are 3 types of material are commonly used:

1. High-Chromium Cast Iron Roller Tyres

For bowl-type grinding roller tyres, high-chromium cast iron (Cr15–Cr26) is widely adopted. This material offers:

- Surface hardness of HRC 60–65

- Impact toughness ≥12 J/cm²

- Excellent resistance to abrasive and sliding wear

Such properties make it particularly suitable for the grinding of cement clinker, granulated blast furnace slag, and other high-hardness materials, where sustained abrasion dominates the wear mechanism.

2. Ni-Hard and Modified High-Chromium Cast Iron Liners

For grinding table liners and auxiliary liners, two material options are commonly applied:

- Ni–Hard 4 cast iron, with hardness in the range of HRC 58–62, containing a high volume fraction (≥20%) of hard carbides, delivering stable wear resistance under moderate-to-high impact conditions.

- Modified high-chromium cast iron, produced through inoculation and microstructure refinement, which significantly improves resistance to spalling and crack propagation, achieving a 30% or greater improvement in anti-delamination performance compared with conventional high-chromium grades.

3. Ceramic-Particle-Reinforced Metal Matrix Composite (MMC) Solutions

High-performance applications increasingly adopt metal matrix composite (MMC) materials, as utilized by suppliers such as Magotteaux. These materials consist of a high-chromium cast iron matrix reinforced with 15%–30% volume fraction of ceramic particles, typically silicon carbide (SiC) or alumina (Al₂O₃). This composite structure combines:

- The toughness of the metallic matrix (fracture toughness ≥12 J/cm²)

- The extreme hardness of ceramic reinforcements (HRC 62–68)

As a result, service life is extended by 40%–60% compared with conventional high-chromium cast iron rollers, making MMC solutions suitable for medium-to-high impact load grinding conditions.

4. Hardfaced Composite Structures

In certain high-load operating scenarios, hardfaced composite designs are employed. These typically use a structural steel substrate (e.g., Q345B) combined with a hardfacing layer such as Cr28C4. This configuration ensures:

- Adequate structural strength of the base material

- Restorability and life extension through repeated hardfacing cycles

Why is high-chromium cast iron commonly used for bowl-type grinding rollers?

Owing to its balanced mechanical properties, controllable hardness, strong wear resistance, and clear cost advantage, high-chromium cast iron remains the mainstream material choice for bowl-type grinding rollers in the vertical roller mill industry. Its combination of technical reliability and economic efficiency is a key reason for its continued dominance in large-scale cement and mineral grinding applications.

1. Microstructural Advantages of High-Chromium Cast Iron

High-chromium cast iron (typically Cr15–Cr26) is widely used for bowl-type grinding rollers primarily due to its optimized microstructure. During solidification, a large volume of M₇C₃-type carbides is formed, with individual carbide hardness reaching HV 1800–2200. These carbides are uniformly dispersed within a martensitic or bainitic matrix, enabling the material to achieve an excellent balance between abrasive wear resistance and impact toughness. Compared with ordinary cast iron, the wear resistance is improved by approximately 3–5 times, while maintaining an impact toughness of ≥12 J/cm², sufficient to withstand both abrasive wear and impact loads commonly encountered in vertical roller mill operation.

2. Hardness Control and Application Adaptability

High-chromium cast iron bowl-type grinding rollers typically achieve a working surface hardness of HRC 60–65. Through controlled heat treatment, the matrix structure can be tailored to match different operating conditions, allowing stable performance in the grinding of cement clinker, granulated blast furnace slag, and other high-hardness materials. This adaptability, combined with reliable wear behavior, makes high-chromium cast iron suitable for a wide range of cement and mineral grinding applications.

3. Cost Comparison: High-Chromium Cast Iron vs MMC and Ceramic Materials

From a cost perspective, high-chromium cast iron offers a clear economic advantage over advanced composite and ceramic solutions.

- In 2025, the typical ex-works price in China for Cr15–Cr26 high-chromium cast iron roller tyres or liners is approximately

- USD 2,700–3,100 per metric ton.

- By comparison, ceramic-particle-reinforced metal matrix composite (MMC) rollers—such as Magotteaux XCC® series—are priced at approximately

- USD 3,500–4,200 per metric ton, representing 1.6–2.0 times the cost of high-chromium cast iron.

- Monolithic ceramic components (e.g. full alumina ceramic parts) are significantly more expensive, typically reaching

- USD 4,200–5,600 per metric ton, with additional machining costs of 30%–50% due to processing complexity.

4. Repairability and Lifecycle Cost Advantage

Beyond initial procurement cost, repairability plays a critical role in lifecycle economics:

- High-chromium cast iron rollers can be refurbished at a cost of only 20%–30% of a new component, significantly extending service life.

- MMC materials are difficult and costly to repair due to ceramic reinforcement.

- Pure ceramic components are generally non-repairable, resulting in higher replacement frequency and lifecycle cost.

As a result, when considering initial cost, repair feasibility, and total service life, high-chromium cast iron consistently delivers a lower total cost of ownership (TCO).

What hardness range is recommended for bowl-type grinding roller liners?

1. For Standard Operating Conditions

Under normal operating conditions, such as cement raw meal or coal grinding with stable material beds, bowl-type grinding roller liners are commonly manufactured from Ni-Hard 4 cast iron or high-chromium cast iron in the Cr15–Cr20 range. For these materials, the recommended working surface hardness should be maintained within HRC 58–62. This hardness range provides a balanced combination of:

- Adequate resistance to abrasive and sliding wear

- Sufficient impact toughness to tolerate feed size fluctuations and material bed instability

- Stable fatigue performance under continuous rolling and compressive loading

2. For Heavy-Duty and High-Hardness Grinding Applications

In heavy-load grinding conditions, particularly when processing high-hardness materials such as cement clinker or certain slag compositions, higher liner hardness is required to withstand intensified contact stress and abrasive action. In such applications, liners are often produced from Cr20–Cr26 high-chromium cast iron or ceramic-particle-reinforced metal matrix composite (MMC) materials, with hardness levels increased to HRC 62–68. At this hardness range, the liner microstructure contains a significantly higher volume fraction of M₇C₃-type carbides, typically reaching 25%–30%. These hard carbides act as the primary wear-resistant phase, substantially reducing material loss and extending liner service life under severe grinding conditions.

3. Dont get too hard!

It should be noted that liner hardness should not exceed HRC 68. Excessive hardness leads to increased matrix brittleness, which under impact loading can result in:

- Edge chipping

- Surface spalling

- Impact-induced cracking

- Premature liner detachment or failure

How does bowl-type grinding roller wear affect grinding efficiency and output?

Excessive wear of bowl-type grinding rollers affects VRM performance primarily through loss of contact geometry, inefficient particle size control, and electrical and mechanical instability.

1. Loss of Effective Grinding Contact and Pressure Uniformity

Wear of bowl-type grinding rollers destroys the designed curvature matching between the roller tyre and the grinding table liner. This reduces the effective grinding contact area by approximately 15%–30%, leading to uneven pressure distribution across the material bed. As a result, local slippage and over-grinding occur simultaneously, weakening the bed compression mechanism that is essential for stable and efficient grinding.

2. Reduced Grinding Efficiency and Higher Circulating Load

As roller wear progresses, the roller–table clearance increases, allowing more coarse particles to escape effective compression. The proportion of particles failing to reach target fineness typically rises by 8%–12%, which drives the circulating load ratio up by 20%–40%. This directly reduces overall grinding efficiency by 10%–25% and causes a mill output reduction of 8%–20% under otherwise unchanged operating conditions.

3. Increased Power Fluctuation and Energy Consumption

Instability of the material bed caused by worn bowl-type rollers leads to fluctuating grinding resistance. This is reflected in main motor current fluctuations exceeding 15%, indicating unstable mechanical loading. Consequently, specific power consumption increases by 5%–10%, negatively impacting both energy efficiency and long-term equipment reliability.

What are the typical wear patterns on bowl-type grinding roller sleeves?

1. Abrasive Wear Under High Grinding Pressure

Abrasive wear is the most dominant wear mechanism of bowl-type grinding roller tyres, accounting for more than 70% of observed failures in industrial operation. Under normal VRM grinding conditions, the material bed is subjected to a compressive grinding pressure typically ranging from 20 to 35 MPa. Hard mineral particles within the feed act as cutting and ploughing tools, continuously removing material from the roller surface. This process produces uniform, groove-shaped wear patterns aligned with the rolling direction. Although abrasive wear progresses relatively slowly and predictably, excessive material hardness, insufficient material bed thickness, or reduced surface hardness of the tyre can significantly accelerate wear rates.

2. Contact Fatigue Spalling in High-Stress Zones

Fatigue spalling occurs when the roller tyre surface is exposed to repeated cyclic contact stresses, with peak contact stress values often exceeding σₘₐₓ ≥ 450 MPa. Over time, microcracks initiate beneath the surface and propagate parallel to the contact plane. Once these cracks coalesce, surface fragments detach, forming spalling pits typically 5–20 mm in diameter. This wear mode is most frequently observed at the transition zone between the hardened working layer and the base material of high-chromium cast iron roller tyres. Improper heat treatment, excessive hardness gradients, or unstable grinding conditions can further promote fatigue-related damage.

3. Localized Impact Wear from Oversized Feed or Tramp Metal

Localized impact wear is caused by large feed particles or metallic foreign objects entering the grinding zone. These events generate extreme localized stress concentrations far exceeding the material’s design limits, resulting in deep craters or edge breakage with depths of 10–30 mm. Such damage is most commonly found near the feed inlet side of the grinding table, where material size distribution is less uniform. Unlike abrasive wear, impact damage is sudden and irreversible, often leading to premature roller replacement or emergency shutdown if not detected early.

What causes uneven wear on bowl-type grinding roller tyres?

Uneven wear of bowl-type grinding roller tyres is primarily caused by four key factors.

- First, non-uniform material distribution on the grinding table is a major contributor. Malfunction of the table material distributor or feed segregation can cause local fluctuations in material bed thickness exceeding ±5 mm, resulting in 20%–30% differences in roller contact stress. This imbalance leads to unilateral or localized accelerated wear on the roller tyre surface.

- Second, roller-to-table clearance deviation plays a critical role. If the clearance between the grinding roller and the table liner deviates by more than 0.5 mm during installation or adjustment, the load carried by the roller becomes uneven. This condition promotes edge loading and localized high-stress wear, particularly at the roller shoulder or outer track.

- Third, material and heat-treatment deficiencies in the roller tyre itself can significantly affect wear uniformity. In high-chromium cast iron roller tyres, non-uniform carbide distribution (segregation rate > 5%) or a matrix hardness variation exceeding HRC 3 can lead to inconsistent wear resistance across the working surface, resulting in localized rapid wear zones.

- Finally, operating parameter fluctuations exacerbate unstable contact conditions between the roller and the material bed. Variations in grinding pressure exceeding ±0.2 MPa or roller/table speed deviations greater than ±2 r/min disturb the material bed stability, intensifying stress concentration and ultimately accelerating uneven wear development.

For more information about wearness of the grinding roller the cause and the solution please check here.

When should a bowl-type grinding roller liner or sleeve be replaced?

When the wear depth of the liner or grinding roller tyre reaches 40%–50% of the original thickness (or when the absolute wear exceeds 20–30 mm), the stability of the material bed deteriorates, and grinding efficiency typically decreases by 5%–10%. Under such conditions, timely replacement is recommended to prevent further performance loss. If localized spalling or chipping occurs, with the damaged area exceeding 10% of the working surface, or if crack depth exceeds 5 mm, abnormal dynamic behavior may develop. This often results in excessive mill vibration (vibration velocity > 5.5 mm/s²), posing a serious operational and safety risk. In such cases, the mill must be shut down immediately and the affected components replaced. In addition, replacement is advised when the clearance between the table liner and the grinding roller exceeds twice the original design value, or when the cumulative number of hardfacing repairs reaches three or more within a single maintenance cycle. Continuing operation beyond these limits significantly increases the likelihood of unplanned shutdowns and negatively impacts production continuity and equipment reliability.

Can bowl-type grinding roller tyres be refurbished or hardfaced?

Yes, bowl-type grinding roller tyres can be effectively refurbished through hardfacing welding, which is the most widely adopted maintenance solution in large-capacity vertical roller mills. This method restores the roller’s working profile, contact geometry, and wear resistance without replacing the entire component, making it a cost-efficient and technically mature practice in cement, slag, and coal grinding applications.

What is the Hardfacing Process and Surface Preparation?

The refurbishment process begins with comprehensive surface pre-treatment of the worn roller tyre. This includes mechanical grinding to remove the fatigue-affected surface layer, ultrasonic or magnetic particle inspection to detect subsurface and surface cracks, and dimensional checks to ensure the roller core remains within allowable tolerances. After preparation, high-chromium alloy wear-resistant welding wires (such as AWS D256 or D322 equivalents) are applied using multi-layer hardfacing techniques. The resulting overlay typically achieves a hardness of HRC 58–62, with a microstructure dominated by M₇C₃-type hard carbides uniformly dispersed within a martensitic or bainitic matrix. This structure provides excellent resistance to abrasive wear under high contact pressure conditions. For details of In-situ vertical roller mill grinding roller hard-facing repair click here.

Service Life Recovery and Economic Advantages

When properly executed, hardfacing refurbishment allows the restored roller tyre to achieve 80%–90% of the service life of a new component, while maintaining stable material bed formation and grinding efficiency. From an economic perspective, the cost of a single hardfacing repair is typically only 20%–30% of the price of a new roller tyre, significantly reducing maintenance expenditure and downtime-related losses. In practice, most bowl-type roller tyres can undergo two to three refurbishment cycles before dimensional limits or core fatigue necessitate replacement.

Material Limitations and Special Considerations

It should be noted that ceramic particle–reinforced metal matrix composite (MMC) roller tyres can also be repaired by hardfacing; however, this requires specially matched welding consumables and strictly controlled heat input to avoid thermal mismatch and interfacial damage. By contrast, monolithic ceramic roller components are inherently brittle and cannot be refurbished by welding. Once damaged or excessively worn, such components must be completely replaced, resulting in higher lifecycle costs and longer maintenance shutdowns.

How is a bowl-type grinding roller sleeve installed or replaced in a VRM? 4 stpes

The installation and replacement of bowl-type grinding roller tyres in a vertical roller mill (VRM) must follow a standardized procedure. First, the mill shall be shut down, electrically isolated, and locked out/tagged out (LOTO). The roller end cover, bearing housing clamp, and sealing assemblies are then removed.

A 50–100-ton hydraulic puller, in combination with an induction or resistance heating furnace, is used to heat the roller tyre to 150–200 °C. By utilizing the principle of thermal expansion, the assembly clearance is increased to approximately 0.15–0.30 mm, allowing the worn tyre to be smoothly and evenly extracted from the roller shaft.

After removal, the roller shaft surface is thoroughly cleaned to eliminate oxide scale, debris, and residual contaminants, followed by the application of a high-temperature anti-seizure compound. The new roller tyre is then heated to the same temperature range and rapidly mounted onto the roller shaft to the specified reference position. Upon natural cooling to ambient temperature, a stable interference fit is formed between the tyre and the shaft.

Finally, the coaxiality between the roller tyre and the shaft is re-checked, with allowable deviation limited to ≤0.05 mm per meter. The bearing housing, sealing components, and end cover are reinstalled, and the specified grade of lubricating grease is applied. A trial run under no-load conditions is then conducted to verify operational stability, ensuring that the vibration level does not exceed 2.8 mm/s. For detail please check out this article how to replace vertical roller mill grinding roller liner?

FAQ Frequently Asked Questions About Vertical roller mill Grinding Roller Liner Tyre Sleeve Supplier

We specialize in the manufacture and supply of bowl-type flat type conical type vertical roller mill grinding roller liners, tyres, and sleeves used in cement, raw meal, coal, slag, and mineral grinding applications. Our products are compatible with major vertical roller mill brands, including Loesche LM, Gebr. Pfeiffer MPS, FLSmidth ATOX, UBE, Polysius, CITIC, ZGM, HRM, and TRM series mills. Both standard and customized designs are available to meet different operating requirements. (Owner provide drawing)

We offer a performance-based warranty to ensure customer confidence. The warranty covers compliance with the specified hardness (HRCC as agreed) or a minimum of 2,000 grinding hours under normal operating conditions. If any quality issue related to material or manufacturing occurs within the warranty scope, we will provide replacement or compensation in accordance with the contract terms.

Quality control is implemented throughout the entire manufacturing process, from raw material inspection to final shipment. We have ISO9001, ISO14001, ISO45001. Each grinding roller liner undergoes chemical composition analysis, hardness testing, dimensional inspection, and visual examination. Upon delivery, we provide complete quality inspection reports and material certificates, ensuring traceability and compliance with technical requirements.

Our standard payment terms are 30% T/T advance payment and 70% T/T balance before shipment. For long-term partners or large-volume orders, alternative payment options such as L/C at sight may be discussed. We aim to provide flexible and secure payment solutions to support stable cooperation.

All grinding roller liners are packed using export-grade, sea-worthy packaging to ensure safe transportation. Depending on product size and weight, we use fumigated wooden boxes or reinforced steel frames, combined with plastic film and moisture-proof protection. This packaging effectively prevents corrosion, impact damage, and deformation during long-distance ocean shipment.

Yes, we offer OEM manufacturing and reverse engineering services. Customers can provide technical drawings, original samples, or vertical roller mill model information. Our engineering team will evaluate the data and ensure that the supplied grinding roller liners fully match the original dimensions, installation requirements, and performance standards.

Sorry no, we have signed NDA non-disclosure agreement for product we supplied to big company like loesche and pfeiffer, therefore we can not.

2000h or more depends on the material and your requirement of the composition.

We provide 24/7 technical support both before and after delivery. Our services include material selection recommendations, installation guidance, wear analysis, and operational optimization advice. By working closely with customers, we help improve liner wear life and enhance vertical roller mill efficiency. In-situ hard facing as well.

Our vertical roller mill grinding roller liners are widely used in cement plants, power generation facilities, steel plants, and mining operations. We supply to customers across Asia, the Middle East, Africa, Europe, and South America, with proven experience in international project execution.

Customers choose us for our specialized expertise in VRM wear parts, consistent product quality, competitive factory pricing, reliable delivery schedules, and professional technical support. We are committed to building long-term partnerships by delivering durable grinding roller liners that improve mill performance and reduce total cost of ownership.

The profile (contour) design of bowl-type grinding rollers such as circular arc profiles, involute profiles, and composite broken-line profiles—directly influences bed stability by altering the contact mode between the grinding roller and the grinding table, pressure distribution, and the stress state of the material bed. When the profile curvature matches the interlocking characteristics of the material particles, the roller applies a more uniform compaction force to the material bed, effectively preventing localized stress concentration that may lead to over-compaction or material bed lifting/voiding.

A circular arc profile increases material residence time within the grinding zone, enhances inter-particle interlocking forces, and helps maintain a stable material bed thickness. An involute profile, by contrast, optimizes material conveying and grinding rhythm, reducing material bed thinning caused by excessive material flow velocity.

Composite profiles integrate the advantages of different profile geometries across multiple zones: achieving pre-compaction in the feed zone, intensified comminution in the grinding zone, and reduced material adhesion in the discharge zone. Ultimately, by regulating force equilibrium, material motion trajectory, and bed thickness distribution during the grinding process, optimized roller profiles ensure the material bed remains in a stable dynamic equilibrium, preventing excessive vibration, reduced grinding efficiency, and other operational issues caused by material bed instability.

The bowl-type grinding roller direct affects mill vibration behavior and operational stability through its structural design—including the roller diameter-to-width ratio and roller surface curvature—its material properties, such as the balance between hardness and toughness, and its assembly accuracy, including uniformity of the roller-to-table clearance and roller shaft coaxiality.

When the roller surface adopts symmetric or asymmetric curved profiles, the material grinding trajectory and stress distribution are optimized, effectively reducing impact-induced vibration caused by material uneven loading or sudden fluctuations in material bed thickness. The use of high-chromium cast iron or hardfacing layers based on cemented carbide alloys significantly enhances wear resistance and prevents localized surface spalling, thereby avoiding periodic vibration resulting from uneven roller surface topography.

If the coaxiality deviation during roller assembly exceeds 0.1 mm, uneven contact stress between the grinding roller and grinding table may occur, potentially inducing low-frequency resonance in the mill system. In addition, the grinding roller’s elastic floating mechanism—such as spring-loaded or hydraulic damping systems—can absorb impact energy generated during grinding, further suppress vibration amplitude and ensure long-term stable operation of the vertical roller mill.

The selection of a bowl-type vertical roller mill grinding roller tyre (tread) The core principle is to prioritize tyre material selection based on the hardness of the feed material (Mohs hardness), abrasiveness (wear index), feed particle size, and required production capacity. For materials with low to medium abrasiveness, such as limestone, high-chromium cast iron (Cr15–Cr20) is typically sufficient. For highly abrasive materials, such as quartz sand or slag, Ni-Hard cast iron or composite wear-resistant alloy materials are recommended.

At the same time, the roller-to-table clearance, applied grinding pressure, and mill rotational speed must be considered to determine the tyre structural configuration, such as symmetric or asymmetric profiles, as well as the appropriate radius of curvature. This ensures that the tyre profile fully conforms to the grinding trajectory of the table liner, thereby reducing the risk of edge wear. In addition, verification of the tyre thickness, hardness gradient—with a surface hardness of ≥60 HRC and a core hardness of ≥30 HRC—and the heat treatment process is essential to ensure adequate impact resistance and wear life. Through this integrated approach, an optimal balance between grinding efficiency and spare part cost can be achieved.

1. Segmented tire rollers consist of a roller core and multiple wear-resistant tire blocks. The tire blocks are fixed to the roller core surface using high-strength bolts, dovetail grooves, or wedge structures. Their core features and advantages are as follows: Partial replacement, extremely low maintenance costs.

2. During grinding, only the tire blocks come into contact with the material. When a tire block wears to its wear threshold, it can be individually removed and replaced without replacing the entire roller. Compared to the "whole scrap" mode of integral tire rollers, spare parts costs can be reduced by 60%~70%, making them particularly suitable for unevenly abrasive materials (such as clinker mixed with slag) causing localized uneven wear.

3. The roller core is made of high-strength cast steel (such as ZG35CrMo) to ensure impact resistance. The tire blocks can be flexibly selected from different wear-resistant materials based on the abrasiveness of the materials—for example, high-chromium cast iron (Cr20) is used for medium- to low-abrasive materials such as limestone, while nickel hard alloy (Ni-Hard 4) is used for highly abrasive materials such as slag and quartz sand. Different materials can even be combined on the same roller core to solve grinding problems caused by fluctuations in material composition.

4. Lower processing difficulty and significant advantages in large-scale production. For large vertical mills (e.g., roller diameter ≥ 2.8m), the casting, heat treatment, and machining of integral tire rollers are extremely difficult, easily resulting in defects such as internal shrinkage cavities and uneven hardness. In contrast, segmented tire blocks can be cast in small batches, offering greater quality control and better meeting the high-capacity requirements of large vertical mills.

5. Easy installation and maintenance, short downtime. Tire block disassembly and installation do not require large hoisting equipment and can be completed in part within the mill cavity. The replacement time for a single tire block is only 2 to 4 hours; while the replacement of an integral tire roller requires hoisting as a whole, and the downtime is usually more than 12 hours.

1. High-Chromium Cast Iron (Cr16–Cr30): Excellent abrasion resistance, ideal for hard and highly abrasive ores.

2. Ceramic-Metal Composite: Combines ceramic hardness with metal toughness, offering high wear resistance and extended service life.

3. High Manganese Steel: Good impact resistance, suitable for softer ores or high-impact applications.

4. Medium Alloy Steel: Provides balanced toughness and wear resistance for moderate grinding conditions.

5. High Manganese Steel + TiC Alloy Bar: Enhanced abrasion and impact resistance, ideal for highly abrasive, hard, or sticky materials.

1. Concave liners: Fit concave grinding tables and are commonly used in mid- to large-capacity mills.

2. Flat plate liners: Designed for flat grinding tables, often found in standard VRM installations.

3. Bowl-type liners: Correspond to tapered or cylinder-type grinding rollers and are mainly used in mills with bowl-shaped tables.

Ceramic grinding rollers are a new type of composite wear-resistant roller designed for vertical roller mills (VRMs). They are manufactured using one-step pouring and casting technology, combining:

Matrix: High-chromium cast iron provides structural strength, toughness, and impact resistance.

Embedded Ceramic Layer: Wear-resistant industrial ceramic particles are inlaid into the matrix, with a thickness of 40–60 mm, providing exceptional abrasion resistance.

This combination makes ceramic grinding rollers one of the most wear-resistant solutions for VRMs. They are widely used in industries such as cement, metallurgy, power generation, construction, and mining, offering longer service life, reduced maintenance costs, and stable grinding performance compared with conventional rollers.

How does a bowl-type grinding roller liner increase the motor amperage during operation?

1. Increased Material Bed Thickness and Accumulation

When the roller liner profile or wear condition causes material to accumulate in the grinding zone, the material bed becomes thicker and denser. This increases the resistance against the grinding table rotation, requiring higher torque from the main motor. As a result, motor current (amperage) rises. Excessive material accumulation may also lead to unstable bed conditions, further amplifying current fluctuations.

2. Higher Grinding Pressure Due to Liner Profile Design

Certain bowl-type roller liner profiles, especially those with larger curvature radius or aggressive grinding geometry, increase the effective contact area between the roller and the material bed. This enhances grinding intensity but also increases compressive and shear forces, leading to higher power demand and elevated motor amperage.

3. Increased Friction from Worn or Improperly Matched Liners

If the roller liner and grinding table liner are not well matched in profile, or if the liner surface becomes uneven due to wear, the material experiences irregular shear and sliding resistance. This increases friction losses within the grinding zone, causing the drive system to draw more current.

4. Reduced Material Discharge Efficiency

A bowl-type liner that restricts material flow toward the discharge area can slow down material evacuation. This causes material to remain longer in the grinding zone, increasing the circulating load and internal resistance, which directly raises motor amperage.

5. Increase in System Load Due to Higher Fineness Demand

If the liner design improves grinding efficiency but the classifier settings or airflow are not adjusted accordingly, the mill may grind material more intensively than required. This increases the specific energy consumption and results in higher motor current.

6. Abnormal Roller-to-Table Contact Conditions

Poor liner installation, incorrect clearances, or excessive wear may cause localized metal-to-material or near-contact conditions, significantly increasing mechanical resistance. Even slight abnormalities in contact stress can lead to a noticeable rise in motor amperage.

What Are the Advantages of Bowl-Type Vertical Roller Mill Grinding Rollers?

Compared with conventional conical grinding rollers, bowl-type VRM grinding roller tyres offer distinct technical advantages centered on conformal grinding contact, double-sided reusability, and optimized wear resistance. These advantages directly improve grinding efficiency, operational stability, and spare-part utilization.

1. Double-Sided Reversible Design for Maximum Utilization

Bowl-type grinding roller tyres feature a symmetrical arc-shaped tread profile, allowing both sides of the tyre to be used alternately. After one working surface reaches its wear limit, the tyre can be reversed and reinstalled to utilize the opposite side without performance loss. In contrast, conical grinding rollers have a fixed single working surface, making reversal impossible. This reversible structure increases roller body utilization by more than 50%, significantly extending replacement intervals and reducing spare-part consumption. For cement and slag grinding plants operating under continuous duty, this translates into lower maintenance frequency and reduced lifecycle cost.

2. Full-Surface Curved Contact for Uniform Stress Distribution

The arc-shaped tyre surface forms a conformal, full-area contact zone with the grinding table liner. Grinding pressure is therefore distributed evenly across the entire contact surface, eliminating the localized stress concentration typical of line-contact grinding found in conical roller designs. This uniform pressure distribution reduces the risk of over-grinding and excessive fines generation, while simultaneously improving grinding efficiency for hard and abrasive materials such as clinker and granulated blast furnace slag. The result is more stable material bed formation and improved energy utilization.

3. Customized Curvature Matching the Grinding Table Trajectory

Bowl-type roller tyre curvature can be custom-designed to precisely match the grinding track of the table liner. This high level of geometric compatibility minimizes mismatched contact zones and prevents material instability during grinding. Because the material remains consistently engaged between the roller and table, the likelihood of material slipping or “skidding” is significantly reduced. This leads to smoother operation, lower vibration levels, and superior mill stability compared with conical roller configurations.

4. Optimized Wear Layer Design with Gradient Hardness Structure

The wear layer of bowl-type grinding roller tyres can be manufactured using composite hardfacing or gradient alloy casting technologies. These processes create a gradual hardness transition from the surface to the core, typically with:

- Surface hardness ≥ 62 HRC for superior abrasion resistance

- Core hardness ≥ 32 HRC to provide impact resistance and structural toughness

This graded hardness profile aligns well with the stress characteristics of curved grinding surfaces, enhancing resistance to impact loading, abrasive wear, and surface spalling. As a result, bowl-type grinding roller tyres typically achieve a 30–50% longer service life compared with traditional conical grinding rollers under equivalent operating conditions.

Integral vs Segmental Grinding Roller Tyre Sleeves for Vertical Roller Mills

Segmented grinding roller liners, also called piece-type or modular roller sleeves, are a modern wear-part solution for vertical roller mills (VRMs). Unlike traditional integral (monoblock) liners, segmented liners are made up of multiple individual segments mounted on a roller body, allowing partial replacement of worn sections and reducing both downtime and maintenance costs.

What are the adventages of segmented grinding roller tyre?

1. Maintenance Efficiency and Operational Flexibility

One of the main advantages of segmented roller liners is their ease of maintenance. Large monoblock liners are heavy and difficult to handle, requiring full removal for replacement. Segmented liners, however, allow maintenance teams to replace only the worn segments on-site, minimizing mill shutdowns and production losses. This feature is particularly beneficial in high-capacity cement, coal, and mineral grinding applications.

2. Optimized Grinding Contact and Wear Performance

Each segment can be custom-designed to match the grinding table trajectory and the characteristics of the processed material. This ensures even pressure distribution, maintains a stable material bed, and prevents edge wear or spalling. Segmented liners can therefore improve grinding efficiency for both soft and highly abrasive materials, such as clinker, slag, or quartz.

3. Advanced Materials and Manufacturing

Segmented liners are typically made from high-chromium cast iron, Ni-Hard alloys, or composite wear-resistant alloys. They often feature a surface hardness of 60–62 HRC and a core hardness of 30–35 HRC, forming a graded hardness structure. Advanced manufacturing methods such as hardfacing, composite welding, or gradient casting ensure the liners withstand impact, abrasion, and thermal stresses, making them highly durable under heavy-duty grinding conditions.

4. Cost and Lifecycle Advantages

By combining modular maintainability, tailored wear resistance, and operational stability, segmented liners help achieve longer service life and lower total cost of ownership compared with traditional integral roller sleeves. Partial replacement reduces spare part consumption, while optimized contact and wear performance improve mill efficiency and reliability.

What are the limitations of segmented grinding roller tyre?

1. Strict Assembly Precision Requirements May Cause Uneven Wear

Segmental wear blocks are fixed onto the roller core using high-strength bolts or wedge systems. If the flatness or coaxiality deviation of a single wear segment exceeds 0.1 mm during assembly, it can result in uneven grinding surfaces. Under operation, this leads to localized overloading, accelerating the wear rate of the affected segment. In addition, it can induce synchronous uneven wear on the grinding table liner, ultimately reducing the service life of the entire grinding assembly.

2. Poor Sealing Can Lead to Roller Core Erosion

The interface between the wear segment and the roller core is difficult to fully seal. During grinding, fine powder particles (e.g., cement clinker dust or ground slag fines) can infiltrate these gaps, causing roller core corrosion or wear. In cases where the feed material has high moisture content (e.g., wet grinding conditions), the connecting bolts may corrode and lose pretension, increasing the risk of segment displacement during operation.

3. Lower Overall Rigidity Compared to Integral Rollers Limits High-Pressure Applications

An integral roller has a one-piece structure combining the roller core and tyre surface, providing high stiffness and strong deformation resistance, suitable for high roller pressures of 30–40 MPa. Segmental rollers, however, contain assembly gaps between segments, reducing overall deformation resistance by 15–25%. Under high roller pressure, segments may slightly deform, causing the grinding trajectory to deviate from the design profile, which can reduce grinding efficiency.

4. Increased Complexity in Spare Parts Management

Different segments experience different wear rates depending on their location on the roller, requiring separate spare segments for center and edge positions. Additionally, connection components—such as high-strength bolts, wedges, and positioning pins—must strictly match original manufacturer specifications. Any mismatch in part models or delays in supply can extend mill downtime and increase maintenance management costs.

Manufacturers of Segmental Grinding Roller Tyres for Vertical Roller Mills

FLSmidth – Industry Benchmark for Segmental Roller Tyre Design

Among global vertical roller mill manufacturers, FLSmidth is the most well-known and widely recognized supplier associated with segmental grinding roller tyre technology. Its ATOX vertical roller mill series extensively uses segmented roller tyres composed of multiple curved wear segments mounted on a common roller body. Each segment can be replaced individually, which significantly reduces maintenance time and minimizes mill downtime. This design is particularly advantageous for large-capacity raw mills, coal mills, and cement mills operating under high grinding pressure.

Loesche – Primarily Integral Design with Limited Segmented Applications

Loesche vertical roller mills traditionally employ integral (monoblock) grinding roller tyres, focusing on structural rigidity, precise geometry, and vibration control. However, segmented or partially segmented roller tyre solutions may be applied in special circumstances, such as very large mill sizes, retrofit projects, or customer-specific maintenance strategies. Despite this, segmented roller tyres are not a standard feature in Loesche’s mainstream mill design philosophy.

Gebr. Pfeiffer – Emphasis on Integral Roller Tyres

Gebr. Pfeiffer, particularly in its MPS mill series, predominantly uses integral grinding roller tyres. The design approach prioritizes uniform stress distribution, stable material bed formation, and long-term operational stability. As a result, segmented roller tyres are rarely adopted in standard Pfeiffer mill configurations and are generally not part of their regular product offering.

Polysius (thyssenkrupp) – Selective Use in Special Projects

In the Polysius vertical roller mill portfolio, segmented grinding roller wear parts have been used in certain customized or large-scale projects. However, these applications are typically project-specific rather than standardized solutions. Polysius mills more commonly rely on integral roller tyre designs to maintain system stiffness and consistent grinding performance.

Chinese Vertical Roller Mill Manufacturers – Widespread Use of Segmental Tyres

Among Chinese VRM manufacturers, segmented grinding roller tyres are widely adopted, particularly in large raw material mills and slag grinding applications. Companies such as CITIC Heavy Industries, TONGLI, and manufacturers of ZJTL, HRM, ZGM, and TRM series mills frequently apply segmented designs to improve maintenance efficiency and reduce spare-part replacement costs. These designs are well suited to high-capacity industrial environments where operational continuity is critical.

Conical Grinding roller vs Bowl type roller sleeve

The conical grinding roller has a frustum-shaped roller surface, with the radial dimension gradually varying along the shaft axis. During grinding, the material is primarily subjected to radial compression, and the self-cleaning effect of the conical surface makes it more suitable for grinding high-hardness or easily agglomerating materials. Moreover, because the contact line is linearly distributed, the unit surface pressure is more uniform. After wear, grinding efficiency can be maintained by adjusting the roller gap.

The tire-type grinding roller features a cylindrical-arc, tire-shaped roller surface. During operation, it forms area contact with the grinding table, and the material experiences a combination of compressive and shear forces, making it more suitable for large-scale grinding of medium- to low-hardness materials. Its curved surface increases the grinding contact area, enhancing grinding capacity; however, the unit pressure distribution is uneven, and local wear tends to occur at both ends of the roller. Tire-type rollers are also more sensitive to material moisture, making roller sticking more likely.

In terms of structural design, the cone angle of a conical roller directly affects grinding efficiency and energy consumption, while the arc curvature of a tire-type roller must match the curvature of the grinding table liner to ensure stable grinding performance. For more detaill please check our our next article: "Conical shape grinding roller" and "Vertical roller mill Spare Parts: Coal Mill Dynamic Ring Static Ring Pallet"

Are the grinding roller tyre and grinding table liners in a vertical roller mill made of the same material and hardness?

No, the grinding rollers and grinding table (bowl) liners in a bowl-type vertical roller mill are not made of the same material or hardness, because their working conditions differ.

- Grinding rollers liner: These are subjected to high compressive and impact forces, so they typically use high-chrome cast iron (Cr ≥ 20%, HRC 58–62), Ni-hard alloys, or even composite wear-resistant materials for extreme applications. The hardness and toughness of the roller material are designed to resist abrasion, impact, and potential cracking.

- Grinding table (bowl) liners: These mainly experience shear and compressive forces from the material pressed by the rollers. They can also be made from high-chrome cast iron or composite materials, but the hardness is often slightly lower than that of the rollers to balance wear rates and maintain stable grinding performance. Some high-end applications may use ceramic segments for additional wear resistance.

What is the Process of Bowl Type Mill Liner Manufacturing?

Bowl-type vertical roller mill liners are manufactured from high-chromium cast iron (Cr16–Cr30) through casting, heat treatment, precision machining, and non-destructive testing to achieve a martensite–carbide structure with HRC ≥58 and a service life exceeding 8,500 hours. If you want to know more detail please check our article: "How to manufacturer a vertical roller mill grinding roller tyre, Step by Step"

Material Selection

The vertical roller mill liner is made from high-chromium cast iron, with grades such as Cr16, Cr20, Cr26, and Cr30. The selection depends on the type of mineral or material being ground and the mill model, ensuring optimal wear resistance and performance. In operation, the liner works together with the grinding roller to crush and grind ore or slag, and its main mode of failure is abrasive wear.

Casting

The manufacturing process starts with casting, using resin sand molding. The high-chromium cast iron is melted in an intermediate frequency furnace, followed by refining outside the furnace to ensure a clean and uniform chemical composition. Proper casting is critical for achieving dimensional accuracy and a defect-free structure.

Heat Treatment

After casting, the liners undergo heat treatment consisting of normalizing and tempering. The normalizing process uses spray cooling to control cooling rates and achieve the desired microstructure. Heat treatment produces a matrix of martensite and carbide, providing a balance of hardness and toughness.

Machining

Once heat-treated, the liners are machined to precise dimensions, ensuring perfect fit and alignment with the grinding rollers and table. Machining accuracy is essential for uniform contact, which directly impacts grinding efficiency and liner service life.

Non-Destructive Testing (NDT)

Before delivery, each liner undergoes non-destructive testing to detect internal defects such as cracks or porosity, ensuring that only high-quality, reliable components reach the customer.

Performance Specifications

The finished liners achieve a hardness of HRC ≥ 58, and in typical applications, the service life can exceed 8,500 operating hours, depending on the material being processed and operating conditions.

Can vertical roller mill grinding roller bowl type liner tires be rebuilt?

Yes, some vertical roller mill (VRM) grinding roller liners can be rebuilt, but the feasibility depends on the material type and wear condition.

High-Chromium Cast Iron or Medium/High Alloy Steel Liners:

These materials can often be rebuilt through surfacing (weld overlay) using wear-resistant welding rods. This restores the liner profile, adapts to different operating conditions, and allows multiple service cycles from a single roller or table, reducing overall replacement costs.

Ceramic or Ceramic-Metal Composite Liners:

Due to their brittle structure, ceramic-based liners generally cannot be rebuilt. Attempting welding or resurfacing may cause cracking or detachment, so replacement is typically required when worn.

What are the material options for vertical roller mill grinding roller and bowl-type liners, and what are their typical applications?

Vertical roller mill (VRM) liners, including bowl-type liners and grinding rollers, are manufactured from different wear-resistant materials depending on the working conditions, impact loads, and material abrasiveness. Common options include:

1. Manganese Steel (Mn14, Mn18, Mn14Mo, Mn18Mo):

- Working Conditions: Suitable for smaller milling operations where liners must withstand severe impact.

- Advantages: Work-hardens under stress, maintaining a tough substrate that resists fracturing.

- Drawbacks: Can spread under heavy impact, making liners difficult to remove, and may damage the mill shell if stresses accumulate.

- Typical Use: AG mills, SAG mills, Ball mills.

- VRM Relation: For VRMs, manganese steel can be used in certain low-capacity bowl liners where impact loads are moderate.

2. Low Carbon Chrome Moly Steel (300–370 BHN):

- Working Conditions: Previously widely used for mill liners; suitable where moderate impact resistance is required.

- Advantages: Good wear resistance with some impact tolerance.

- Typical Use: AG mills, SAG mills, Ball mills, discharge grates, thin liners.

- VRM Relation: Can be considered for thin-section bowl-type liners where abrasiveness is moderate and cost sensitivity is a factor.

3. High Carbon Chrome Moly Steel (325–380 BHN):

- Working Conditions: The current primary material for SAG mill liners. Available in variations of carbon and chrome content.

- Advantages: Enhanced wear and impact resistance; adaptable thickness and size.

- Typical Use: SAG mill liners.

- VRM Relation: Suitable for bowl-type VRM liners under high abrasion conditions, providing a balance of toughness and wear life.

4. High Chrome Irons (+600 BHN, Cr Iron):

- Working Conditions: High abrasion resistance; more brittle than chrome-moly steels.

- Typical Use: Vertical roller mill parts, rod mill parts, ball mill liners.

- VRM Relation: This is the most commonly used material for VRM bowl liners, providing superior wear resistance under high-pressure grinding.

5. Chrome Moly White Irons (600–700 BHN, WI):

- Working Conditions: Ultimate abrasion-resistant material developed for extreme milling applications.

- Typical Use: Large ball mill liners, cement mill liners.

- VRM Relation: For VRMs handling extremely abrasive materials, white irons may be applied in specialized bowl-type liners to maximize service life.

Conclusion:

Bowl-type grinding roller liners absorb the majority of friction and impact wear, safeguarding the mill’s core structures and extending equipment service life. It effectively transmitting grinding forces and guiding material trajectories to form a stable grinding bed, ensuring consistent milling efficiency. Bowl-type grinding roller liners are widely used across industries—including cement, mining, metallurgy, and power generation—and are compatible with major VRM models such as Loesche, Polysius, ATOX, MLS, and LM mills(of course owner provide drawing).

About us:

At present, Tongli Heavy Machinery can produce a full range of bowl-type grinding roller and disc lining boards for vertical roller mills, including models compatible with large-capacity cement and raw material mills such as HP 37.5, HP 40, HP 42.5, HP 50, HP 52.5, HP 57.5, TRM33-4, TRM36-4, and others. Our products feature excellent wear resistance and high hardness, minimizing the risk of cracking even under high-hardness materials like iron. Hardness is consistently maintained above HRC60, ensuring reliable performance in demanding operating conditions. The wear-resistant parts produced by Tongli Heavy Machinery incorporate advanced R&D in materials and heat treatment, with independent intellectual property rights. Compared with domestic counterparts, our products offer over 10% longer service life, and deliver significantly higher cost performance than imported alternatives, including roller sleeves, lining plates, and other high-wear components. We also provide customized solutions tailored to specific mill models or operating conditions. Founded with a focus on wear-resistant, surfacing, heat-resistant, and corrosion-resistant metal materials, Tongli Heavy Machinery has decades of experience in manufacturing high-performance wear parts. Our products are widely applied in cement, power generation, mining, and building materials industries, supporting vertical roller mills and other grinding systems. We have established long-term collaborations with major cement groups, power plants, and mill manufacturers, both domestically and internationally, and our wear-resistant components are exported to regions including Germany, Denmark, Argentina, Greece, Colombia, Russia, and the Far East. Alright see you next time!