Ball mills are core grinding equipment in numerous industries, including metallurgy, mining, cement, and ceramics. Their grinding efficiency and final product quality are determined not only by their massive cylinder but also by the grinding media within. While the ball mill appears to be a massive, slowly rotating steel cylinder, its interior harbors a dynamic world of intense impact and friction. From cement used in construction to the electrodes in smartphone batteries, the raw materials for countless products pass through ball mills. A ball mill is a rotating cylindrical container filled with grinding media to break down ore particles. The grinding media plays a crucial role in ore pulverization in these mills. The ball mill operates on the principle of impact and friction. The impact force is the size reduction of the balls as they fall from almost the top of the shell. The balls are the grinding media and can be made of ceramic, rubber, steel, and other materials. The ball mill rotates around a horizontal axis that is nearly filled with the material to be ground and the grinding media. The end result is a fine powder. Ball mills are used not only for grinding but also for cold welding. A major advantage of ball mills is their adaptability to grinding materials of varying hardness and strength, thanks to their diverse selection of grinding media. This article introduces the application of ball mills in mineral processing and analyzes their construction materials and mass loss, which is influenced by three basic wear mechanisms: impact, abrasion, and corrosion. This article also reviews the effects of grinding media geometry and density on mill performance to identify the most suitable grinding media for different grinding applications, as recommended in this study.

How does a ball mill work?

Ball mill structure

- Cylinder: The main body of the equipment is a horizontal or slightly tilted rotating cylinder made of thick steel plates.

- Liners: Laid on the inner wall of the cylinder, their main function is to protect the cylinder from wear and tear, while raising the height of the grinding media, optimizing its movement trajectory, and enhancing grinding efficiency.

- Feed & Discharge Ends: used for input of materials and discharge of ground products respectively.

- Drive System: includes motor, reducer, etc., which provides power for the rotation of the cylinder.

- Grinding Media: The balls, segments, rods, etc. filled in the cylinder are the actual grinding actuators.

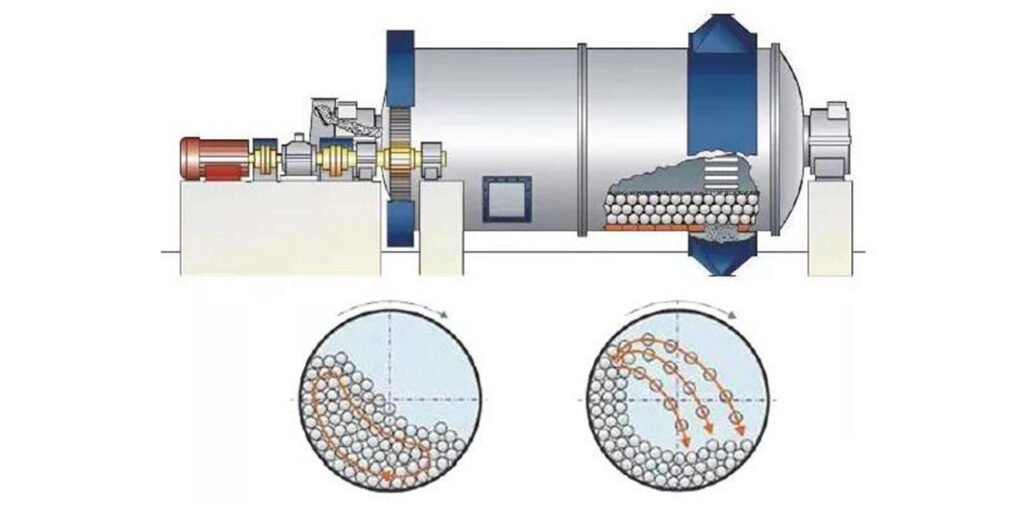

Working principle of ball mill

A ball mill uses steel or ceramic balls to grind materials into a fine powder. It operates based on the principles of impact and friction. Impact occurs when the balls are lifted by the rotating mill and then fall onto the material being ground. The impact force breaks the material into smaller fragments. Wear occurs when the balls rub against each other and the material being ground. This friction helps grind the material into a powder. Ball mills are widely used in industries such as mining, cement production, ceramics, and pharmaceuticals. They are also used in research laboratories to grind analytical materials. The material to be ground is fed into the mill through the feed port. The grinding media rotates inside the mill, driving the steel balls to impact the material. The ground material exits the mill through the discharge port. The critical speed of a ball mill is the speed at which the grinding media reaches the centrifugal force required to adhere to the mill walls. At this speed, the grinding media rotates around the mill shell, and no grinding action occurs. For efficient grinding, the ball mill must operate above the critical speed. This ensures that the grinding media continuously tumbles and impacts the material being ground.

What is the grinding media in a ball mill?

Grinding media are solid objects (usually spheres, but they can also be cylinders or other shapes) that are loaded into the ball mill. As the ball mill rotates, these media tumble and pour, impacting and grinding the material, thereby reducing its particle size. The effectiveness of this process depends largely on the characteristics of the media itself. The functions of the grinding media include:

- Energy transfer: The mechanical energy of the cylinder rotation is converted into impact energy and friction energy, which acts on the material particles.

- Size reduction: Through collision and shear force, the material particles are reduced from large to small, from coarse to fine.

- Mixing and homogenizing: It also plays a stirring role during the grinding process to make the material components mixed evenly.

The choice of grinding media affects the following aspects:

- Product particle size: The size and shape of the medium affect the final powder fineness and distribution.

- Product purity: The material of the medium determines whether it will introduce contamination (such as metal ions) to the product.

- Production efficiency and energy consumption: Suitable media can improve grinding efficiency and reduce energy consumption per unit product.

- Operating costs: The wear rate of the media directly affects the frequency of replacement and production costs.

Common grinding media types used in ball mills

Steel grinding media

is the first choice in heavy industry due to its high density, high hardness, high impact toughness and relatively low cost.

steel ball

- Characteristics: Spherical shape provides multiple points of contact for uniform grinding action; strong impact force; good wear resistance. Typically made of forged steel, cast steel, or high-chromium alloy steel, and available in a wide range of sizes (φ20mm–φ120mm).

- Application: Widely used in cement, mineral secondary grinding, ceramic raw materials and other processes that require fine grinding. A mixture of large and small balls is often used to balance the impact force and grinding fineness.

Steel Section

- Characteristics: The shape is a short cylinder or ellipsoid, somewhere between a ball and a rod. Compared to steel balls, it has a larger contact area, a higher grinding frequency per unit time, a more stable motion trajectory, and more uniform wear.

- Application: It is particularly suitable for the intermediate stage grinding of metal ores (iron, copper, gold), and can effectively improve the grinding efficiency in the medium particle size range.

steel rod

- Features: It has linear contact characteristics and moves parallel to the axis of the mill. It mainly plays the role of crushing and stripping, can effectively control over-grinding, and produce a more uniform product particle size.

- Application: It is mainly used in rod mills to process coarse-grained materials such as quartz sand, limestone, and coal powder, and is often used at the front end of the grinding circuit.

Ceramic grinding media

Ceramic media are made of high-performance non-metallic materials with good chemical stability and no metal pollution. They are used in the production of high-purity, high-value-added products.

Alumina balls

- Features: Alumina (Al₂O₃) content 75%-99%, high hardness, wear resistance, corrosion resistance, high temperature resistance, moderate density, and high cost performance.

- Applications: ceramic glazes, glass powder, lithium battery materials, coatings, inks, etc.

Zirconia balls

- Features: Made of zirconium oxide (ZrO₂), high density (>6.0g/cm³), extremely high hardness, good fracture toughness, extremely low wear, and almost no pollution.

- Applications: Pharmaceuticals, electronic pastes, high-end lithium battery materials, catalysts, semiconductor powders, and other fields requiring extremely high purity. Although expensive, it is often more cost-effective in terms of overall lifespan and product yield.

Zirconium silicate balls

- Features: Its performance and cost are between alumina balls and zirconia balls, making it an ideal compromise. It has high hardness, moderate density, and low contamination risk.

- Applications: ceramic glazes, pigments, electronic ceramics, architectural ceramics, etc.

Special grinding media

glass ball

- Features: low density, good chemical stability, low cost, and little wear on equipment.

- Application: Suitable for dispersion and light grinding of low hardness materials such as coatings, inks, cosmetics, food additives, etc.

Quartz ball

- Features: Metal-free, extremely chemically inert, and high temperature resistant.

- Applications: photovoltaic silicon materials, laboratory high-purity powders, and fine chemical industries.

plastic balls

- Features: extremely low density, good flexibility, almost zero wear on equipment, but low strength and not wear-resistant.

- Application: Mainly used for mixing and dispersing in the cosmetics and food industries, or for small batch sample preparation in the laboratory.

Effects of different grinding media on ball mill performance

Effect of Grinding Media Size on Mill Performance

Different grinding media sizes have different effects on grinding performance. The balls used in grinding should be large enough to crush the largest and hardest ore particles. The optimal ball size depends on the feed/product size ratio, mill size, and crushing dynamics. Generally, larger balls effectively grind coarser ore particles, while smaller balls are more effective at grinding fine particles. Larger balls break particles by impact, while smaller balls break them by friction. Sometimes, smaller balls do not have enough impact energy to break ore particles; therefore, both media sizes are crucial. The optimal ball size range should provide enough energy to break coarse ore particles, but at the same time should not produce unnecessary ultrafine particles.

Despite their smaller surface area, larger balls are more effective for larger feed sizes due to their greater impact force, while smaller balls are more effective for smaller feed sizes due to their greater friction and larger surface area. When grinding quartzite ore with a feed size of -8 to +5.6 mm, 30 mm diameter balls performed better than 10 mm and 20 mm diameter balls. However, efficiency improved when grinding feed sizes of -2 mm to +1.4 mm with 20 mm diameter balls.

Effect of Grinding Media Shape on Mill Performance

Grinding media shape is crucial in the grinding process and significantly impacts downstream processes such as flotation. It is also an important parameter in mass transfer, with studies demonstrating that power consumption is sensitive to media shape at varying charge levels. Differences in media shape result in varying surface area, bulk density, and contact mechanisms during grinding. Grinding media of varying shapes exhibit different toe and shoulder positions within the mill, resulting in varying power consumption and load behavior. The toe and shoulder positions are the angular positions where the liner contacts the material and where the material leaves the liner, respectively. The coefficients of friction between the media and the lifter, and between the media themselves, influence the position of the media within the mill. Furthermore, the surface area affected by media shape allows the material to resist and move between the media layers, effectively lifting the load.

Spherical balls are primarily used in ball mill processes, but casting production is more expensive than other media types. Spherical balls change shape over time due to wear of the outer layer. Compared to worn balls, spherical balls produce 27% finer particles and consume 5% less power, suggesting that worn balls should be removed from the mill more frequently because they affect ore particle crushing dynamics. Compared to spherical balls, worn balls reduce the grinding surface area. However, it is necessary to investigate the relationship between worn balls and mill speed, liner profile, or fill ratio.

When the critical speed exceeds 60%, steel-jacketed media has the highest shoulder position and the lowest toe position compared to spherical and wear balls. The higher shoulder position of steel-jacketed media compared to other media shapes is due to internal damming and premature centrifugation. The lower toe position of steel-jacketed media is due to the tight packing and locking of the media, resulting in a stacking velocity that is lower than the mill speed. The shoulder position of spherical and wear balls increases with increasing material charge, but the toe position is similar for all media shapes below 70% of the critical speed. The shoulder position of steel-jacketed media shows little change with mill speed. When the speed is below 72% of the critical speed, steel-jacketed media consumes the most power, followed by wear balls, and finally spherical balls.

Effect of Grinding Media Density on Mill Performance

To improve mill efficiency, increase the density of the grinding media. When grinding materials using ultrasonic grinding, low-density balls are less efficient than high-density balls. Grinding media density is listed as one of the variables affecting power consumption. When using grinding media of different densities, mill power consumption is linearly proportional to media density. However, for grinding media with densities of 4,000 kg/m³ and 7,800 kg/m³, the difference in specific power consumption is negligible.

What should I consider when choosing ball mill grinding media?

Selecting the right grinding media requires a comprehensive evaluation of the following four aspects:

- Material Properties: The material's hardness, brittleness, viscosity, and sensitivity to metal ions. For example, pharmaceuticals, cosmetics, and electronic materials must be made of ceramic or glass media that are free of metal contamination.

- Product Requirements: Is the target particle size coarse or fine? Is a narrow or wide particle size distribution required? Is extremely high purity required? Zirconia balls are suitable for ultrafine grinding, while steel rods are suitable for coarse grinding and high-volume operations.

- Cost Budget: Don't just look at the unit price; calculate the "full lifecycle cost." While ceramic balls are expensive, they have a long lifespan and high yield, so their overall cost may be lower than steel balls, which require frequent replacement.

- Application Scenario: Is it large-scale continuous production or small-batch experiments? Industrial applications focus on efficiency and wear resistance, while laboratories prioritize compatibility and flexibility.

FAQ Ball Mill Inside

Inside a ball mill there's cylindrical shell, grinding media (balls), and liners. The cylindrical shell rotates around a horizontal axis, and inside, steel, ceramic, or rubber balls are used as grinding media. The liners, often made of manganese steel or rubber, protect the shell and improve grinding efficiency by lifting the balls as the mill rotates.

The grinding balls occupy about 30–50% of the mill volume, depending on the type of material and desired fineness. During rotation, the balls cascade, tumble, and sometimes centrifuge along the shell, which creates the impact and attrition forces needed to break down the material.

Liners serve multiple purposes:

1. Protect the steel shell from wear and abrasion.

2. Improve grinding efficiency by lifting and dropping the balls effectively.

3. Reduce energy loss during grinding.

Linings can be made of steel, rubber, or composite materials depending on the material being processed.

The mill rotates slowly (typically 15–80% of critical speed) causing the balls to rise along the shell due to friction and then fall, impacting the material. This creates a combination of impact force and shear force, effectively reducing particle size.

Yes. Wet ball mills have water or liquid slurry, which aids in material flow and reduces dust. Dry ball mills operate without liquid, so internal liners and grinding media are optimized to prevent excessive wear and ensure proper material movement.

No, a Vertical Roller Mill (VRM) does not require traditional grinding media like balls. Instead, it uses a combination of pressure and shear forces generated by rollers pressing against a rotating grinding table. Material fed into the mill is crushed and ground as it passes between the rollers and table, while centrifugal force moves it outward toward a classifier, which separates fine particles from coarse ones. This design eliminates the need for balls, reduces energy consumption, and minimizes wear compared with ball mills. VRMs are particularly efficient for grinding cement, coal, and raw minerals, producing uniform fine powders with lower maintenance.

Conclusion

For many years, research has focused on improving grinding media quality to withstand the highly abrasive and corrosive environments found in ball mills. Grinding media have also been refined to minimize slurry contamination, thereby impacting downstream processes such as flotation. High-chromium white cast iron is used in highly abrasive environments, while high-chromium steel balls are used where minimal slurry contamination is crucial. Production methods (whether forged or cast) and heat treatment processes have been studied to determine their impact on the microstructure of grinding media. However, research is still ongoing on how to make grinding media both wear-resistant and impact-resistant, while also extending their service life. Grinding media have been manufactured in a variety of shapes, including cylindrical, elliptical, cubic, and truncated-conical, which rival the performance of commonly used spherical grinding media. Grinding media properties influence the overall performance of the grinding process, with particle size distribution being more important than density, shape, and hardness. Operating parameters such as grinding media packing, pH, mill speed, and wear also influence ball mill efficiency. Grinding media with low wear rates are most suitable because they have a longer service life and generate less debris, thereby reducing the impact on downstream processes. However, there are still many aspects of the role of grinding media in ball mill operation that need to be studied to gain a deeper understanding of the grinding process. Grinding media characteristics such as shape, hardness and size should be further studied to improve mill efficiency. Since most grinding media currently used, such as high-chromium cast iron and high-carbon low-alloy steel, contain a certain level of martensite and austenite, high hardness of martensite and austenite should be used in the ball structure to minimize grinding wear. Certain ores, such as gold and copper, are highly abrasive and can lead to high wear rates of the grinding media.