A powder grinding mill uses mechanical force to grind solid materials into fine particles or powders. Its main function is to process bulk or granular raw materials into powders. With advances in vertical roller mill technology, the powder grinding mill have continuously improved in efficiency, precision, and environmental performance, becoming an indispensable piece of equipment in modern cement production and mineral processing. This differs from crushing or granulation, which grind materials to the size of rocks, pebbles, or grains. Grinding can be used to produce a variety of materials that have end uses themselves or as raw materials or additives for the manufacture of other products. A wide variety of grinding mills have been developed by us tongli for specific applications. Some types of our powder grinding ball mills can be used to grind a wide range of materials, while others are designed to meet specific grinding requirements. In most cases, the powder grinding mill can be the single most expensive piece of equipment in your production process. If grinding is involved, installing a suitable grinder is one of the main requirements for cost-effective and trouble-free material processing.

Definition and historical background of powder grinding mill

Definition

A powder grinding mill is a device that breaks down solid materials into fine particles or powders through mechanical forces such as compression, impact, shear, and friction. Based on the particle size of the ground material, powder grinding mill can be categorized as coarse grinders (with a final particle size of 1-3 mm), fine grinders (with a final particle size of 0.1-1 mm), and ultrafine grinders (with a final particle size of micrometers or nanometers). Pulverizer design and operating parameters (such as rotational speed, grinding media, and airflow velocity) are typically optimized based on the material's physical properties, such as hardness, moisture, and viscosity, as well as the desired particle size of the final product. The grinding process involves applying pressure, impact, shear, or abrasion to the material, causing it to break and reduce its size. Grinding mills can process a wide variety of materials, including minerals, ores, chemicals, and foods. The basic components of a grinding mill typically include a grinding chamber, grinding media (such as balls, rods, or pebbles), and a drive mechanism. The material to be ground is fed into the grinding chamber, where it comes into contact with the grinding media. As the grinding media moves and collides with the material, it breaks it down into smaller fragments. The ground material then exits the mill through an outlet.

Powder Grinding Mill Historical background

Grinding technology has ancient origins. The earliest grinding tools can be traced back to the Stone Age stone mills used to grind grain. With the advent of the Industrial Revolution, steam-powered mechanical mills appeared in the early 19th century, marking the transition from manual to mechanized grinding equipment. In the 20th century, advances in electricity and motor technology led to the emergence of modern grinding equipment such as ball mills and Raymond mills. Since the 21st century, the introduction of ultrafine grinding technology and intelligent control systems has enabled significant breakthroughs in the efficiency, precision, and environmental performance of grinding mills. Today, grinding mills have become critical equipment for efficient production across many industries.

The basic working principle of powder grinding machine

Despite the wide variety of types, the working principle of all powder grinding mills is based on one thing in common: applying mechanical force to the material to overcome the cohesive force between its internal molecules, causing it to break and refine. These mechanical forces mainly include:

- Impact: The high-speed moving grinding body (such as hammers, blades) or material particles themselves collide violently with the fixed liner or other particles, generating a huge instantaneous force that breaks the material. It is suitable for medium and fine crushing of brittle materials.

- Attrition: The friction and shearing between the relatively moving grinding media (such as balls and rods) and the material, or between the material particles, results in a fine grinding of the material. Suitable for ultrafine grinding of tough materials.

- Compression: Materials are crushed by the slowly increasing pressure between two hard surfaces. Suitable for coarse and medium crushing of hard materials.

- Shear force: The directions of the forces are intertwined, cutting or tearing the material like scissors. It is particularly effective for grinding fibrous and tough materials.

In actual applications, a grinder is often the result of the coordinated action of multiple forces, but one or two of them will be the main crushing methods.

Classification of powder grinding mill

There are many types of powder grinding mill, which can be divided into the following main types according to their working principle, structure and application scenarios:

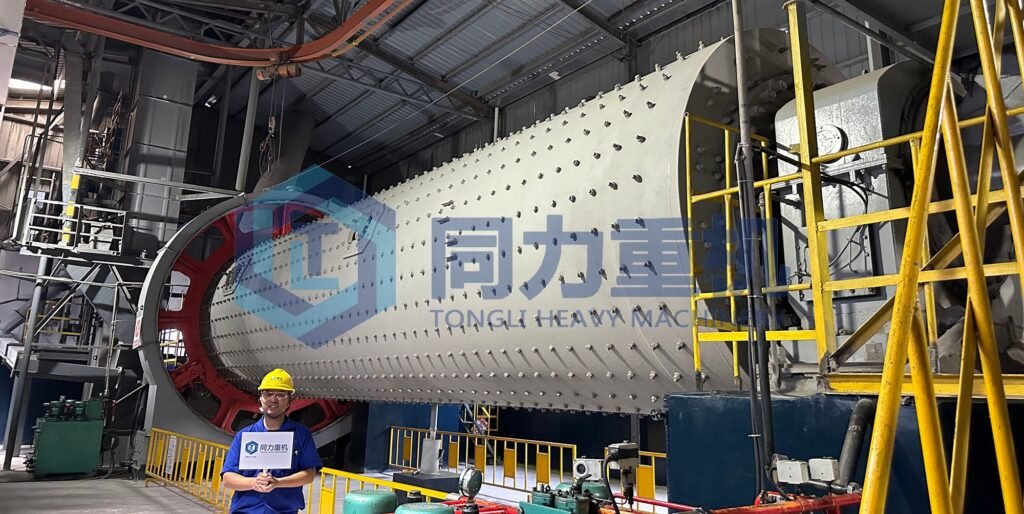

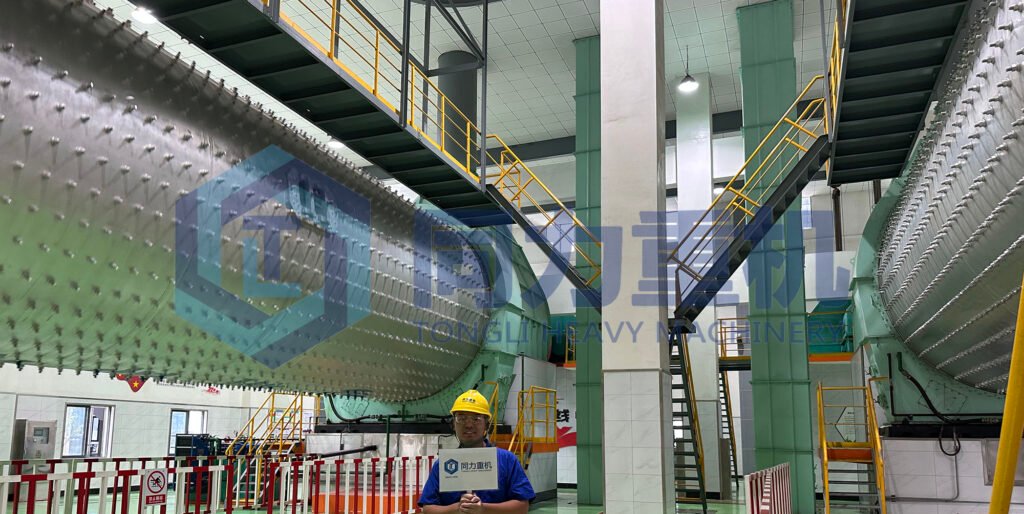

Ball mill

A ball mill is a type of grinding mill, a cylindrical device used to grind (or mix) materials such as ores, chemicals, ceramic raw materials, and paints. The ball mill rotates about a horizontal axis and is partially filled with the material to be ground and grinding media. A variety of media materials are used, including ceramic balls, flint pebbles, and stainless steel balls. An internal cascade effect reduces the material to a fine powder. Industrial ball mills can operate continuously, with material fed at one end and discharged at the other. Large and medium-sized ball mills rotate mechanically about their axis, but small ball mills typically consist of a cylindrical, covered container resting on two drive shafts (pulleys and belts are used to transmit the rotational motion). The ball mill consists of a hollow cylindrical shell that rotates about its axis. The shell's axis can be horizontal or at a slight angle to the horizontal. It is partially filled with balls. The grinding media is balls, which can be made of steel (chrome steel), stainless steel, ceramic, or rubber. The inner surface of the cylindrical shell is often lined with a wear-resistant material, such as manganese steel or rubber lining. Rubber-lined mills experience less wear. The length of the mill is approximately equal to its diameter.The general idea behind a ball mill is an old one, but it wasn't until the Industrial Revolution and the invention of steam power that an efficient ball mill could be built.

Raymond mill

A Raymond mill is a fine grinding device based on the principle of suspended roller compaction. It primarily consists of a main unit, a fan, an analyzer, and a dust removal system. The material is crushed between the rollers and the grinding ring, and an air separation system separates the qualified powder. Raymond mills are suitable for fine grinding of non-metallic minerals (such as limestone, calcite, and talc), with the finished product particle size typically ranging from 80-325 mesh (approximately 44-180 microns). Raymond mills, an ultra-fine grinding device based on the compaction and shearing action of vertical rollers and a stationary grinding ring, originated in Germany and were improved in 1925 to include a mechanical spring-loaded device. The main unit utilizes a sealed gearbox and pulley drive, high-quality steel wear-resistant parts, a three-dimensional structure, and a centralized control electrical system. After being crushed by rod hammers, the material is conveyed by air to the analyzer, where it is centrifuged by a two-stage impeller. Coarse particles return to the crushing zone for further grinding, while qualified fine powder is collected by the airflow into a bag filter. Raymond mills can process non-flammable and non-explosive materials with a Mohs hardness of less than 7 .

Vertical roller mill

A vertical roller mill, also known as a vertical powder grinding mill, is used for grinding cement raw materials, cement clinker, slag, and coal cinder. It features a simple structure and low manufacturing and operating costs. It consists of a machine body, a grinding disc assembly, and a transmission mechanism. A centering structure is located between the machine body and the grinding disc assembly to determine the center of rotation. A rotating guide rail is fixed to the bottom of the grinding disc assembly, which rotatably supports the grinding disc assembly on the machine body. The grinding disc assembly is connected to the transmission mechanism. Because the transmission mechanism does not bear high axial loads such as the weight of the grinding disc and grinding pressure, it can utilize a universal reducer. This results in a compact and reliable structure, shortened grinding downtime, and reduced equipment operation and maintenance costs.

Ultrafine grinder

Ultrafine mills are designed for producing micron- or nanometer-sized powders and are typically equipped with a high-precision classifier (such as an airflow classifier). Their grinding process combines mechanical force with airflow separation, making them suitable for high-value-added products such as electronic materials, pharmaceutical raw materials, and high-end ceramics. Ultrafine mills can produce finished products with particle sizes of 3000 mesh (approximately 5 microns) or finer.

Working principle of powder grinding mill

Although the working principles of different types of grinding mills vary, the basic process includes four stages: material input, grinding, classification, and product output. The following uses a typical device as an example to explain its working principle in detail:

Ball mill

Ball mill structure

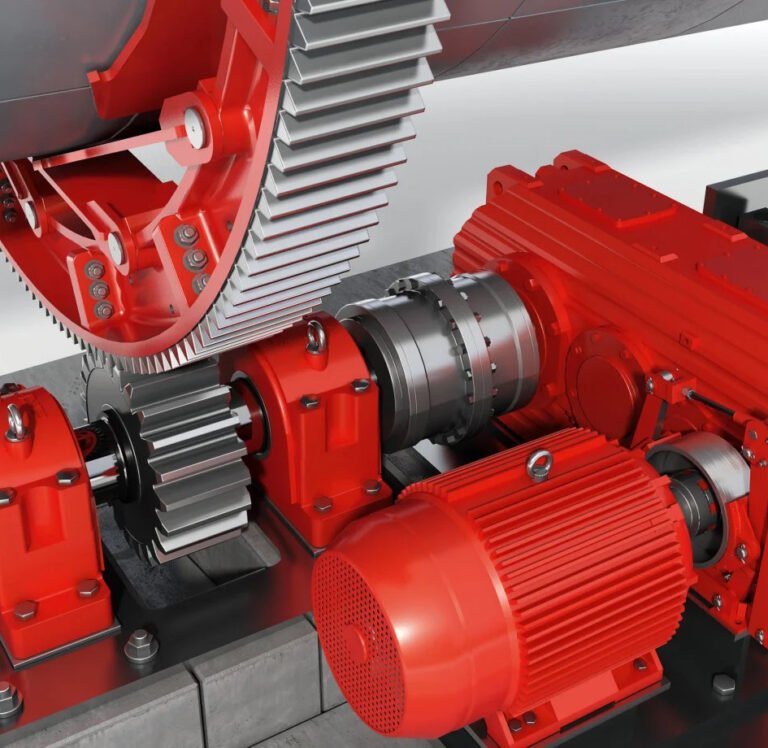

A ball mill consists of a feeder, discharger, rotary unit, and transmission unit (reducer, small transmission gear, motor, and electronic control). The hollow shaft is cast steel with a removable inner lining. The large rotating gear is hobbed from a casting, and the barrel is lined with a wear-resistant liner for excellent wear resistance. The main unit of the ball mill includes a barrel lined with a wear-resistant material, bearings that support the barrel and maintain its rotation, and a drive unit consisting of an electric motor, transmission gears, pulleys, and V-belts.

How it works

A ball mill consists of a horizontal drum, hollow feed and discharge shafts, and a grinding head. The drum is a long, cylindrical structure containing the grinding media. Made of steel plate and secured to the drum by a steel liner, the grinding media are typically round steel balls, arranged in varying diameters and proportions. Steel segments can also be used. The materials are selected based on the particle size of the material being ground. The material is fed into the drum through the hollow shaft at the feed end. As the drum rotates, the grinding media, due to inertia, centrifugal force, and friction, cling to the drum liner and are carried away by the mill. When carried to a certain height, they are thrown down by gravity, acting like projectiles and crushing the material within. The material is fed from the feed device through the hollow feed shaft, spirally and evenly into the first chamber of the mill. This chamber has stepped or corrugated liners and is filled with steel balls of various sizes. The centrifugal force generated by the drum's rotation carries the balls to a certain height, where they fall, impacting and grinding the material. After coarse grinding in the first chamber, the material passes through a single-layer partition wall into the second chamber, which is lined with flat linings and filled with steel balls for further grinding. The powdered material is discharged through the discharge grate, completing the grinding process. As the cylinder rotates, the grinding media slide, grinding the material. To effectively utilize this grinding effect, for grinding larger particles, typically 20-mesh, the mill cylinder is divided into two sections by a partition wall, creating a double-chamber mill. As the material enters the first chamber, it is crushed by the steel balls. As it enters the second chamber, it is ground by the steel segments, and the qualified material is discharged from the hollow shaft at the discharge end. For grinding smaller feed materials, such as sand, grade 2 slag, and coarse fly ash, the mill cylinder can be constructed without partition walls, creating a single-chamber mill, and the grinding media can also be made of steel segments.

Raw materials are fed through a hollow shaft into a hollow cylinder for grinding. The cylinder is filled with grinding media of various diameters (steel balls, steel rods, gravel, etc.). As the cylinder rotates at a constant speed around its horizontal axis, the media and raw materials within the cylinder, under the influence of centrifugal force and friction, break away from the inner wall of the cylinder and are ejected or rolled down when the cylinder reaches a certain height. The impact crushes the ore. Simultaneously, the sliding motion of the grinding media against each other during the mill's rotation also grinds the raw materials. The ground material is discharged through the hollow shaft.

Raymond mill

Main structure

- Core components: main machine (including grinding roller, grinding ring, scraper, frame, etc.), analyzer.

- Auxiliary systems: blower, dust collector, jaw crusher, bucket elevator, electromagnetic vibrating feeder, and electronic control system.

- Key structures: overlapping multi-pole sealing device (to prevent dust leakage), high-pressure spring system (to enhance crushing force).

How it works

Material pretreatment

The raw materials are coarsely crushed to the specified particle size (usually ≤30mm) by jaw crushers and other equipment, and then sent to the storage hopper by elevator.

Grinding process

- The material enters the main grinding chamber evenly through the vibrating feeder.

- The grinding roller presses the grinding ring tightly and rotates under the action of centrifugal force, forming a "laminated crushing" effect. The material is crushed into powder under the action of extrusion and shearing.

- The scraper scoops up the material and sends it into the gap between the grinding roller and the grinding ring for continuous grinding.

Classification and collection

- The blower generates airflow to carry the fine powder away from the grinding chamber, and is screened by the analyzer (classifier): qualified fine powder enters the cyclone powder collector and is discharged as the finished product through the powder outlet pipe; the coarse particles fall back to be re-ground.

- Air circulation system: Part of the air flows into the dust collector through the residual air duct and is purified before being discharged to ensure that environmental protection standards are met.

Dynamic Loop

The system forms a closed loop to ensure continuous and stable operation of the equipment.

Vertical roller mill

Structural composition

A vertical grinding mill (often called a vertical mill or vertical roller mill) is a highly efficient grinding equipment that integrates crushing, grinding, grading, and drying. Its structure mainly consists of the following core parts:

What are the parts of a coal powder grinding mill?

- Grinding plate and roller system: The grinding plate is a horizontal rotating disc, and the grinding rollers (usually 3-4) are arranged vertically under a pressure frame above the grinding plate. The grinding rollers apply pressure through a hydraulic system to crush the material.

- Grinding shell and material layer: The grinding shell surrounds the entire grinding disc, forming a closed space to prevent dust leakage. The material forms a material layer between the grinding disc and the grinding roller, and is crushed through extrusion and shearing.

- The transmission system consists of a main motor, a speed reducer, and a coupling, which drives the grinding disc to rotate at a speed of 20-30 rpm. The motor power varies from tens of kilowatts to thousands of kilowatts depending on the equipment model.

Grading System

- Dynamic Powder Classifier: Located on top of the main unit, it uses a high-speed rotating impeller to create an airflow classification effect. Coarse powder is centrifugally returned to the grinding disc for further grinding, while fine powder is carried by the airflow into the subsequent dust removal system.

- Grading blade adjustment mechanism: By adjusting the blade angle or speed, the finished product particle size can be flexibly controlled (80-600 mesh).

Feeding and conveying system

- Feeding device: usually equipped with a quantitative feeder to ensure that the material enters the mill evenly and continuously to avoid overloading or empty grinding.

- Elevator and conveying pipeline: lift the raw materials to the top of the grinding mill and connect various systems through pipelines to realize the circulation or transportation of materials.

Hydraulic and lubrication systems

- Hydraulic system: used to control the pressurization and lifting of the grinding roller, adjust the grinding pressure (range 0-20MPa) to adapt to materials of different hardness.

- Automatic lubrication system: Regularly lubricate key transmission components (such as bearings and gears) to extend equipment life.

Dust removal and environmental protection system

- Pulse bag dust collector: captures fine powder through bag filtration, and the emission concentration can be lower than 10mg/m³, which meets environmental protection standards.

- Muffler and sealing device: reduce noise and prevent dust leakage.

Intelligent control system (PLC)

- Centralized control cabinet: Integrates the control of motor, hydraulic, classification and other systems to achieve "one-button start and stop", parameter setting, fault diagnosis and alarm.

- Remote monitoring module: supports real-time viewing of equipment operating status and adjustment of parameters (such as feeding amount and classification speed) via mobile phone or computer.

Auxiliary components

- Hot air system (optional): used to dry wet materials and improve grinding efficiency by introducing hot air to exchange heat with the materials.

- Inspection door and observation window: convenient for daily maintenance and internal inspection.

How it works

The working principle of the vertical grinding mill can be summarized as a closed-loop process of "material bed crushing + airflow classification + circulating grinding". The specific steps are as follows:

- Material Entry and Pre-crushing: Raw materials enter the mill through the feeder and fall onto the rotating grinding disc. Under the action of centrifugal force, the materials move toward the edge of the grinding disc, forming a stable material bed.

- High-pressure crushing: The grinding rollers, under the action of a hydraulic system, apply pressure (adjustable) to the material bed, crushing the material through crushing, shearing, and impact. Larger particles are repeatedly ground between the grinding rollers and the grinding disc until they reach a desired fineness.

- Airflow Classification and Separation: The pulverized material rises in the airflow generated by the rotating grinding disc and enters the dynamic classifier. The classifier's impeller rotates at high speed, generating a centrifugal force field. Due to its high inertia, the coarse powder is thrown back to the grinding disc for further grinding, while the fine powder (particles that meet the required size) is carried by the airflow into the dust removal system.

- Finished Product Collection and Discharge: Fine powder is filtered and collected by a dust removal system (bag or electrostatic precipitator) and ultimately transported to the finished product warehouse by conveying equipment. Exhaust gas is purified and discharged in compliance with emission standards.

- Circular Grinding and Control: Coarse powder that fails to pass classification re-enters the grinding disc through the return pipe, forming a closed-loop circulation. By adjusting parameters such as hydraulic pressure, classifier speed, and feed rate, the fineness and output of the finished product can be dynamically controlled.

Application areas of powder grinding mill

- Mining : Vertical powder grinding mill are used to grind ore into fine powder for subsequent beneficiation or smelting. For example, ball mills are widely used to grind gold, copper, and iron ores. The particle size of the finished product directly affects the recovery rate of the beneficiation process.

- Building Materials Industry : In cement production, vertical mills are used to grind cement clinker and additives (such as gypsum and slag), while Raymond mills are used to process non-metallic materials such as limestone and clay. The efficiency of the grinding mill directly affects the fineness and strength of the cement.

- Chemical Industry : Pulverizers are used to produce pigments, fillers, catalysts, and chemical raw materials. For example, jet mills are used to grind high-purity chemical raw materials, and ultrafine grinders are used to produce nano-scale calcium carbonate.

- Pharmaceuticals and Food : In the pharmaceutical industry, ultrafine grinders are used to grind medicinal materials to improve drug solubility and bioavailability. In the food industry, pulverizers are used to process flour, spices, and additives.

- New Energy and Electronic Material Powders : Grinding mills are crucial in the preparation of lithium battery materials (such as graphite and lithium iron phosphate), electronic ceramics, and semiconductor materials. Ultrafine grinders and jet mills are widely used in these areas due to their high precision and pollution-free properties.

How to choose a suitable powder grinding machine

When choosing a grinding machine, the hardness of the material is perhaps the most critical consideration. Using sandpaper on hard materials like gravel can easily damage the equipment, leading to costly repairs and potentially overwhelm a typical hammer mill. Most common agricultural hammer mills are unsuitable for mineral grinding, as the varying hardness of different materials can be a significant issue. The hardness of minerals is measured on the Mohs scale, which ranges from 1 for talc (the softest mineral) to 10 for diamond (the hardest known material). The table below shows the Mohs hardness scale.

| Hardness number | Minerals (Example) | Routine practical test |

| 1 | Talc or graphite | Marker paper – like a pencil |

| 2 | rock salt or gypsum | - |

| 3 | calcite | Can be marked with fingernails |

| 4 | fluorite | Can mark copper coins |

| 5 | apatite | - |

| 6 | feldspar | Markable window glass |

| 7 | quartz | Markable blades |

| 8 | Topaz | - |

| 9 | sapphire | - |

| 10 | diamond | - |

the more specialized and expensive the grinding equipment required . Furthermore, if a particular grinder is suitable for multiple hardness ranges, the harder the material, the less efficient it will be at meeting specific size requirements. Another characteristic to consider is brittleness , or how easily the material breaks. Most minerals are brittle, while metals are mostly ductile, though this varies from metal to metal. It's important to note that brittleness is not the same as hardness—some brittle materials can be very hard, while others are not hard at all. Non-brittle materials, such as metals or soft plastics, are generally not suitable for grinding due to their tendency to deform during processing . In dry grinding, the free moisture content of the material should be as low as possible. However, this can be a problem in practice, especially in humid regions, where moisture can cause the material to adhere to the grinding media. Different grinders handle wet materials differently, and in some cases, drying the raw material is necessary. The final particle size specification is also crucial. The table below details some materials that require grinding and the required fineness. Technical specifications often stipulate that the material must contain fine particles below a certain particle size. Typically, this ratio is 90% or 95%, but in demanding applications, it can be increased to 99%. Certain applications may also require a specific particle size range.

| Materials and applications | Particle size, unit: mm |

| Feldspar (ceramic flux) | 0.075 |

| Talc (paper and cosmetics) | 0.01 |

| Limestone - (Agricultural lime) | 1.2 |

| Ordinary Portland cement | < 0.10 |

| chalk | 0.05 |

| Powdered charcoal or coal for fuel briquettes | <0.10 |

| Paint pigments (various materials) | ~ 0.005 |

| Quartz sand (glass manufacturing) | 0.01 |

| Phosphate (fertilizer) | 0.075 |

| iron ore | 0.2 |

| Lime (industrial applications, such as detergents) | 0.1 |

| Chinese clay | 0.002 |

| Alumina | 0.005 |

Rod mill

Describe

A rod mill is another type of drum mill, but one that has a large portion of its volume (30-40%) filled with steel rods. The rods are placed axially inside the mill, loose and free to move within the mill. The drum is lined with a series of lifting devices that lift the rods and place them into position. Mineral is fed in from one end, with a maximum particle size of about 25 mm. The rods crush the rock, and as the material passes through the mill, the particle size is reduced to between 2 mm and 0.1 mm. The mill can be fed from one end and discharged from the other, or it can be fed from both ends.

Discharge is from the center. The process can be wet or dry, but wet is more common. The maximum rod length is approximately 6 to 7 meters, otherwise there is a risk of rod bending. The drum diameter is limited to 0.6 to 0.7 times the mill length.

Feature

Rod mills are used to grind hard minerals. This type of mill is usually used as the first stage of the grinding process to provide smaller particle size raw materials for subsequent grinding processes. The material applicability of rod mills is as follows

| coke | Products for the glass industry |

| Cement clinker (needs to be dried) |

Ball mill

Describe

The concept of a ball mill is similar to that of a rod mill, except that the rods in a ball mill are filled with steel balls. A ball mill consists of a cylindrical drum, sometimes tapered at one end, typically filled with steel balls (up to 40% by volume), with large ball mills using balls up to 125 mm. Ball mill product size can be as small as 0.005 mm, but product size depends on the time the material spends in the grinding zone, so the crushing rate is related to throughput. Lining material is crucial, as the action of the steel balls causes significant wear. The optimal rotational speed is approximately 75% of the critical speed. Some mills use a zoned design, with each subsequent zone equipped with smaller balls. Minerals can pass through the previous zone, but the steel balls cannot. This ensures that smaller particles are impacted by the smaller grinding media.

Feature

This versatile mill has a wide range of uses. Available in a variety of sizes, from small batch mills to mills with outputs of hundreds of tons per hour, it is the most widely used mill. In Bolivia, small manual ball mills are used for pre-processing of ores, sand, and gravel .

| iron ore | Coal for combustion |

| Limestone and lime | talc |

| cement | sandy land |

| gold mine |

Roller mill

Describe

There are two main types of roller mills. The first uses multiple sets of rollers rotating around a central axis within a drum to achieve grinding, with deceleration occurring between the rollers and the drum. The second type utilizes a combination of fixed rollers and a rotating table, with grinding occurring between the rollers and the table. This type is suitable only for dry grinding and requires specialized equipment. A single roller mill processes relatively soft ores. Small machines can process only a few dozen kilograms per hour, while larger machines can process 40 to 50 tons or more per hour. Feed size varies depending on the machine model. These machines are typically equipped with a screen for closed-circuit grinding. Replacing the screen allows for control of the finished product particle size.

| barite | Phosphate |

| limestone | coal |

| Stone | Miscellaneous chemicals |

Choosing the right powder grinding mill

Choosing the right equipment is a complex system project that requires comprehensive consideration of the following factors:

- Material properties: hardness, brittleness/toughness, moisture, viscosity, flammability and explosiveness, required purity, etc. are the primary considerations.

- Feed and discharge particle size: The initial particle size and the desired final fineness determine the required crushing ratio, which in turn affects the equipment selection.

- Capacity requirements: The amount of material that needs to be processed per hour or day directly affects the model and scale of the equipment.

- Investment and operating costs: including equipment purchase cost, installation cost, energy consumption, consumption of wearing parts (grinding roller, grinding ring, liner) and maintenance cost.

- Supporting process: whether it is necessary to carry out drying, surface modification, grading and other operations at the same time, select integrated equipment (such as vertical mill) or supporting system with corresponding functions.

Conclusion

As core equipment in modern industrial production, powder grinding mill are irreplaceable in fields such as mining, building materials, chemicals, pharmaceuticals, and new energy. From traditional ball mills to modern ultrafine mills and jet mills, pulverizers have continuously innovated to meet diverse needs, from coarse grinding to nano-grinding. Despite challenges such as energy consumption, wear, and environmental protection, breakthroughs in efficiency, precision, and green performance from new pulverizers are providing strong support for industrial production. Currently, powder grinding technology is facing a new paradigm shift. Single-piece pulverization functions are no longer sufficient to meet the comprehensive needs of high-end manufacturing. Future equipment will increasingly integrate integrated solutions encompassing pretreatment, pulverization, classification, modification, and conveying. By integrating online monitoring and adaptive control systems, the grinding process will shift from empirical reliance to data-driven, enabling precise control of particle size distribution and morphology, thus enabling customized powders for downstream applications. In summary, this article provides guidance on selecting the appropriate powder grinder based on material properties , final product requirements, production capacity requirements, and project budget.