In mineral processing and manufacturing, the choice of grinding equipment significantly impacts the efficiency and quality of the final product. Among various types of grinding equipment, rod mills and ball mills are the two most commonly used. While both are used to grind materials, their respective characteristics make them suitable for different applications. Rod mills excel in coarse grinding applications due to their unique selective grinding characteristics and more uniform product particle size, while ball mills dominate the fine grinding stage with their superior fine grinding capabilities and high throughput. Grinding operations are a critical step in the production process in industries such as mining, metallurgy, building materials, and coal, and equipment performance directly impacts product quality, energy consumption, and production costs. Among various grinding equipment types, rod mills and ball mills are the two most common types of pulverizing machinery, each with unique operating characteristics and application advantages. While rod mills and ball mills share certain similarities in appearance and basic principles, they differ significantly in media shape, grinding mechanism, product characteristics, and applicable applications. Research suggests that rod mills, due to their selective grinding characteristics, are particularly suitable for applications that require minimizing over-grinding. Ball mills, with their wide adaptability and efficient fine grinding capabilities, have become the preferred equipment for fine grinding operations . In this blog post, we will delve into the differences between rod mills and ball mills, exploring their operating mechanisms, advantages and disadvantages, and ideal applications to help you determine which one is best for your project.

What are ball mill and rod mill

What is a rod mill

A rod mill is a mill that uses long rods as the grinding medium. The rods are typically made of steel and placed in a rotating cylinder. While the primary function of a rod mill is to crush material into a fine powder, its design makes the grinding mechanism different from other mills. The rods are arranged parallel to each other and can move freely within the mill, producing a grinding action different from that of a ball mill.

What is a ball mill

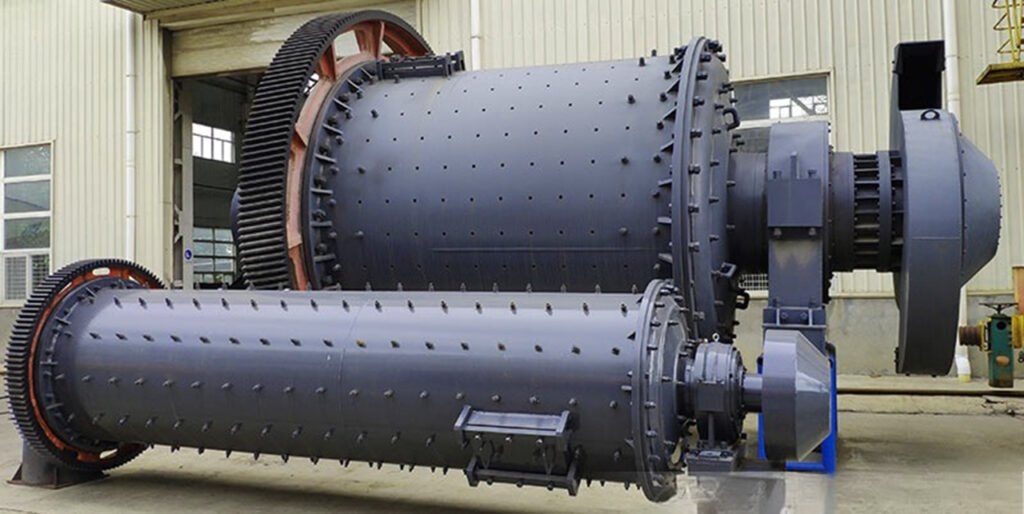

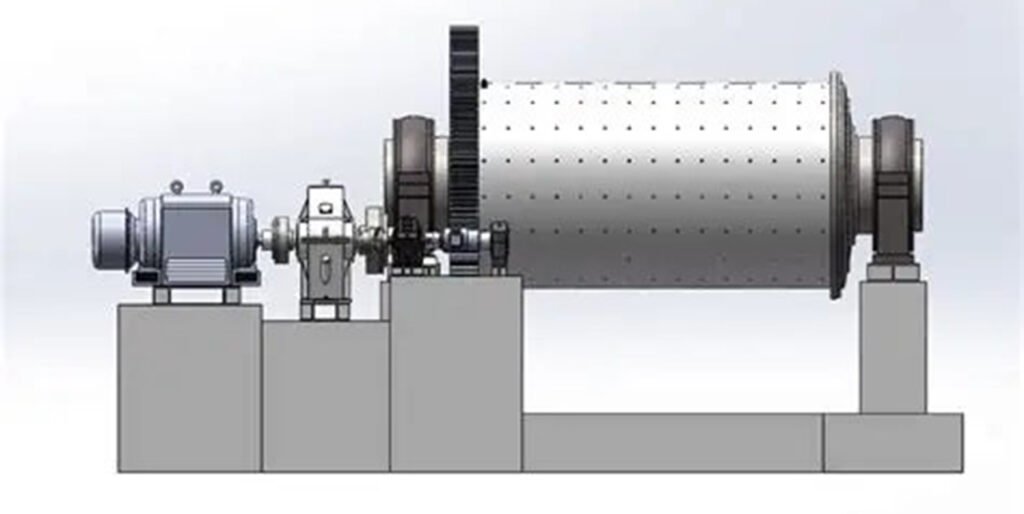

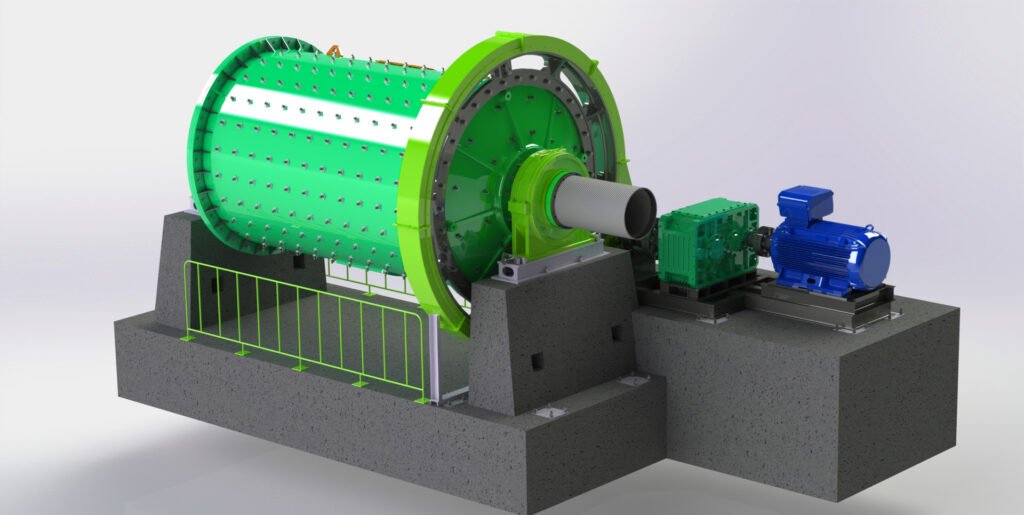

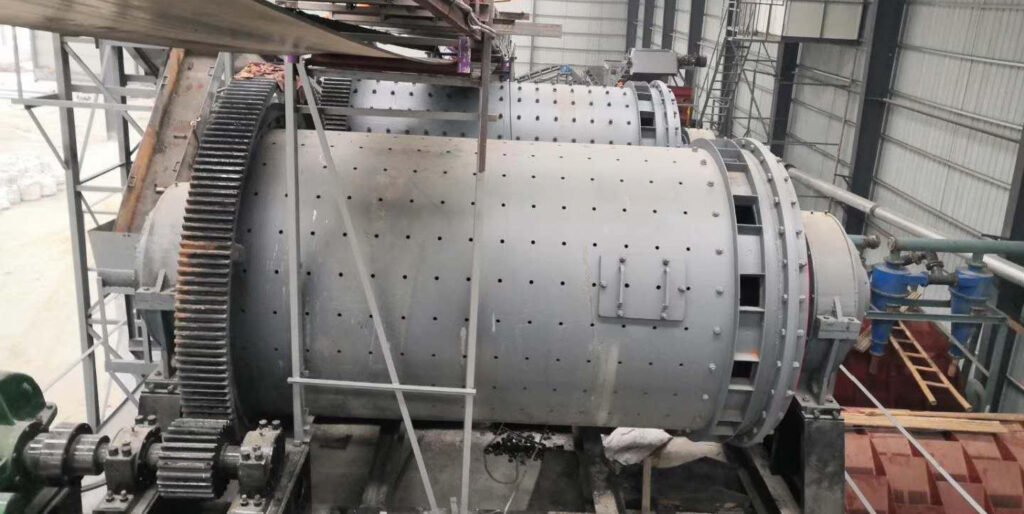

A ball mill, on the other hand, is a cylindrical device that rotates around an axis and uses balls as the grinding medium. The balls can be made of a variety of materials, including steel, ceramic, or rubber. As the mill rotates, the balls are lifted and dropped, creating a tumbling action that grinds the material. Ball mills are widely used in various industries, including mining, cement, and chemical manufacturing.

Working principle and structural characteristics

Working mechanism and design features of rod mill

A rod mill is a grinding device that uses oblong metal rods as the grinding medium. Its structural design is similar to that of a ball mill , but the rod mill's barrel aspect ratio (L/D) is typically 1.5-2.0, significantly larger than that of a ball mill. This design allows the rods to move in a parallel arrangement within the barrel, resulting in a unique grinding behavior. The rod mill's discharge end lacks a grate, instead featuring a larger discharge opening. This not only facilitates smooth discharge but also facilitates rod loading and removal of broken or bent rods.

The rod mill is characterized by its linear contact grinding mechanism. During operation, the rods form linear contact with each other and with the material, creating a unique "selective grinding" effect. As the rod media ascend, finer particles escape through the gaps between the rods, while coarser particles are trapped between the rods and subjected to greater crushing forces. This automatic grading function enables the rod mill to produce a uniformly sized product with minimal over-crushing.

| Parameter Type | Typical values | Remark |

| Medium filling rate | 30%-35% | Lower than ball mill |

| Rotation rate | 60%-75% | Lower than ball mill |

| Operation rate | 80%-88% | Regular shutdown inspection is required |

| Rod length | 100-150mm shorter than the cylinder | Prevent interference with end lining |

| Rod diameter | 60-120mm | Too thin and easy to break, too thick and easy to damage the lining |

Working mechanism and design features of ball mill

A ball mill is a type of grinding equipment that uses steel balls or steel segments as the grinding medium. Its main working parts include the cylinder and grinding media. Ball mill specifications are typically expressed in terms of cylinder diameter and length (m). Based on the length-to-diameter ratio of the cylinder, ball mills can be divided into short mills (with an aspect ratio of less than 2), medium-long mills (with an aspect ratio of approximately 3), and long mills or tube mills (with an aspect ratio greater than 4).

The working mechanism of a ball mill is based on three basic states of motion of the grinding body: "circulation" (when the speed is too fast), "cascading" (when the speed is too slow), and "dropping" (when the speed is moderate). The "dropping" state is considered the most effective crushing state. In this state, the grinding body is lifted to a certain height and then dropped in a nearly parabolic trajectory, exerting a strong impact on the material and achieving a good crushing effect. The basic effect of the grinding body on the material is the result of the combined effects of various motions, with impact and grinding being the main effects.

| Parameter Type | Typical value/range | Remark |

| Medium filling rate | 35%-45% | Higher than rod mill |

| Rotation rate | 70%-80% | Higher than rod mill |

| Operation rate | 90%-95% | Higher than rod mill |

| Cylinder speed | 15-20r/min | Speed reduction device required |

| Grinding media consumption | 500-1000g/t cement | Large consumption |

The core difference between ball mill and rod mill

1. Differences in structure and grinding media

- Cylinder ratio: The length-to-diameter ratio of the rod mill cylinder is generally 1.5-2.0, and the length-to-diameter ratio of the ball mill cylinder is generally 1 or slightly greater than 1;

- Grinding method: ball mill uses steel balls (diameter <100mm) to crush by point contact impact, while rod mill uses steel rods (length close to the cylinder) to grind by line contact;

- Speed and motion state: The rod mill has a low speed and the steel rods move in a stacking manner; the ball mill has a high speed and the steel balls mainly move in a throwing manner.

2. Working Principle and Performance Comparison

- Particle size control: Rod mill has uniform particle size (1-3mm) with less over-crushing, suitable for coarse grinding; ball mill has finer material (0.074-0.4mm), suitable for fine grinding or ultrafine grinding;

- Crushing characteristics: Rod mill has a selective crushing effect on ore, protecting the crystal structure; ball mill has dispersed crushing force and wider applicability.

3. Energy consumption and maintenance

Rod mills generally consume less energy than ball mills, but their processing capacity is greatly affected by the particle size of the ore;The steel balls of the ball mill wear out quickly and need to be replaced regularly; the steel rods of the rod mill wear out evenly and have a longer maintenance cycle.

Key factors in equipment selection

1. Material properties and process requirements

- Coarse grinding scenario: rod mill is preferred (such as artificial sand, tungsten/tin ore roughing pre-selection grinding);

- Fine grinding requirements: ball mill (e.g., secondary fine grinding of cement clinker and metal ores);

- Excessive crushing sensitivity: Rod mills are more suitable when the mud content is high or when protection of mineral crystals is required.

2. Balance between economy and efficiency

- Energy sensitivity: Rod mills have lower operating costs and are suitable for small and medium-sized production;

- Large-scale continuous operation: The ball mill can be combined with classification equipment to form a closed loop circulation with higher efficiency.

3. Special scenario adaptation

- Materials containing metallic impurities: Autogenous grinding mills can avoid contamination of the steel medium (e.g. high purity mineral processing);

- High hardness ores: Ball mills with ceramic linings can reduce wear.

Advantages and disadvantages of ball mill and rod mill

Advantages of Rod Mill

1) Coarse Grinding: Rod mills are well-suited for grinding materials that require a coarser product, making them suitable for primary grinding applications.

2) Uniform Particle Size: The grinding action of the rods produces a more uniform particle size distribution, which is beneficial in a variety of applications.

3) Lower energy consumption: Rod mills generally consume less energy than ball mills, making them a more cost-effective choice for certain projects.

4) Reduced over-grinding: The rod mill design minimizes the risk of over-grinding, thereby avoiding the generation of unwanted fine particles.

Disadvantages of Rod Mill

1) Limited Versatility: Rod mills are not as versatile as ball mills and may not be suitable for all applications.

2) Lower production capacity: Rod mills generally have lower output compared to ball mills, which can be a limiting factor for large projects.

3) Higher initial cost: The initial investment for a rod mill may be higher than that for a ball mill, which may be prohibitive for some project managers.

Advantages of ball mill

1) Versatility: Ball mills can be used in a wide range of applications, including dry and wet grinding processes.

2) Finer particle size: Ball mills are able to produce finer particle size, making them suitable for industries that require high-quality powders.

3) Higher capacity: Compared with rod mills, ball mills generally have higher throughput, which is advantageous for large projects.

4) Adaptability: The ball mill is designed so that parameters such as rotational speed and ball size can be easily adjusted, enabling it to be customized for specific projects.

Disadvantages of ball mill

1) Higher energy consumption: Ball mills tend to consume more energy, which increases operating costs.

2) Risk of over-grinding: The vigorous grinding action of a ball mill may lead to over-grinding and the creation of unwanted fine particles.

3) Less uniform particle size: Compared with rod mill, the particle size distribution produced by ball mill is less uniform.

How to choose ball mill or rod mill

1. By raw materials

- Choose a ball mill: Ball mills are suitable for grinding hard materials such as iron ore, copper ore, slag, etc. If the abrasive is molybdenum ore, aluminum ash, lime, cement, etc., the ball mill has a stronger processing capacity.

- Select rod mill: Rod mill is suitable for grinding brittle materials and is commonly used for tungsten ore, tin ore, rare metal ore, coal and other materials.

2. According to the particle size of finished product

- Select ball mill: The ball mill has higher requirements on the fineness of the finished product. When the product particle size is less than 0.5mm, it is recommended to use a ball mill.

- Choose a rod mill: The products of a rod mill are rough, but the quality of the finished product is uniform. When the product particle size is 1~3mm, it is recommended to use a rod mill.

3. By work site

When designing a mineral processing plant, the floor plan of the grinding workshop is usually designed in advance, so the floor space of the equipment needs to be considered.

- Choose a ball mill: The ball mill is cylindrical in shape, with a small aspect ratio and a small footprint.

- Selecting a rod mill: The rod mill has a long barrel, a large aspect ratio, and occupies a large area. Therefore, when selecting a rod mill, you should consider whether it can meet the equipment installation conditions.

Applications of ball mills and rod mills

ball mill

Ball mills have a wide range of applications and can grind metal ores and non-metallic ores, especially hard materials such as quartz, gold ore, copper ore, iron ore, potassium feldspar, etc.Ball mills can also be used in cement, building materials, refractory materials, glass, ceramics and other industries, and the finished product particle size can reach 800 mesh.

Rod mill

Rod mills are commonly used in gravity or magnetic separation of rare metal ores such as tungsten and tin to prevent over-crushing. Rod mills are also suitable for crushing relatively hard, brittle materials, serving as a fine crushing alternative to short-head cone crushers. In a two-stage grinding process, rod mills are typically used as the first stage, offering high throughput and efficiency.

Conclusion

Rod mills, with their unique selective grinding mechanism and uniform product particle size, excel in coarse grinding and minimizing over-grinding, making them suitable for processing brittle soft ores such as tungsten and tin. Their high energy efficiency and low over-grinding make them advantageous in specific applications. However, limitations of rod mills, such as low processing capacity, complex operation and maintenance, and limited fine grinding capabilities, restrict their application. Ball mills, with their wide adaptability, higher processing capacity, and excellent fine grinding performance , are the most widely used grinding equipment, particularly suitable for large-scale production and fine and ultrafine grinding. However, ball mills also have disadvantages such as low energy efficiency, severe over-grinding, and bulky equipment requiring high investment. When selecting grinding equipment, comprehensive considerations should be made based on factors such as the specific ore properties, processing scale, product requirements, energy costs, and economic viability, So this article ends here, if you want to know about vertical roller mill please click on the link here.