Urea sulfurization coating production line uses combination of equipment like rotary drum coating machine, cooling machines, rotary screener and auxiliary machine to produce sulfur-coated urea which is a type of slow-controlled release fertilizer. This fertilizer can control the nitrogen release rate, so that the nutrient release is continuous and stable, meeting the nutritional needs of crops throughout the growth period.

What is the process and working principle of SCU Production Plant?

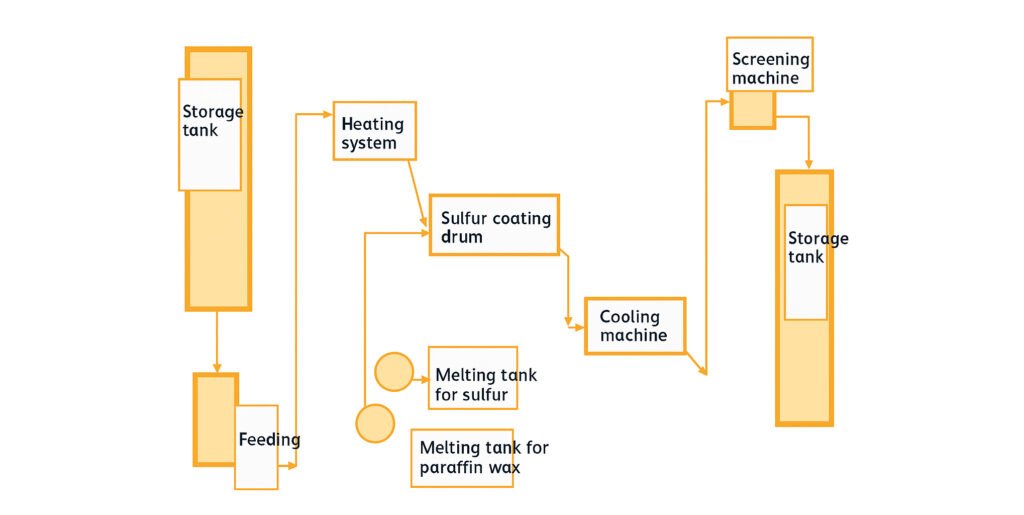

Urea sulfurization coating production process first melts solid sulfur into liquid sulfur in a melting tank then uses an electric heating device, and prepares granular urea at the same time. The liquid sulfur is transported to the rotary drum coating machine through a conveying device. In the coating machine, the liquid sulfur is evenly sprayed on the surface of the granular urea by a nozzle. Depends on the formula microcrystalline wax sealants will also be added to form the final product.

What equipment is needed for urea sulfur coating process?

So the SCU coating proces generally can be divided into 3 stages: Raw material preparation, sulfur melting, coating. So now lets list these 3 stages one by one.

1. Raw material preparation: urea screening and heating

Large urea granules are transported to bucket elevators via belt conveyors, and then transported to rotary screening machines by bucket elevators to filter out fine urea powder or oversized particles to obtain large urea granules with a particle size of 2.0-4.75mm. After being measured by belt weighing scales, the air is preheated through a heat transfer oil heating system (oil temperature 200-250℃) to maintain the temperature of the coating equipment at 150-180℃, and the urea granules are preheated to 50-70℃ to improve surface adsorption.

2. Sulfur melting process

Solid sulfur is conveyed to the sulfur melting tank by a TD 75 type belt conveyor, where it is heated and melted into a liquid state. The liquid sulfur flows by gravity into the sulfur filter tank for purification, and then flows by gravity into the sulfur spray tank, where modified talcum powder is added, stirred evenly, and then stored in a heat-insulated state.

3. Coating and granulation process

Start the sulfur metering pump on the top of the sulfur spray tank, spray the metered molten sulfur onto the surface of the large urea granules preheated to 50-70℃, and rotate the sulfur coating dryer to make the large urea granules rotate and spray in the machine. At the nozzle pressure of 0.3-0.7MPa, the spray angle should be 50°-60°, and the spray distance should be about 190mm.

4. Cooling(optional)

In the urea vulcanization coating production line, cooling is an important process to ensure product quality, which is usually achieved by a drum cooler. The main body of the drum cooler is a horizontal drum with an inclination of 3°-5°. A lifting plate is set inside. The urea particles at 60-80℃ after coating are continuously thrown at a speed of 8-12r/min, and fully contacted with the room temperature air (20-25℃, air volume 5000-10000m³/h) introduced from one end. After 8-15 minutes of treatment, the particle temperature is reduced to 35-45℃, and the liquid sulfur coating is quickly solidified. The drum cooler consumes about 3-5kWh of electricity per ton of product, and the heat exchange coefficient is about 20-30W/(m²・K). The air outlet is connected to the dust removal system to ensure that the dust emission concentration is ≤30mg/m³.

5. Screening(optional)

Use equipment such as vibrating screens or drum screens, the screen aperture or I mean the screen mesh which the size of the hole on the screen is set according to the product particle size requirements (usually 2.0-4.75mm), and large particles that stick together, fine powder produced by crushing, and unqualified products are separated and removed. The screening efficiency is over 95%, which effectively guarantees the uniformity of the finished product particles in a long term. The temperature of the screened qualified products must be controlled below 30℃ before they can be packaged and stored, and the screened waste is returned to the raw material processing process for reprocessing, realizing a closed loop for the entire production line.

What are the special design consideration of sulfur coated urea production line equipment?

1. Specially patented design rotary drum coating machine

- Using an inclined drum inclination angle 2.5° with a lifting plate structure, the urea particles form a uniform falling motion in the drum, ensuring that the sulfur melt spray coverage rate is ≥95%. For example, the drum diameter is usually 1.5~3m depend on the capacity, and the length is 6~8m, and the rotation speed is 5-15rpm, ensuring that the particles stay in the drum for 5-6 minutes to be fully coated.

- The inner wall is lined with corrosion-resistant alloy (such as 316L stainless steel) or ceramic coating to prevent corrosion from sulfur melt and acidic gas, and extend the life of the equipment (corrosion rate ≤0.1mm/year).

- An infrared temperature patrol meter is set on the outer wall of the drum to control the temperature in the drum at 50-70℃ to ensure uniform preheating of urea particles; an independent temperature control module is equipped at the sulfur melt nozzle to stabilize the temperature of the molten sulfur at 130-150℃ (error ±5℃) to avoid cracking of the coating layer due to temperature fluctuations.

2. Ultra sulfur melting and spraying system

- Melting kettle design: An anchor stirrer with a speed of 20-40rpm is used in conjunction with a bottom heating coil to ensure that the sulfur melting efficiency is ≥98% and the melting time is ≤30 minutes; the kettle body is equipped with a liquid level sensor and a temperature interlocking device, which automatically starts heating when the temperature is lower than 120℃ to prevent sulfur solidification and blockage.

- Spraying device: Multiple groups of atomizing nozzles are used with a pressure of 0.3-0.5MPa. The nozzle material is Hastelloy, which is resistant to sulfur corrosion, with an aperture of 1-2mm and a spraying angle of 30°-45°, ensuring that the sulfur liquid atomization particle size is 50-100μm and evenly covers the particle surface. For example, the nozzle flow rate of a 10,000-ton SCU production line needs to be controlled at 5-8kg/min.

3. Efficient Screening and cooling system

- The coated particles are graded by the drum screen with 2-4mm mesh. The recovery rate of unqualified particles (uneven coating or broken particles) is ≥90%. The drum screen has a three-sided maintenance platform. The motor and gearbox are both Siemens.

- The cooling section uses a drum cooler with a centrifugal fan, with an air temperature of 20-30℃, which reduces the particle temperature to ≤40℃ to prevent the coating layer from softening and sticking due to high temperature.

4. Tail gas treatment dedusting system

- Exhaust gas purification: A two-stage desulfurization tower water washing + activated carbon adsorption is configured to treat the SO₂ gas generated during the spraying process, with an outlet concentration of ≤50mg/m³ (national standard ≤300mg/m³); the tower filler uses polypropylene ball rings with a contact area of ≥100m²/m³ to ensure a desulfurization efficiency of ≥95%.

- Explosion-proof design: Explosion-proof membranes burst pressure 0.2MPa and temperature alarms (threshold 180℃) are installed at key locations such as melting kettles and pipelines, and electrical equipment uses Ex d IIBT4 explosion-proof grade to prevent the risk of sulfur dust explosion.

5. Automatic control system

- PLC + touch screen control is used to monitor key parameters in real time:

- Urea granule temperature: 50-60℃ (deviation ±3℃)

- Sulfur melt viscosity: 10-20cP (at 25℃)

- Coating weight gain rate: set 5%-15% according to the sustained release requirements (e.g., the coating weight gain rate of SCU with a sustained release period of 90 days needs to be ≥12%)

What is the final product characteristic of sulfur coated urea plant?

| Type | Core Parameters (N≥, S≥) | Slow-release Cycle | Adaptable Agricultural Scenarios | Application Advantages |

| Type I (Quick-acting) | N≥39, S≥10 | 1–2 months | Topdressing during the seedling period of vegetables; short-term leafy vegetable planting (e.g., lettuce). | Rapid early-stage nitrogen release ; sulfur regulates seedling matrix pH and promotes root development. |

| Type II (Medium-term stable supply) | N≥37, S≥15 | 2–3 months | Spring shoot growth in fruit trees; jointing and tasseling stages of corn. | A 2–3 month slow-release cycle ensures continuous nitrogen supply for fruit tree shoot development and corn stalk thickening. |

| Type III (Long-term fertilizer) | N≥34, S≥19 | 3–5 months | Orchard basal fertilization (e.g., citrus, apple); perennial forage planting. | A 3–5 month slow-release profile meets nutrient demands from spring shoots to young fruit development in fruit trees when applied as basal fertilizer. |

What are the adventages of sulfur coated urea?

1. Precise and slow-release nitrogen:

The nitrogen nutrition in urea is slowly released through sulfur coating. It can match the fertilizer requirements of crops at different growth stages, so that nitrogen will not be concentratedly released in the early stage to cause waste and seedling burning. In the later stage, nitrogen can also be continuously supplied to meet the needs of crops throughout the entire growth period. For crops with a long growth period such as rice and corn, the nitrogen fertilizer utilization rate can be increased by more than 30% after use, reducing the loss of nitrogen due to volatilization and leaching.

2. Supplementary sulfur fertilizer:

Sulfur is an essential medium element for plants. The coated sulfur can be gradually oxidized into sulfate ions for crop absorption under the action of soil microorganisms. It can improve the sulfur deficiency in the soil, especially for sulfur-loving crops (such as rice, corn, onions, cabbage, peanuts, forage, etc.), promote the synthesis of sulfur-containing amino acids and proteins, and improve yield and quality, such as making the grains fuller and the quality of vegetables and forage better.

3. Enhance stress resistance:

Sulfur has a certain bactericidal and insect repellent effect. After coating, it can enhance the cold resistance and drought resistance of crops. For example, in low temperature and drought environments, it can help crops better resist adverse environments and reduce the occurrence of pests and diseases, such as reducing the damage of underground pests to crop roots.

Adapt to mechanization and simplify management: The particles are not easy to solidify, have low hygroscopicity, and are highly miscible, making them suitable for mechanized fertilization or mixing with other fertilizers. One fertilization can basically meet the needs of the crop growth stage, reduce the number of fertilizations, reduce labor costs, and facilitate large-scale agricultural production management.

What factors affect urea sulfur coating?

The effect and quality of urea sulfur coating are affected by a variety of factors, the first of which is the coating process.

Coating Process:

The melting temperature and spraying amount of sulfur are crucial to the coating quality. Sulfur needs to be heated to a molten state of about 115°C for spraying. If the temperature is too low, the sulfur has poor fluidity and is difficult to coat evenly. If the temperature is too high, it may decompose to produce hydrogen sulfide, which affects the stability of the coating and damages the urea particles. The spraying amount determines the coating thickness. Low spraying amount results in thin coating and fast nitrogen release, which is suitable for short-term nitrogen-requiring crops. High spraying amount results in thick coating and long sustained-release cycle, but the initial nitrogen release may be insufficient.

Number of coating layers:

The sustained-release stability of single-layer sulfur coating is poor, while the combination of sulfur and sealing layers such as resin in multi-layer coating can effectively extend the sustained-release cycle, and the ratio of film-forming materials needs to be finely adjusted according to the target sustained-release time. In addition, the cooling and solidification speed of molten sulfur after spraying must be controlled. Too slow will easily cause the particles to stick together and the coating to crack, while too fast will cause residual stress inside the coating and later damage.

Raw material characteristics:

The quality of urea particles affects the coating effect. Particles with uniform spherical shape, particle size of 2-4mm and smooth surface are easier to obtain uniform coating. Irregular or rough particles will cause uneven coating and increase in material consumption. The purity and impurity content of sulfur cannot be ignored. High-purity sulfur can ensure the stability of the coating. Impurities not only reduce the coating strength, but also may have side reactions with urea. At the same time, the fineness of sulfur particles affects the density of the coating. Fine particles can form a better coating layer.

Soil environment:

Soil microbial activity determines the degradation rate of sulfur coating. In the warm, humid, and microbially rich southern red soil, sulfur decomposes quickly and the nitrogen release cycle is shortened. In the cold and arid northern frozen soil, slow decomposition can easily lead to fertilizer loss in the later stage. Soil pH and humidity also play a role. Acidic soil accelerates sulfur oxidation, while alkaline soil slows down decomposition. Nitrogen release is accelerated when soil moisture is sufficient, but slow in drought. Temperature and light should not be underestimated. High temperature accelerates the softening of coating materials and microbial metabolism, causing a surge in nitrogen release. Ultraviolet rays may also accelerate the aging of the outer resin and damage the coating.

Crop type:

Different crops have different nitrogen requirements. Rice needs a lot of nitrogen during the tillering period, so it is suitable for medium-speed release sulfur-coated urea. Fruit tree basal fertilizer requires a long-acting slow-release type;

Fertilization method:

Fertilization method and depth affect the coating effect. Broadcasting is easily disturbed by the external environment, resulting in coating damage and unstable nitrogen release. Deep application in the 10-15cm soil layer can allow the coating to degrade evenly in a stable soil environment and improve fertilizer utilization.

Challenges in SCU Manufacturing & How to Overcome Them

What are the challenges facing during production of sulfur coated urea?

1. Coating uniformity and integrity problems:

The distribution of sulfur coating materials on the surface of urea particles is prone to uneven distribution, which may form coating layers of varying thicknesses, and may even have defects such as pores and cracks. This will make it difficult to effectively control the urea release rate, thereby affecting the slow-release effect of the fertilizer. Factors such as the surface morphology of urea particles, temperature control during the coating process, and the uniformity of the spraying of sulfur melt will affect the uniformity and integrity of the coating.

2. Adhesion of coating materials:

The adhesion between sulfur and urea particles is insufficient. During storage and transportation, the coating layer is prone to fall off, which will reduce the slow-release performance of the fertilizer and may also cause premature release of urea, resulting in nutrient loss. The humidity on the surface of urea particles, the formula of sulfur coating materials, and coating process parameters are the main factors affecting adhesion.

3. Difficulty in regulating slow-release performance:

Different soil environments and crop requirements have different requirements for the release rate of urea. However, the slow-release performance of sulfur-coated urea is greatly affected by factors such as coating thickness and porosity, and it is difficult to accurately regulate to meet diverse needs. The amount of sulfur used in the coating process, the number of coating layers, and the subsequent treatment process will have an important impact on the slow-release performance.

4. Scaling and clogging during the production process:

During the spraying process of sulfur melt, molten sulfur is easy to solidify and scale on the surface of the equipment, clogging the nozzle and pipeline, which will affect the continuity of production, increase the maintenance cost of the equipment, and also cause uneven coating. Factors such as production temperature control, impurity content in sulfur melt, and equipment design are the main causes of scaling and clogging problems.

5. Environmental protection and safety issues:

Sulfur may produce harmful gases such as sulfur dioxide during melting and spraying. If not handled properly, it will pollute the environment and harm the health of operators. In addition, sulfur is a flammable substance and there are certain safety hazards in the production process. The sealing of the production process, the efficiency of the exhaust gas treatment equipment, and safety management measures will affect the solution of environmental protection and safety issues.

How to overcome the challenges of producing SCU? What are the attempts?

1. Optimize coating process parameters

- Temperature control: Precisely control the preheating temperature of urea granules and the spraying temperature of sulfur melt to ensure that the sulfur melt can be evenly spread when sprayed on the surface of urea granules to form a complete coating layer. For example, preheat the urea granules to 50-60℃ and control the temperature of sulfur melt at 130-150℃.

- Spraying rate and pressure: Reasonably adjust the spraying rate and spraying pressure of sulfur melt to ensure the uniformity of spraying. Multi-nozzle uniform spraying can be used to improve the uniformity of coating.

- Coating environment: Control the humidity and ventilation conditions during the coating process to avoid moisture absorption on the surface of urea granules and affect the adhesion of sulfur.

2. Improve the coating material formula

- Adding binder: Adding an appropriate amount of binder, such as paraffin, polyethylene, etc., to the sulfur coating material to improve the adhesion between sulfur and urea particles and reduce the shedding of the coating layer.

- Optimizing the purity of sulfur: Using high-purity sulfur as a coating material to reduce the content of impurities and reduce the possibility of scaling and clogging.

- Composite coating material: Using a coating method that combines sulfur with other materials, such as sulfur-polymer composite coating, to improve the performance of the coating and improve the controllability of the sustained-release effect.

3. Accurately control the slow-release performance

- Control the coating thickness: By adjusting the amount of sulfur and the number of coating layers, the coating thickness can be accurately controlled to control the release rate of urea. For example, when the coating thickness is 0.1-0.3mm, the release period of urea can be controlled within 30-90 days.

- Adjust the porosity: During the coating process, add some pore-forming agents, such as starch, ammonium bicarbonate, etc., to adjust the porosity of the coating layer, change the diffusion rate of water and urea, and achieve the regulation of the slow-release performance.

- Customized according to needs: According to different soil environments and crop needs, formulate personalized coating plans to achieve accurate regulation of the slow-release performance of sulfur-coated urea.

4. Improve production equipment and processes

- Equipment optimization: Design reasonable coating equipment, such as using a rotary drum coating machine, to improve the contact uniformity between urea particles and sulfur melt. At the same time, optimize the design of nozzles and pipelines to reduce scaling and blockage.

- Online monitoring and control: Install online monitoring equipment to monitor parameters such as temperature, humidity, spray rate, etc. during the coating process in real time, and adjust them through the automatic control system to ensure the stability of the production process.

- Regular cleaning and maintenance: Develop regular cleaning and maintenance plans to promptly remove scaling on the surface of the equipment to ensure the normal operation of the equipment.

5. Strengthen environmental protection and safety management

- Waste gas treatment: Install efficient waste gas treatment equipment, such as desulfurization towers, activated carbon adsorption devices, etc., to treat harmful gases such as sulfur dioxide generated during the production process to ensure that emissions meet standards.

- Safety measures: Strengthen safety management during the production process, set up fire prevention and explosion prevention facilities, and strictly control fire sources and static electricity at the production site. At the same time, provide safety training for operators to improve safety awareness.

- Environmental protection process improvement: Develop environmentally friendly sulfur coating processes, such as using water-based coating technology to reduce the emission of harmful gases.

Should I invest in a normal NPK compound fertilizer production line or a urea coating production line?

From a manufacturer's point of view let us jump to the conclusion: our suggustion is if you are looking for low investment and market universality, the NPK compound fertilizer production line is more suitable; if you are optimistic about high value-added products and the regional market has a large demand for slow-release fertilizers, the urea coating production line has more advantages

- From the market point of view, NPK compound fertilizer is applicable to a wide range of crops, with stable market demand, and is suitable for a variety of crop planting areas; urea coated fertilizer has great potential in areas with high requirements for fertilizer utilization and high economic value crops.

- In terms of cost, the investment and production costs of NPK compound fertilizer production lines are relatively high, and the raw material selection is flexible; the equipment and coating material costs of urea coating production lines are low, but the added value of products is also low.

- From the perspective of investment income and environmental protection, the investment scale of NPK compound fertilizer projects is large, the profit margin and internal rate of return are relatively low, and the investment recovery period is long; the investment of urea coating production lines is relatively small, the profit margin and internal rate of return are high, and the investment recovery is fast.

- In terms of environmental protection, the solid pellet method of NPK compound fertilizer has little pollution, and the slurry method needs to deal with pollutants; the urea coating production line should pay attention to the treatment of waste gas and waste residue generated by the use of coating materials.

How to Choose the Right SCU Machinery Supplier: Quality, Certifications, Price

1. Quality and technical strength

Inspect whether the core components of the equipment, such as the coating drum, spraying system, and temperature control device, are made of wear-resistant materials, and whether the process design can ensure the uniformity and stability of the coating. Tongli Heavy Machinery's drum coating equipment has high-precision temperature control and multi-nozzle uniform spraying technology. Refer to the supplier's actual cases to understand the operating effect of the equipment in similar enterprises. Tongli Heavy Machinery has many years of equipment supply experience in the fertilizer industry and mature technology.

2. Certification and qualifications

Confirm whether the supplier has industry standard certification, ISO 9001 quality management system certification, and special equipment manufacturing license to ensure that the equipment meets the requirements of safe production and environmental protection. Tongli Heavy Machinery can provide relevant qualification documents and the process meets the national fertilizer equipment standards.

3. Price and cost-effectiveness

When comparing quotations from different suppliers, it is necessary to combine equipment configuration, after-sales service, installation and commissioning, and warranty period for comprehensive evaluation. As a professional manufacturer, Tongli Heavy Machinery has reasonable pricing and can provide customized solutions to avoid insufficient equipment performance or increased maintenance costs due to low prices.

Summary:

A complete SCU (sulfur coated urea) production line integrates advanced technology, precision engineering and strict quality control to meet the needs of modern agriculture. The key to its design is to optimize the coating process, which requires fine control of parameters such as temperature, spray pressure and coating thickness. For example, the sulfur melt temperature is maintained at 130-150°C and the coating thickness is controlled between 0.1-0.3 mm to ensure stable sustained release performance, with an initial dissolution rate of ≤15% within 24 hours and a cumulative release rate of ≤75% within 28 days. The equipment of the TONGLI SCU production line coating machinery must be made of corrosion-resistant materials (such as 316L stainless steel) or coated with an anti-corrosion layer to withstand harsh chemical environments. This not only extends the service life of the equipment, but also ensures the stability of production, with the goal of more than 8,000 hours of continuous operation per year and a failure rate of ≤5%.