Portland pozzolana cement (PPC) is a mixed hydraulic cementitious material made by grinding silicate cement clinker with pozzolanic materials: fly ash, volcanic ash or calcined clay and gypsum . The amount of pozzolanic mixed materials is >20% and≤40% by mass. This cement is used in ancient Roman architecture - for example, the dome of the Pantheon built with volcanic ash still stands today - it also plays a key role in modern architecture. The invention of Portland cement can be traced back to 1824, when British craftsman Joseph Aspdin obtained clinker by calcining limestone and clay, and drew on the experience of ancient Rome in adding volcanic ash to create a material that hardened with a color and strength similar to Portland Island stone, hence the name "Portland cement"7. As an important branch of it, Portland pozzolana cement (PPC) inherits the basic properties of silicate cement, while achieving dual improvements in performance and environmental benefits by adding pozzolanic materials. In this article we will briefly introduce the manufacturing process and the basics of this type of cement.

What is Portland Pozzolana Cement?

Hydraulic cementing materials made of Portland cement clinker, pozzolanic materials and appropriate amount of gypsum are collectively called Portland pozzolanic cement (PPC cement). It is a mixed cement made by mixing and finely grinding silicate cement clinker, pozzolanic materials and gypsum.Pozzolanic materials contain active silicon and aluminum and usually do not have any gelling properties. However, when they are mixed with water and lime at room temperature, they react with calcium hydroxide to form compounds with gelling properties. Commonly used pozzolanic materials can be divided into natural pozzolanic materials and artificial pozzolanic materials:

- Natural volcanic ash materials: volcanic ash, pumice, calcined clay, diatomaceous earth, etc.

- Artificial volcanic ash materials: fly ash, silica ash, rice husk, blast furnace slag, etc.

- Its content in Portland pozzolanic cement is about 15%~35%, and gypsum is about 3%~6%.

Core Definition

According to European standard EN 197-1:2012 and relevant Chinese standards, the core definition of PPC includes:

- Based on calcium silicate-based clinker (usually 60-80%)

- Pozzolanic materials (natural volcanic ash, fly ash or calcined clay) as active admixtures (20-40%)

- Gypsum as retarder (about 5%)

This composition structure gives PPC a unique "secondary hydration reaction" mechanism: the active silica in the volcanic ash reacts with calcium hydroxide, a cement hydration product, to generate additional calcium silicate gel (CSH), thereby improving long-term density and strength .

Portland Pozzolan Cement Properties

- PPC cement has a long curing time, and the curing temperature has a great influence on its strength development. The hardening speed is slow when the temperature is low, and the hardening will be accelerated when steam curing or wet heat treatment is used. Therefore, it is not suitable for winter construction.

- PPC cement has a lower initial strength but a higher final strength due to the interaction of the active silica in the pozzolanic material with calcium hydroxide to produce a large amount of hydrated calcium silicate.

- PPC cement has a large water requirement due to the porous mixture and fine particles. The water requirement for standard consistency varies with the type and dosage of admixtures.

- Portland pozzolana cement takes a long time to set, with an initial setting time of at least half an hour and a final setting time of up to 10 hours.

- The drying shrinkage of silicate pozzolanic cement should not be greater than 0.15%, and the fineness of pozzolanic cement should not be less than 300m2/kg.

- PPC cement has good compressive strength, which can reach 13MPa in 3 days, 22MPa in 7 days and 33MPa in 28 days.

- The hydration rate and hydration heat of PPC cement are relatively low, which are related to the type and quantity of added materials.

- PPC cement has strong resistance to sulfate attack in acidic water and carbonic acid environments.

Types of Portland Pozzolana Cement

Portland pozzolana cements vary according to their pozzolan content and additives. The following are the main types:

1. Portland pozzolana cement based on fly ash

- Contains 15-35% fly ash, a byproduct of burning coal in thermal power plants.

- Best for: Large concrete works, marine structures

- Advantages: High processability, reduced heat generation

2. Calcined clay-based Portland pozzolana cement

- Heat-treated clay is used as the pozzolanic material.

- Best for: Plastering, masonry work

- Advantages: Improved sulfate resistance, reduced permeability

3. Portland pozzolana cement based on silica fume

- Contains silicon fume (a by-product of metallic silicon production).

- Best suited for: high-strength concrete, precast elements

- Advantages: Excellent compressive strength, less bleeding

4. Pozzolan-based Portland pozzolan cement

- Utilize natural volcanic ash as the pozzolana component.

- Best for: Historic restoration, environmental projects

- Advantages: Natural material, slow setting time

Physical and Mechanical Properties of Portland Pozzolana Cement

Portland Pozzolana Cement ( PPC ) are significantly different from those of Ordinary Portland Cement (OPC):

- Strength development characteristics: Early strength (3 days) is usually about 10-20% lower than OPC, but the later strength (after 90 days) exceeds it, and the final strength can reach more than 40MPa. For example, PPC prepared with 8% of Cameroon Foumbot volcanic ash groudn by vertical roller mill can reach 40MPa

- Thermal properties: Hydration heat is reduced by 30-50%, greatly reducing the risk of temperature cracks in large concrete volumes

- Workability and durability:

- The standard consistency has a high water requirement, but low water seepage and excellent water retention, making it suitable for pumping construction .

- The ability to resist sulfate corrosion is increased by 2-3 times, and the chloride ion permeability is reduced, making it suitable for marine environments .

- It has poor frost resistance and wear resistance and should be avoided in areas with fluctuating water levels or on roads in extremely cold regions .

Effect of volcanic ash content on PPC properties

| Volcanic ash content (%) | 3-day strength (MPa) | 28-day strength (MPa) | 90-day strength (MPa) |

| 0 (Pure OPC) | 22.5 | 42.1 | 48.3 |

| 6 (Penja Gray) | 18.3 | 38.7 | 50.2 |

| 8 (Foumbot Grey) | 17.1 | 36.9 | 49.8 |

Activity mechanism of volcanic ash

The activity of pozzolan depends on its amorphous silica and alumina content and fineness. When cement hydrates to release Ca(OH)₂, SiO₂ and Al₂O₃ in the pozzolan react with it:

Ca(OH)₂ + SiO₂ → CSH gel

Ca(OH)₂ + Al₂O₃ → Calcium aluminate hydrate

This reaction not only consumes the soluble calcium hydroxide, but also refines the pore structure, reducing the permeability of PPC to 1/5-1/10 of that of OPC, significantly improving resistance to chemical corrosion.

How is Portland Pozzolana Cement produced?

Pozzolan cement (PPC) is made by mixing ordinary Portland cement (OPC) with pozzolanic materials. The production process involves several key steps, each of which contributes to the quality and properties of the final product.

1. Selection of raw materials

The main raw materials for PPC production are:

Clinker: Clinker is the main component of OPC and is produced by heating limestone, clay and other materials in a rotary kiln .

Pozzolanic materials: include natural volcanic ashes such as volcanic ash or artificial volcanic ashes such as fly ash, silica fume or burnt clay. Pozzolanic materials have active support and structure, which contributes to the performance of cement.

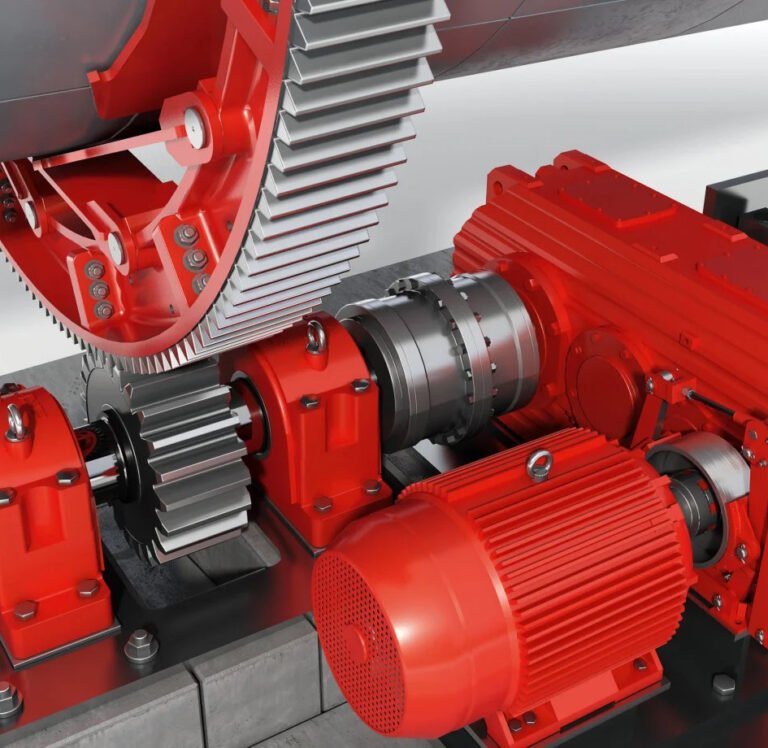

2. Grinding of clinker

The clinker produced during the OPC manufacturing process is ground into a fine powder using cement clinker grinding ball mill. This step is crucial because the fineness of the clinker affects the overall strength and hydration rate of the cement.

3. Mix with volcanic ash

After the clinker is finely ground, it is mixed with the selected pozzolanic material. The mixing ratio of pozzolanic material is usually between 15% and 35%, depending on the desired characteristics of the final product. The mixing process must be thorough to ensure a uniform mixture.

4. Grind and mix the materials

The combined blend of clinker and pozzolan is then ground together to produce a fine, uniform powder. This grinding process is critical as it determines the particle size distribution of the cement, which in turn affects the cement’s strength, setting time and overall performance.

5. Mix

During the final grinding process, a small amount of gypsum is added to the mixture. Gypsum controls the setting time of the cement, ensuring that it does not mix with the water too quickly.

6. Quality Control

Throughout the production process, strict quality controls are applied to ensure that the final product meets the required standards. Chemical composition, fineness and setting time are carefully monitored to produce a consistent and reliable pozzolan cement.

7. Packaging and distribution

After grinding, the finished PPC is stored in silos and then packed into bags or delivered in bulk, ready to be used in various construction projects. The packaging is designed to protect the cement from evaporation and infusion during transportation and storage.

Production process

PPC production uses the same clinker preparation system as OPC, with the key difference being in the mixing and grinding stage:

- Clinker production: Limestone and clay are calcined in a rotary kiln at 1400°C to form calcium silicate clinker.

- Mixed grinding: clinker + gypsum + volcanic ash are ground together in proportion to a specific surface area of 350-450m²/kg.

- Quality control: The volcanic ash activity index needs to be tested (e.g. ASTM C618 requires a 7-day index ≥ 75%).

Diversity of sources of volcanic ash materials

- Natural volcanic ash: such as the volcanic ash from the Pozzuoli region of Italy (the source of the ancient Roman name "Pozzolana")

- Industrial by-products: fly ash (coal-fired power plants), silica ash (ferrosilicon alloy plants)

- Artificial calcined materials: calcined clay or shale (such as metakaolin)

Benefits of Using Portland Pozzolan Cement

Portland Pozzolan Cement (PPC) has many significant advantages that make it a top choice for construction projects. These benefits stem from its unique composition that enhances the overall performance of the cement and the long-lasting pozzolan material.

Improved durability

One of the main advantages of PPC is its enhanced durability. The pozzolanic material that forms PPC reacts with calcium hydroxide released during cement hydration to form additional calcium silicate water complexes (CSH). This process thus increases the density of the cement matrix, making it more resistant to chemical penetration, including sulfate and chloride penetration. As a result, structures built using PPC have a longer service life, especially in environments such as neighboring areas, sewage treatment plants, and industrial sites.

Reduced permeability

PPC has a lower permeability than ordinary Portland cement (OPC). The pozzolanic reaction fills the air in the cement paste, reducing the penetration of water and other harmful materials. This property makes PPC well suited for structures exposed to water, such as dams, bridges and marine structures, where reduced permeability is critical to longevity.

Environmental Sustainability

PPC is an environmentally friendly cement option. The use of pozzolanic materials (which are often industrial byproducts such as fly ash) reduces the amount of clinker required in cement production. This in turn reduces the amount of explosions associated with cement manufacturing. By using PPC, builders help reduce the overall environmental impact of their construction projects.

Cost-effectiveness

Portland pozzolana cement generally adds cost benefits over regular Portland cement. The addition of pozzolanic materials is generally less expensive than clinker, thereby reducing the overall cost of cement. Additionally, the enhanced durability and service life of structures built using PPC can reduce maintenance and repair costs over time.

Improved processability

PPC has better workability compared to OPC. Finer particles and pozzolanic reaction improve the cohesion of the concrete mix and the formulation is easier to work during construction. This feature is particularly beneficial for large projects where ease of application and smooth surface finish are important.

Heat crack resistance

The heat of hydration in PPC is lower than that in OPC, which reduces the risk of thermal cracking in large concrete cast masonry. This makes PPC a suitable choice for large structures such as dams, where controlling temperature rise is critical to prevent cracks and ensure structural integrity.The benefits of Portland pozzolana cement—from increased durability and reduced permeability to environmental sustainability and improved cost-effectiveness—make it an excellent choice for a variety of construction applications. Its ability to improve the performance of concrete, especially in challenging environments, highlights its importance in modern construction practices.

Application of pozzolana cement

Portland Pozzolana Cement (PPC) is versatile and suitable for a wide range of construction applications. Its unique properties, such as enhanced durability, reduced permeability, and environmental sustainability, make it an ideal choice for various types of projects. Here are some of the main applications of PPC:

Residential and commercial buildings

PPC is commonly used in the construction of residential and commercial buildings. Its improved workability and chemical resistance make it suitable for foundations, walls, floors and roofs. The long-term durability of PPC ensures that these structures remain reinforced and resilient over time, even in areas with close environmental conditions.

Marine structures

One of the most important applications of PPC is in marine structures such as piers, docks and breakwaters. PPC has low permeability and high resistance to sulfate and chloride monitoring, making it an ideal choice for exposure to seawater environments. The cement can withstand the cyclic conditions of the marine environment, helping to extend the service life of these structures and reduce maintenance and repair costs.

Hydraulic structure

PPC is used in the construction of a wide range of hydraulic structures, including dams, spillways, canals and water treatment plants. The cement’s low heat of hydration reduces the risk of thermal cracking, which is critical in these large-scale concrete placements. In addition, its resistance to water ingress and chemical resistance is suitable for structures that are in regular contact with water.

Industrial Structure

PPC is the preferred choice in industrial environments where structures are often exposed to chemicals and other corrosive agents. It is used to construct silos, storage tanks, chimneys, and cooling towers. The cement’s durability and overall chemical resistance ensure that these structures can withstand the oxidant conditions common in industrial environments.

Bridges and overpasses

PPC’s durability and structural strength make it an excellent choice for bridge and overpass construction. These structures withstand heavy loads, weather conditions, and exposure to vehicular chemicals. PPC’s ability to withstand these challenges ensures the long-term stability and safety of bridges and overpasses.

Sewage and water treatment plants

PPC is commonly used in sewage and water treatment plants where the structure must be able to withstand exposure to water and corrosion. The cement’s low permeability and high resistance to chemical preservatives make it ideal for these applications, ensuring the ultimate retention of contaminants in the treatment plant over time.

Road construction

PPC is also used in the construction of roads, especially tires on concrete pavements. Its improved workability and durability are suitable for creating smooth, long-lasting pavement that can withstand occasional traffic and sleepless weather conditions. The cement's resistance to cracking and wear extends the life of the road and reduces the need for maintenance.

Mass concrete works

For large concrete projects such as the construction of dams, retaining walls and heavy foundations, PPC is the preferred choice. Its low heat of hydration minimizes the risk of thermal cracking, a common problem in large-scale concrete pours. PPC ensures that these giant structures are strong, stable and durable.

Environmental benefits and sustainable development

The cement industry contributes 8% of global CO₂ emissions, mainly from limestone calcination (CaCO₃ → CaO + CO₂) and fuel consumption. PPC has outstanding environmental advantages:

- Carbon emission reduction: PPC reduces carbon footprint by 200-300kg per ton compared to OPC (due to less clinker usage).

- Solid waste utilization: 1 ton of fly ash-based PPC can consume 0.3 tons of industrial waste, avoiding landfill pollution.

- Energy saving: No-burning volcanic ash saves 40-60% energy compared to clinker production.

The Cameroon case shows that using local Foumbot pozzolana (SiO₂ content up to 62%) can reduce cement production costs by 15% while reducing emissions from imported clinker transportation.

| index | Ordinary Portland Cement (OPC) | Portland Pozzolana Cement (PPC) | Rate of change |

| Clinker dosage (kg/t) | 950 | 600-750 | ↓21-37% |

| Production energy consumption (GJ/t) | 3.8 | 2.5-3.0 | ↓21-34% |

| CO₂ emissions (t/t) | 0.85 | 0.55-0.65 | ↓24-35% |

Difference Between Portland Cement and Portland Pozzolana Cement

Both Portland cement (OPC) and pozzolanic cement (PPC) are widely used in construction, but they differ significantly in composition, properties and applications :

Composition

Portland Cement (OPC): OPC is made primarily from clinker, which is produced by heating materials such as stone and clay in a kiln. The clinker is then ground into a fine powder and a small amount of gypsum is added to control the setting time.

Portland Pozzolana Cement (PPC): PPC is produced by mixing OPC with pozzolanic materials such as fly ash, volcanic ash or silica fume. These pozzolanic materials react with the calcium hydroxide in cement to form additional calcium silicate hydrate (CSH), which enhances the properties of cement.

Features and Performance

- Strength Development: OPC has high early strength, making it ideal for projects that require rapid setting and early split formwork. However, PPC, while slower in initial strength development, continues to strengthen over time, and long-term strength generally exceeds that of OPC.

- At the same time: PPC has higher durability than OPC, especially in environments exposed to corrosive chemicals such as sulfates and chlorides. The pozzolanic reaction in PPC reduces the amount of free lime, making the concrete denser and more permeable.

- Permeability: PPC has a higher permeability than OPC, which means it can better resist water ingress and protect epoxy concrete from corrosion. This property is particularly beneficial in marine structures and areas with high groundwater levels.

- Heat of hydration: OPC generates more heat during the hydration process, which may cause thermal cracking in large concrete cast structures. PPC has a lower heat of hydration and is less prone to this problem, making it suitable for large concrete structures.

- Workability: PPC generally has better workability than OPC due to its finer particles and pozzolanic reaction. This makes PPC easier to mix and spread, resulting in a smoother surface.

Uses and Applications

Portland Cement (OPC): OPC is often used in projects that require rapid construction and early strength, such as precast concrete, pavements, and high-rise buildings. It is also the first choice in cold weather conditions where rapid strength development is required.

Portland Pozzolana Cement (PPC): PPC is well suited for structures that require long-term durability and resistance to corrosive environments, such as marine structures, dams, bridges, and sewage treatment plants. Its low permeability and high workability also make it suitable for large concrete projects and residential construction.

Cases where one takes precedence over the other

When to choose OPC

Rapid construction projects where early strength is critical.

Weather concrete pouring for cold fast network and operations.

Precast concrete production requiring fast formwork turnaround.

When to Choose PPC

Long-term durability and chemical resistance are overall top priorities.

Large concrete projects such as dams and retaining walls where low heat of hydration is important.

Marine and industrial structures exposed to alligator environmental conditions.

Sustainable building practice as PPC uses industrial by-products like fly ash.

Conclusion

Portland pozzolana cement (PPC) is a valuable material considered in modern construction, with significant advantages in durability, environmental sustainability, cost and benefits. Its enhanced chemical resistance and reduced permeability have made it an ideal choice for structures in hazardous environments, while its lower carbon footprint supports sustainable building practices. From the dome of the Pantheon in ancient Rome to modern cross-sea tunnels, the evolution of pozzolana cement is a resonance of human material wisdom and the power of nature. Portland pozzolana cement is playing a central role in the global green building wave with its excellent long-term performance, environmentally friendly characteristics and diverse volcanic ash resources. Understanding the advantages of PPC enables builders and engineers to choose the most appropriate cement for their specific needs, ensuring the immediate performance and long-term durability of the project.