3. How to join a Steel cord rubber conveyor belt on-site (in-situ)?

Belt conveyors often experience surface damage or even breakage after prolonged high-speed operation or operation in harsh environments. Therefore, proper installation and regular replacement of severely damaged belts are crucial. During belt replacement, re-joining is often necessary. There are three common methods for joining belts: buckle joints, cold bonding joints, and hot vulcanization joints.

1. Belt Buckle Method: This method uses a belt buckle to connect the two ends of a belt. It’s typically used on small belt conveyors. First, adjust the buckle length to approximately 5cm narrower than the belt. Then, secure the buckle to the lower template and insert the locating pin. Next, insert the belt into the buckle, ensuring that its front section completely touches the bottom. Ensure the belt and buckle are symmetrical. When attaching the buckles, first secure the buckle in the center, then secure the buckles near the edges. This means positioning the belt first, then starting from the center and working your way out. When attaching each buckle, ensure the bottom of the handheld upper punch is in close contact with the top surface of the buckle. First, tap the punch gently to ensure contact between the buckle plate and the belt. Then, firmly hammer the punch, driving the buckle in until it penetrates the belt and automatically bends. While the belt buckle method is simple to use, it has certain limitations. Because this method is easily damaged and can affect the life of the conveyor equipment, watering is recommended for conveyor belt connection when possible. However, for some rubber conveyor belts used in compound fertilizer production lines, this method can be used for jointing, as the loads are not heavy. However, this method is prone to leakage. Due to the lack of cold-bonding watering equipment at our African project site, we had no choice but to use belt buckles, but this is not recommended for long-term use.

2. Cold bonding: Another commonly used belt joint method. This method uses a cold-vulcanized adhesive to bond the belt, achieving a single-piece structure. Suitable for medium-sized belt conveyors, cold bonding offers advantages such as wide application, ease of use, and high joint strength. Before cold bonding, ensure all necessary tools and materials are readily available, including SK313 cold-vulcanized adhesive, SK353 cleaning agent, RIT repair strips, a wallpaper knife, a ruler, an angle grinder, a tungsten carbide grinding disc, a hair dryer, gasoline, oil-resistant gloves, and a stencil brush. The cold bonding process requires stringent environmental conditions, including suitable temperatures and humidity to avoid rain, dew, and dust (though this is not strictly necessary; ensuring the belt joint is clean is sufficient). Preparation is crucial for cold bonding. A stable working platform should be established to secure the belt and expose only the portion to be bonded. The formula for calculating the length of a flat joint is: L = (Z – 1) × b + 50, where L represents the joint length, Z represents the number of canvas layers, b represents the overlap length, and 50 represents the overlap length of the cover adhesive. During operation, pay attention to the belt’s running direction and the orientation of the joint’s bevel. Depending on the belt width, accurately score the cut into a straight line or at a 30° angle to the belt edge. Follow the scoreline closely. Use an angle grinder with a tungsten carbide grinding disc to finely grind the belt joint to remove the existing adhesive layer, exposing the belt core. Use a hair dryer to remove any debris generated during the grinding process. Cut and strip the conveyor belt into a stepped pattern as required, roughen the surface with propylene glycol, and evenly mix two-component conveyor belt adhesive according to the mixing ratio specified in the instructions. Apply evenly to the cut and stripped layer, applying to both sides. After the first coat, let it sit for 5-10 minutes. When the adhesive is no longer loose when touched, apply a second coat. Let it sit for another 10-15 minutes. When the adhesive is no longer sparse when touched, press the two layers together in a stepped pattern, tamping them evenly with a flat-head hammer. Apply adhesive evenly to the joint, applying pressure evenly. Allow to sit for 24 hours before use.

3. Hot Vulcanization Splicing Method: The hot vulcanization splicing method uses a heated and pressurized belt vulcanizer to achieve high-quality belt splices. This method is particularly suitable for large conveyor equipment and is currently one of the most ideal splicing methods. The necessary tools are assembled, including a work platform, belt vulcanizer, pressure pump, RIT core adhesive, RIT surface adhesive, hot vulcanizing agent SK823, a cooling water source, an angle grinder, a steel tape measure, a square, wire cutters, a brush, and a hair dryer. Next, the belt to be spliced is pulled into place and centered, ensuring that the splice overlaps smoothly and that the overlap is at least the length of the splice. A splicing platform is set up and the components of the belt vulcanizer are positioned in order. The appropriate splice length is calculated based on the splice specifications, and the positions of the individual lines are precisely measured. Using a knife, the cover adhesive on both the top and bottom of the belt is cut horizontally, to a depth close to the wire rope. The surface of the wire rope is then sanded to a rough finish. Lay a layer of vulcanized paper on the surface of the lower heating plate, and then lay RIT surface glue and RIT core glue in sequence, and apply hot vulcanizer SK823 to the junction of the two, ensuring that the material laying matches the inclined surface of the joints at both ends. Lay RIT core glue and RIT surface glue in sequence on the upper part of the steel wire, and also apply hot vulcanizer SK823 to the junction of the two. After completing the production of the steel wire core belt joint, pressurize the water pressure plate to 1.0MPa. After checking that all components are correct, power on the vulcanizer to start vulcanization and cooling, and set the heating power supply temperature to 140-150℃. After completing the joint, it is necessary to cool naturally and check the joint part and make necessary adjustments.

4. 23 Types of Rubber Conveyor Belts in Modern Conveyor Systems, we are manufacturer and we produce!

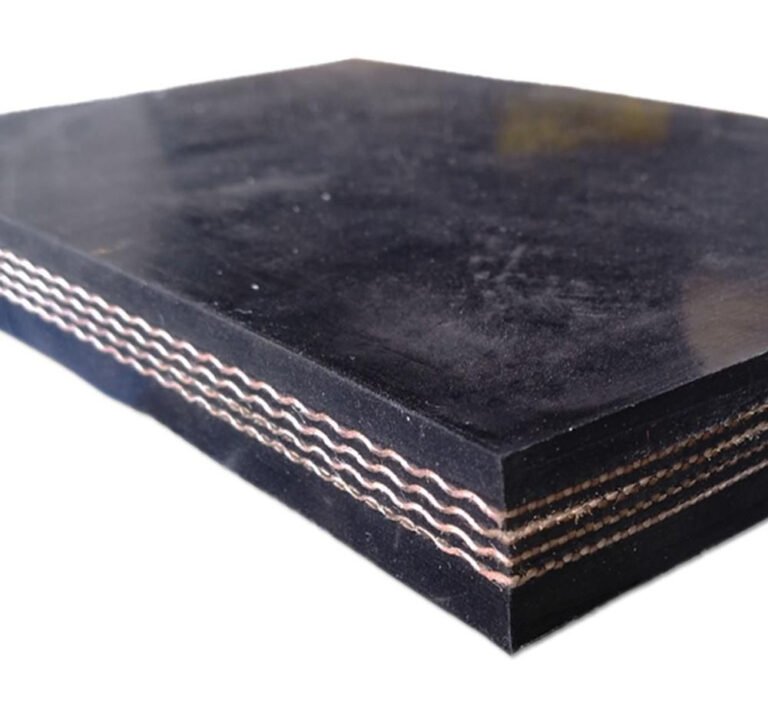

1. Steel cord rubber belt:Steel cord rubber conveyor belts are designed with longitudinally arranged high-tensile steel cords embedded in a rubber matrix, enabling uniform load distribution and minimal elongation under tension. With tensile strengths ranging from ST630 to ST7000 N/mm, these belts are ideal for long-distance, high-capacity material conveying systems in mining, cement, and power plants, ensuring excellent splice performance and reduced downtime.

2. low rolling resistance energy saving rubber belting: Low rolling resistance energy saving conveyor belts use a special compound bottom cover with optimized viscoelastic properties that significantly reduce indentation rolling resistance on idlers. Field tests have shown energy consumption reductions of 15–20% compared to conventional belts, making them essential in bulk material handling systems where operational cost and CO₂ emissions are critical concerns.

3. steel cord pipe rubber belting conveyor: Steel cord pipe conveyor belts are constructed with circular cross-sections that encapsulate material within a closed tube, preventing spillage and protecting against environmental contamination. Their bending stiffness and transverse rigidity allow pipe diameters from 150mm to 600mm, making them suitable for complex horizontal and vertical curve layouts in ports, power plants, and environmentally sensitive areas.

4.flame resistant steel cord solid rubber belt underground use:Flame resistant steel cord belts for underground applications are engineered with low-smoke, halogen-free rubber compounds that comply with MSHA, EN 14973, and AS 4606 safety standards. The steel cords are zinc-coated to resist corrosion in humid mine environments, and the belts maintain tensile strength even at elevated temperatures during fire tests.

5. Intelligent Anti-tear Steel Cord Conveyor Belt: Intelligent anti-tear steel cord conveyor belts integrate embedded sensor loops and conductor wires within the carcass, enabling real-time monitoring of belt health. These systems detect longitudinal rips or splice failures instantly, allowing predictive maintenance and avoiding catastrophic downtime. Typical monitoring accuracy is within ±1 meter along the belt length.

6. Fabric endless belt: Fabric conveyor belts are reinforced with multi-ply EP (polyester/nylon) or NN (nylon/nylon) fabrics, offering excellent troughability, impact absorption, and flexibility on short to medium conveying distances. With standard tensile classes ranging from EP100 to EP630, they are widely used in quarries, sand plants, and material recycling facilities where adaptability and cost-effectiveness are crucial.

7. Heat Resistant, High Temperature Resistant Steel Cord rubber transport belt: Heat resistant steel cord conveyor belts are manufactured with specialized cover compounds capable of withstanding continuous service temperatures up to 200°C and short peaks up to 400°C. They maintain steel cord adhesion strength and carcass integrity under thermal aging, making them suitable for cement clinker, sinter, and foundry applications.

8. IW/SW Steel Mesh Conveyor Belt (NEW): IW (interwoven) and SW (straight-warp) steel mesh conveyor belts combine the benefits of textile flexibility with steel reinforcement. The open mesh carcass enhances tear resistance and puncture tolerance while maintaining superior rip propagation control. These hybrid belts are gaining adoption in industries with sharp, heavy materials such as crushed stone and scrap metal.

8. Straight Warp rubber drive belt: Straight warp conveyor belts utilize a single-ply carcass with warp yarns running parallel to the belt length, creating exceptional tear resistance and impact absorption compared to multi-ply belts. This structure reduces carcass fatigue and delamination risk, making them reliable for applications involving sharp-edged ores and large drop heights.

9. Aramid rubber cover belt: Aramid conveyor belts use Kevlar® or Twaron® fibers as the tensile member, delivering strength comparable to steel cords while reducing belt weight by up to 40%. This results in lower power consumption, easier installation, and suitability for long-distance conveying systems with steep gradients where weight reduction is critical.

10. Oil Resistant Steel Cord multi-ply rubber belting:Oil resistant steel cord belts are designed with special NBR (nitrile butadiene rubber) covers that resist swelling and degradation when exposed to petroleum-based oils, solvents, or greases. This ensures dimensional stability and maintains tensile performance when conveying oily materials such as coal tar, wood chips, or grain by-products.

11. Acid-alkaline Resistant Steel Cord EP rubber belt: Acid-alkaline resistant steel cord belts feature chemically engineered rubber compounds that withstand pH ranges from 3 to 11, preventing surface cracking or cover hardening. They are commonly applied in fertilizer production, chemical handling plants, and metallurgical processes where corrosive materials degrade conventional belts.

12. Cold Resistant Steel Cord Conveyor Belt: Cold resistant steel cord belts maintain flexibility and tensile performance at ambient temperatures as low as -60°C. With ozone-resistant cover formulations, these belts remain crack-free and reliable in arctic mining, outdoor aggregate handling, and frozen food logistics.

13. Fabric Pipe Conveyor Belt:Fabric pipe conveyor belts use high-modulus polyester or nylon fabrics for carcass strength while forming a sealed tubular shape to enclose materials. With pipe diameters typically between 100mm and 400mm, they are well-suited for medium-capacity conveying in environmentally sensitive sites where spillage control is required.

14.Flame Resistant Fabric bulk material belt: Flame resistant fabric belts are built with low-smoke, anti-static, and flame-retardant rubber compounds that meet ISO 340 and EN 12882 standards. Their textile carcass structure allows high flexibility and easy splicing, making them suitable for underground mines and grain handling where fire hazard is a critical risk.

15. Heat Resistant, High Temperature Resistant Fabric Conveyor Belt: Fabric carcass heat resistant conveyor belts can handle continuous material temperatures of 150–180°C, with peak resistance up to 200–250°C depending on compound selection. The EP carcass minimizes elongation under thermal stress, ensuring stable operation when transporting hot clinker, coke, or sinter.

16. Cold Resistant Fabric Conveyor Belt: Cold resistant fabric belts incorporate special cover rubber with low glass transition temperature (Tg) and high elasticity at subzero conditions, allowing them to operate effectively in temperatures down to -50°C. They are extensively used in outdoor mining, snow-covered loading sites, and cold storage facilities.

17. Acid-Alkaline Resistant Fabric Conveyor Belt: Acid-alkaline resistant fabric belts are made with synthetic EP or NN fabrics and chemically resistant rubber covers that withstand prolonged exposure to corrosive materials. Industries such as phosphate fertilizer production, pulp & paper, and battery manufacturing rely on these belts to prevent premature cover degradation.

18. Oil Resistant Polyester-Nylon Fabric Conveyor Belt: Oil resistant fabric conveyor belts are reinforced with multiple EP/NN layers and a nitrile-based cover rubber that prevents volume expansion, cracking, and hardening in oily environments. They are particularly effective for transporting oily grains, wet wood chips, and crushed mineral ores.

19. Sidewall industrial rubber belting(Skirting belt): Sidewall conveyor belts incorporate corrugated rubber sidewalls and cross cleats vulcanized to the base belt, enabling steep incline conveying up to 90°. Their high edge-sealing strength prevents spillage, making them indispensable for space-constrained conveying systems in mining, tunneling, and dockside loading.

20. Anti-tear Steel Cord rubber bulk material belt: Anti-tear steel cord conveyor belts are reinforced with breaker plies or transverse steel wires above the cords, providing high resistance to sharp object penetration and longitudinal ripping. They are engineered for transporting large, sharp materials such as limestone blocks and iron ore.

21. Anti-tear Fabric Conveyor Belt: Anti-tear fabric belts include extra reinforcement layers of canvas or breaker fabrics within the carcass, improving resistance to impact and longitudinal rips. These belts are commonly used in crushing plants and aggregate quarries where large lumps and irregular materials are handled.

22. Profiled Conveyor Belt:Profiled conveyor belts feature molded cleats, ribs, or patterns up to 32mm in height, enabling steep-angle conveying of bulk materials. They are widely used for transporting grains, coal, and wet sand on inclined conveyors where flat belts would cause material slippage.

23. Patterned Conveyor belt/rubber troughing belt: Patterned conveyor belts incorporate various surface profiles such as chevron, herringbone, and diamond shapes, designed to increase grip and prevent rollback on inclined transport lines. These belts are effective for conveying loose bulk materials like fertilizer granules, wet coal, and crushed stone.