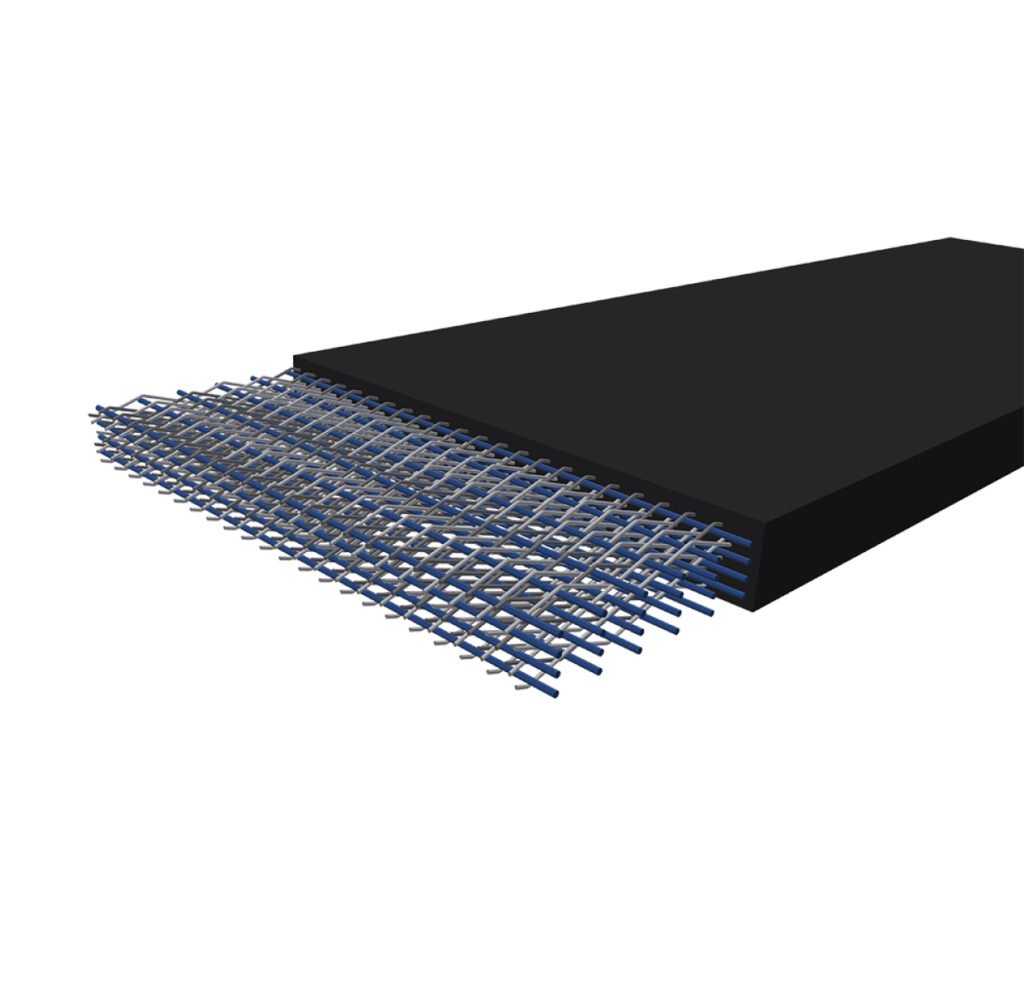

Solid woven conveyor belts are high-performance belts designed for harsh industrial environments. Their core structure utilizes a unique monolithic weaving technique, with multiple layers of high-quality warp yarns (typically polyester) and weft yarns (usually cotton or nylon) interwoven on heavy-duty looms to create a complete, dense skeleton. This one-piece fabric structure eliminates the delamination risk associated with traditional multi-layer belts, resulting in exceptionally high longitudinal tensile strength and excellent lateral rigidity. This ensures excellent operational stability even under heavy loads and high-impact conditions, effectively preventing deviation. After weaving, the belt core undergoes a thorough impregnation and sealing process, typically with polyvinyl chloride (PVC) or rubber compounds such as PVG. This process fully saturates the belt, creating a non-porous, completely sealed protective layer. This property gives solid woven conveyor belts , particularly PVC and PVG types, excellent flame retardancy and antistatic properties, making them a preferred choice for use in underground coal mines, mining laneways, and other flammable and explosive environments where safety is critical. Its airtight structure effectively resists corrosion from moisture, mold, oil, and various chemicals, extending its service life in harsh operating conditions. Depending on the rubber cover material, solid woven conveyor belts are primarily categorized into two types: PVC and PVG. PVC conveyor belts, coated with PVC, offer excellent corrosion resistance and cost-effectiveness, making them suitable for transporting materials subject to moderate abrasion. PVG conveyor belts, on the other hand, feature a more wear-resistant rubber layer covering the upper and lower surfaces of the solid woven core, resulting in superior impact, cut, and abrasion resistance. They are particularly suitable for conveying large, sharp, and heavy materials such as ore and rock. In addition to exceptional safety and durability, solid woven conveyor belts also offer excellent flexibility, robust troughing, and high-strength joints. Joints are typically secured using highly efficient mechanical vulcanization, achieving 70%-90% of the belt's original strength, ensuring continuous and reliable conveyor line operation. With these comprehensive advantages, solid woven conveyor belts have become an indispensable component in mining, ports, power generation, metallurgy, and various bulk material handling industries, providing a solid foundation for long-distance, efficient, and high-safety material transportation.

High Quality Solid Woven Conveyor Belts Manufacturer

A MACHINE YOU CAN DEPEND ON!

Solid woven conveyor belts are made of high- strength synthetic fibers that are formed into a dense, seamless core on the loom at one time, making it a structurally complete, safe, reliable and durable material conveying solution.

The skeleton of the conveyor belt is a single, dense whole formed by interweaving multiple layers of warp and weft yarns. This structure fundamentally avoids the problems of delamination and peeling, and provides extremely high dimensional stability and impact resistance .

This product's design balances multiple key performance characteristics. It offers high strength and excellent flexibility, facilitating deep groove formation and tight-radius turns. A special impregnation formula and process impart flame retardancy and antistatic properties, ensuring compliance with stringent industry safety regulations. It's a comprehensive industrial choice.

Depending on the application requirements, the integral braided core is equipped with a cover with different performance characteristics . PVC (polyvinyl chloride) covers offer excellent corrosion resistance and cost-effectiveness, suitable for moderate wear conditions and dry environments. PVG (rubber-faced) covers provide superior impact, cut, and abrasion resistance, and are suitable for steeper inclinations and wet environments.

| Strength level | Minimum warp tensile strength (N/mm) | PVC cover thickness (mm) | PVG cover thickness (mm) | Bandwidth (mm) |

| 680s / Level 4 | 680 | 0.8+0.8 | 1.5+1.5 | 650~1600 |

| 800s / Level 5 | 800 | 0.8+0.8 | 1.5+1.5 | |

| 1000s / Level 6 | 1000 | 0.8+0.8 | 1.5+1.5 | |

| 1250s / Level 7 | 1250 | 0.8+0.8 | 1.5+1.5 | |

| 1400s / Level 8 | 1400 | 0.8+0.8 | 1.5+1.5 | |

| 1600s / Level 9 | 1600 | 0.8+0.8 | 2.0+2.0 | |

| 1800s / Level 10 | 1800 | 0.8+0.8 | 2.0+2.0 | |

| 2000s / Level 11 | 2000 | 0.8+0.8 | 2.0+2.0 | |

| 2240s / Level 12 | 2240 | 0.8+0.8 | 2.0+2.0 |

Antistatic performance: The average resistance on both surfaces of the conveyor belt is required to be 3.0 × 10⁸ ohms. This performance ensures that the fabric can effectively conduct static electricity, preventing charge accumulation and sparks, which is crucial in flammable and explosive environments such as coal mines.

High temperature resistance and resistance to friction fire sources:

Roller friction test: This simulates the extreme situation of a conveyor belt slipping on the drive pulley. Standards require that the pulley surface temperature must not exceed 325°C, and that the tested sample must not exhibit any open flames or smoldering (glowing) activity. This demonstrates that the conveyor belt is extremely safe, even under conditions of severe frictional heating, and will not become an ignition source.

Flame retardant performance: This test is divided into two types:

Alcohol Burner Test: Evaluates the conveyor belt's ability to self-extinguish after exposure to a small flame.

When the belt is covered with rubber: the requirements are more stringent, the average flame burning time of 6 samples shall be ≤ 3 seconds, and any sample shall not exceed 10 seconds.

When there is no covering rubber: the average flame burning time of 6 specimens is ≤ 5 seconds, and any specimen shall not exceed 15 seconds.

Propane torch test: This simulates the impact of a more intense flame. The standard requires that after the flame is extinguished, the conveyor belt must remain unburned for a length of 250 mm or more. This demonstrates its ability to resist flame spread and maintain structural integrity, buying valuable time for underground escape and fire extinguishing.

A solid woven conveyor belt is constructed from multiple layers of high-strength synthetic fibers (such as polyester or nylon) woven into a single piece. The belt is typically coated with a polymer material such as PVC (polyvinyl chloride) or PVG (polyvinyl alcohol). This design provides exceptional tear and abrasion resistance, as well as overall stability. Compared to other conveyor belts (such as steel cable conveyor belts or traditional multi-layer conveyor belts), solid woven conveyor belts are lighter, more flexible, and require no additional carcass, reducing the risk of delamination. These conveyor belts are particularly well-suited for heavy loads and harsh environments, such as those in the mining and construction industries.

PVC conveyor belts: These belts are impregnated with polyvinyl chloride (PVC), offering excellent fire resistance and general durability. They are suitable for a wide range of above-ground applications and some underground applications. However, compared to PVG, PVC is less resistant to chemicals, temperature, and humidity. They are a versatile and cost-effective solution for many material handling tasks.

PVG conveyor belts: These belts feature a solid braided core impregnated with a blend of PVC and rubber and typically covered with a rubber cover. This combination provides superior performance. PVG conveyor belts offer enhanced resistance to water, moisture, and abrasion. They are a premium choice for the most demanding and humid environments, such as deep underground mining where waterlogging is present, or surface applications requiring weather resistance.

If your application involves high amounts of moisture, more aggressive chemicals, or requires the highest level of abrasion resistance, a PVG conveyor belt may be a more suitable choice.

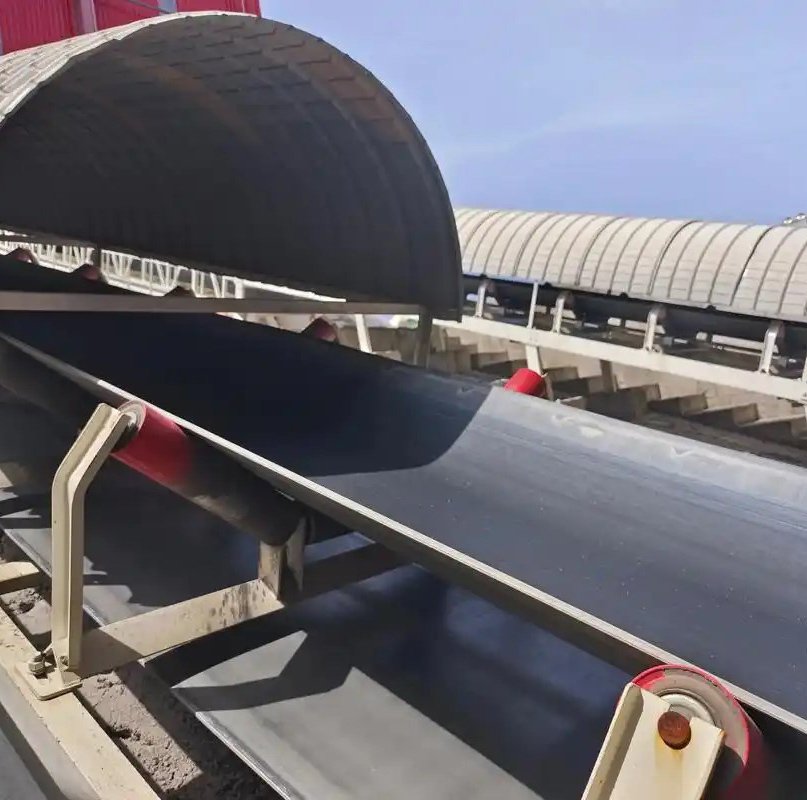

Underground mining: This is their primary application area, especially when transporting coal, potash and metal ores, where fire safety is a rigid requirement.

Tunneling and Civil Engineering: Used in tunnel and large-scale infrastructure construction projects to reliably transport soil and materials.

Surface mining and quarrying: Used for handling overburden, minerals and aggregates, where tear and impact resistance are crucial.

Ports and terminals: used for loading and unloading ships and handling bulk cargoes such as grains, fertilizers and minerals.

Power stations and steel mills: used to transport coal, ash and sintered materials, often in harsh high-temperature environments.

Solid woven conveyor belts are designed for long-term use in harsh conditions. Their service life is directly derived from their robust construction—the solid woven core resists internal damage, while the impregnated polymer protects against abrasion and environmental factors. However, actual service life depends on several variables:

Material characteristics: abrasiveness, sharpness and weight of the conveyed material.

Environmental conditions: Exposure to UV rays, ozone, moisture, chemicals, and extreme temperatures.

System Design and Maintenance: Proper belt tension, alignment of idlers and pulleys, condition of cleaners, and quality of joints all play a vital role.

Standard PVC solid woven conveyor belts are typically suitable for environments ranging from -10°C to +80°C, while PVG types may have extended temperature ranges (e.g., -40°C to +100°C). For extreme high or low temperatures, specialized cover materials may be required. Solid woven construction is stable in humid or corrosive environments, but it is not recommended for long-term exposure to extremely high temperatures.

PVG solid woven conveyor belts, in particular, excel in this regard. Their hydrophobic rubber covering effectively prevents moisture from penetrating the belt core, thus preventing the loss of strength caused by moisture absorption and mold. Furthermore, the rubber surface provides improved grip in wet conditions, reducing slippage, making it ideal for use in the humid environments of coal washeries, tunneling, and open-pit mines.

There are two main types of joints used in solid woven conveyor belts:

Mechanical splices use metal or plastic staples and splice plates. This method is quick and economical, making it suitable for applications where belts need to be frequently replaced. However, its joint strength and sealing are not as good as those of vulcanized splices.

Vulcanized joints: Through a hot vulcanization process, the two ends of the belt are fused together under high temperature and pressure using unvulcanized rubber to form a seamless, integral unit with similar strength to the belt itself. This is the most reliable, durable, and commonly used method, providing a smooth transition and reducing leakage and wear.

Yes. In addition to the standard black PVC or PVG covering, manufacturers often offer a variety of options, including specialty coverings in olive green. These special coverings may offer enhanced resistance to oil, chemicals, or abrasion, or may be color-coded to distinguish different conveyor lines.

The selection process is a systematic project that requires consideration of several parameters:

Application scenario: Is it mining, port, power plant or chemical plant?

Safety requirements: Are fireproof and antistatic certifications required?

Material characteristics: including material type, particle size, temperature, angle of repose, etc.

System parameters: conveyor length, lifting height, belt speed, maximum tension, etc.

Environmental factors: ambient temperature, wetness and dryness, presence of chemicals or oils.

Solid woven conveyor belts are generally quieter than some metal-based belts. Their fabric core and polymer cover provide natural vibration and sound absorption. However, overall noise levels depend more on the condition of the entire conveyor system, such as the quality of the idlers and pulleys, belt alignment, and drive performance. A well-maintained system with solid woven belts can achieve relatively quiet operation.

PVC (polyvinyl chloride) types are suitable for general material handling. Typical applications include ports and terminals (loading and unloading grain, fertilizer, etc.), the construction aggregate industry (sand, gravel), fertilizer plants, and power plants. They offer excellent resistance to wear, oil, and chemicals, making them suitable for relatively dry environments where fire protection is not a requirement.

PVG (rubber/PVC composite) types are designed for high-safety and high-impact environments. They are primarily used in underground mining (such as coal mines), tunneling, heavy ore extraction, and any wet or muddy working conditions. The PVG overlay provides unmatched fire resistance, slip resistance, and impact resistance.

In addition to the natural impact resistance provided by the strong solid braided core, Tongli also offers additional reinforcement options. For example, Rip Guard can be integrated. This is a high-strength synthetic fiber mesh embedded in the belt core that effectively prevents cracks caused by impact from expanding into large-scale longitudinal tears, thereby minimizing local damage and preventing catastrophic belt failure.

Yes, the smooth polymer cover is inherently easy to clean. For sticky materials, Fenner offers cover options with a special "low-stick" or "clean-type" surface. This surface effectively reduces the adhesion of wet, sticky materials (such as clay, filter cake, etc.), thereby reducing downtime for cleanup, improving conveying efficiency and maintaining a cleaner working environment.

Regarding the wear and cutting properties of materials:

The abrasiveness or cutting properties of the material are the most direct challenge to the cover. We grade the cover according to international standards (such as DIN) to match the material with different abrasiveness:

Highly abrasive materials: such as clinker, iron ore, quartz, glass powder, etc. These materials have a strong wear effect on the conveyor belt surface.

Recommendation: Use DIN W grade covering. This grade of covering has the highest wear resistance and can effectively resist the continuous wear of sharp and hard materials.

Moderately abrasive materials: such as coal, ash, gravel, sand, concrete, etc.

Recommendation: Use DIN grade Y covering. This covering provides balanced and good wear resistance and is suitable for most common industrial materials.

Materials with cutting properties: such as large pieces of waste, andesite, schist and all fresh rocks with a particle size greater than 100 mm. These materials not only wear the belt surface, but are more likely to cause cuts and scratches.

Recommended: Use DIN X grade cover. This cover is specially designed for excellent cut and tear resistance to withstand the impact of large, sharp materials.

Regarding fire safety requirements:

If a conveyor belt is operated in an environment where there may be a risk of flammability, fire safety is a primary consideration.

Our conveyor belts are manufactured in strict accordance with European standard EN 12882 and are anti-static and fire-resistant.

The standard defines corresponding safety requirements for different risk categories, ensuring that conveyor belts are suitable for various ground industrial applications, can withstand flammable environments, and minimize fire risks.

For the transportation of high temperature materials:

When conveying materials with temperatures consistently above 80°C (176°F), specialized heat-resistant conveyor belts are required.

Our heat-resistant conveyor belts comply with the international standard ISO 4195 (Parts 1 and 2).

Important note: The maximum temperature a conveyor belt can withstand depends on the type of hot material being conveyed. When selecting a belt, please provide the specific material and temperature range so that we can recommend the most suitable heat resistance grade.

For working conditions containing oil or chemical materials:

When the conveyed material contains oily components or specific chemicals, the ordinary cover will quickly age and be damaged due to oil corrosion.

Applicable scenarios:

Fuel oils from coal or fertilizers, lubricating oils in metal recovery and waste treatment.

Oily environments in foundries and steel processing.

Conveys chemical components that have good chemical compatibility with nitrile rubber (NBR).

Solution: In this case, you must choose an oil-resistant conveyor belt. Its cover layer mainly uses nitrile rubber (NBR) as the elastomer, which can effectively resist the erosion of oils and certain chemicals and prevent the cover layer from swelling, softening or losing strength.

The maximum slope or incline angle for conveying with a PVC solid woven conveyor belt depends on the material handled and the belt surface profile. For standard smooth PVC conveyor belts, the safe incline angle is typically 15°–18°. When PVC belting is manufactured with a rough top or shallow profile, the allowable slope can increase to around 22°–25°. For applications requiring steeper conveying, specially designed PVC conveyor belting with chevron, cleats, or sidewalls can handle inclines up to 30°–35°, provided the bulk material has favorable flow properties. Engineers must also consider particle size, moisture content, and stickiness, since fine or sticky products may limit incline angles to 10°–12° even on a profiled PVC belt. In practice, experts recommend staying below the theoretical maximum to ensure reliable operation, minimize spillage, and extend service life of the PVC conveyor belt. Correct belt selection is essential for safe and efficient conveying.

Choosing the right belt carcass material—specifically the warp (longitudinal) and weft (transverse) fibres—is critical to conveyor belt performance, cost, and service life. The carcass is the “skeleton” of the belt, and its fibre selection defines tensile strength, elongation, impact absorption, and stability.

Warp fibres carry tensile loads.

A polyester conveyor belt (PET warp) offers low elongation (~1.5–2%) and high dimensional stability, ideal for long-distance or high-tension systems. A nylon conveyor belt (PA warp) provides higher elongation (~4%) and outstanding fatigue resistance, making it suitable for short conveyors with frequent impacts. In heavy-duty applications, metallic woven belts or steel cord belts deliver strengths up to ST5400 N/mm, supporting long hauls and extreme loads.

Weft fibres control impact resistance and troughability. Nylon weft improves flexibility and shock absorption, while polyester weft improves edge stability and reduces distortion in high-speed operations. Special carcass types like cloth conveyor belts balance cost and flexibility for light to medium-duty uses, while felt belts excel in abrasion control and temperature resistance in textile or polishing applications.

Niche options include yellow woven belts, which are visually distinct and often used in inspection or light-duty transport, and metallic woven belts, favored in high-heat or cutting environments where tear resistance is paramount.

Application guidelines:

Long, high-tension conveyors → Polyester warp + polyester weft (EP belts).

Short, impact-heavy conveyors → Polyester warp + nylon weft (PN belts).

Extreme tear/heat conditions → Aramid or metallic woven belt.

Globally, EP fabric belts dominate (~65% export share), while steel and metallic woven belts serve specialized mining and cement markets. Correct carcass choice ensures efficiency, safety, and lower lifecycle cost.

A cotton conveyor belt (also called cotton belting, fabric belt, or woven cloth belt) is a carcass constructed from multi-ply cotton fabric impregnated with rubber. Its primary advantage lies in its high friction coefficient with pulley surfaces and excellent adhesion with rubber covers, which minimizes belt slip and delamination.

Typical tensile strengths range from 120 to 250 N/mm per ply, with elongation at working load of around 4–5%, higher than polyester but lower than nylon. This makes cotton belts stable under moderate loads yet flexible enough for smaller pulley diameters.

When compared with other conveyor belt materials: Polyester conveyor belts (EP belts): Deliver lower elongation (1.5–2%), higher strength-to-weight ratio, and better resistance to moisture, making them preferred in long-distance, high-capacity systems.

Nylon conveyor belts (NN belts): Offer superior impact resistance and fatigue life, with elongation up to 4%, suitable for heavy impact applications such as mining and quarrying.

Rubber belting: Provides abrasion resistance and chemical stability, often paired with synthetic fabrics or steel cords for durability.

Cotton belting is still selected in grain handling, flour mills, cement packaging lines, and light-duty industrial conveying, where static-free operation, natural fibre carcass, and reliable grip are required. In contrast, felt belts and metallic woven belts serve niche roles in textile finishing or high-heat conditions.

In export markets, cotton conveyor belts represent a declining but specialized share, with EP and NN fabrics dominating (>65% global trade), yet cotton remains relevant in industries prioritizing natural-fibre compatibility and low equipment wear.

A fabric conveyor belt—also known as fabric belting, cloth conveyor belt, or textile belting—is built from multiple layers of woven fabric plies bonded with rubber or PVC to form the carcass. These fabric conveyor belts remain the most widely used type worldwide, accounting for more than 65% of industrial installations, because they provide a balance of tensile strength, flexibility, and cost-effectiveness. Different fabric belting materials deliver distinct performance:

Polyester fabric conveyor belts (EP belts): Warp and weft = polyester. Tensile strength up to 3150 N/mm, low elongation (1.5–2%), and high dimensional stability. Best for long-distance, high-capacity conveyors.

Nylon fabric conveyor belts (NN belts): Both warp and weft = nylon. They offer higher elasticity (~3–4% elongation) and superior impact resistance, ideal for impact-heavy applications such as mining, stone crushing, and recycling.

Cotton fabric belts: Lower tensile strength (120–250 N/mm per ply) and higher elongation (~4–5%), but excellent rubber adhesion and reduced pulley wear. Still applied in flour mills, grain handling, and light-duty conveying.

Compared to steel cord belts or metallic woven belts, fabric conveyor belts are lighter, easier to splice, and more economical for medium-duty conveying. In advanced systems, aramid-reinforced fabric belting provides strength-to-weight advantages for steep-incline or long-distance conveyors.

Strength grades in a fabric conveyor belt or solid woven conveyor belt define the tensile strength of the carcass in kilonewtons per meter of belt width (kN/m). For example, a 680S belt has a breaking strength of 680 kN/m, while a 1000S belt reaches 1000 kN/m. These grades ensure tongli engineers can match conveyor design loads with belt performance.

In multi-ply fabric belting like EP or NN), warp fibres longitudinal carry the main tensile load, while weft fibres transverse provide impact resistance and troughability. A 1000S fabric conveyor belt might consist of 4 plies of EP250 fabric: each ply = 250 N/mm, producing a total of 1000 N/mm tensile rating.

At a standard 10:1 safety factor, it can continuously handle ~100 kN per meter width of working load. For underground and flame-resistant applications, a solid woven PVC conveyor belt is often specified. Unlike layered fabric plies, the solid woven conveyor belt carcass is made from a single interlocked woven fabric structure impregnated with PVC.

This design improves tear resistance, maintains low elongation (<2%), and provides high dimensional stability, making it widely used in coal mining, power plants, and bulk material handling. Compared with steel cord belts, both fabric conveyor belts and solid woven PVC conveyor belts are lighter, easier to splice, and more economical, while still offering reliable tensile grades ranging from 500S up to 2000S for heavy-duty operations.

In the deep tunnels of underground mines, safety is paramount. Solid woven conveyor belts, particularly those with PVG (rubber coating) or flame-retardant PVC, are the preferred choice for coal and other underground mines. Not only do they offer exceptional strength to withstand the impact of heavy loads of ore and coal, but crucially, their excellent flame retardancy and antistatic properties effectively prevent the risk of fire and explosion caused by friction or electrical sparks, providing a safe and reliable lifeline deep within the mines.

Whether in coal-fired or biomass power plants, stable fuel delivery is essential for continuous power output. In power plants, conveyor belts are required to handle highly abrasive coal or ash for extended periods. Solid woven conveyor belts, with their exceptional wear and impact resistance, ensure reliable operation of fuel delivery systems. Furthermore, their flame-retardant properties are crucial safety features for coal accumulation, effectively preventing fire risks.

In sandstone plants, cement plants, and concrete batching plants, conveyor belts are constantly exposed to sharp, coarse gravel, sand, and cement raw materials, resulting in severe wear. Solid woven conveyor belts, with their robust construction and thick, wear-resistant cover, are ideal for handling these highly abrasive materials. They effectively resist cutting, gouging, and abrasion, ensuring a long operating life even under demanding conditions.

In the chemical industry and salt fields, conveyor belts often come into contact with chemicals, fertilizers, or highly corrosive sea salt. Solid woven conveyor belts, particularly those with a PVC cover, offer excellent chemical and salt spray resistance. Their dense cover effectively resists attack by a wide range of chemicals, preventing corrosion and damage to the belt, ensuring stable, contamination-free material conveying in chemically challenging environments.

In waste recycling centers and processing plants, conveyor belts must handle complex material mixes, often containing sharp metal scraps, broken glass, and other hard waste. The excellent puncture and tear resistance of solid woven conveyor belts plays a key role in this. Their one-piece core effectively prevents the spread of damage even in the event of a local puncture, significantly reducing unplanned downtime. Furthermore, their easy-to-clean surface is suitable for some applications.

Fertilizer manufacturing is a typical application for solid woven conveyor belts. Throughout the production process, from receiving raw materials (such as phosphate rock, potash, sulfur, and urea) to mixing, granulation, drying, and packaging the finished product, conveyor belts are subject to the rigors of corrosive chemicals, hygroscopic materials, and high temperatures. PVC/PVG conveyor belts offer excellent chemical and permeability resistance, effectively resisting the erosion of fertilizer raw materials and ensuring the belt remains intact. They also facilitate cleaning and prevent cross-contamination.

The grain industry places extremely high demands on hygiene and cleanliness. Food-grade solid woven conveyor belts offer a smooth, seamless surface that resists material absorption and is easy to clean and disinfect, effectively preventing bacterial growth and product residue. They are strong enough to handle materials like grains and legumes, while being gentle enough to protect grain particles from damage during transport. Compound fertilizer production also requires these sanitary conveyor belts for handling organic raw materials or finished products, which require high cleanliness.

Cement production requires conveying a variety of materials, including limestone, clay, gypsum, pulverized coal, and clinker. These materials are often highly abrasive and, in the case of cement clinker, hot. Solid woven conveyor belts, with their robust braided core, offer exceptional impact and tear resistance. Their wear resistance effectively extends their service life when conveying highly abrasive materials, making them key components for ensuring continuous and efficient operation of cement production lines.

You can get in touch with us through the following contact information

AddressNo. 2289 Huancheng South Road, Tongxiang, Jiaxing, Zhejiang Province, China. Zip code:314500

Please fill in the sales inquiry form and our sales representatives will be in touch shortly.